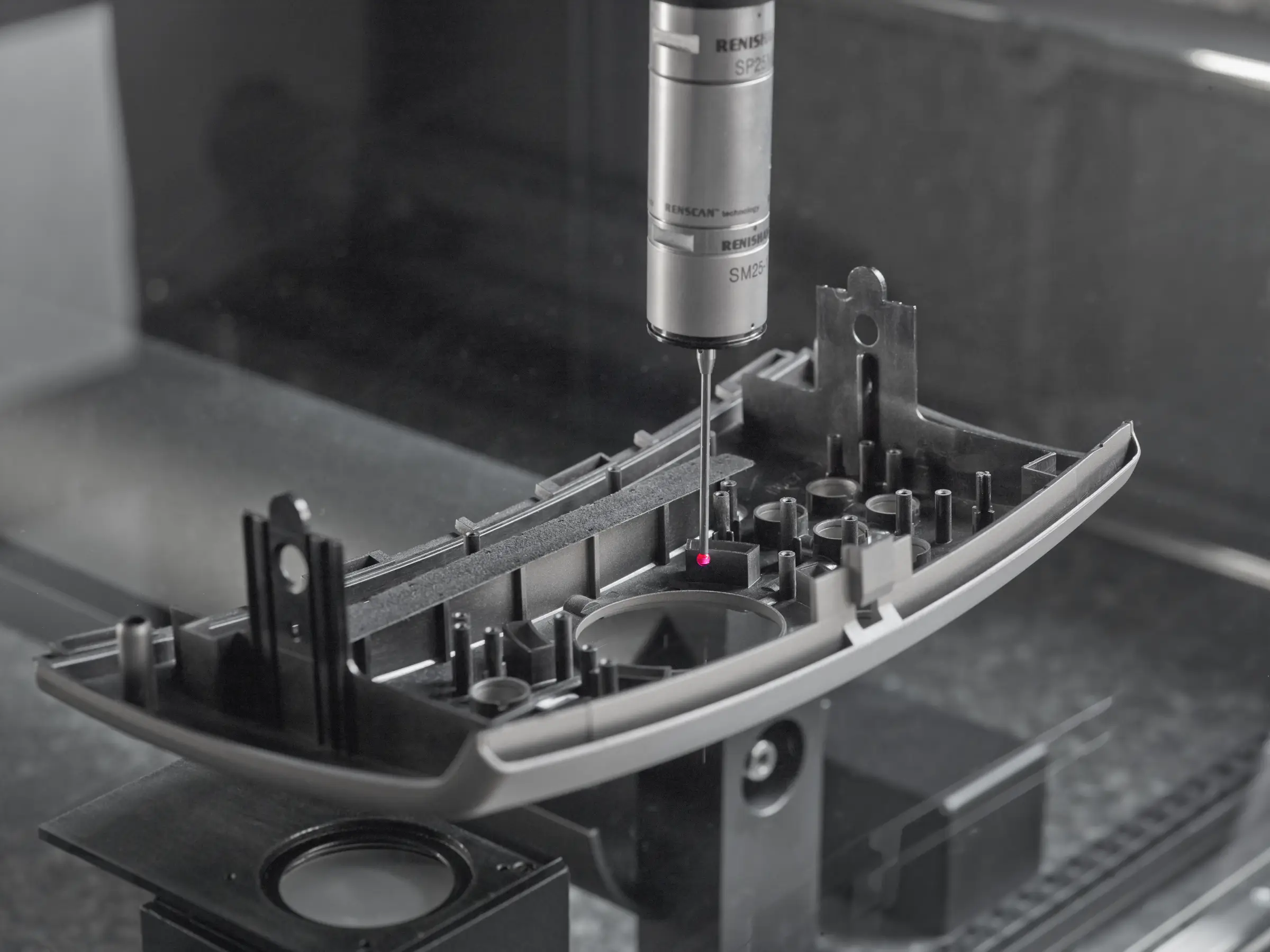

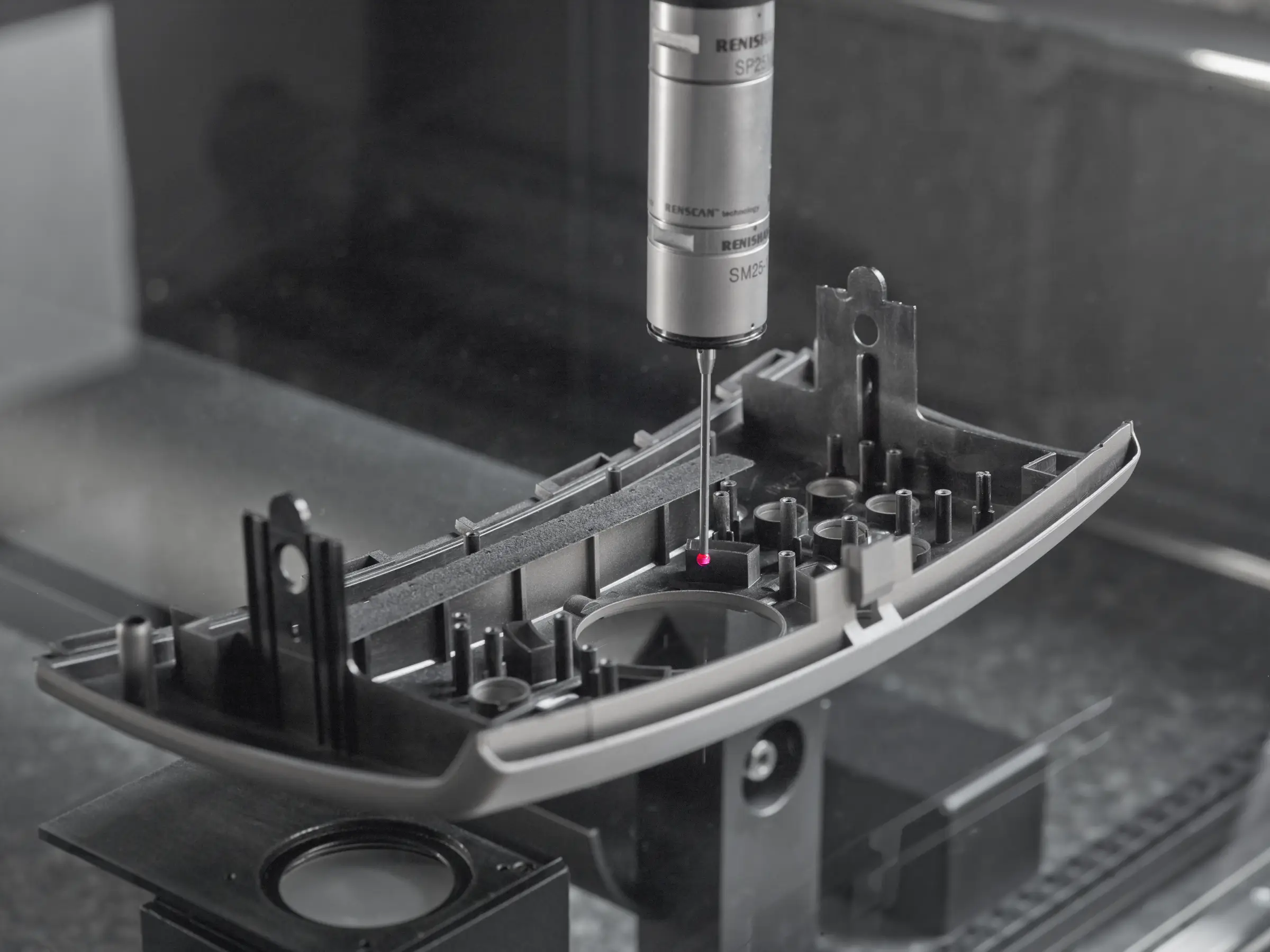

SP25M, kompakt tasarımlı bir ölçüm dokunsal sensörüdür. 3B tarama probu, isteğe bağlı olarak tarama ve koordinat ölçüm cihazında nokta nokta 3B ölçümler için kullanılabilir. Farklı tarama modülleri, farklı prob uzunluklarıyla optimum sonuçlar sağlar. Dokunsal ölçüm sistemi, kalıp ve geometri ölçümleri için idealdir ve Werth çoklu sensör konseptine tamamen entegredir.

Ölçüm Probu SP25M

Kompakt tasarımı, SP25M'yi PH6M sabit montaj aparatı ve PH10 döner/eğimli kafa ile uyumlu hale getirir

Üç (FCR25-L3) veya altı (FCR25-L6) depolama alanına sahip SP25M prob sistemlerinin, ölçüm cihazına doğrudan montaj için değiştirme rafı olarak hızlı bir şekilde değiştirilmesi

Modüler değiştirme rafı MRS'ye doğrudan montaj için ek ünite olarak FCR25 değiştirme rafı

Sensör prensibi

Dokunsal-elektrikli

Hassasiyet

0,75 µm'ye kadar izin verilen ölçüm hatası

İşlevsellik

İş parçasıyla temas ettiğinde, iğne koordinat eksenlerinin yardımıyla nominal sapmaya getirilir. Kesin sapma, üçgenleme işlemi kullanılarak ölçülür, makinenin ölçek sistemlerinin koordinatlarıyla üst üste bindirilir ve bir ölçüm noktası olarak kaydedilir.

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...