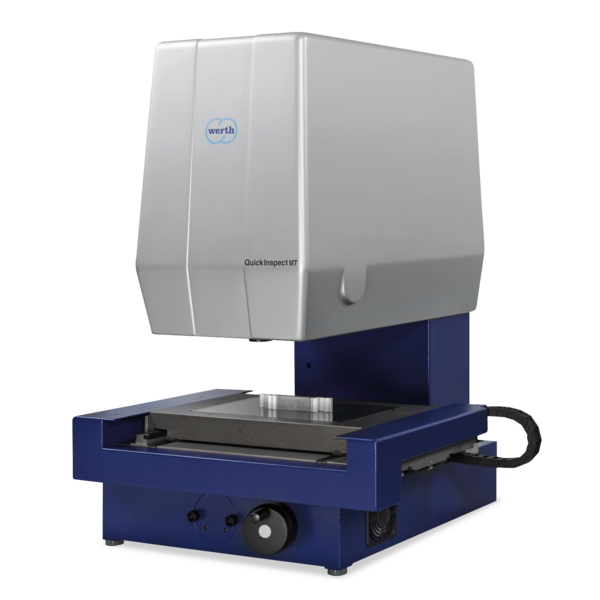

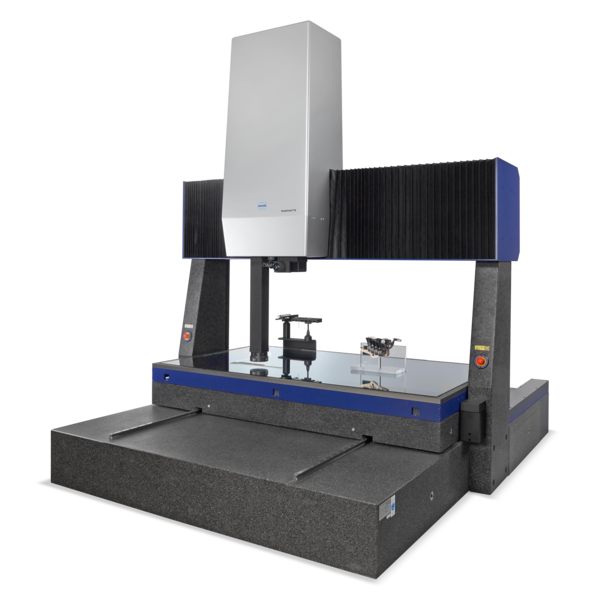

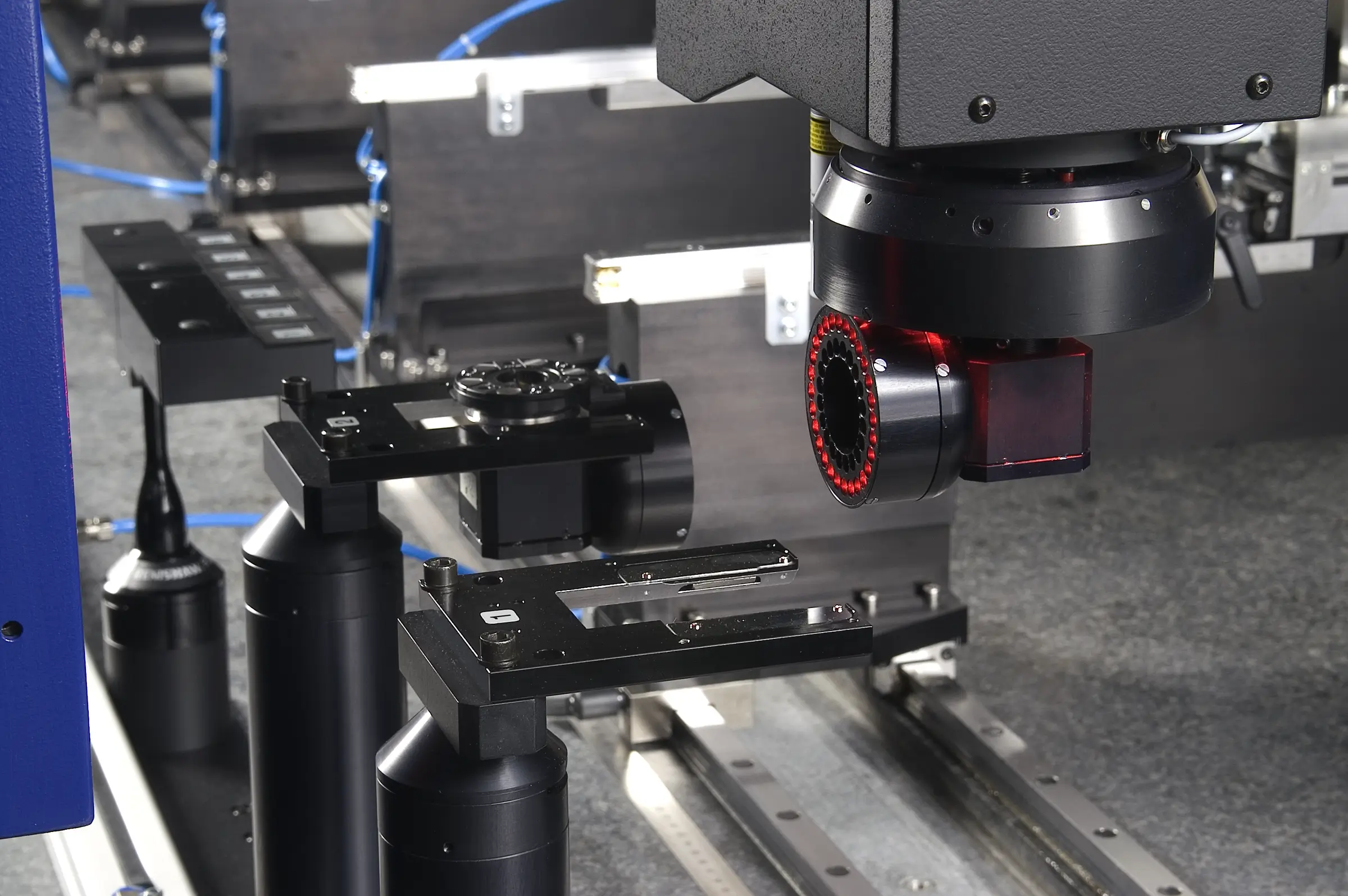

Akıllı kontur görüntü işleme sayesinde ölçüm penceresinde birden fazla geometrik elemanın ve serbest formun hızlı tespiti

