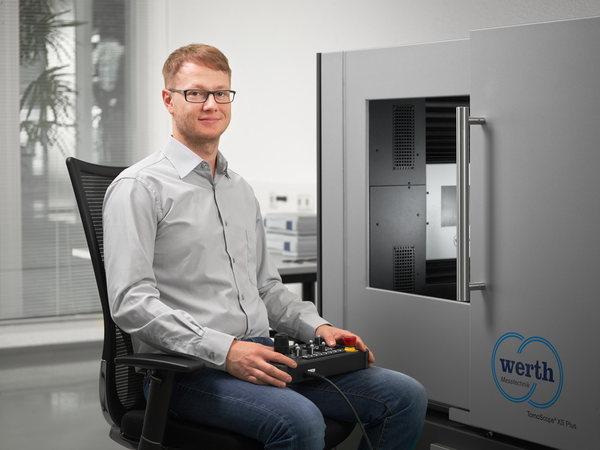

Werth ölçüm makinesi hemen verimli bir şekilde kullanılabilir. Werth, belirli iş parçaları için aparatlar ve ölçüm programları dahil olmak üzere anahtar teslim bir ölçüm makinesi tedarik eder. Ölçüm ekipmanının yeterliliğinin kanıtlanması, güvenilir çalışmayı garanti eder. Oluşturulan ölçüm programları kullanıcı tarafından tamamlanabilir veya alternatif olarak Werth uzmanları tarafından yönetilebilir. Bu, Werth koordinat ölçüm makinelerinin optimum sonuçlarla ekonomik kullanımını garanti eder.

Servis

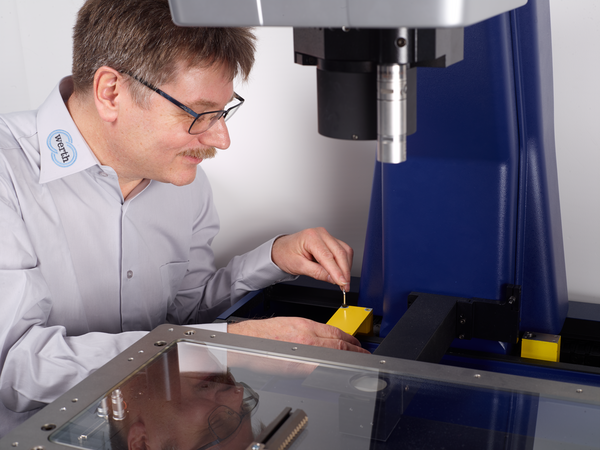

Teslimattan önce gerçekleştirilen bir ölçüm makinesi yetenek analizi, koordinat ölçüm makinesinin iş parçalarındaki gerekli toleransları güvenilir bir şekilde yeniden doğrulayabileceğinden emin olmanızı sağlar.

Çeşitli prosedürler yardımıyla operatörün, ortamın ve iş parçalarının etkileri dikkate alınır. VDI/VDE 2617 Sayfa 8'e göre "kalibre edilmiş iş parçalarının ölçümü" ile ölçüm sürecinin yeterliliği ve ölçümün izlenebilirliği de kontrol edilebilir.

Çok sensörlü koordinat ölçüm makinelerimiz veya endüstriyel bilgisayarlı tomografi cihazlarımızla servis ölçümleri yaptırmakla mı ilgileniyorsunuz? Talep üzerine servis ortaklarımızın iletişim bilgilerini sizinle paylaşmaktan mutluluk duyarız.

Ölçüm makinelerinin onarımları, son derece eğitimli personelimiz tarafından profesyonel ve doğru bir şekilde gerçekleştirilmektedir. Mümkün olan en hızlı onarım ve dolayısıyla yüksek kullanılabilirlik sağlamak için, yerinde 24 veya 48 saat müdahale süreleri de ayarlanabilmektedir.

Düşük ölçüm hataları ve sorunsuz bir üretim süreci sağlanacaksa, makinelerin düzenli bakımı mantıklıdır. Bakımı yapılmayan veya yetersiz bakımı yapılan bir koordinat ölçüm makinesinin tekrar çalışır duruma getirilmesi, bakım maliyetlerinin kat kat fazlasını gerektirir.

Düzenli kalibrasyon, makinenin ulusal standartlara uygunluğunu sağlar ve öngörülemeyen makine arızalarını önler. Werth Messtechnik, 2004 yılında optik ve çok sensörlü koordinat ölçüm cihazlarının kalibrasyonu için ilk Alman laboratuvarı olarak akredite edilmiştir. 2011 yılında ise, bilgisayarlı tomografi koordinat ölçüm cihazlarının kalibrasyonu için ilk ve 2018 yılına kadar tek kuruluş olarak akredite edilmiştir. ISO 17025'e göre DAkkS akreditasyonu, kalibrasyonun standartlara uygun olarak gerçekleştirildiğini garanti eder. İzlenebilirlik kanıtı, IATF gerekliliklerini karşılamaktadır.

Werth ölçüm makinelerinin kurulumu veya taşınması sırasında, deneyimli servis personeli profesyonel devreye alma ve böylece kısa duruş sürelerini garanti eder. Talep üzerine, makine DIN 10360 veya VDI 2617'ye göre kontrol edilebilir.

Makinelerin donanımı eski, işlev yelpazesi sınırlı mı? Modern makine donanımlarının yenilenmesi ve en yeni işlev yelpazesine sahip en yeni ölçüm yazılımının güncellenmesi, yeni bir makineyle benzer bir performans seviyesi sağlar. Bu, verimliliği artırır, bakım ihtiyacını azaltır ve koordinat ölçüm makinesinin değerini korur.

Eğitim kursları, çok sensörlü koordinat ölçüm cihazlarının ve bilgisayarlı tomografinin optimum kullanımını sağlar...