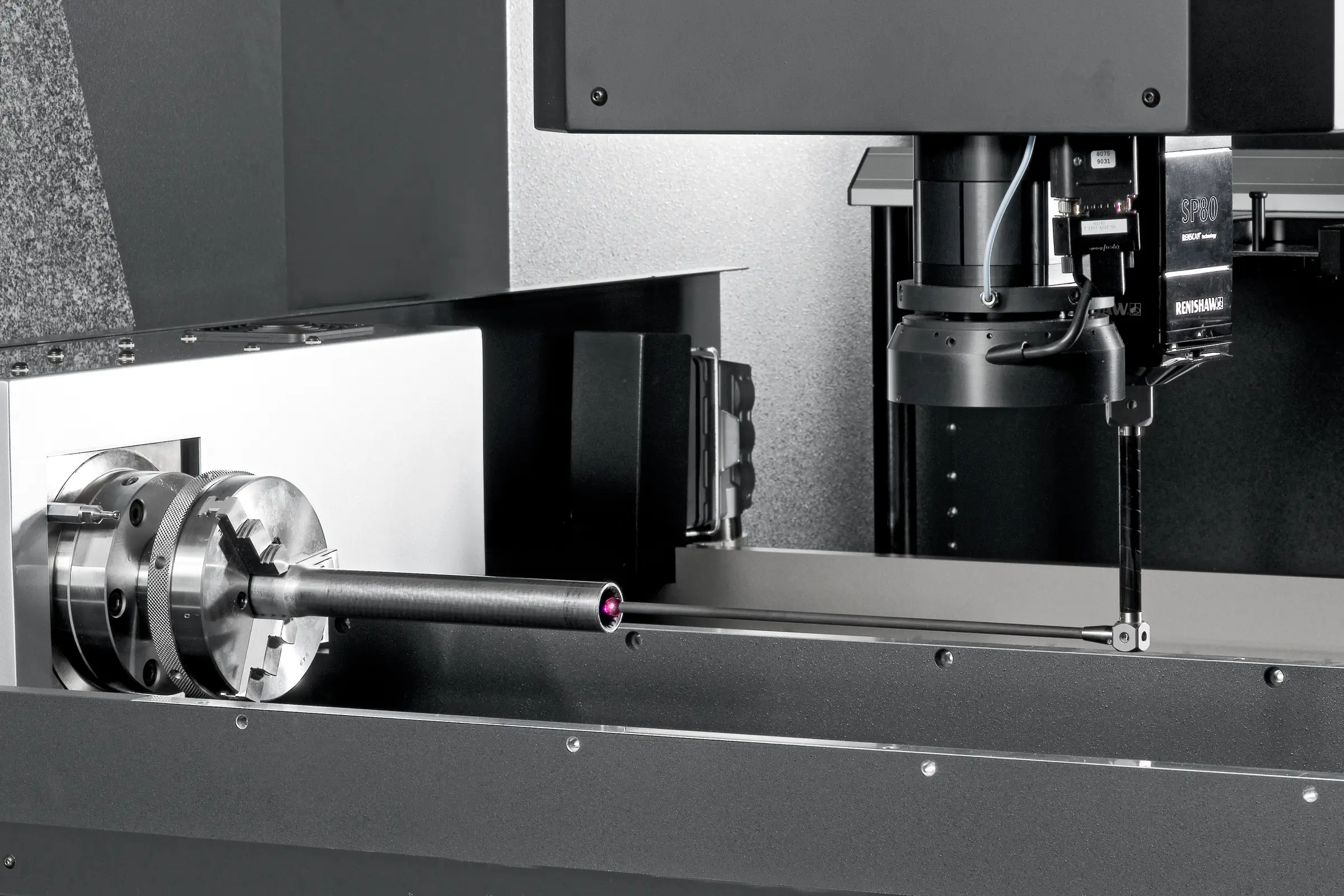

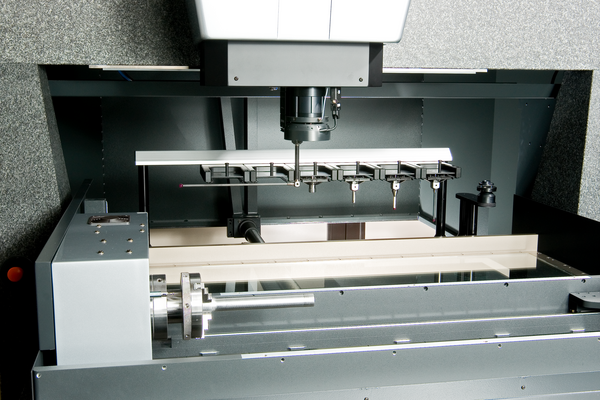

Döner eksen, hem dönme simetrili hem de kübik iş parçalarının farklı görünümlerde eksiksiz ölçümünü sağlar ve çok çeşitli sensörler için iş parçasına optimum erişim imkanı sunar. Yeniden sıkıştırmadan kaynaklanan zaman ve hassasiyet kayıpları ortadan kaldırılır. Yüksek konumlandırma hassasiyeti ve salınım telafisi, örneğin şaftların, takımların, dişlilerin ve 3B iş parçalarının güvenilir bir şekilde ölçülmesini sağlar.

Döner eksen

Patentli Raster Scanning HD ROTARY modunda tüm iş parçasının otomatik olarak yakalanması ve yan yüzeyde "görüntüde" hızlı ölçümler (opsiyonel)

Freze, matkap ve taşlama takımları gibi işleme takımlarının etkin konturunun zarf tarama ile otomatik olarak belirlenmesi (opsiyonel)

RotaryScan HD ile 200 nm aralığında minimum ölçüm hatasıyla yuvarlaklık ölçümleri (opsiyonel)

Neredeyse tüm Werth koordinat ölçüm makineleri için opsiyonel olarak döner eksenler mevcuttur

Aksesuar olarak herhangi bir düzende (A, B, C) monte edilebilirler

Döner eksenlerin yazılıma tam entegrasyonu sayesinde iş parçası koordinatlarında değerlendirme

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...