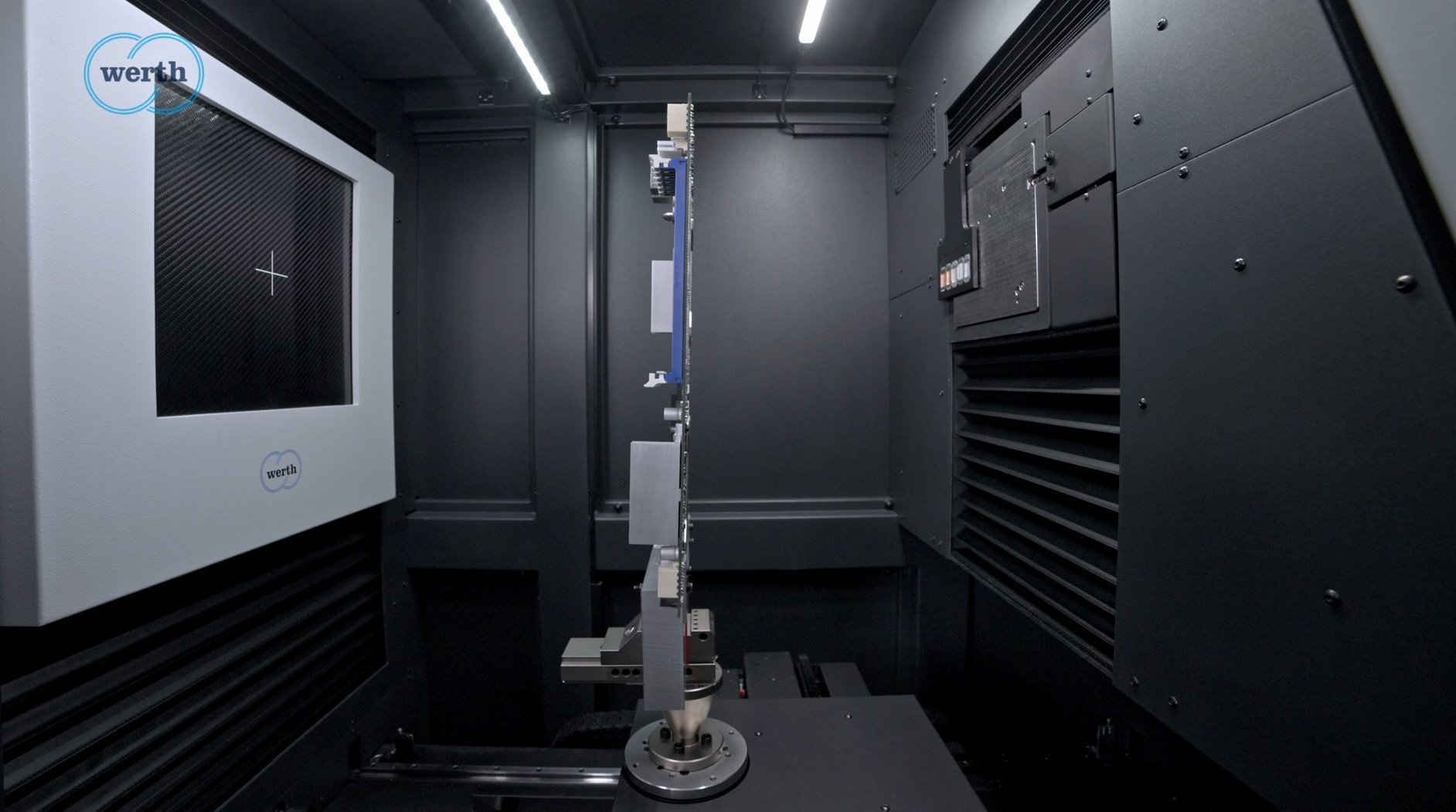

The TomoScope® XS Plus 200 (utility model) has a unique ratio of small size and weight to large measuring volume and enables the measurement of larger workpieces or small objects with high resolution or reduced measuring time. Complete workpiece volumes with almost any adjustable resolution in all coordinate axes (up to 60 billion voxels) are available as measurement results. With 200 kV X-ray voltage, it is possible to measure connectors, sensor assemblies, joint implants and mobile phone lenses, for example.

