Kromatik ölçüm prensibi, düşük ölçüm hataları ve yüzey özelliklerinden yüksek düzeyde bağımsızlık sağlar. Tarama sırasında, kısa sürede çok sayıda ölçüm noktası yakalanır. Bu, ölçüm belirsizliği ve ölçüm süresi açısından yüksek talepler olsa bile geniş bir uygulama yelpazesi sunar. Sıkı toleranslı boyutların yanı sıra küf ve pürüzlülük de ölçülebilir.

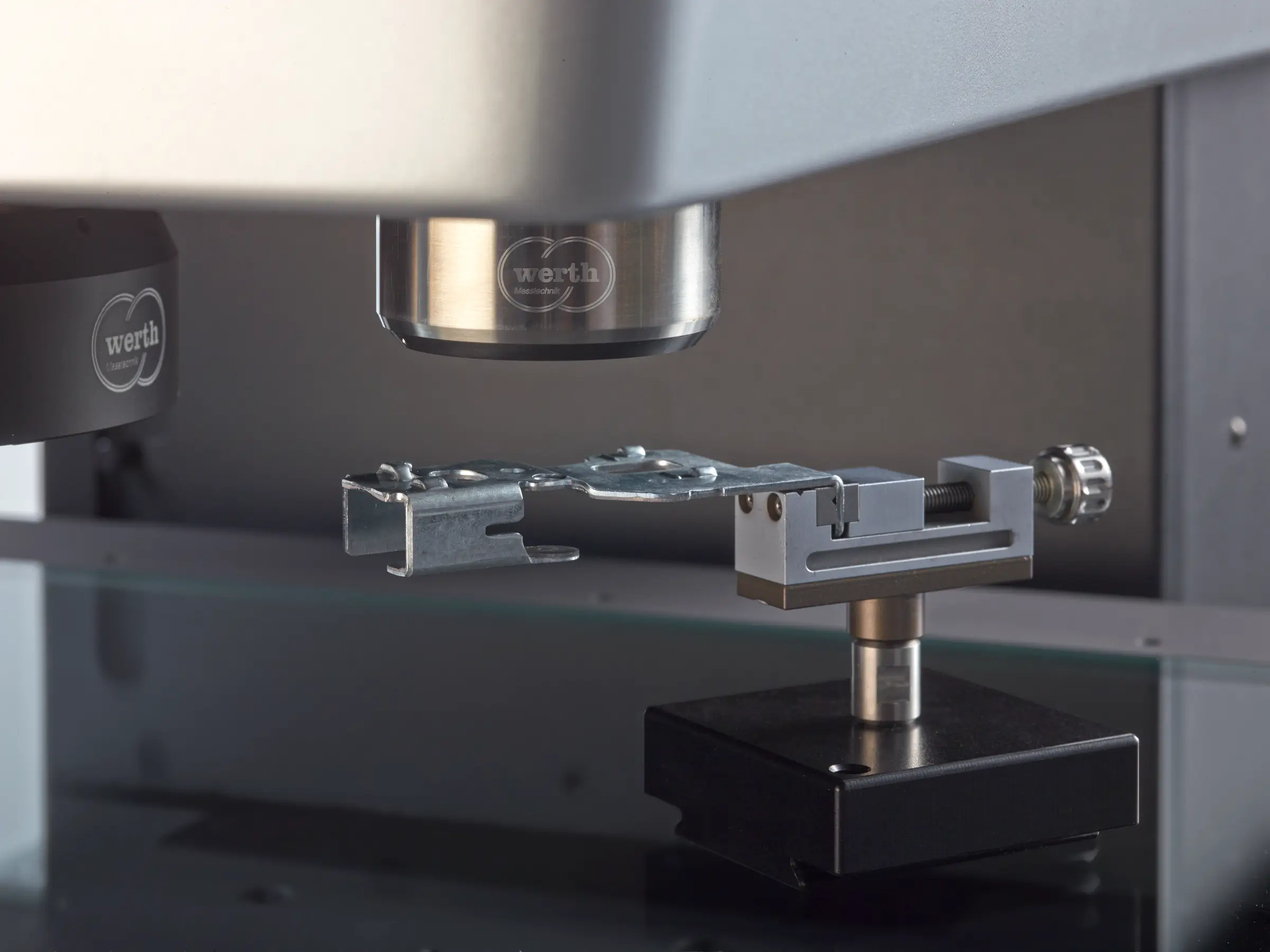

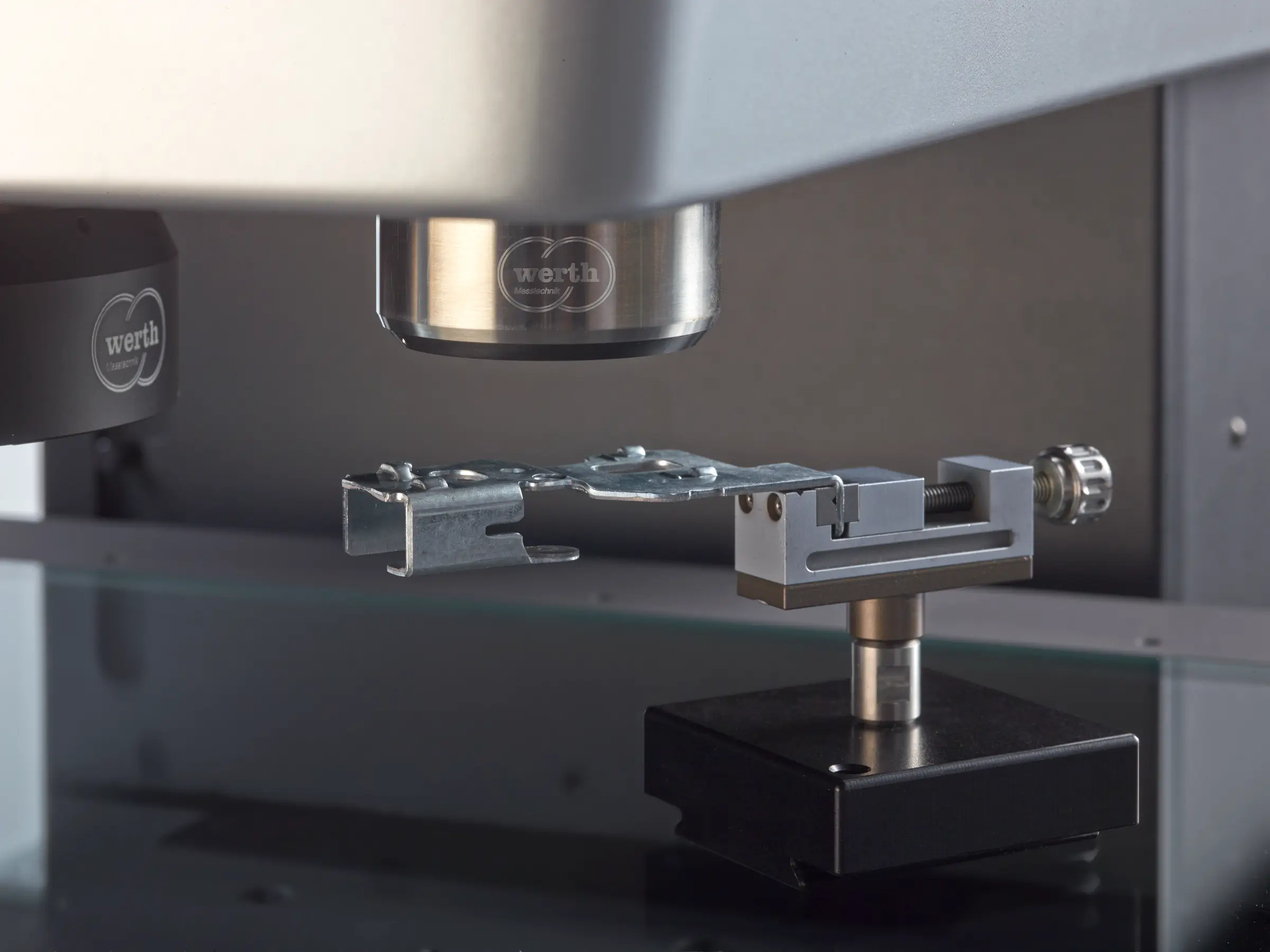

Chromatic Focus Point Sensor CFP

Hassas ve elastik iş parçalarının ölçümü

Sensörün geniş ölçüm aralıkları, cihaz eksenlerini iş parçası yüzeyine hareket ettirmeden hızlı tarama ve böylece daha kısa ölçüm süreleri sağlar

Yansıtıcı veya şeffaf yüzeylerin ölçümü mümkündür

Şeffaf malzemelerin katman kalınlıkları da ölçülebilir (isteğe bağlı)

Sensör prensibi

Optik-eksenel (kromatik sapma)

Ölçüm aralığı

0.3 mm to 3 mm

Hassasiyet

0,25 µm'ye kadar izin verilen ölçüm hatası

İşlevsellik

Geniş bantlı bir ışık kaynağından gelen ışık b) değerlendirme kutusundan a) iş parçasına (konum 1), 2) veya 3) bir fiber kuplör c) bir optik fiber d) ve görüntüleme optiği e) aracılığıyla yansıtılır. Yansıyan ışığın yoğunluğu, iş parçasından f) uzaklığa karşılık gelen renk için en yüksektir. Bu, bir spektrometre g) kullanılarak analiz edilir.

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...