Patentli Werth Fiber Probe® WFP 2D, onlarca yıldır mikro problar için endüstri standardını belirlemiş ve en küçük problama kuvvetleriyle son derece küçük geometrilerin son derece hassas dokunsal ölçümlerini mümkün kılmıştır. Düşük problama kuvvetleri sayesinde WFP®, hassas yüzeyli iş parçalarında optik ölçümlerin kalibrasyonu için de uygundur. Tipik uygulama alanları arasında kauçuk ve plastik parçalar, ölçüm cihazları, eğirme memeleri, enjeksiyon nozulları ve türbin kanatlarındaki mikro delikler ve mikro dişliler bulunur.

Werth Fiber Probe® WFP 2D

Kalem ucunun doğrudan değerlendirilmesi sayesinde WFP®, birkaç onda bir mikrometre aralığında ölçüm hatalarına ulaşır.

Kalem şaftının bükülmesinin ölçüm sonucu üzerinde hiçbir etkisi yoktur.

Fiber probun çözünürlüğü nanometre aralığındadır ve nihayetinde yalnızca kullanılan optiğe bağlıdır.

Tarama modunda, Werth Stylus® çok sayıda ölçüm noktasıyla geniş bir kontur yelpazesi kaydeder ve bu sırada kalem, yapışma-kayma etkilerini önlemek için bir titreşim jeneratörü tarafından sürekli hareket halinde tutulur.

