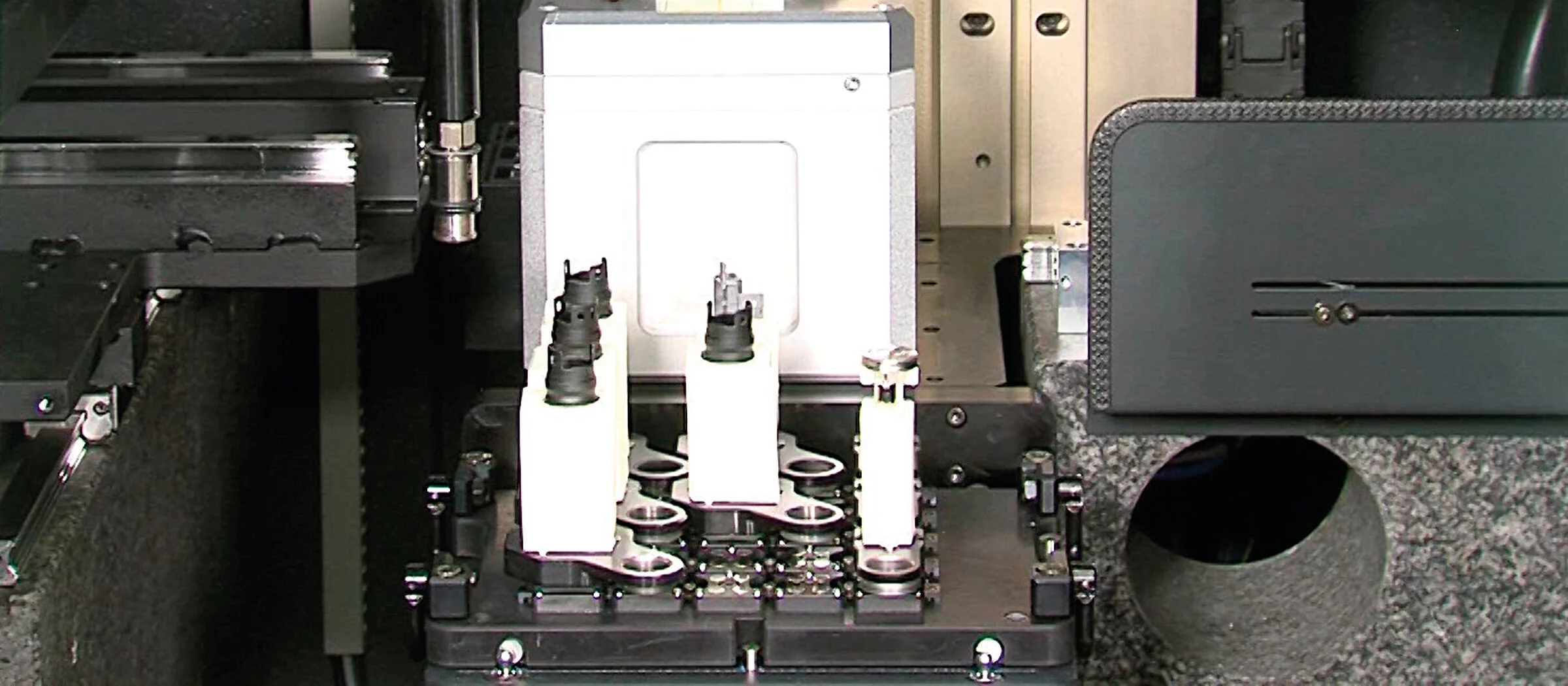

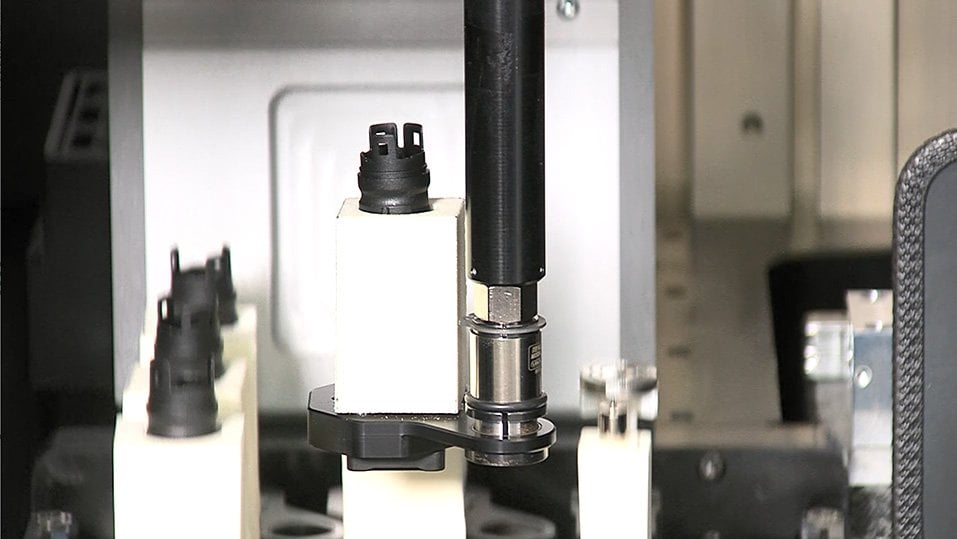

Makineye entegre bir iş parçası değiştirme sistemi, ölçüm hacmi içinde birden fazla aynı veya farklı parçanın, ek kurulum süreleri ve radyasyon koruması açısından ek önlemlere ihtiyaç duyulmadan otomatik olarak beslenmesini sağlar. Ölçüm makinesi, tüm ölçüm serisi boyunca güvenli bir şekilde kapalı kalır ve ölçümler, bir operatörün müdahalesi olmadan "insansız" bir vardiyada yapılabilir.

İş parçası değiştirme sistemi

İş parçası değiştirme sistemi

Kapalı bilgisayarlı tomografi koordinat ölçüm makinesinde otomatik iş parçası değişimi

Avantajlar

Üç vardiyalı çalışmada endüstriyel bilgisayarlı tomografi

Diğer avantajlar

"İnsansız" gece vardiyalarında veya hafta sonları BT ölçümleri

Ölçüm yazılımındaki döngü işlevi, benzer iş parçalarının seri ölçümlerinin zamandan tasarruf sağlayan şekilde öğretilmesine olanak tanır

Ölçüme göre, her iş parçası için bitmiş ölçüm raporu mevcuttur.

CMM'nin radyasyon koruma başlığına entegre edilmiştir

Yazılım

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Servis

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...