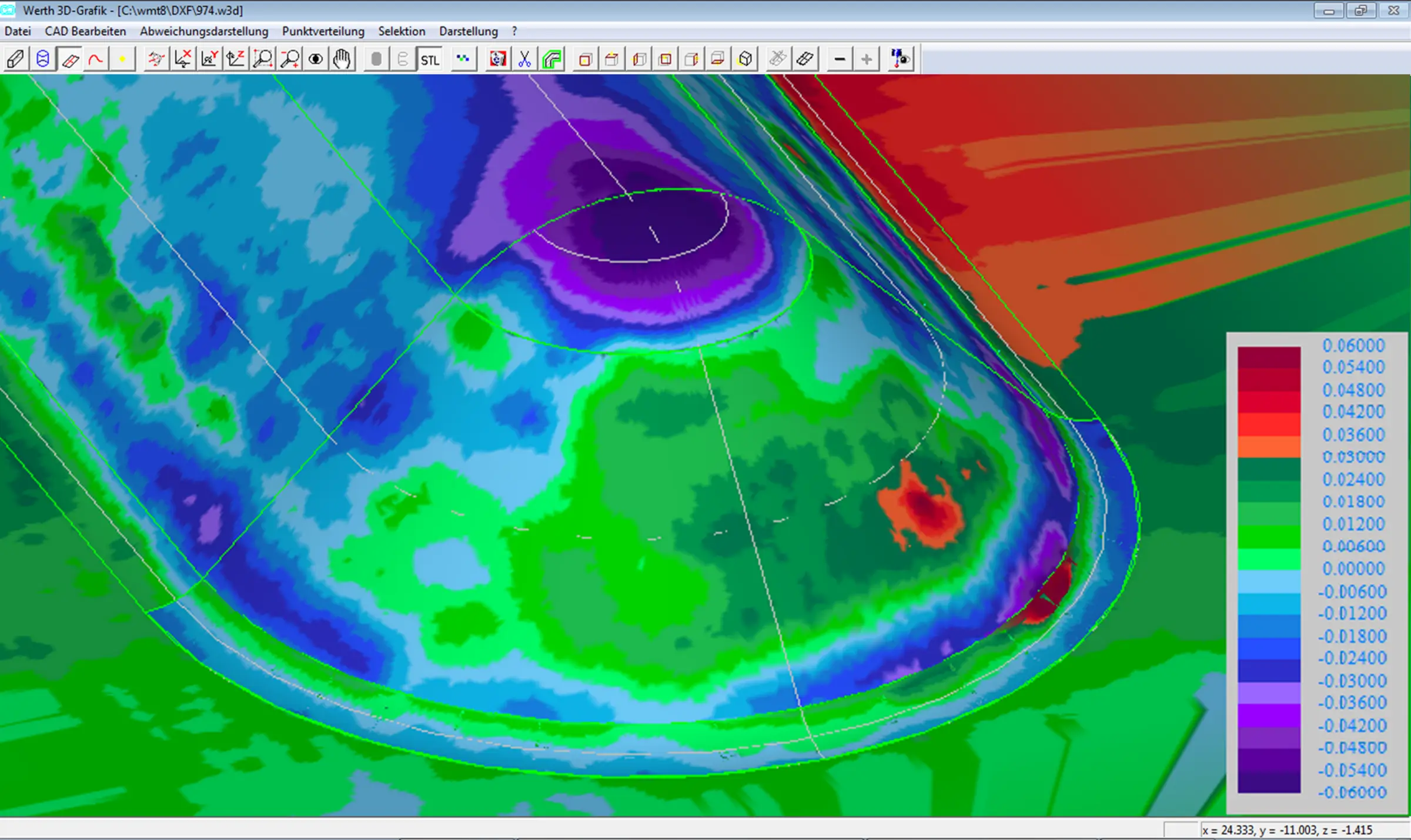

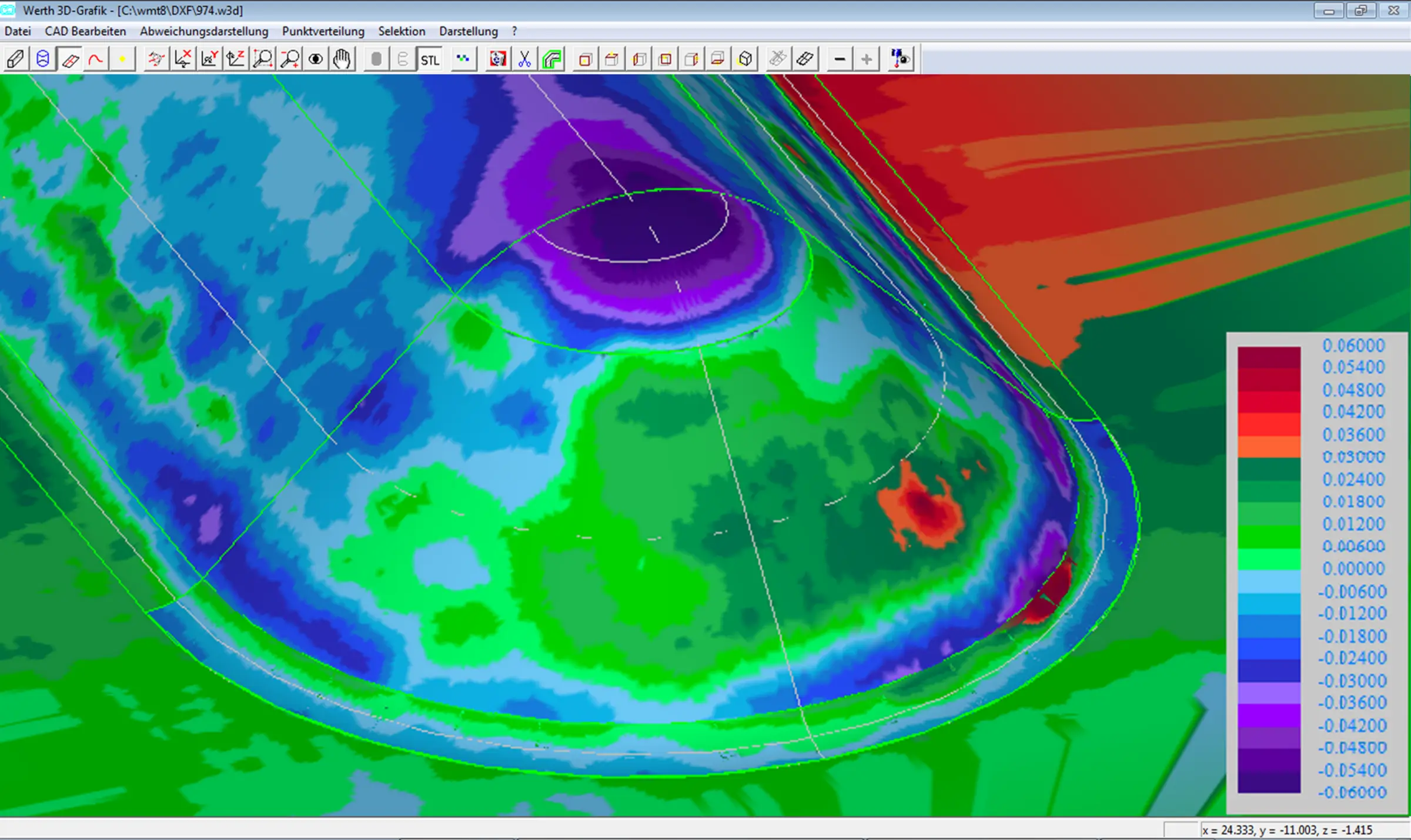

3B yama, odak değişimi prensibine dayanan ve sensör parametrelerini iş parçasının ilgili yüzey özelliklerine otomatik olarak uyarlayan bir alan sensörüdür. Optik sensör, yüzey alanlarının hızlı 3B nominal-gerçek karşılaştırmalarına veya salt boyutsal değerlendirmelere olanak tanır. 3B yama ile, küçük ve detaylı alanların bile topografyası yüksek yanal çözünürlükle optik olarak ölçülebilir.

Werth 3D Patch

HDR işlevi, farklı pozlama sürelerine sahip görüntü yığınlarının yakalanmasını ve eşit olmayan yansıtıcı yüzeylerin ölçülmesini sağlar

Pozlama sürelerinin optimum şekilde ayarlanması için akıllı yazılım işlevleri mevcuttur

Geniş filtre seçenekleri, tekrarlanabilir ve güvenilir sonuçlar sağlar

Otomatik segmentasyon sayesinde kontrol geometrisi elemanlarının hesaplanması mümkündür

Sensör prensibi

Optik-eksenel (odak değişimi)

Hassasiyet

0,25 µm'ye kadar izin verilen ölçüm hatası

İşlevsellik

Görüntü işleme sensörünün donanımı (a) kamera, b) görüntüleme optiği, c) ölçüm nesnesi ve d) gelen ışık aydınlatması) kullanılarak, optik eksende z1 ve z2 arasında farklı konumlarda görüntüler alınır. Kontrast gradyanına dayanarak, iş parçası yüzeyindeki birçok ölçüm noktası aynı anda belirlenir.

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...