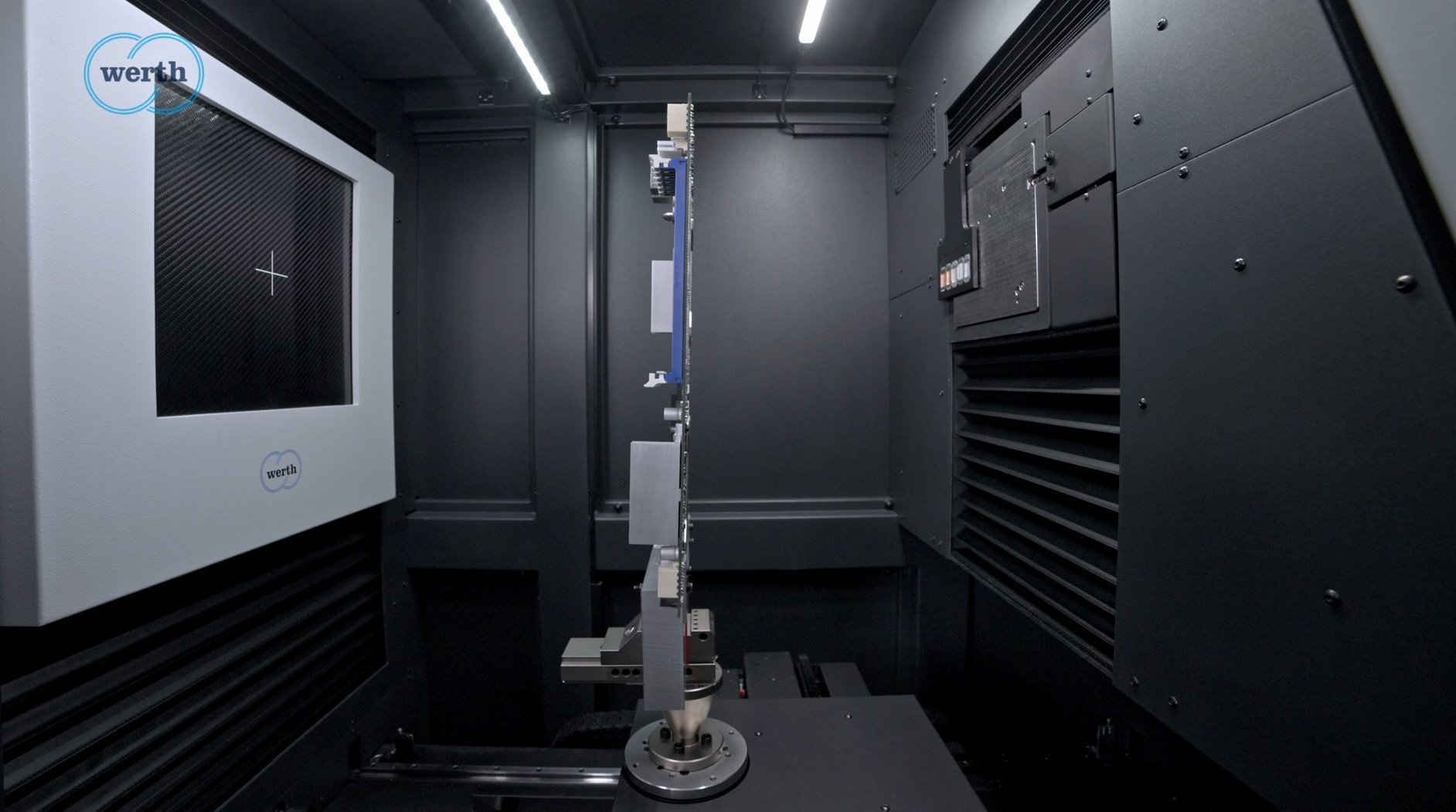

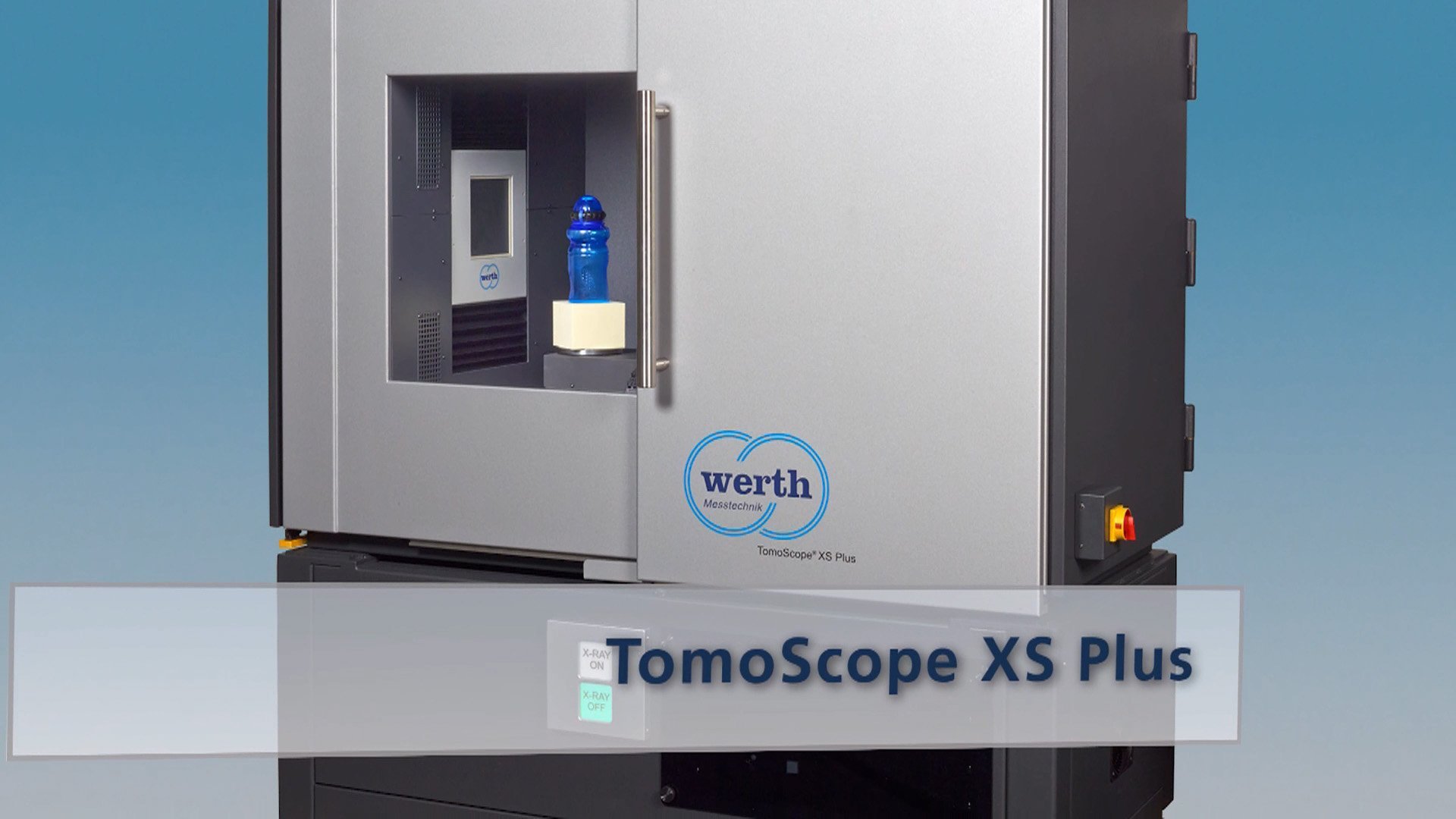

TomoScope® XS Plus (faydalı model), büyük iş parçalarının ve küçük nesnelerin yüksek çözünürlük veya daha kısa ölçüm süresiyle ölçülmesini sağlar. Tüm koordinat eksenlerinde neredeyse her ayarlanabilir çözünürlüğe sahip (60 milyar voksele kadar) tam iş parçası hacimleri ölçüm sonuçları olarak mevcuttur. Uygulama alanları arasında konnektörler, plastik muhafazalar ve kapaklar, 3D baskılı iş parçaları, ambalajlar, PET şişeler ve preformlar gibi malzemelerin 3B ölçümleri yer alır.

