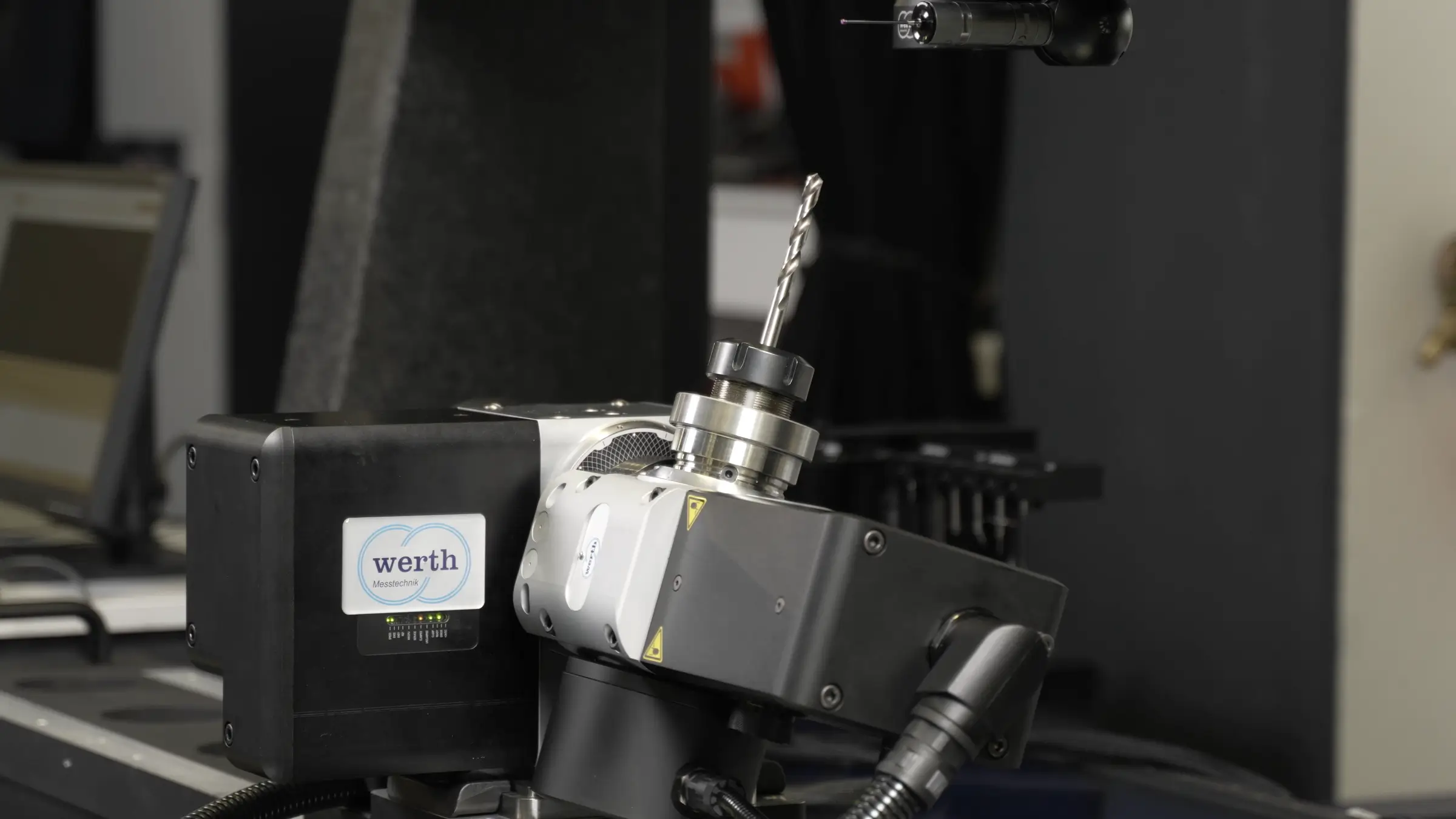

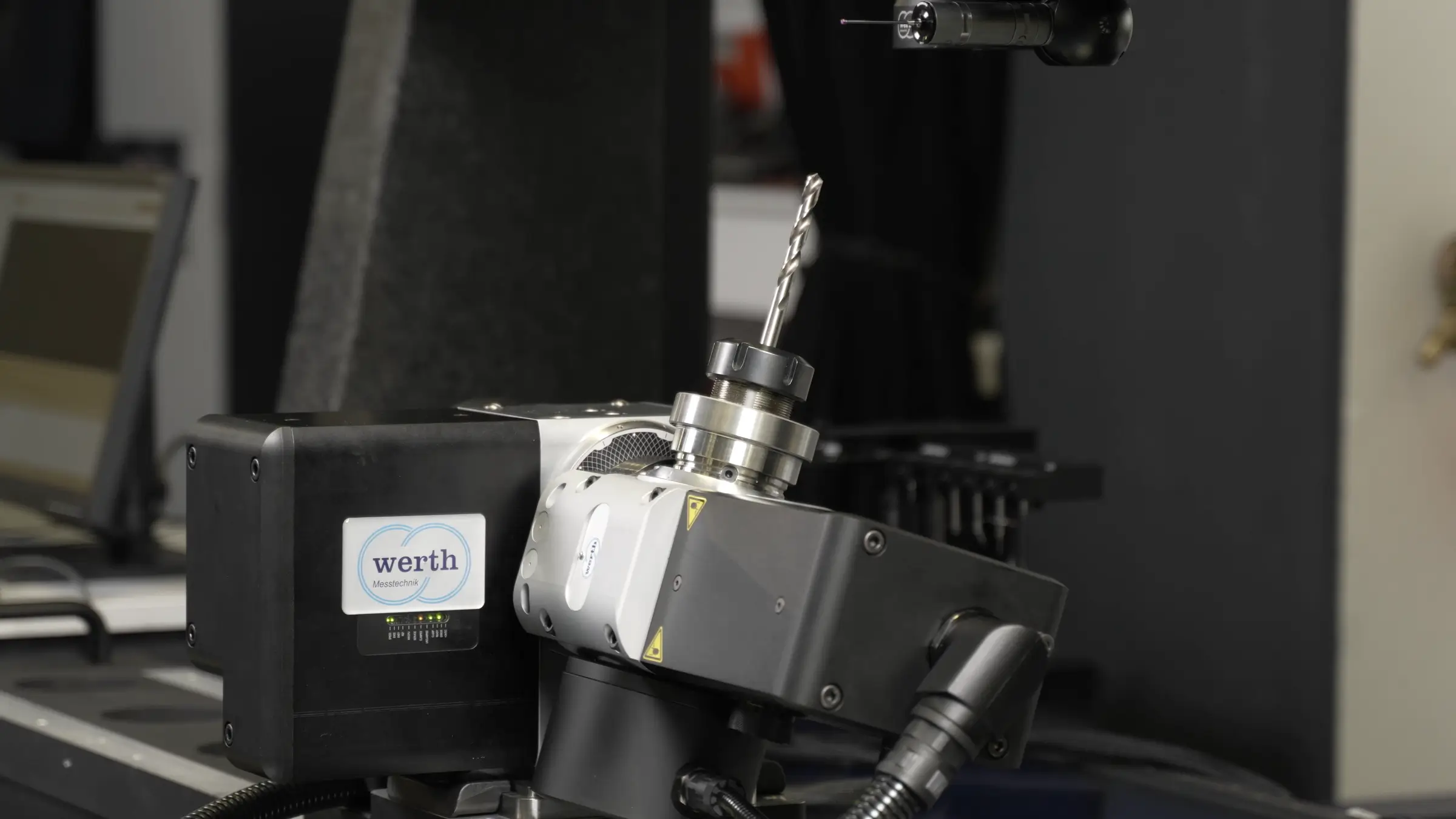

Yüzeyler veya delikler gibi farklı yönelimli geometrik elemanlar, çoklu sensör sistemleriyle optimum hizalamayla ölçülebilir. Büyük sensörler bile tüm iş parçası alanlarına erişebildiğinden, yeniden sıkıştırma ve buna bağlı zaman ve doğruluk kaybı olmadan tüm iş parçası ölçülebilir. Döner/eğimli eksenler üç farklı versiyonda mevcuttur: maksimum doğruluk için hava yataklı, üretim için mekanik yataklı ve örneğin ScopeCheck® S, VideoCheck® S ve VideoCheck® MZ için kompakt versiyon.

Döner/eğim ekseni

Neredeyse tüm Werth ölçüm makineleri için mevcuttur

Aksesuar olarak herhangi bir düzende monte edilebilir

Sensörler için karmaşık konumlandırma ünitelerinin yerini alır

Özel rulman teknolojisi sayesinde büyük ve ağır iş parçaları için de kullanılabilir

Düz yüzeyler veya girintiler optik sensörlerle optik olarak ölçülebilir

Küçük delikler, Werth Fiber Probe® mikro prob ile ölçüm için optik eksene döndürülebilir

Dönme eksenlerinin yazılıma tam entegrasyonu sayesinde iş parçası koordinatlarında değerlendirme

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...