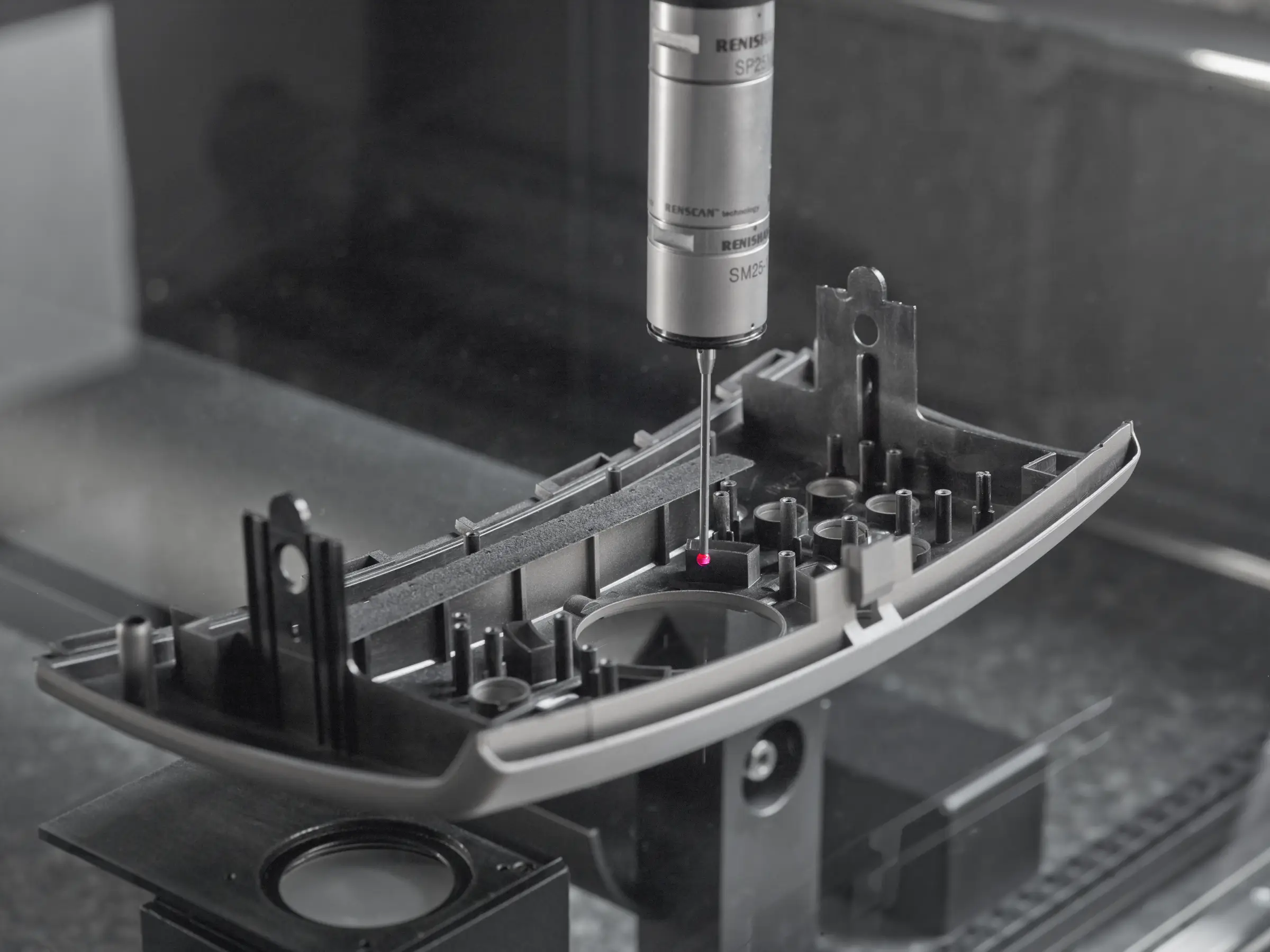

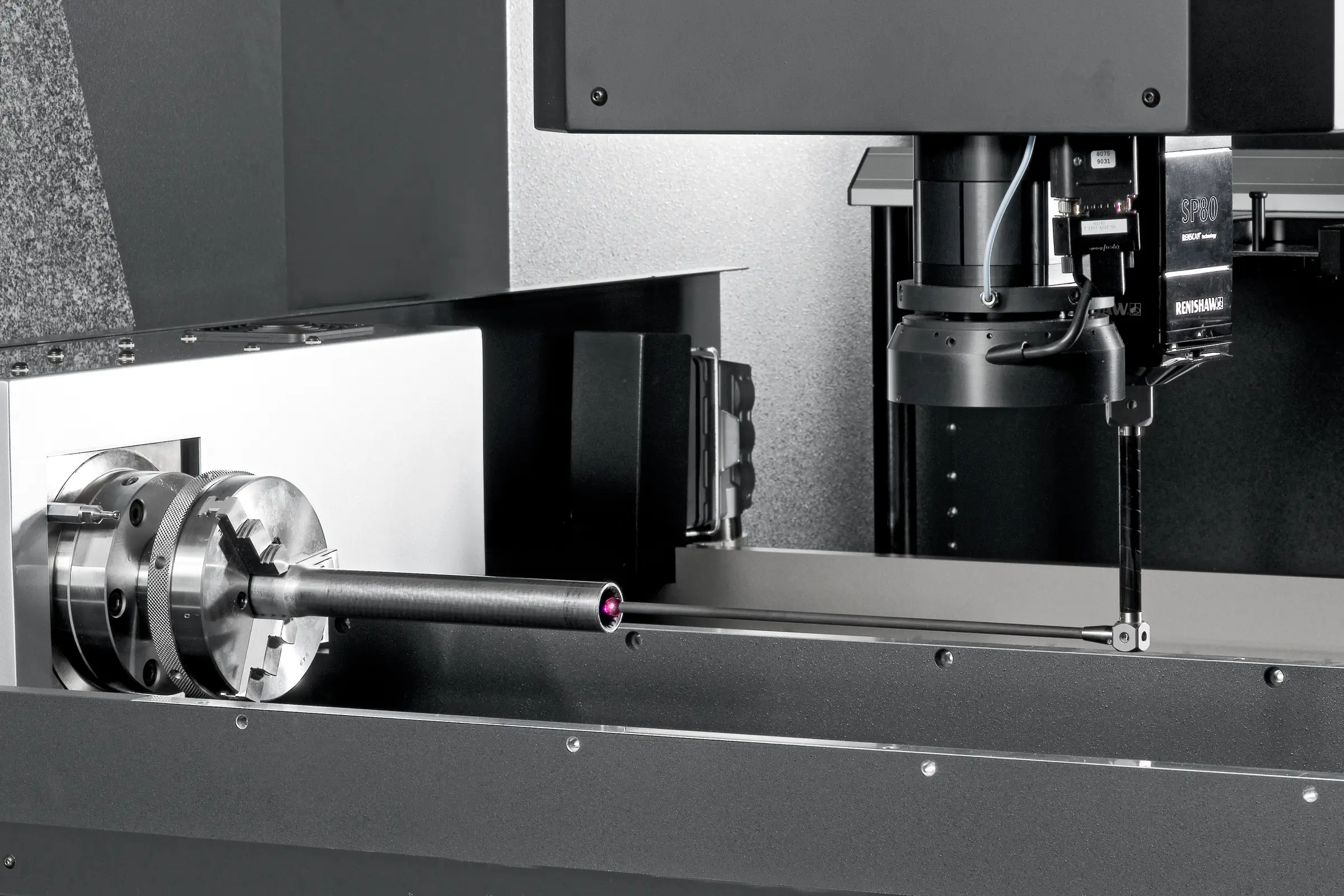

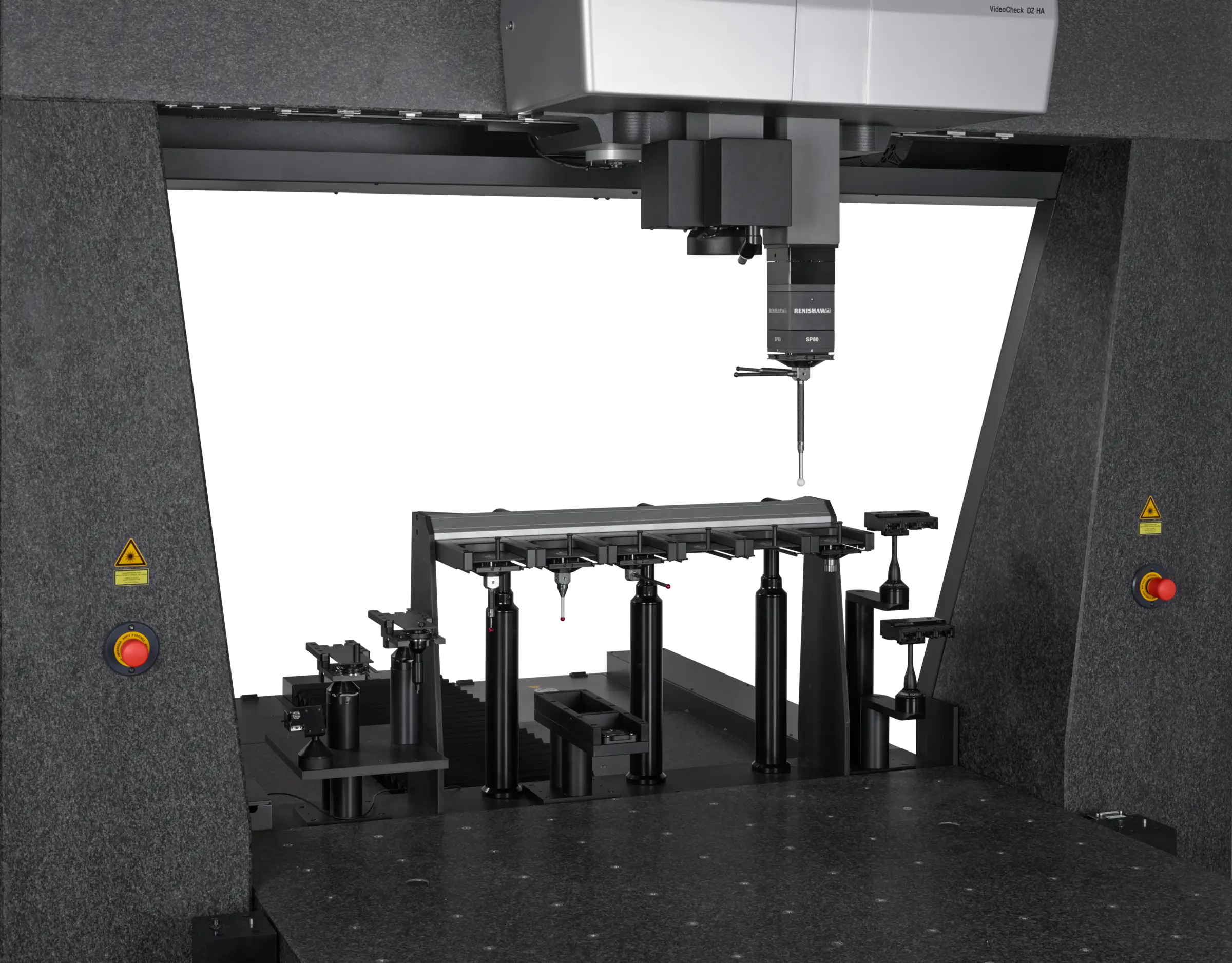

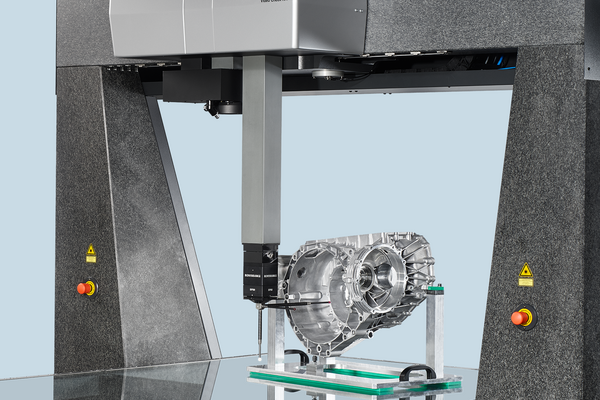

Sabit köprülü koordinat ölçüm makinesi, üç boyutlu geometrilerin tam otomatik olarak yakalanmasını sağlar. İhtiyaca göre ölçüm veya anahtarlamalı dokunsal sensörler kullanılabilir. Uygulama alanları arasında örneğin takım imalatı, makine mühendisliği ve otomotiv endüstrisindeki büyük kübik iş parçaları yer alır.