TomoScope® XS Plus

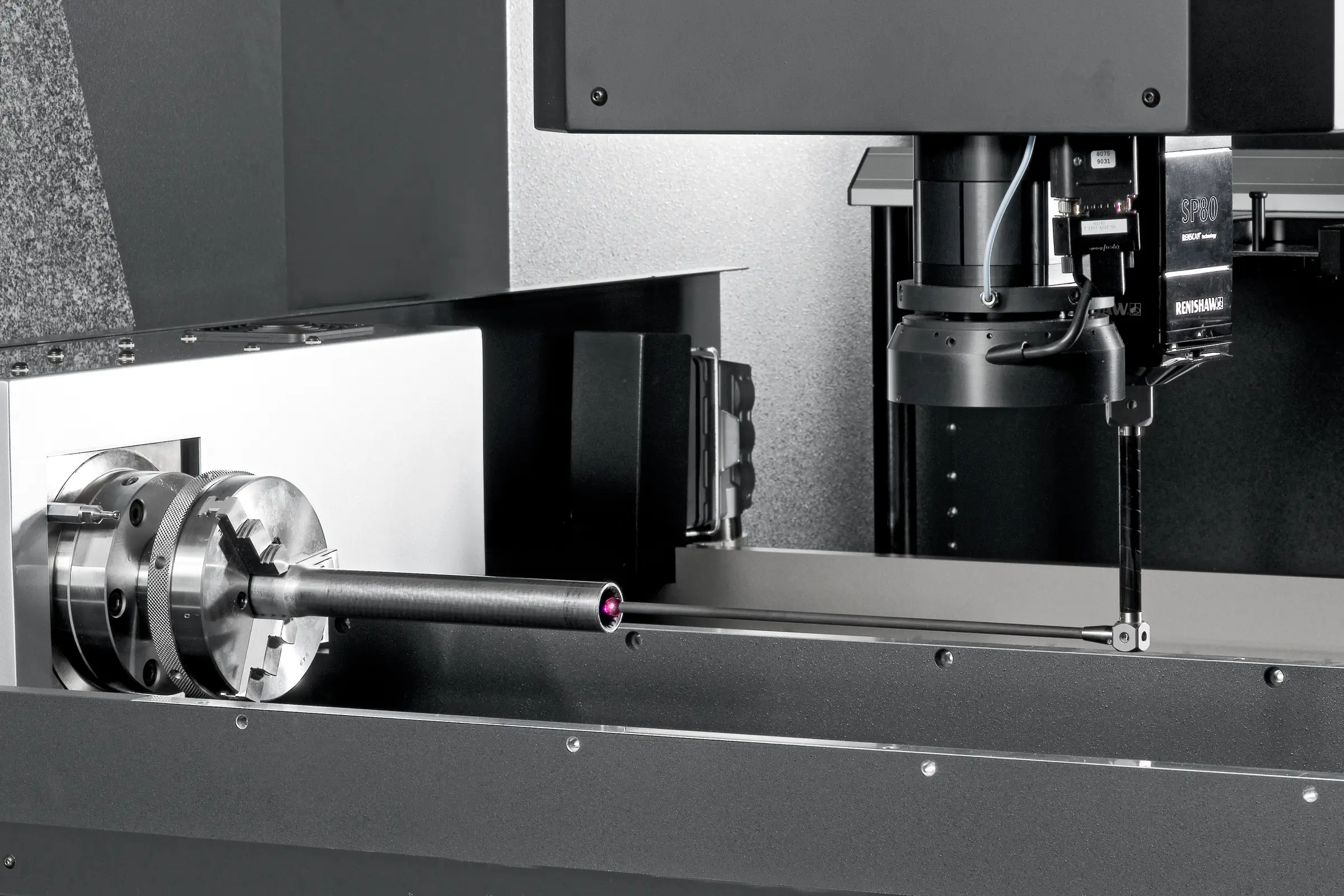

Monoblok tasarımda ilk kez kullanılan transmisyon tüpü sayesinde, yüksek tüp gücünde bile küçük bir odak noktası elde ediliyor ve böylece yüksek çözünürlüklü geleneksel BT cihazlarına kıyasla 5 kat daha hızlı ölçüm yapılabiliyor.

