WIP, geometri, kalıp ve pürüzlülüğün son derece hassas ölçümü için temassız bir fiber optik sensördür. Prob geometrileri, iş parçası yüzeylerinin ölçümü için gerekli çıkış açılarına göre ayrı ayrı uyarlanabilir. Küçük prob boyutları sayesinde WIP, özellikle küçük, erişilmesi zor ve derin geometrilerin ölçümü için uygundur ve bu nedenle Werth'in mikro geometrilerin ölçümündeki özel uzmanlığının bir parçasıdır.

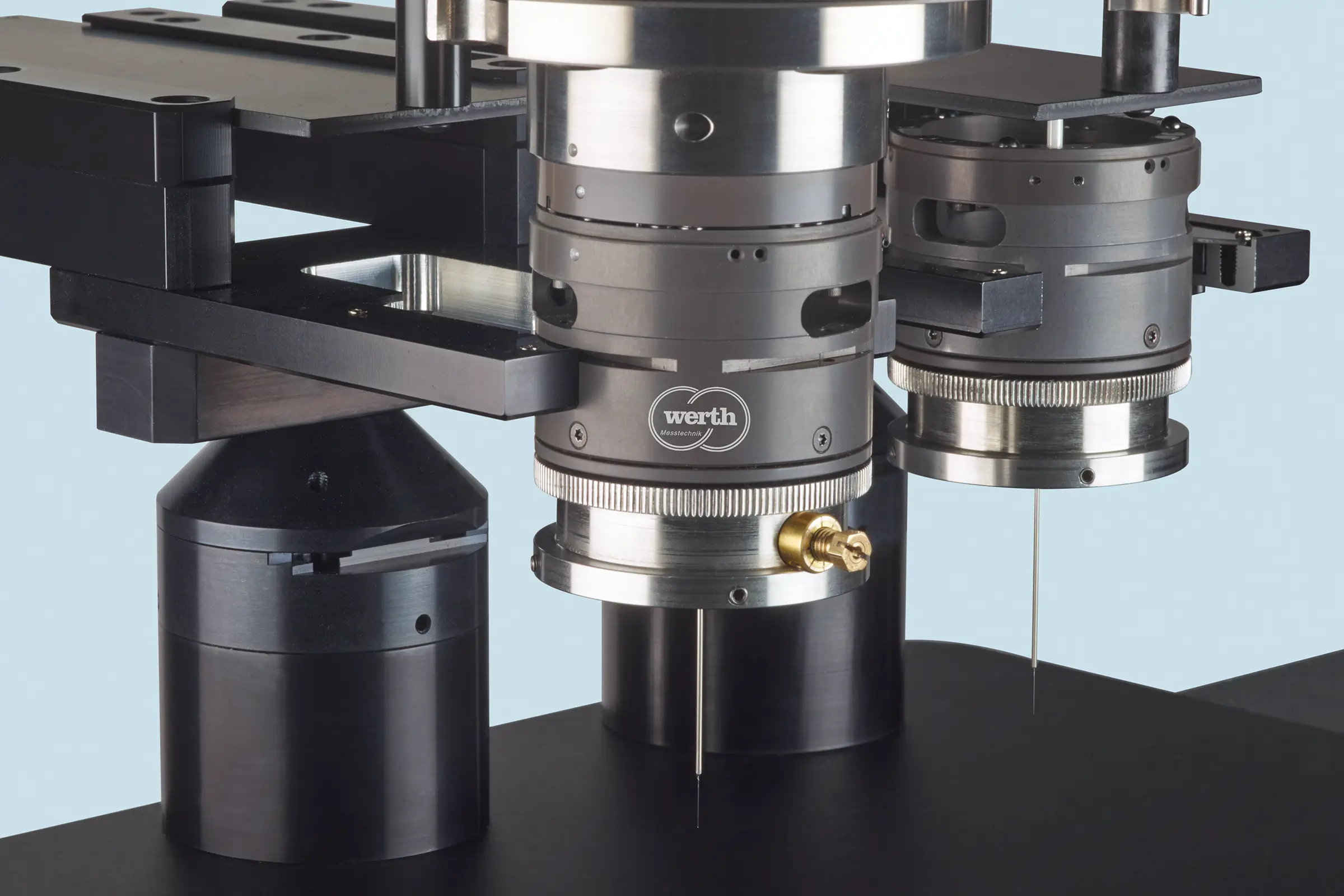

Werth İnterferometre Probu WIP

RS versiyonunda, WIP dönebilen prob ile oldukça hassas yuvarlaklık ölçümüne olanak sağlar

Metal bir tüpteki fiberin kılavuz yolu sayesinde, problar büyük sondaj derinlikleri için çok uzun uzunluklarda da sunulabilir

Probun taşlanması, ölçüm ışınının 0° ile 90° arasındaki çıkış açısını belirler; 90° açılı problar, örneğin küçük deliklerin yan yüzeylerini ölçmek için kullanılır.

Sensör prensibi

Optik (kısa tutarlı interferometri)

Ölçüm aralığı

300 µm

Hassasiyet

0,2 µm'ye kadar izin verilen ölçüm hatası

İşlevsellik

Süperlüminesan diyot a) ve ölçüm probu c) bir fiber kuplör b) üzerinden birbirine bağlandığında, prob çıkış yüzeyinden d) ve iş parçası yüzeyinden e) yansıyan ışığın zaman farkı hakkındaki bilgi ölçülür. c) ve iş parçası yüzeyinden e) yansıyan ışığın zaman farkı, interferometre (görüntüleme optiği f), ışın bölücü g), aynalar h) ve i) ve silindirik mercek j)) tarafından bir çizgisel kamera k) üzerine yansıtılır ve buradan mesafe belirlenir.

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...