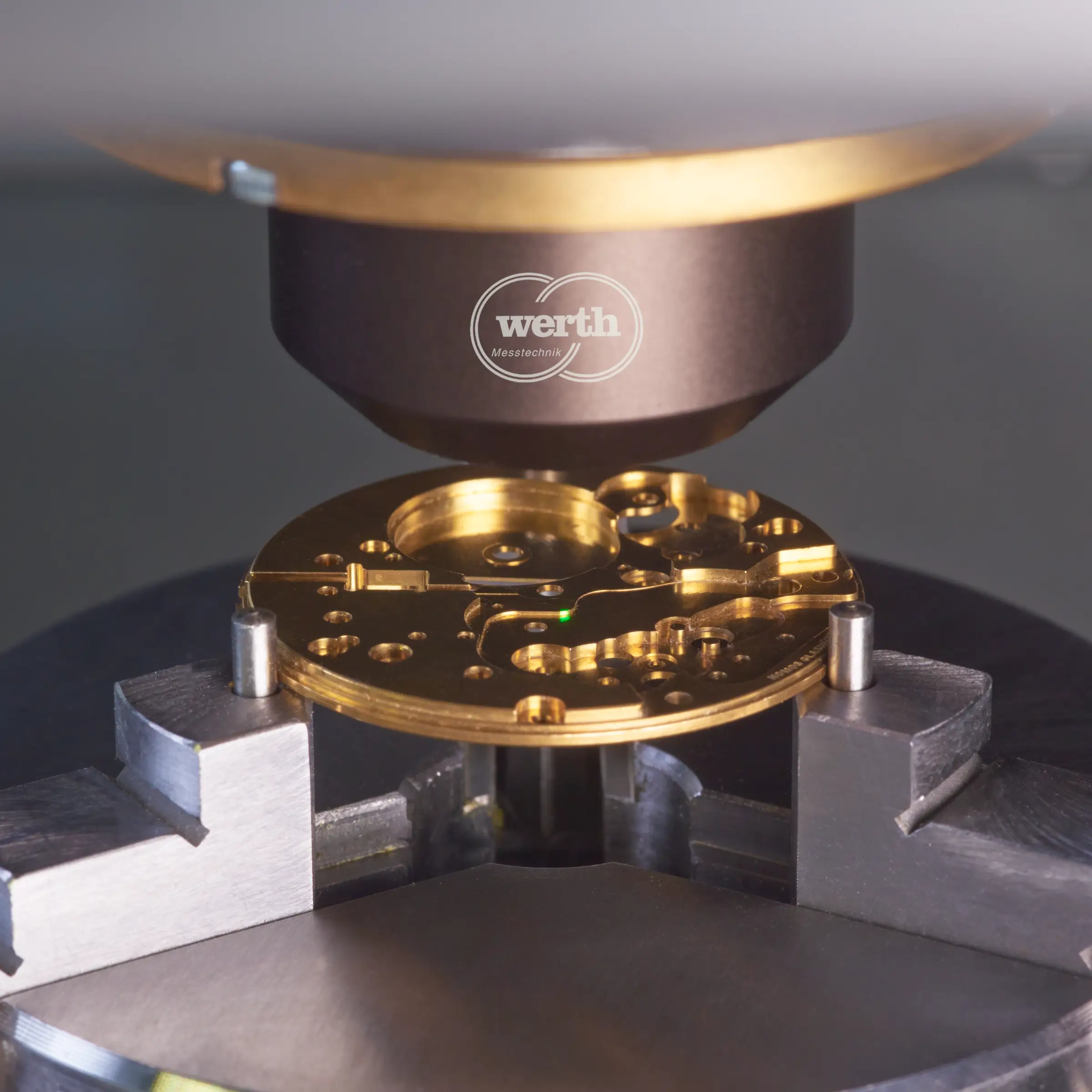

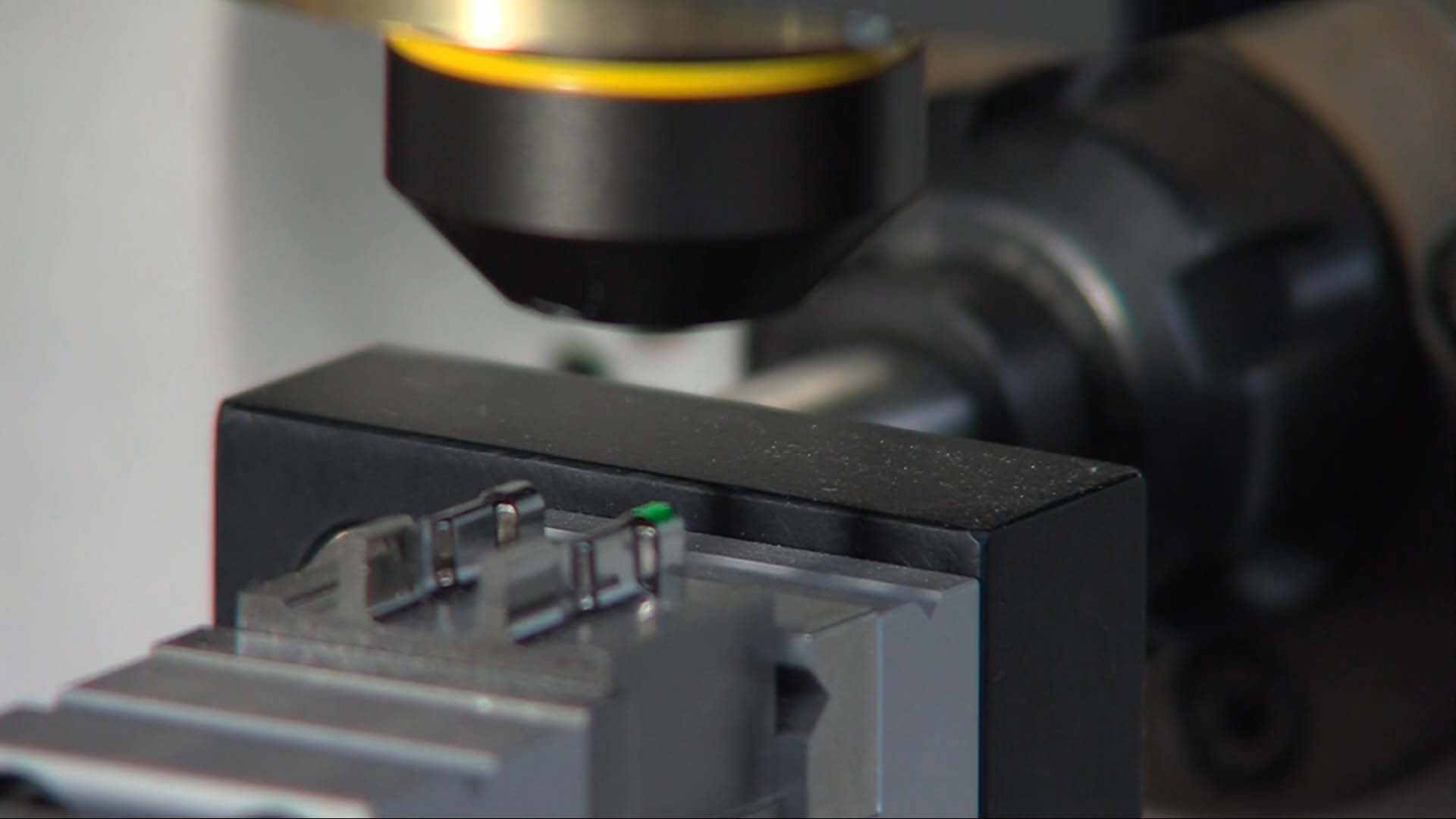

With the Nano Focus Probe, the workpiece surface can be captured as a 3D point cloud and the size, mould, position and roughness of micro-structures can be evaluated. The scattered light suppression enables reliable 3D measurement of the topography, even of reflective surfaces with probing errors in the sub-micrometre range. The confocal optical sensor also delivers good results on steep flanks with large inclination angles.

Nano Focus Probe NFP En

Different lenses allow the sensors to be adapted to the respective task

The sensor can be used in the entire measuring volume of the coordinate measuring machine and the measurement results can be linked in the same coordinate system

An overall surface can be calculated from several neighbouring partial point clouds with virtually no loss of accuracy

Sensor principle

Optical-axial (confocal microscopy)

Measuring range

Measurement "in the image" with integrated Z-axis 250 µm

Accuracy

Permissible probing error up to 0.15 µm

Functionality

By moving the probe head with a) illumination, b) camera, c) pinhole aperture and d) imaging optics relative to the workpiece e), the intensity of the light points f), g) is varied by defocussing. The overlapping of the defocussed light points f) is avoided by using large distances g). Based on the intensity curve, many measurement points on the workpiece surface are determined simultaneously

The universal measurement software for coordinate measuring machines with optics, probe, computed tomography and multi-sensor systems

The operation of machines with a wide variety of sensors, as well as the evaluation of volume data and point clouds ...

Comprehensive service around the coordinate measuring machine

Services from initial commissioning, training and maintenance to retrofitting ...