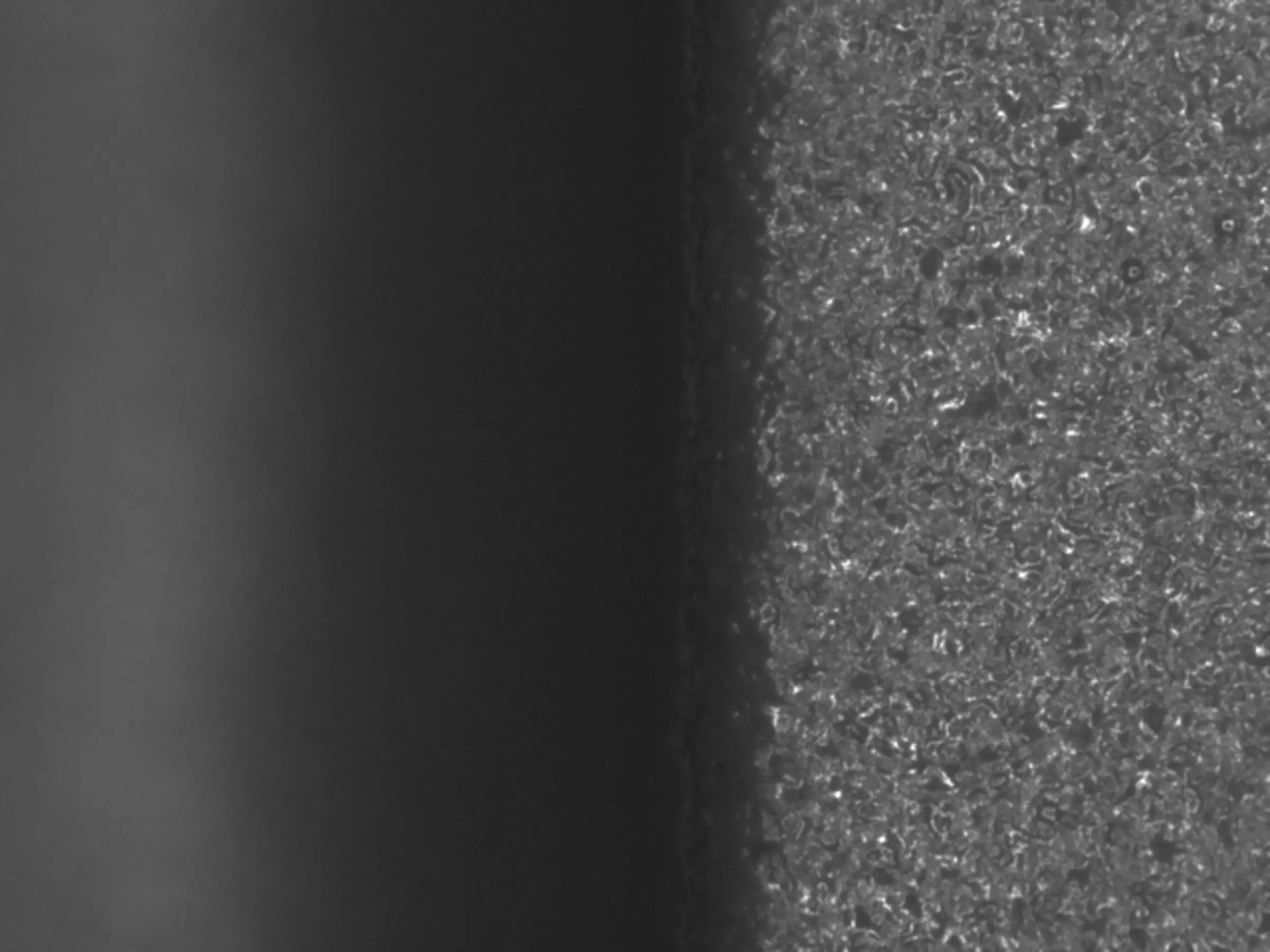

Görüntü, kontur ve eleman filtreleri sayesinde minimum kontrastta bile güvenilir kenar tespiti

Patentli raster tarama HD, sensörün görüş alanından bağımsız olarak cihaz eksenleri hareket halindeyken iş parçasının genel bir görüntüsünü oluşturur

Değişen yüzey özellikleri ve renkler için ışık yoğunluğunun otomatik ayarlanması

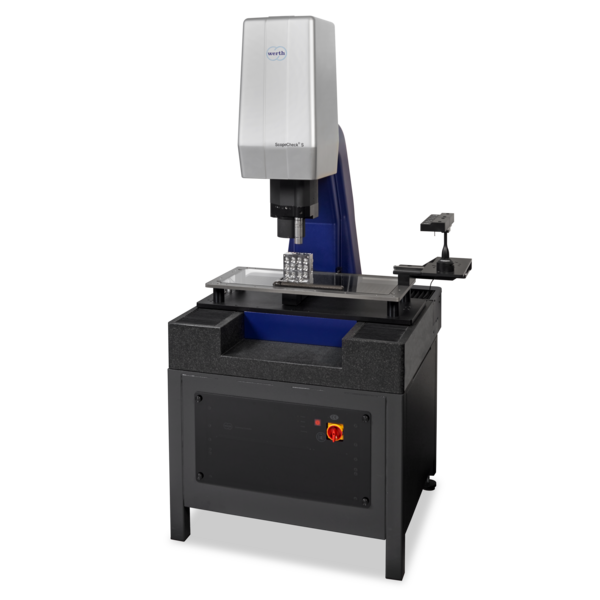

Farklı optik koordinat ölçüm makinelerinden kontrol dosyalarının kolayca değiştirilmesi için aydınlatma özelliklerinin standartlaştırılması mümkündür

