The Chromatic Focus Line sensor uses a linear arrangement of lots of chromatic sensors to capture measured values extremely quickly with up to one million measurement points in less than three seconds. The chromatic measurement principle ensures low measurement errors and a high degree of independence from surface properties. Areas of application include diffusely reflective as well as reflective and transparent workpieces.

Chromatic Focus Line sensor CFL En

Adaptation of measuring uncertainty and measuring range to the respective application with different lenses

Due to a large axial measuring range, it is often not necessary to track the device axes to the workpiece geometry

The possibility to quickly create a raster image of the workpiece surface allows the formation of local coordinate systems for further measurements with other sensors

Layer thicknesses of transparent materials can also be measured (option)

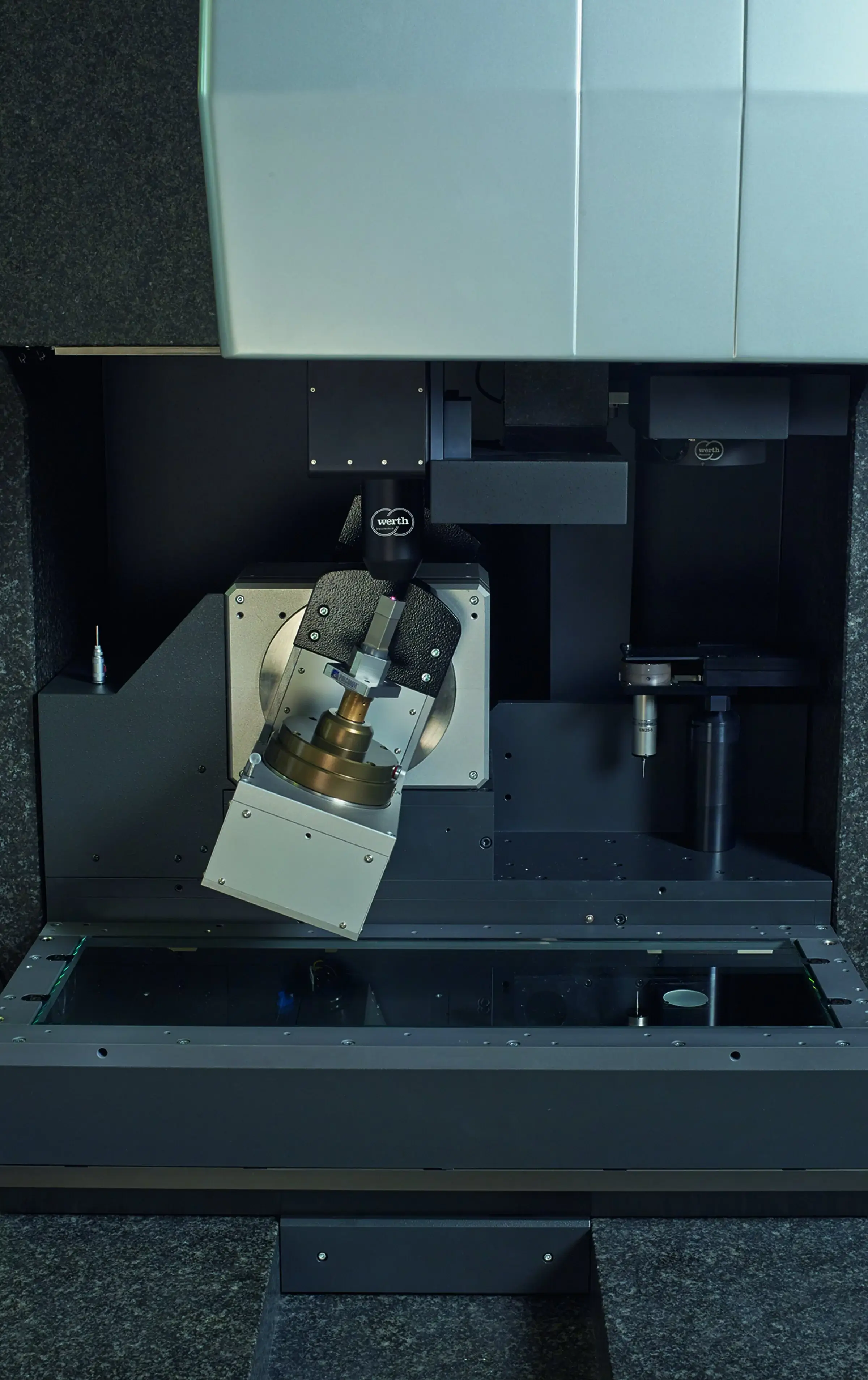