ProbeCheck

Sistemin modüler tasarımı, bireysel çözümler ve yükseltilebilirlik sağlar

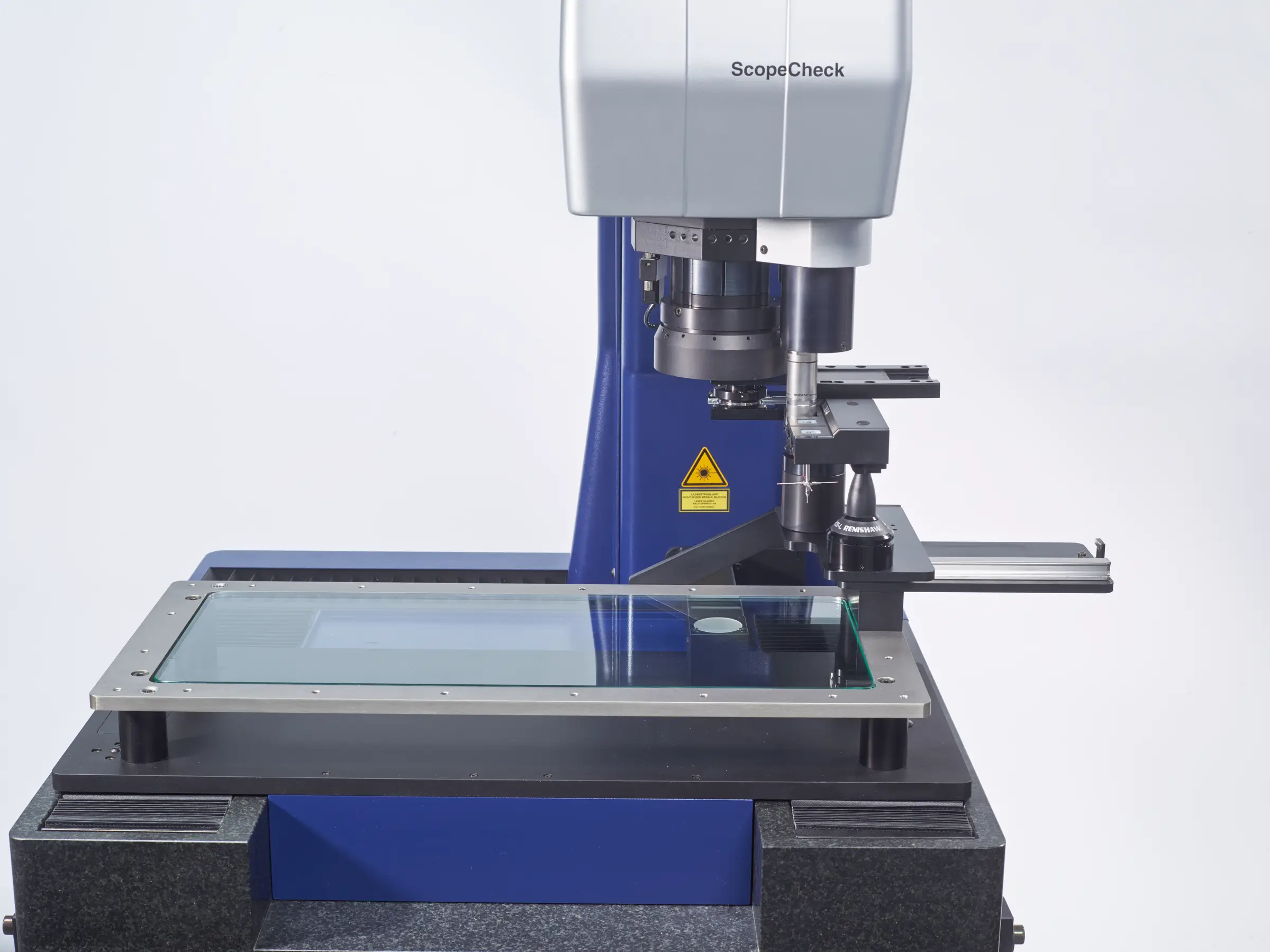

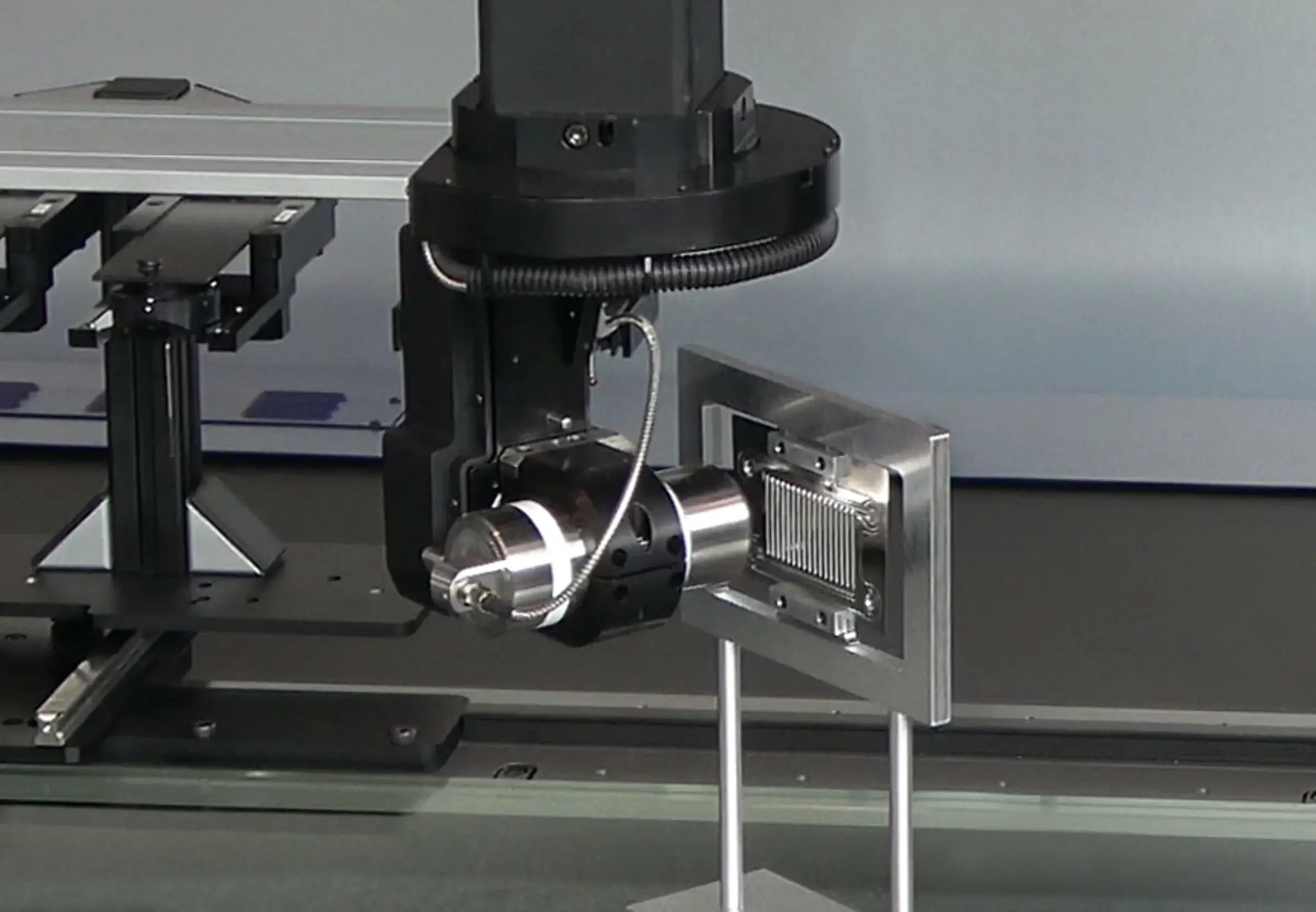

Çok sensörlü bir koordinat ölçüm makinesi oluşturmak için ek sensörlerin entegrasyonu ve böylece ölçüm görevlerini çözmede artan esneklik

Kontrol geometrisi elemanlarının ölçümü veya 3D CAD verileriyle nominal-gerçek karşılaştırmalar için WinWerth® 3D ölçüm yazılımı

Hızlı CNC sürekli yol kontrolü

Tip

Sabit köprülü, yüksek hassasiyetli dokunsal 3D koordinat ölçüm makinesi

Ölçüm aralığı

X = 400 mm ila 2000 mm, Y = 400 mm ila 1350 mm, Z = 200 mm ila 800 mm

Hassasiyet

İzin verilen uzunluk ölçüm hatası 0,5 µm'ye kadar

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...