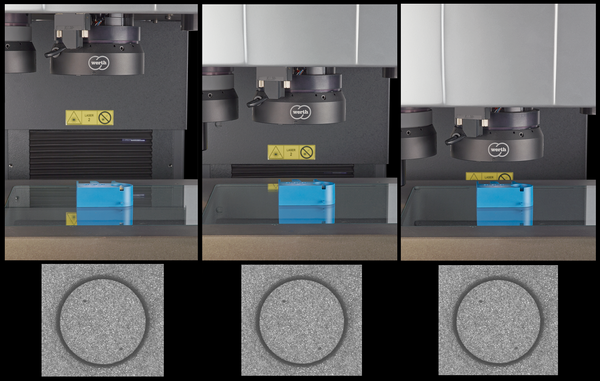

Werth Zoom, büyütmenin yanı sıra, lens ile ölçüm nesnesi arasındaki çalışma mesafesinin "CNC uyumlu" bir şekilde göreve uyarlanmasını da sağlar. Çok geniş çalışma mesafesinin bir avantajı, örneğin, büyük derinlikli kör deliklerin ve büyük çaplı tornalanmış parçaların çarpışma olmadan test edilebilmesidir. Esnek çalışma mesafesinin bir diğer avantajı da aydınlatma açısını değiştirmek için Werth MultiRing® ile kombinasyon imkanıdır. Bu, klasik aydınlatma yöntemleriyle hiç görülemeyecek nesne kenarlarının görselleştirilmesini sağlar.

Werth Zoom

Düşük büyütmede birçok geometrik özelliğin net ve hızlı ölçümü ve yüksek büyütmede düşük ölçüm hataları ile endüstriyel görüntü işleme

20 mm ile 200 mm aralığında esnek çalışma mesafesi

Telesentrik aralıkta sabit görüntü boyutu, doğru ölçüm değerlerini garanti eder

Doğrusal kılavuz sistemleri sayesinde düşük ölçüm belirsizliği ve yüksek tekrarlanabilirlik

Ara kalibrasyon olmadan tüm yakınlaştırma seviyelerinde ölçüm

Yakınlaştırma kafasındaki artımlı ölçüm sistemleri, uzun vadeli istikrarlı ölçüm sonuçları ve tekrarlanabilir büyütmeler sağlar

Entegre sürücüler sayesinde son derece hızlı büyütme değişimi

Eksenel yönde ölçüm aralığının genişletilmesi

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...