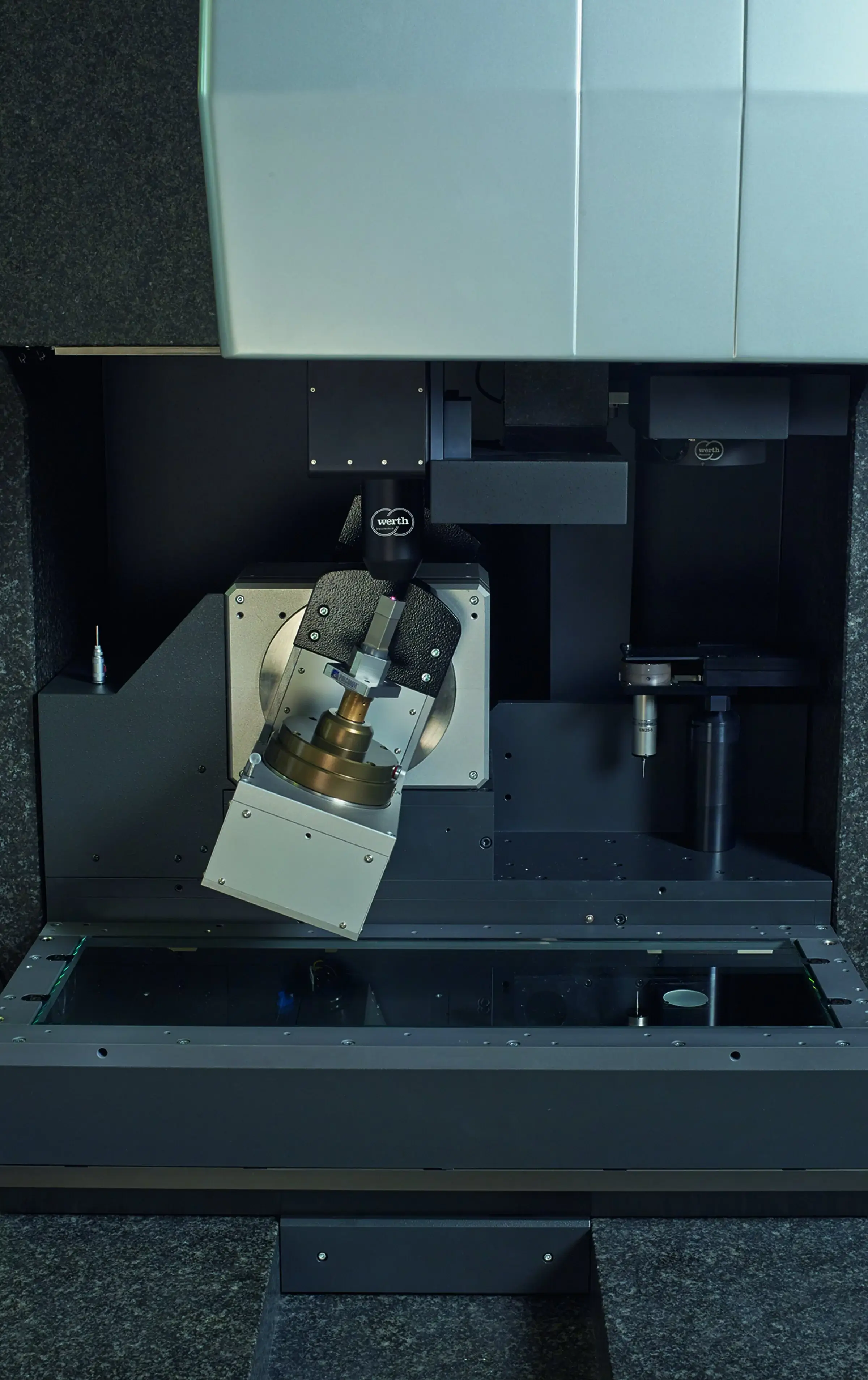

Sensor principle

Optical-axial (chromatic aberration)

Measuring range

0.2 mm to 4 mm

Accuracy

Permissible probing error up to 1 µm

Functionality

From the evaluation box a), the light from a broadband light source b) is projected onto the workpiece (position 1), 2) or 3)) via fibre couplers c), linear optical fibres d) and imaging optics e). The intensity of the reflected light is highest for the colour corresponding to the distance from the workpiece f). This is evaluated via a spectrometer g) for all measurement points on a line simultaneously.

The universal measurement software for coordinate measuring machines with optics, probe, computed tomography and multi-sensor systems

The operation of machines with a wide variety of sensors, as well as the evaluation of volume data and point clouds ...

Comprehensive service around the coordinate measuring machine

Services from initial commissioning, training and maintenance to retrofitting ...