TomoScope® XS Plus 200 En

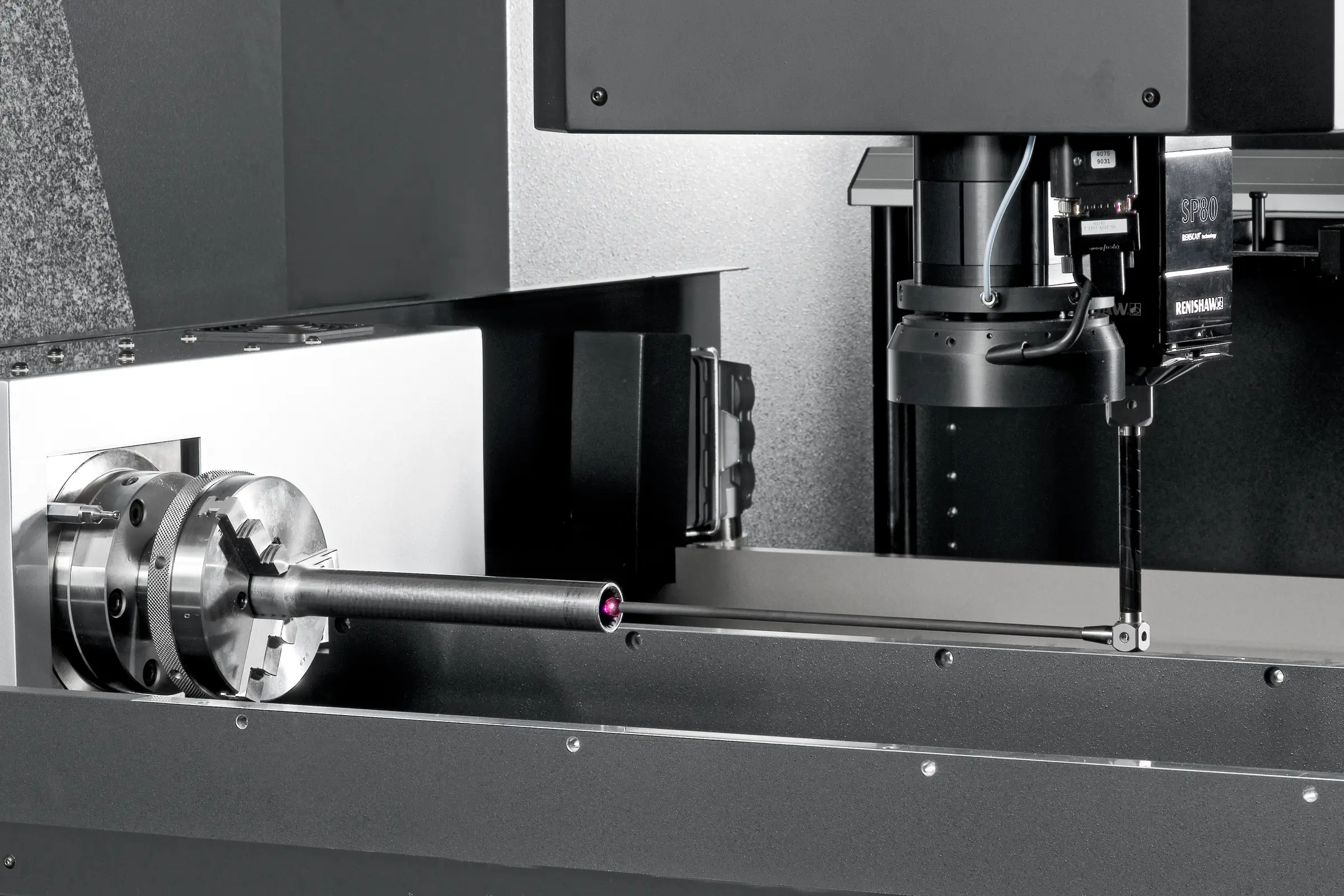

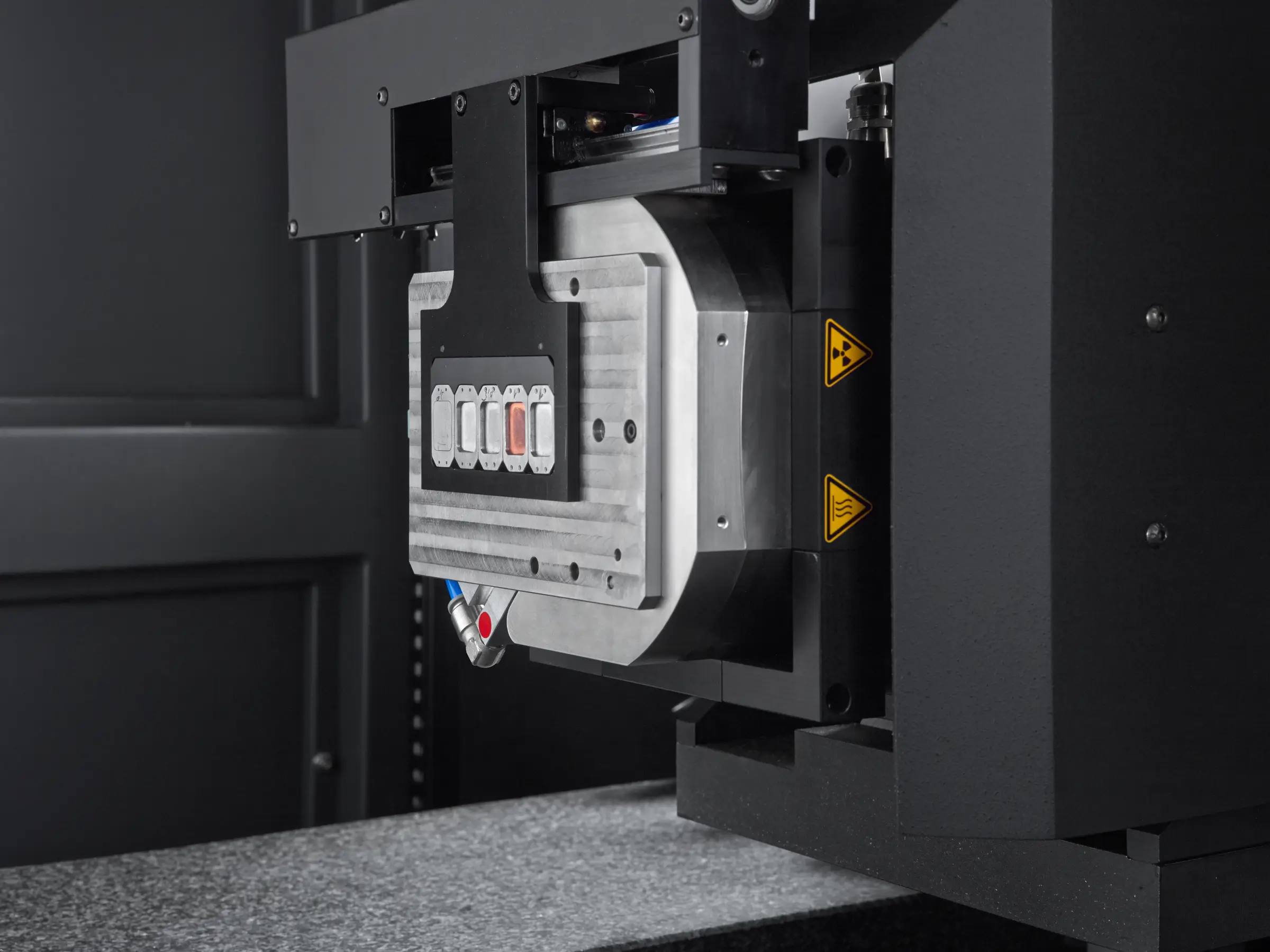

Thanks to the transmission tube – for the first time in monoblock design –, a small focal spot is achieved even at high tube power, so that measurements can be performed 5 times faster compared to conventional CT machines with high resolution

The X-ray source combines the benefits of closed and open microfocus X-ray tubes

Unlimited lifetime and low downtime with maintenance cycle of one year like conventional coordinate measuring machines

