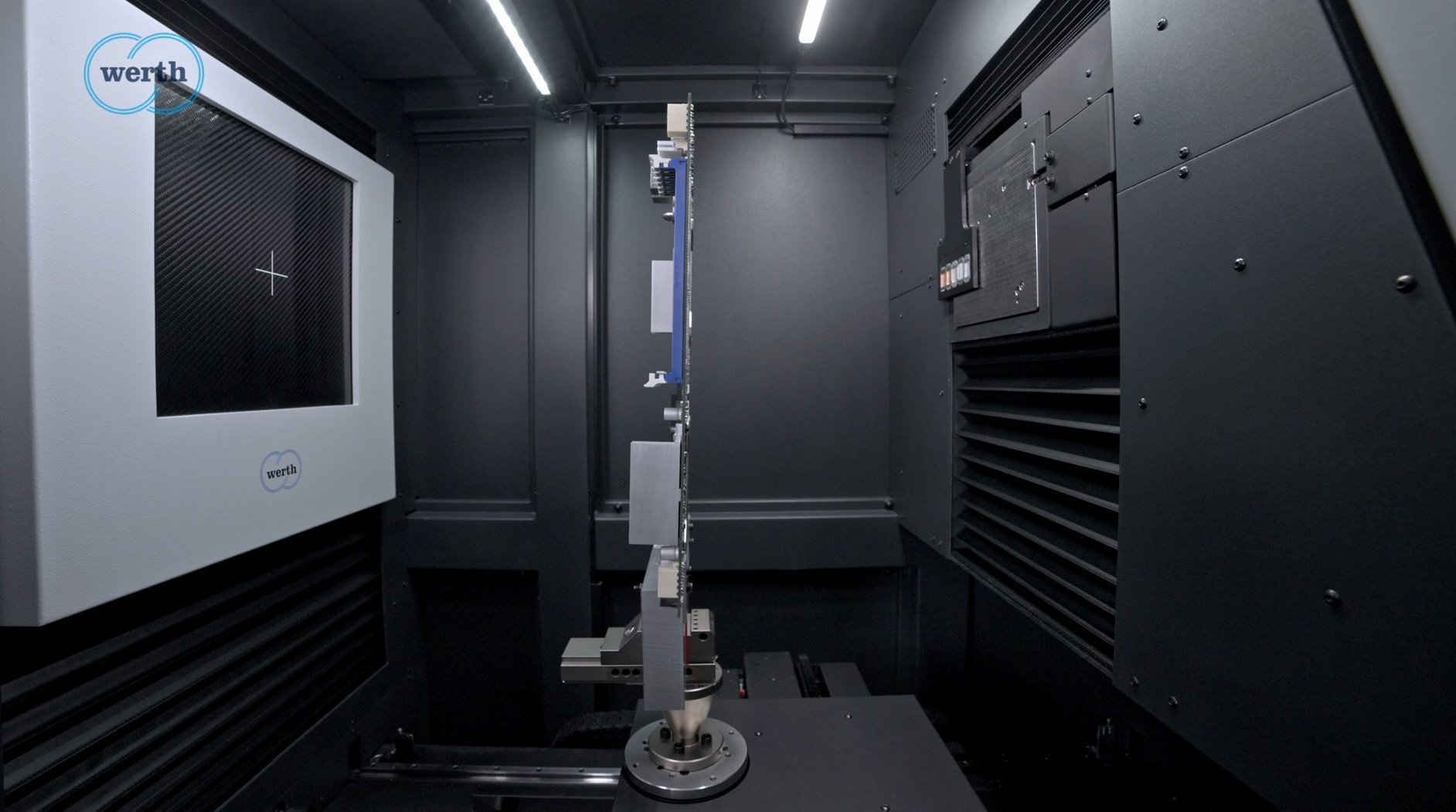

TomoScope® XS FOV 500 (faydalı model), endüstriyel bilgisayarlı tomografi ile hızlı ölçümler için esnek ve kullanımı kolay bir cihazdır. 3B ölçümler, hareketli eksenler olmadan dedektörün görüş alanında gerçekleşir ve tamamen otomatikleştirilebilir. Yüksek performanslı bir X-ışını tüpü, özellikle ışın sertleştirme filtreleri kullanıldığında ölçüm süresini optimize eder. Kapak veya dübel gibi birden fazla küçük iş parçası, uygun aparatlar kullanılarak birlikte ölçülebilir. Diş implantları, hafif metal iş parçaları veya kapı menteşeleri gibi küçük metal parçaların ölçümü de mümkündür.