X-ışını kaynağı, kapalı ve açık mikro odaklı X-ışını tüplerinin avantajlarını birleştirir

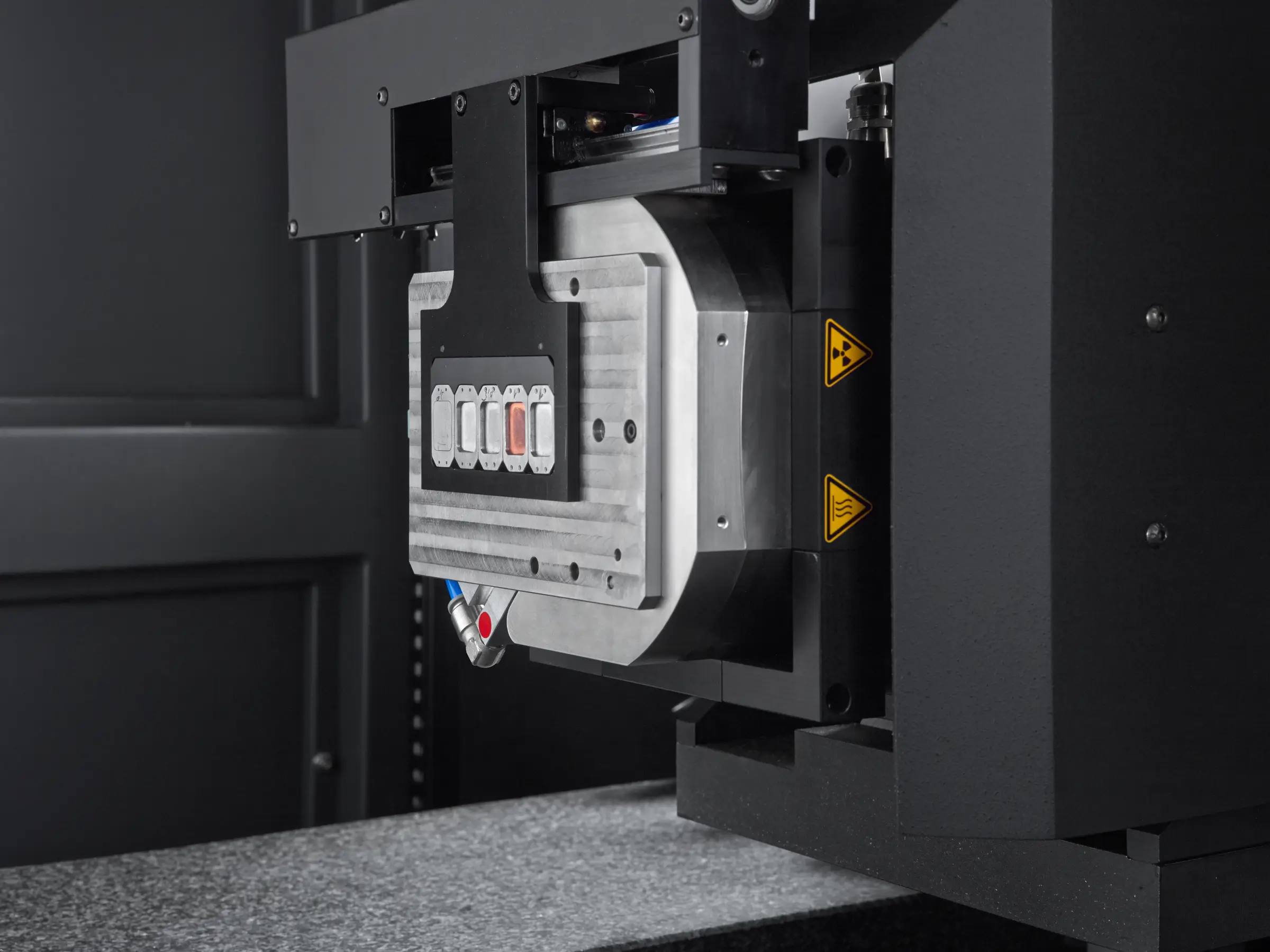

Duruş süreleri ve işletme maliyetleri en aza indirilir

Geleneksel koordinat ölçüm makinelerinde olduğu gibi, tüm cihazın bakım döngüsü yalnızca bir yıldır