Local subvoxeling to reduce probing error

OnTheFly Tomography and reconstruction in real time enable fast measurements

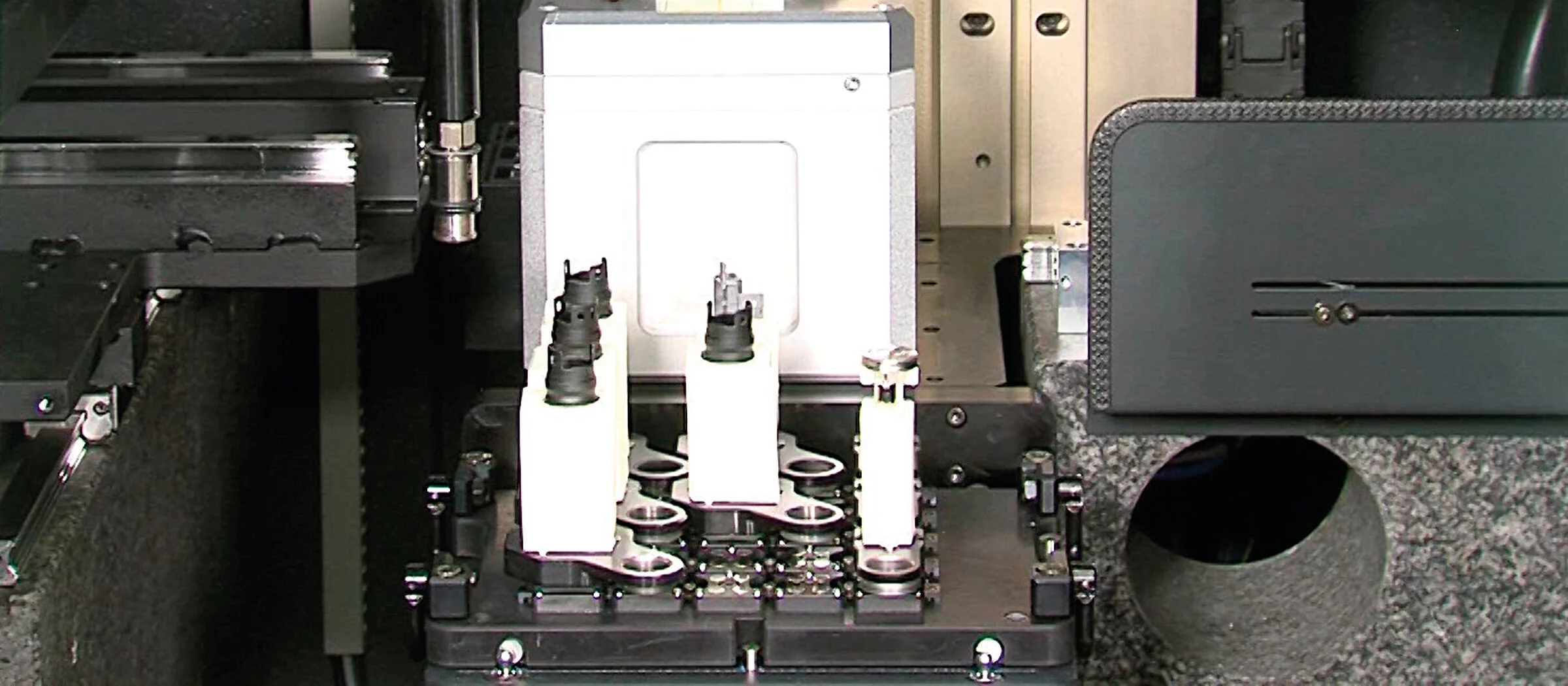

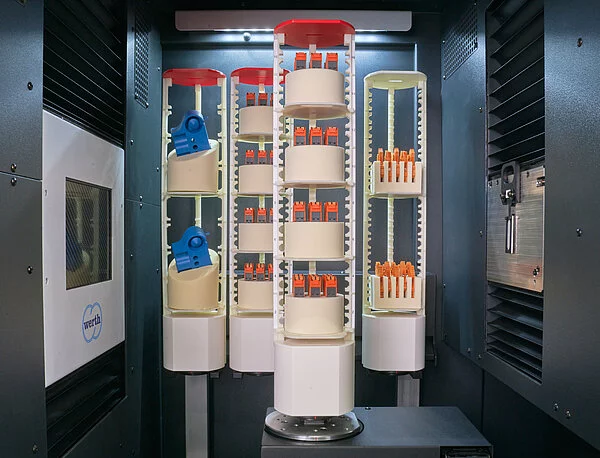

Short measurement times of just a few seconds thanks to multi-object measurement

Corresponds in design to a full protection device according to the Radiation Protection Ordinance

Standard-compliant specification and calibration according to VDI 2617, optionally with DAkkS certificate

Design

3D coordinate measuring machine with computed tomography sensors

Measuring range

Max. Workpiece dimensions D = 289 mm / L = 456 mm (depending on the aspect ratio of the workpieces)

Accuracy

Permissible probing error up to 4.5 µm

The universal measurement software for coordinate measuring machines with optics, probe, computed tomography and multi-sensor systems

The operation of machines with a wide variety of sensors, as well as the evaluation of volume data and point clouds ...

Comprehensive service around the coordinate measuring machine

Services from initial commissioning, training and maintenance to retrofitting ...