TomoScope® XS FOV 500

Ayrıca hat içi uygulamalar için de uygundur

Monoblok tasarımda bakım gerektirmeyen boru sayesinde yüksek kullanılabilirlik

Tüpte 24 ay değişim sınırlaması olmaksızın garanti

Sondalama hatasını azaltmak için yerel subvoxeling

Düşük ölçüm belirsizliği için yüksek hassasiyetli hava yataklı döner eksen

Kompakt tasarım sayesinde düşük alan gereksinimi

Düşük ağırlığı sayesinde hemen hemen her yere kurulabilir

Düşük satın alma maliyetleri sayesinde hızlı amortisman

Gerçek zamanlı OnTheFly Tomografi ve rekonstrüksiyon hızlı ölçümlere olanak tanır

Tasarım olarak Radyasyon Koruma Yönetmeliğine göre tam koruma cihazına karşılık gelir

Güvenilir ve izlenebilir ölçüm sonuçları için VDI 2617'ye göre standart uyumlu kalibrasyon, isteğe bağlı olarak DAkkS sertifikası ile

Tasarım

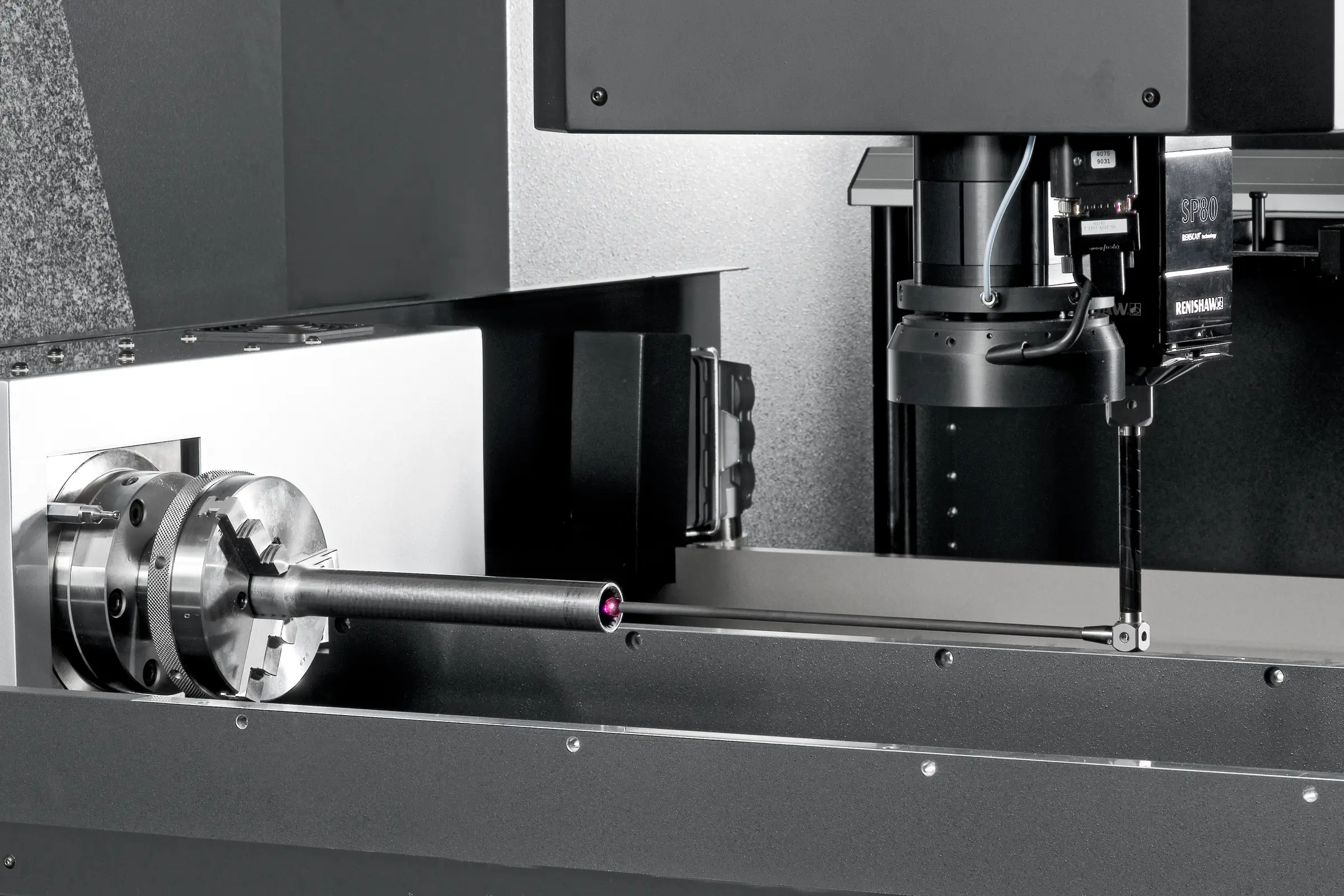

Bilgisayarlı tomografi sensörlü 3 boyutlu koordinat ölçüm makinesi

Ölçüm aralığı

Maksimum İş parçası boyutları D = 280 mm / L = 112 mm (iş parçalarının en boy oranına bağlı olarak)

