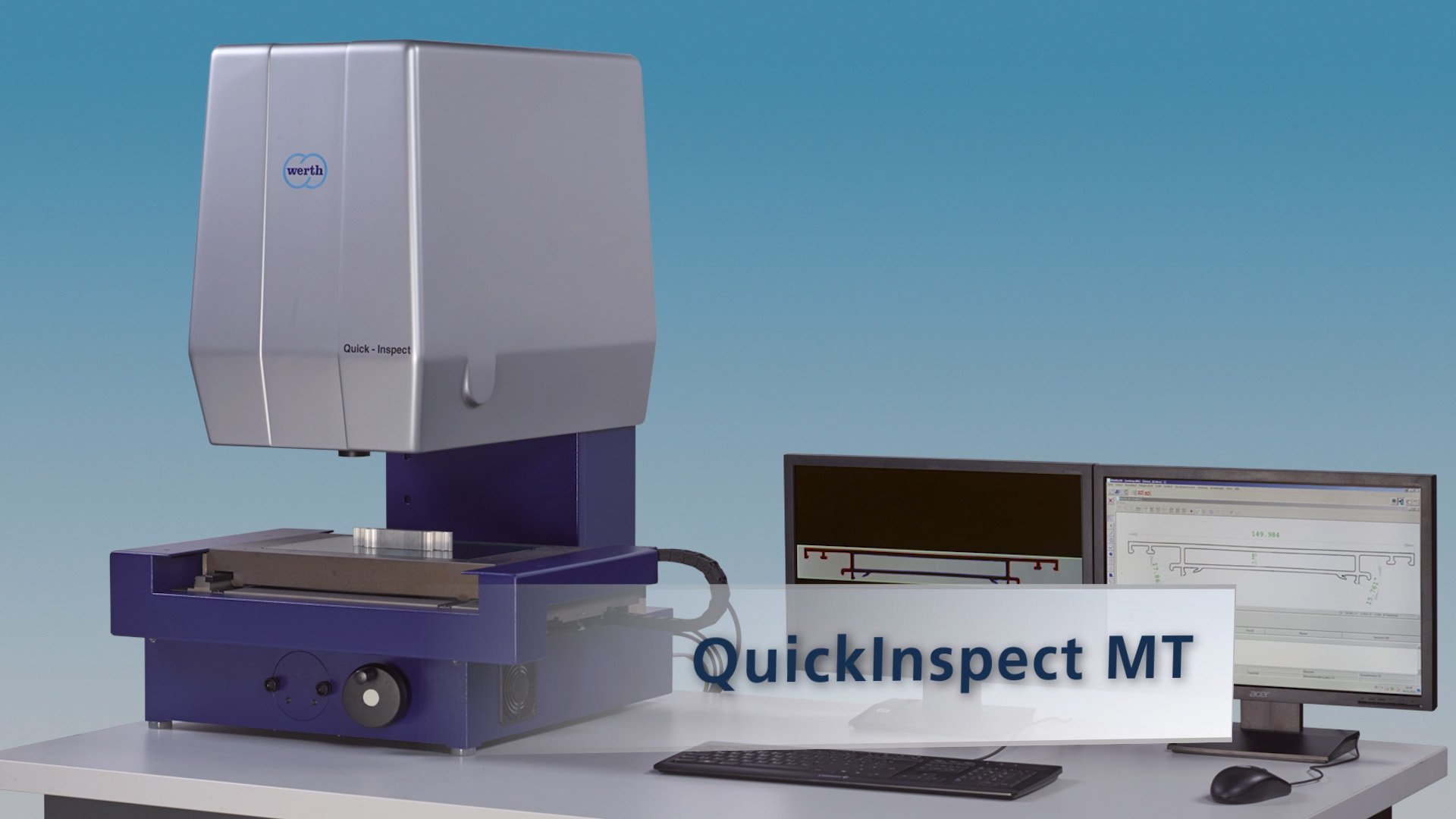

QuickInspect, iş parçasının tek bir görüntüde tamamının yakalanmasını sağlayarak kolay kullanım ve kısa ölçüm süreleri sağlar. Telesentrik lenslerin geniş alan derinliği sayesinde çoğu cihaz çeşidinde odaklama gerekmez. İş parçası, dijital ölçüm projektörünün ölçüm tablasına yerleştirilir, otomatik olarak algılanır ve ölçülür. QuickInspect MT ile, büyük nesnelerdeki küçük veya yüksek hassasiyetli özellikler bile neredeyse her çözünürlükte raster görüntüde görüntülenebilir ve optik olarak ölçülebilir (patentli). Uygulama alanı 2B iş parçalarıdır.

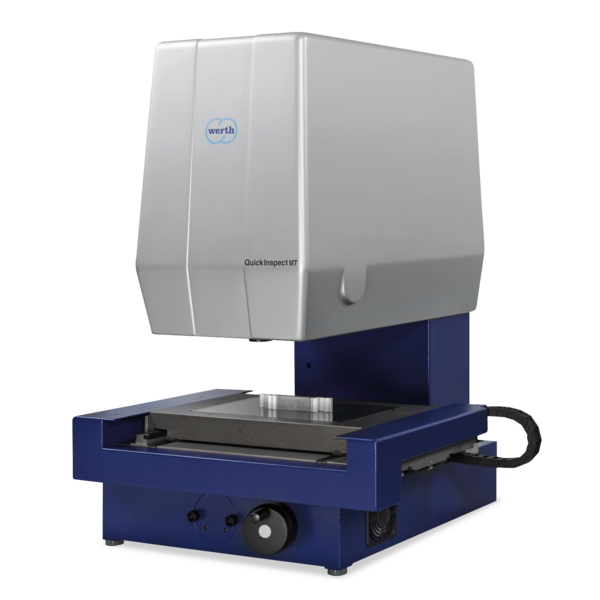

QuickInspect

0,8 mm x 0,6 mm ile 225 mm x 190 mm arasındaki görüş alanları için düşük bozulmalı telesentrik hassas optikler

Neredeyse her büyütmede 10x optoelektronik yakınlaştırma ve elektronik yakınlaştırma

8 segmentli karanlık alan olay ışığı ve Werth FlatLight mümkün

Yüksek büyütme oranları için, ölçüm yazılımındaki kullanışlı odaklama işlevi kolay odaklamayı destekler

Werth BestFit veya ToleranceFit® ile işlevsel denetim ve renk kodlu sapma grafiği

DIN 10360 veya VDI 2617'ye göre spesifikasyon sayesinde geleneksel koordinat metrolojisiyle karşılaştırılabilirlik

250 mm x 125 mm veya 400 mm x 200 mm ölçüm aralıklarıyla QuickInspect MT'ye kolayca sonradan takılabilir

Tip

Masaüstü görüntü işleme ölçüm makinesi

Ölçüm aralığı

Görüş alanları 0,8 x 0,6 mm ile 225 mm x 190 mm arasında (talep üzerine özel boyutlar)

Hassasiyet

İzin verilen uzunluk ölçüm hatası 0,25 µm'ye kadar

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...