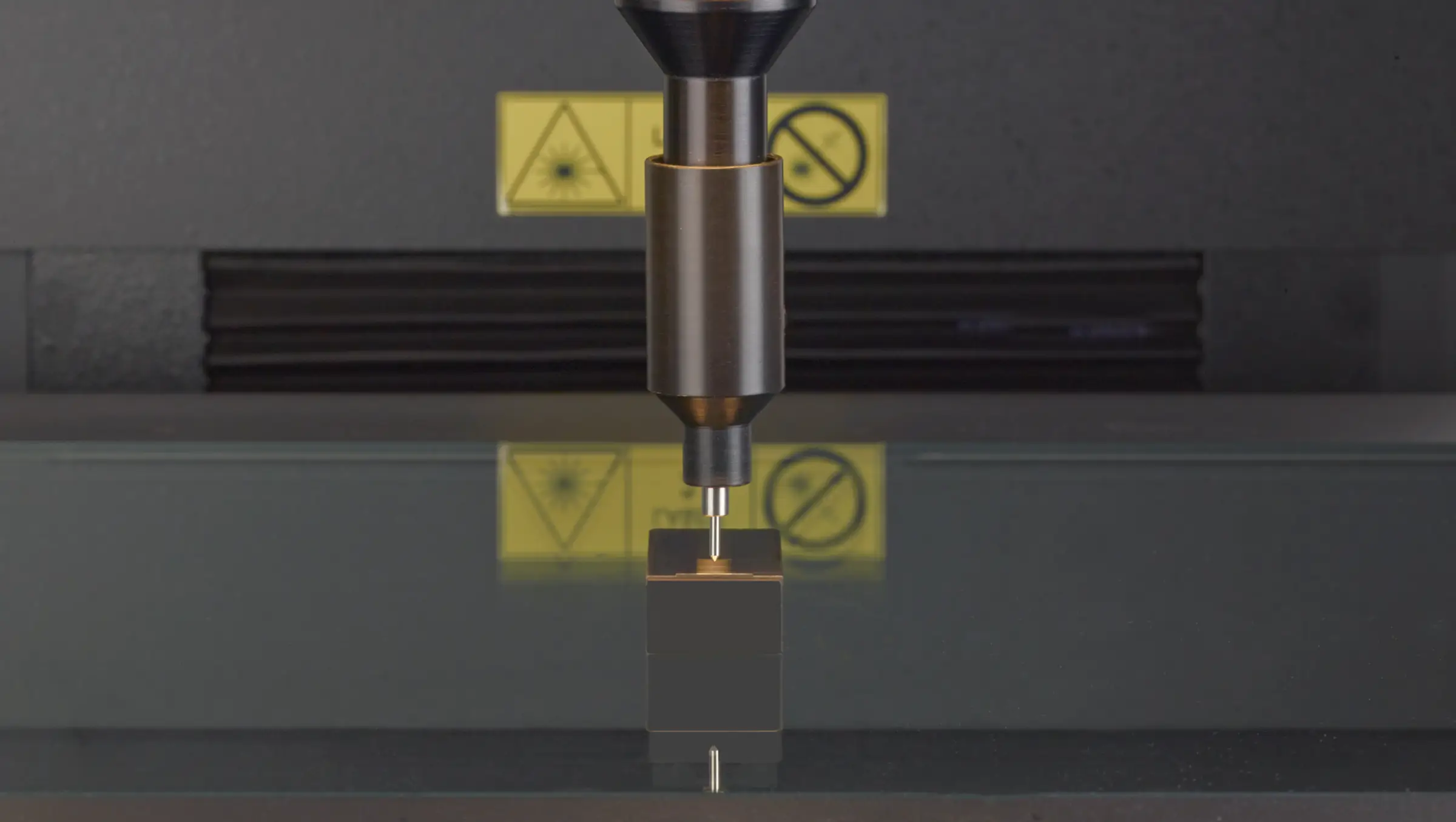

Daha önce kontur ölçüm cihazlarına özgü olan görevler, çok sensörlü koordinat ölçüm cihazındaki Werth Kontur Probu ile çözülebilir. Dokunsal-optik kontur probu, ilk kez, tanımlanmış iş parçası koordinatlarında dokunsal kontur ölçümüne olanak tanır. Klasik kontur ölçüm cihazlarının aksine, WCP'nin özel kılavuz sistemi, tercih edilen bir yön olmaksızın herhangi bir kesitte tarama yapılmasına olanak tanır.

Werth Contour Probe WCP

Pürüzlülük ölçümü CNC kontrollü olarak da yapılabilir ve konturlar, iş parçasını tekrar sıkıştırmadan iş parçası koordinat sisteminde taranabilir.

WinWerth® ölçüm yazılımına entegre pürüzlülük kütüphanesi sayesinde pürüzlülük değerleri standartlara uygun olarak hesaplanabilir.

Sensör, değiştirme rafı aracılığıyla CNC kontrollü olarak değiştirilebilir.

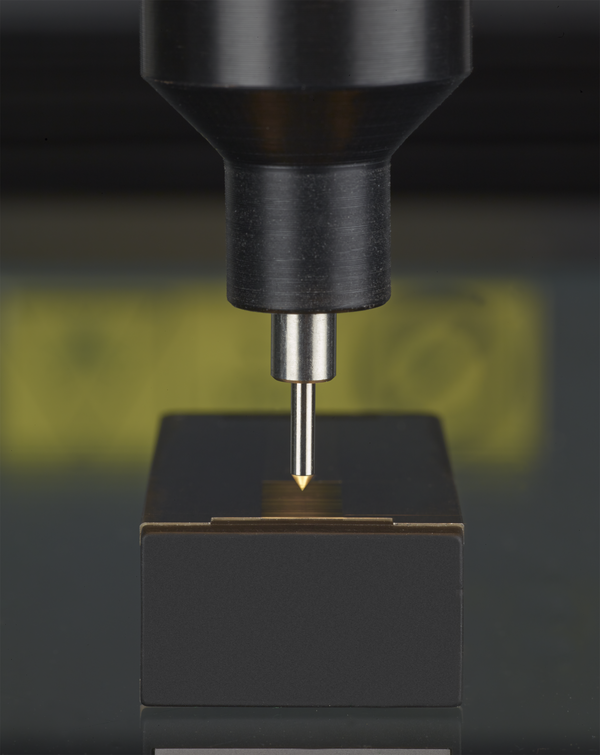

Sensör prensibi

Dokunsal-optik

Hassasiyet

2 µm'ye kadar izin verilen ölçüm hatası

İşlevsellik

Dokunsal-optik kontur sensöründe, lazer mesafe sensörü a) (b) manyetik arayüz, c) ayna, d) yatak) iş parçası yüzeyi taranırken kontur prob ucunun sapması e) ölçülür f).

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...