Hassasiyet

İzin verilen uzunluk ölçüm hatası 5 µm'ye kadar

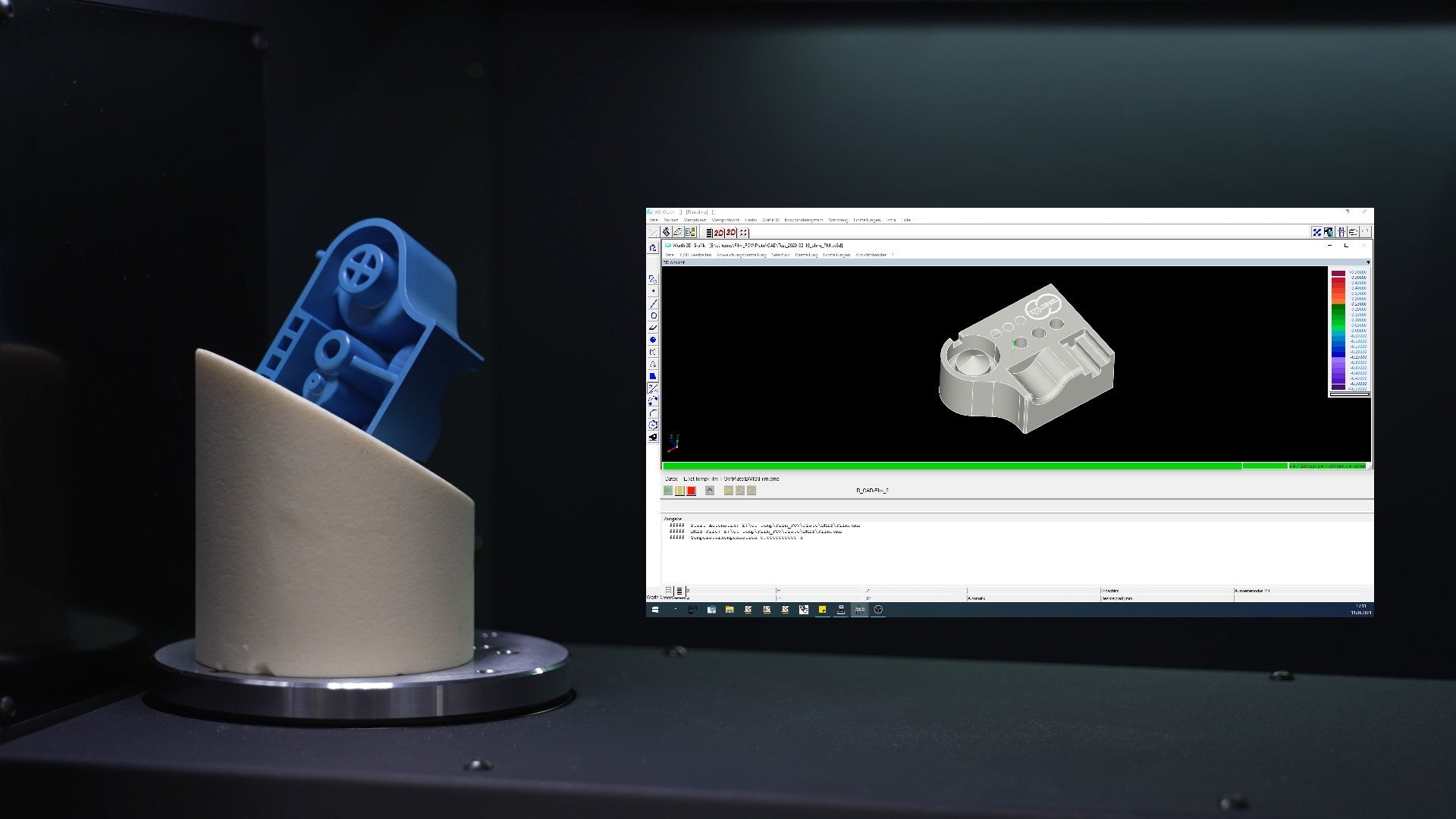

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...