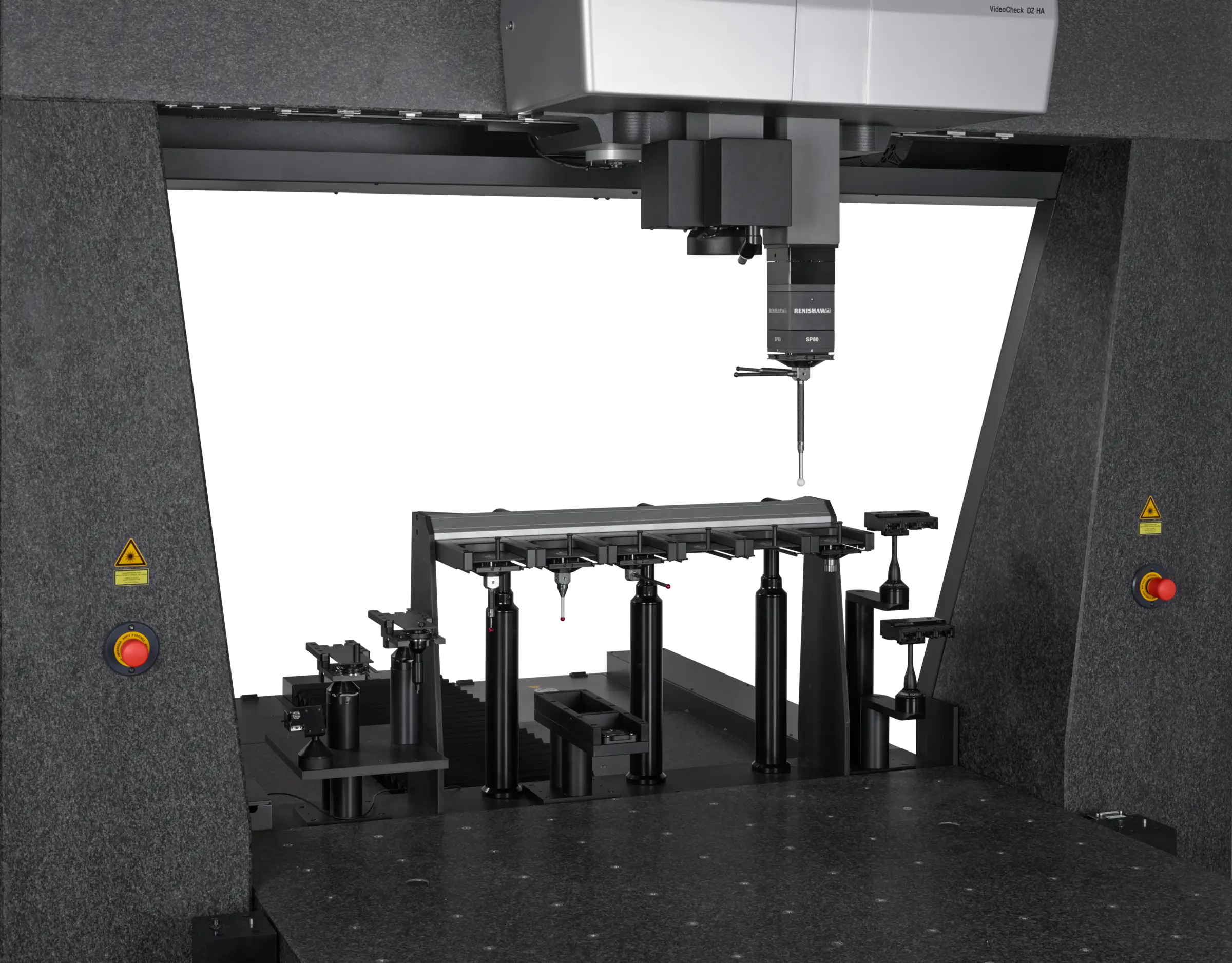

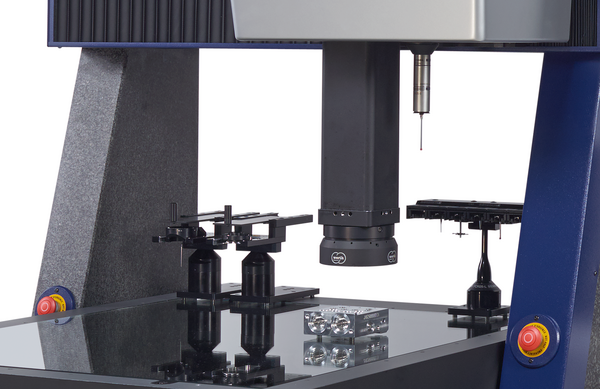

Tactile sensors and tactile-optical micro-probes, styli with different shaft lengths and probe tips as well as accessories for optical sensors, e.g. angle optics, interferometer probes and front lenses for the Werth Laser Probe (patents), are changed fully automatically. This enables reliable serial measurements of all desired geometrical characteristics of the workpiece in a combined measurement sequence.

Changing rack En

Changing rack

Safe parking of sensors and accessories on the measuring machine

Benefits

Automatic sensor change with highest reproducibility for multi-sensor measurements

Other benefits

Operating errors and collisions are almost impossible

Automatic recognition of type, position and correction data of the sensor possible

A fixed parking position is assigned to each sensor

Similar styluses can no longer be mixed up

Software

The universal measurement software for coordinate measuring machines with optics, probe, computed tomography and multi-sensor systems

The operation of machines with a wide variety of sensors, as well as the evaluation of volume data and point clouds ...

Service

Comprehensive service around the coordinate measuring machine

Services from initial commissioning, training and maintenance to retrofitting ...