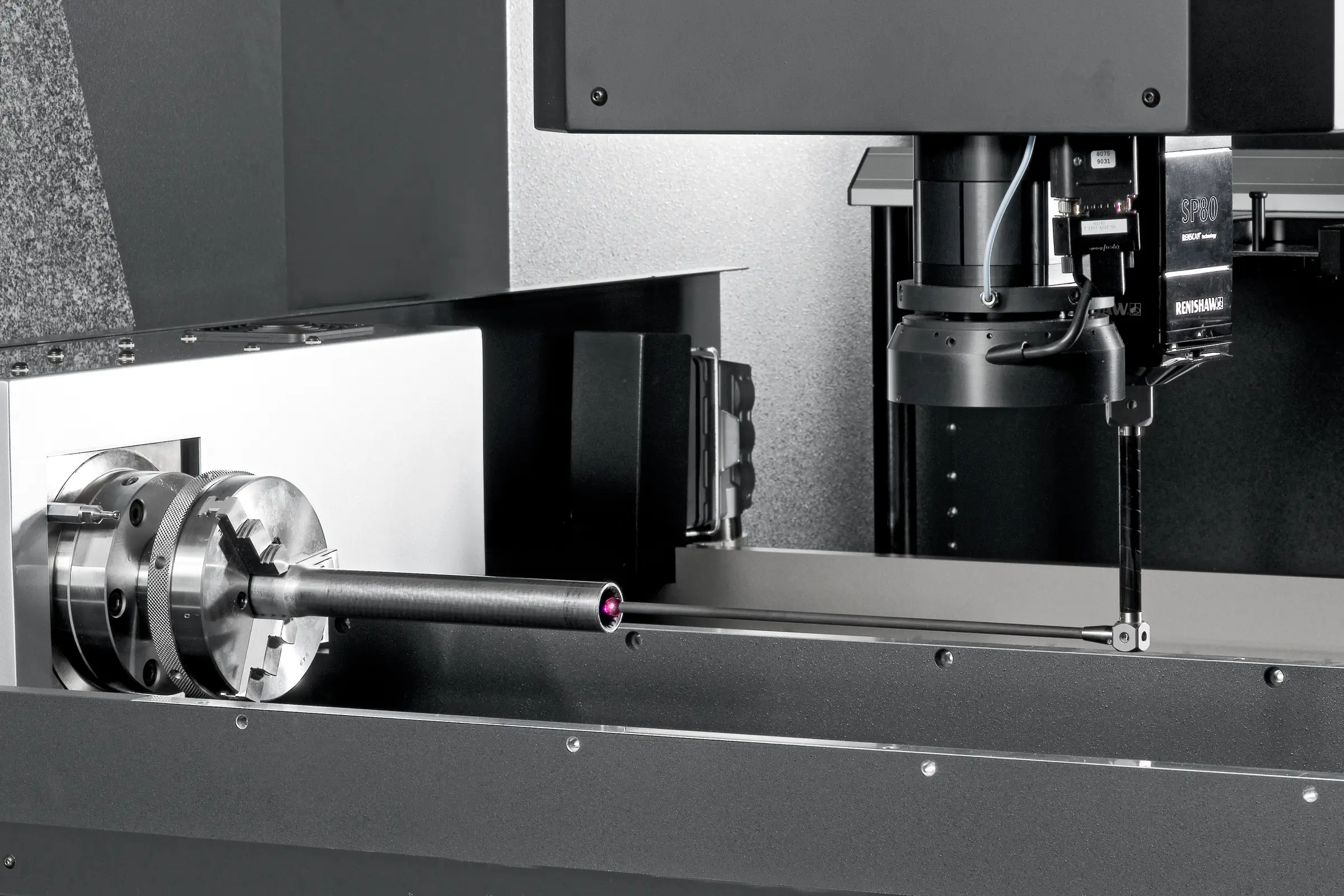

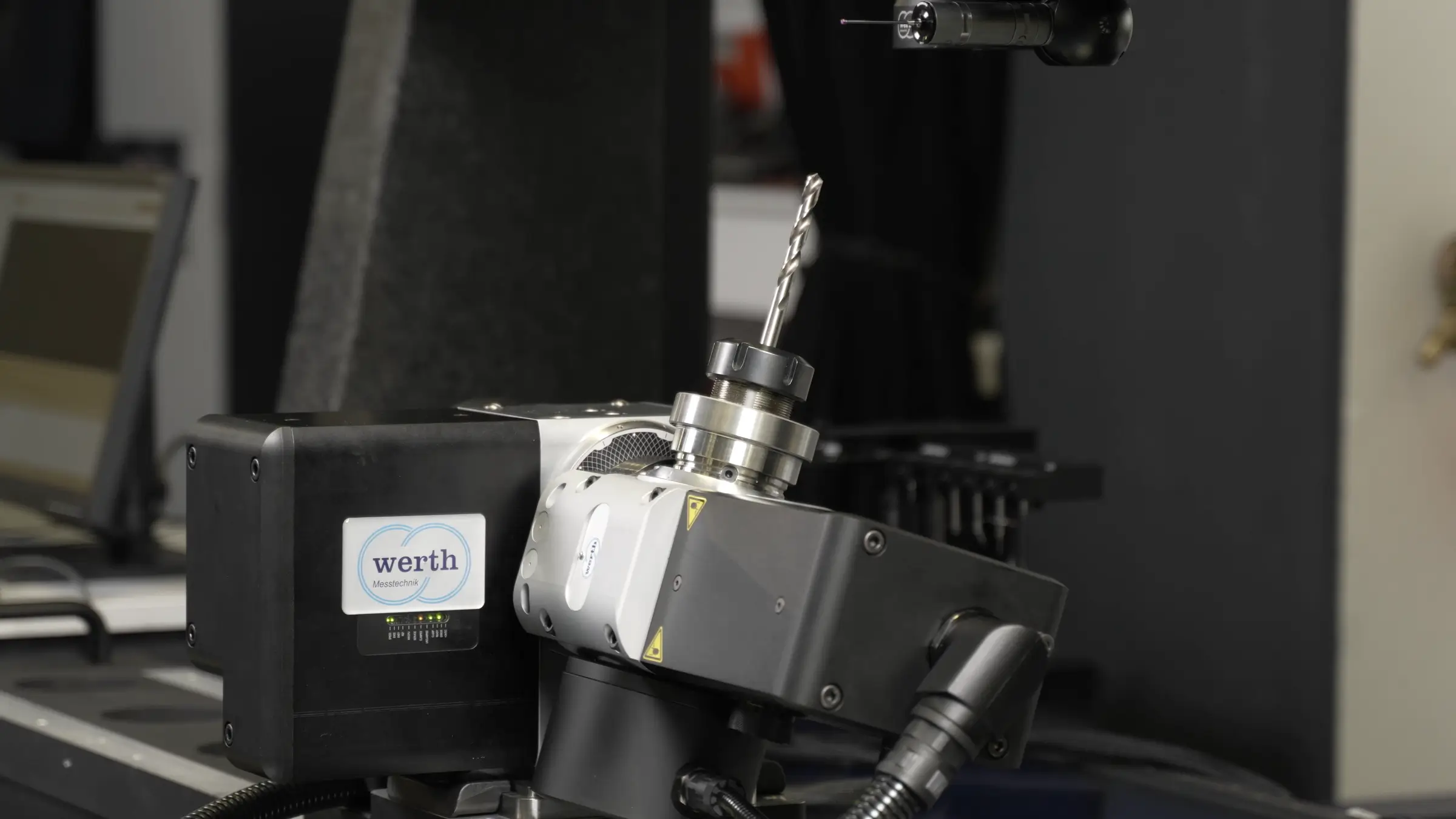

Değişken çalışma mesafesi ve aydınlatma açısı ile Werth Zoom ve MultiRing® tarafından özel çözümler sunulmaktadır