Yüksek performanslı donanım ve akıllı ölçüm yazılımları, bilgisayarlı tomografi özellikli koordinat ölçüm makinelerinin daha yüksek doğruluk ve ölçüm hızlarına ulaşmasını sağlar. Bu, endüstriyel bilgisayarlı tomografinin artık laboratuvar ve ölçüm odası uygulamalarının yanı sıra, üretime yakın hızlı 3B ölçümler ve istatistiksel proses kontrolü (SPC) için de kullanılabileceği anlamına gelir. Diğer sensörlerin aksine, alt kesimler ve iç geometriler de dahil olmak üzere tüm üç boyutlu iş parçası hacmi, tek bir düğmeye dokunarak ölçüm sonucu olarak her zaman kullanılabilir.

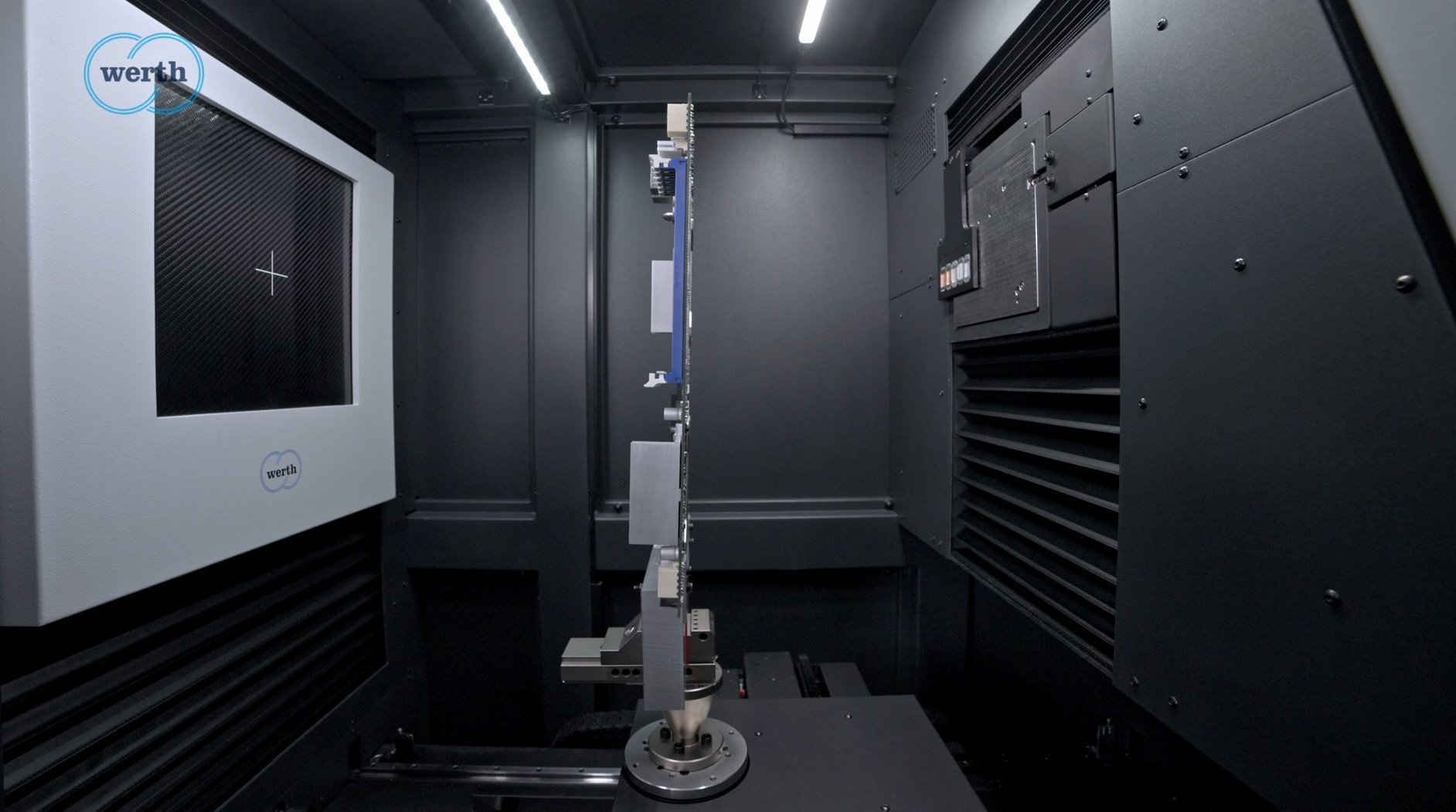

Werth bilgisayarlı tomografi (CT)

Tüm makinelerin standartlara uygun kalibrasyonu, ayrıca DAkkS sertifikası ile

Alt voxelling işlemi yüksek mekansal çözünürlük ve dolayısıyla düşük ölçüm belirsizliğini garanti eder

Çoklu ROI ve Raster Tomografi gibi özel ölçüm yöntemleri kullanılarak yapısal çözünürlük daha da iyileştirilebilir.

Görüntü edinimiyle paralel gerçek zamanlı yeniden yapılandırma, ölçüm sonuçlarının tarama sürecinin sonuna göre anında kullanılabilir olması anlamına gelir

OnTheFly CT ile azaltılmış ölçüm süresi, yüksek verimlilikle üretime yakın ölçümlere olanak tanır

Sensör prensibi

X-ışını tomografisic

Ölçüm aralığı

Maksimum iş parçası boyutları D = 120 mm / U = 93 mm ila D = 500 mm / U = 1010 mm (iş parçalarının en boy oranına bağlı olarak)

Hassasiyet

2,5 µm'ye kadar izin verilen ölçüm hatası

İşlevsellik

X-ışını tüpü tarafından yayılan radyasyon a) iş parçasının X-ışını görüntülerini üretir b) dedektör üzerinde c) Farklı dönme pozisyonlarında alınan X-ışını görüntülerinden sanal bir iş parçası hacmi yeniden oluşturulur.

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...