Sensör prensibi

Dokunsal-optik

Hassasiyet

0,3 µm'ye kadar izin verilen ölçüm hatası

İşlevsellik

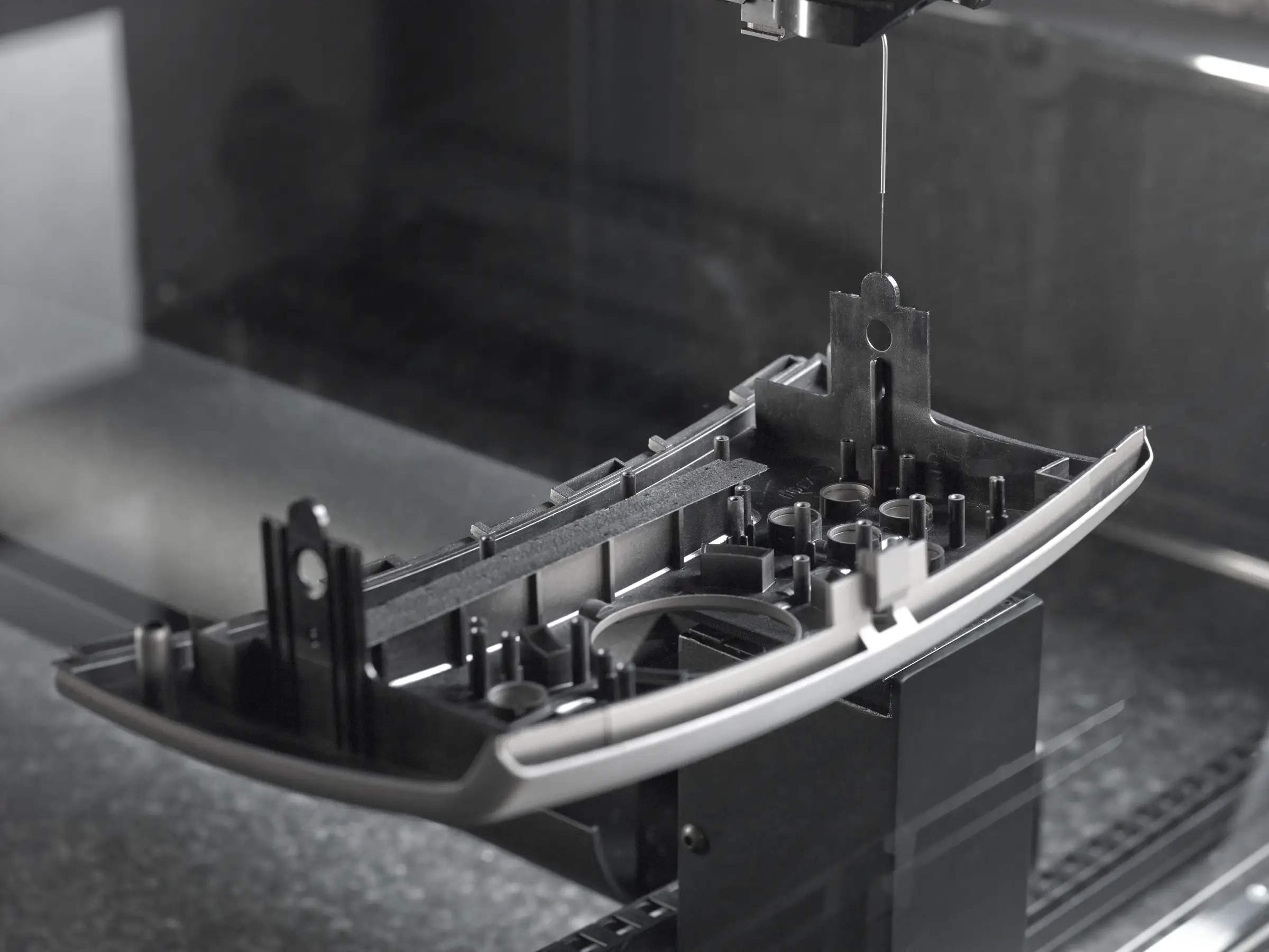

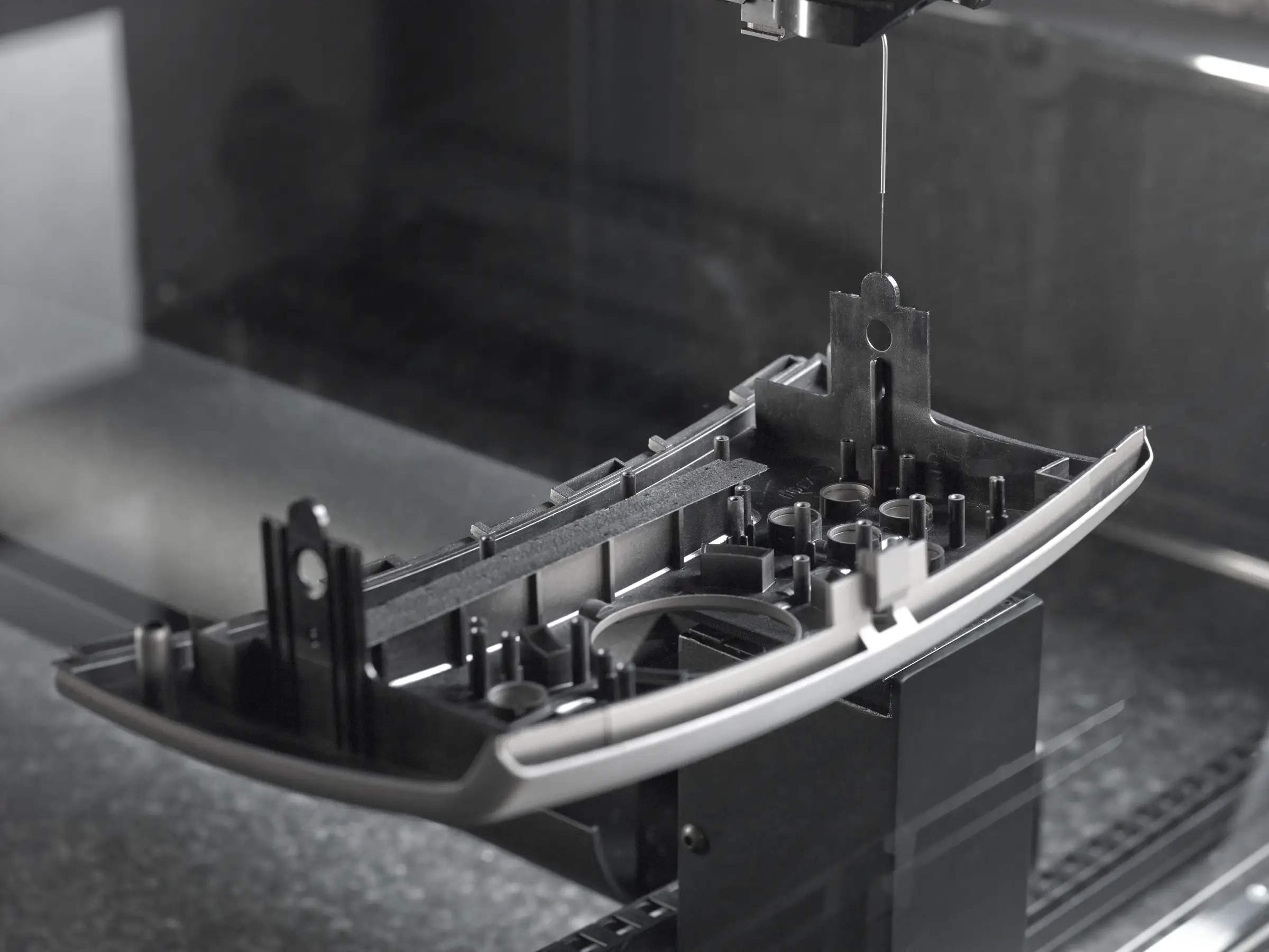

Bir görüntü işleme sensörü (a) kamera, b) görüntüleme optiği) bir LED ile aydınlatılan iğne ucunun sapması ΔL'yi ölçmek için kullanılır. c) iş parçası e) hareket ettiğinde. Hedef sapmasında, iğne ucunun tam konumu, makinenin ölçek sistemlerinin koordinatlarıyla üst üste bindirilir ve ölçüm noktaları olarak saklanır veya tarama işlemi için kullanılır. Çift küreli problar f) tek küreli problara g) göre daha büyük bir sondaj derinliğine ulaşır.

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...