Sondalama hatasını azaltmak için yerel subvoxeling

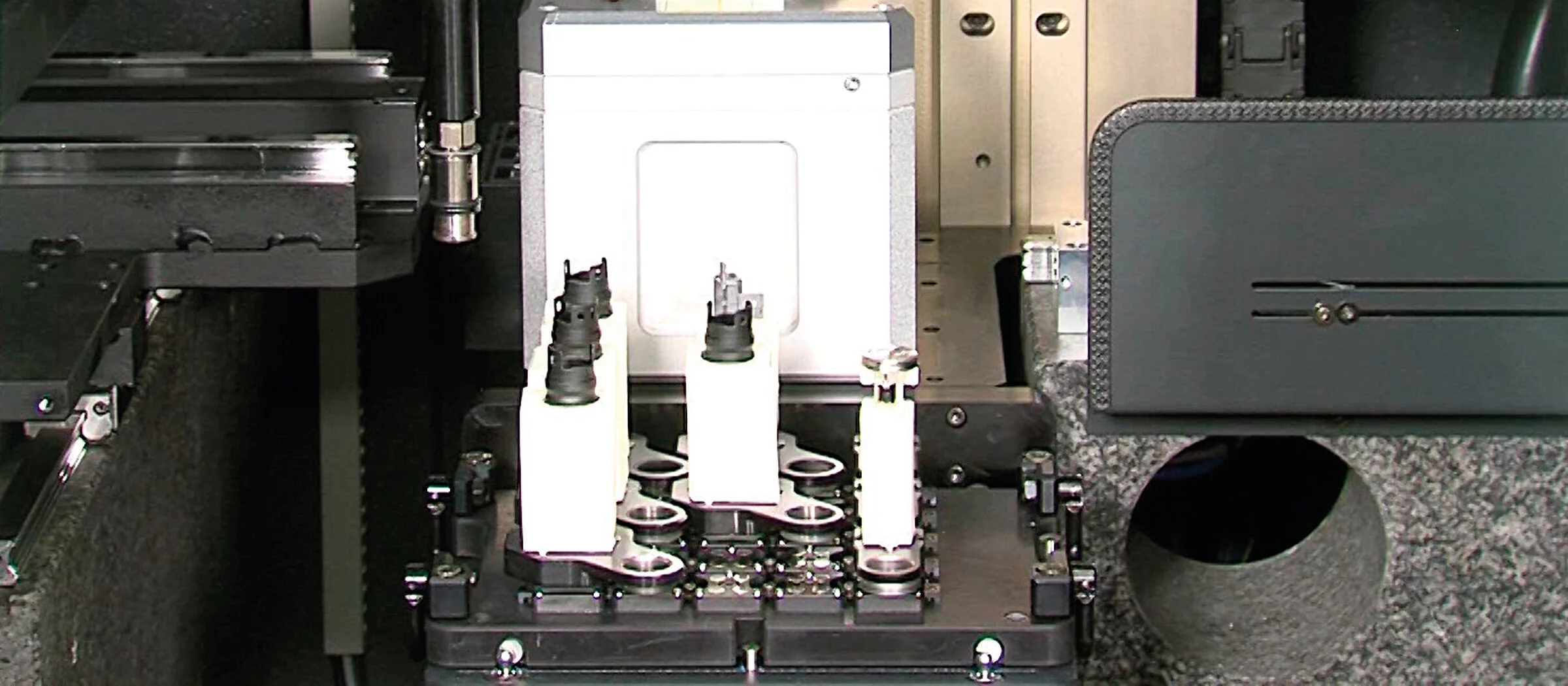

OnTheFly Tomografi ve gerçek zamanlı yeniden yapılandırma hızlı ölçümlere olanak tanır

Radyasyon Koruma Yönetmeliği'ne göre tam koruma cihazına eşdeğer tasarıma sahiptir

Güvenilir ve izlenebilir ölçüm sonuçları için VDI 2617'ye göre standart uyumlu kalibrasyon, isteğe bağlı olarak DAkkS sertifikası ile

Tasarım

Bilgisayarlı tomografi sensörlü 3 boyutlu koordinat ölçüm makinesi

Ölçüm aralığı

Maksimum İş parçası boyutları D = 289 mm / L = 456 mm (iş parçalarının en boy oranına bağlı olarak)

Hassasiyet

İzin verilen uzunluk ölçüm hatası 4,5 µm'ye kadar

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...