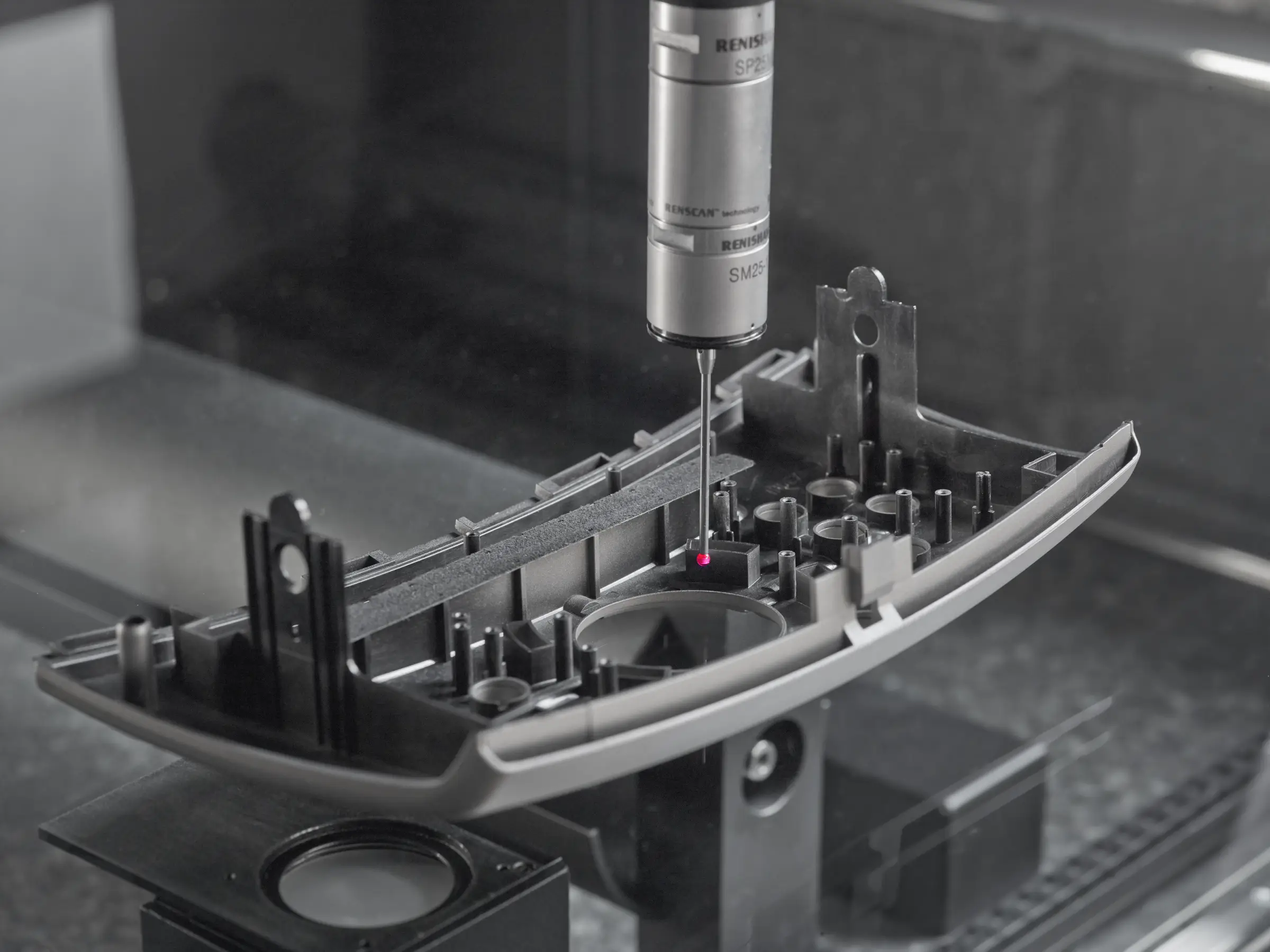

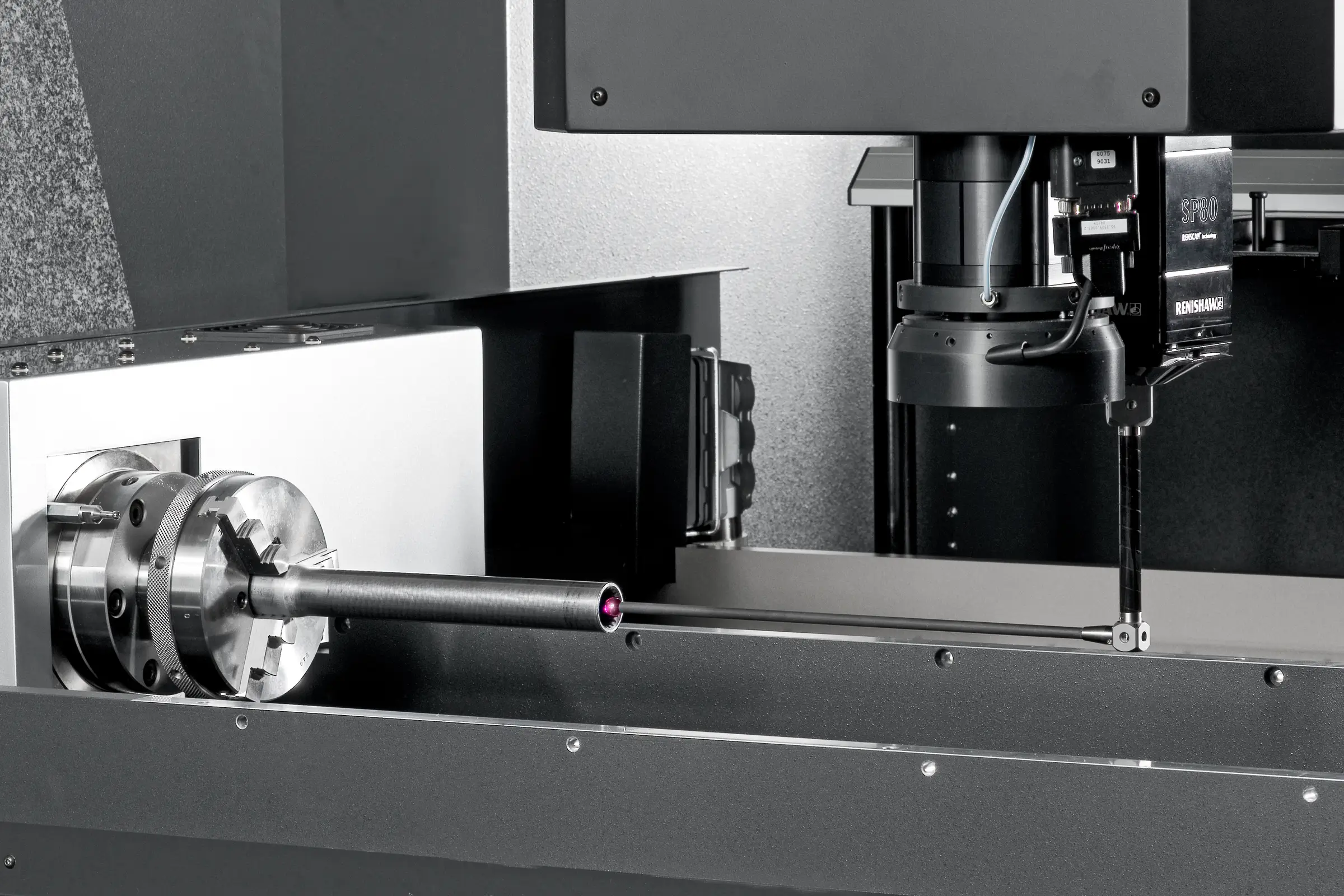

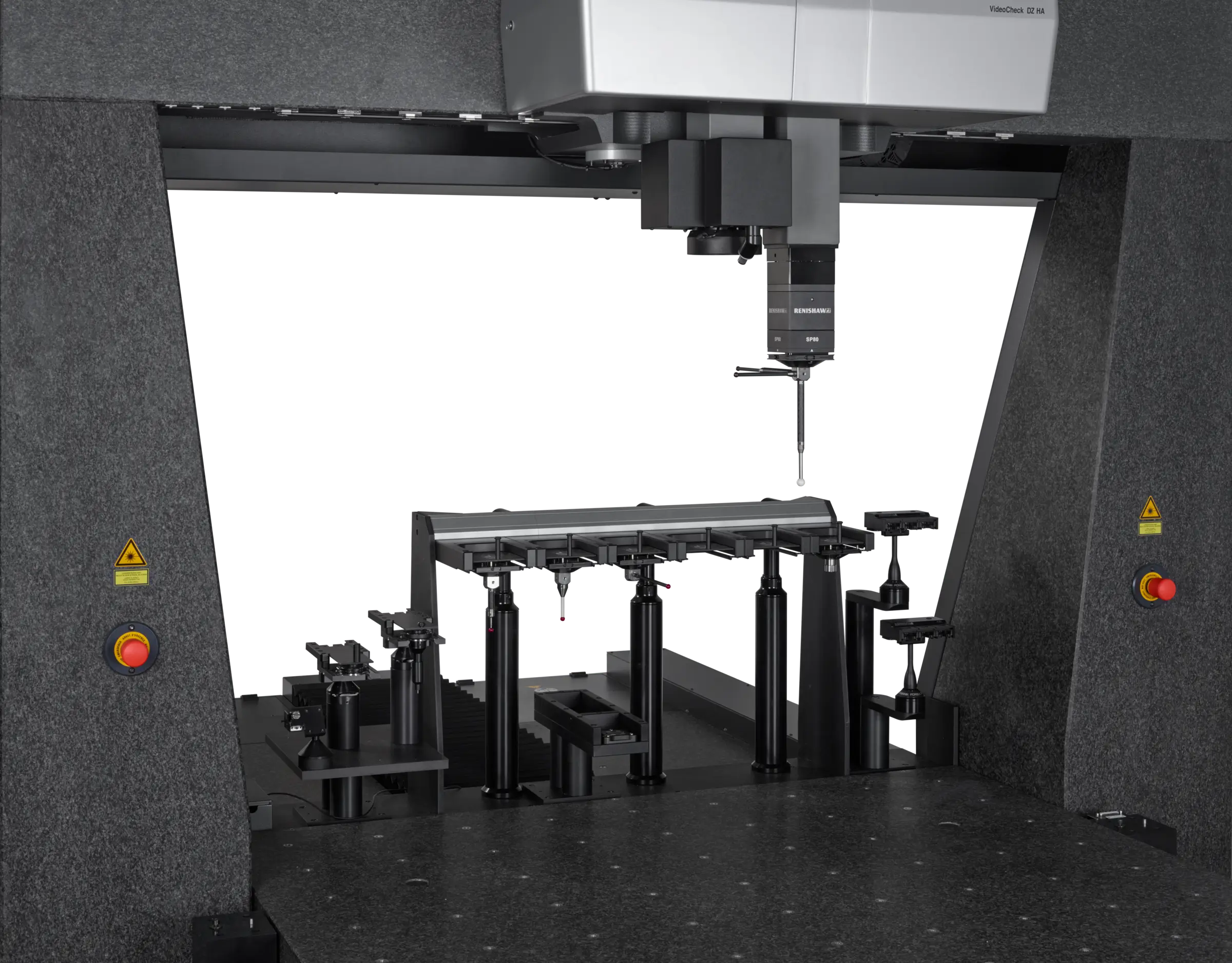

Werth ScopeCheck® S Probu, manuel tezgah ölçüm cihazları, mastarlar ve geleneksel üretim ölçüm istasyonları için ideal bir tamamlayıcı olabilir veya tamamen değiştirilebilir. ScopeCheck® S Probu, yüksek hassasiyetli 3B tarama probu ve hızlı CNC sürekli yol kontrolü sayesinde, daha önce pahalı ve karmaşık koordinat ölçüm makinelerine ayrılmış uygulama alanları için de uygundur.

ScopeCheck S Probe

Sert taş tabanlı ölçüm cihazı hava beslemesi gerektirmez

Mekanik hassas kılavuzlar ve sıcaklık dengelemesi, olumsuz çevre koşullarında bile güvenilir ölçüm sonuçları sağlar

Grafik kullanıcı arayüzüne sahip ergonomik grafik kullanıcı arayüzü, kullanıcının grafiğe tıklayarak boyutları belirlemesini sağlar

Parola koruması, operatöre yeterlilik seviyesine göre ölçüm yazılımına erişim sağlar

Modüler tasarım prensibi, gelecekteki ihtiyaçlar için kolayca genişletilebilir

Tip

Tek bir düzlemde kılavuz yollara sahip dokunsal 3D CNC koordinat ölçüm makinesi

Ölçüm aralığı

X = 400 mm, Y = 200 mm, Z = 200 mm

Hassasiyet

İzin verilen uzunluk ölçüm hatası 2,4 µm'ye kadar

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...