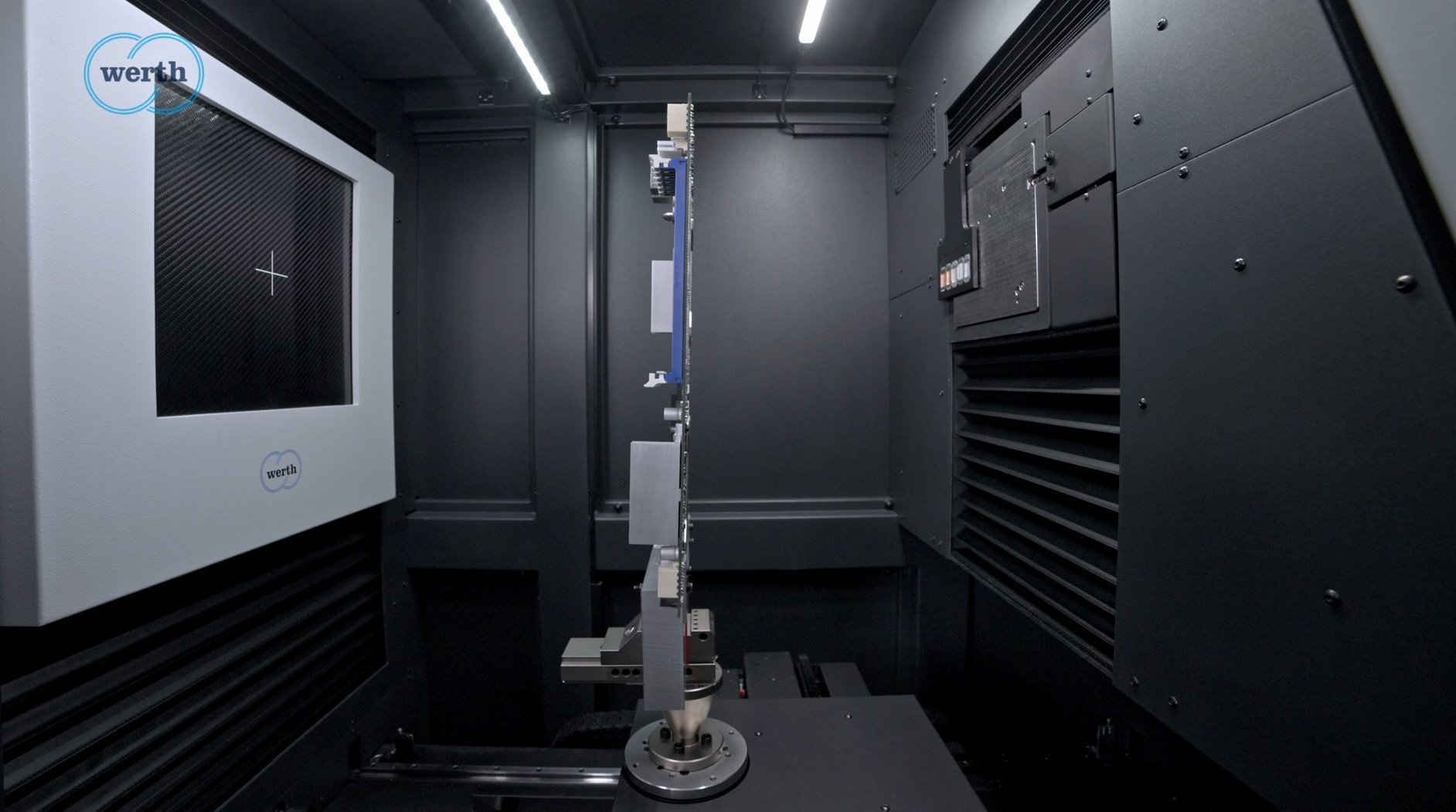

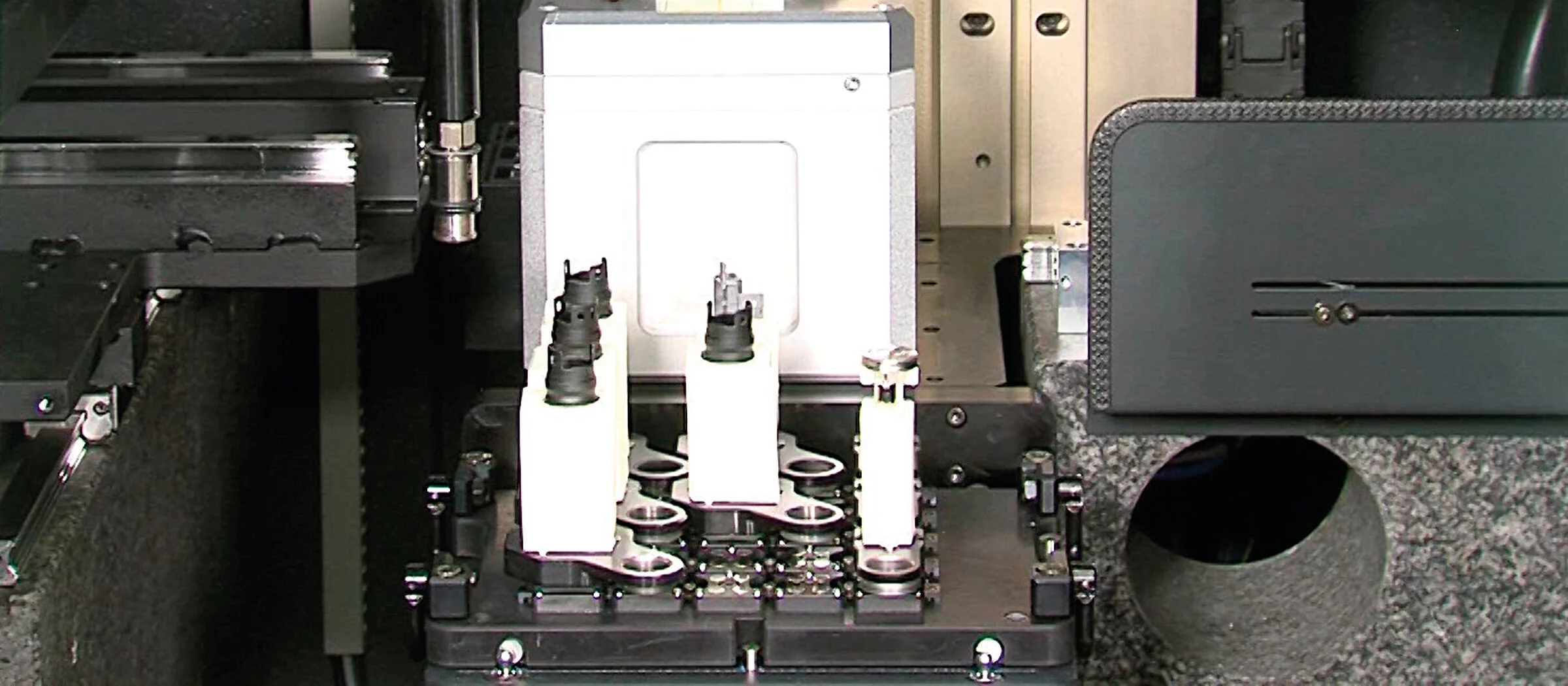

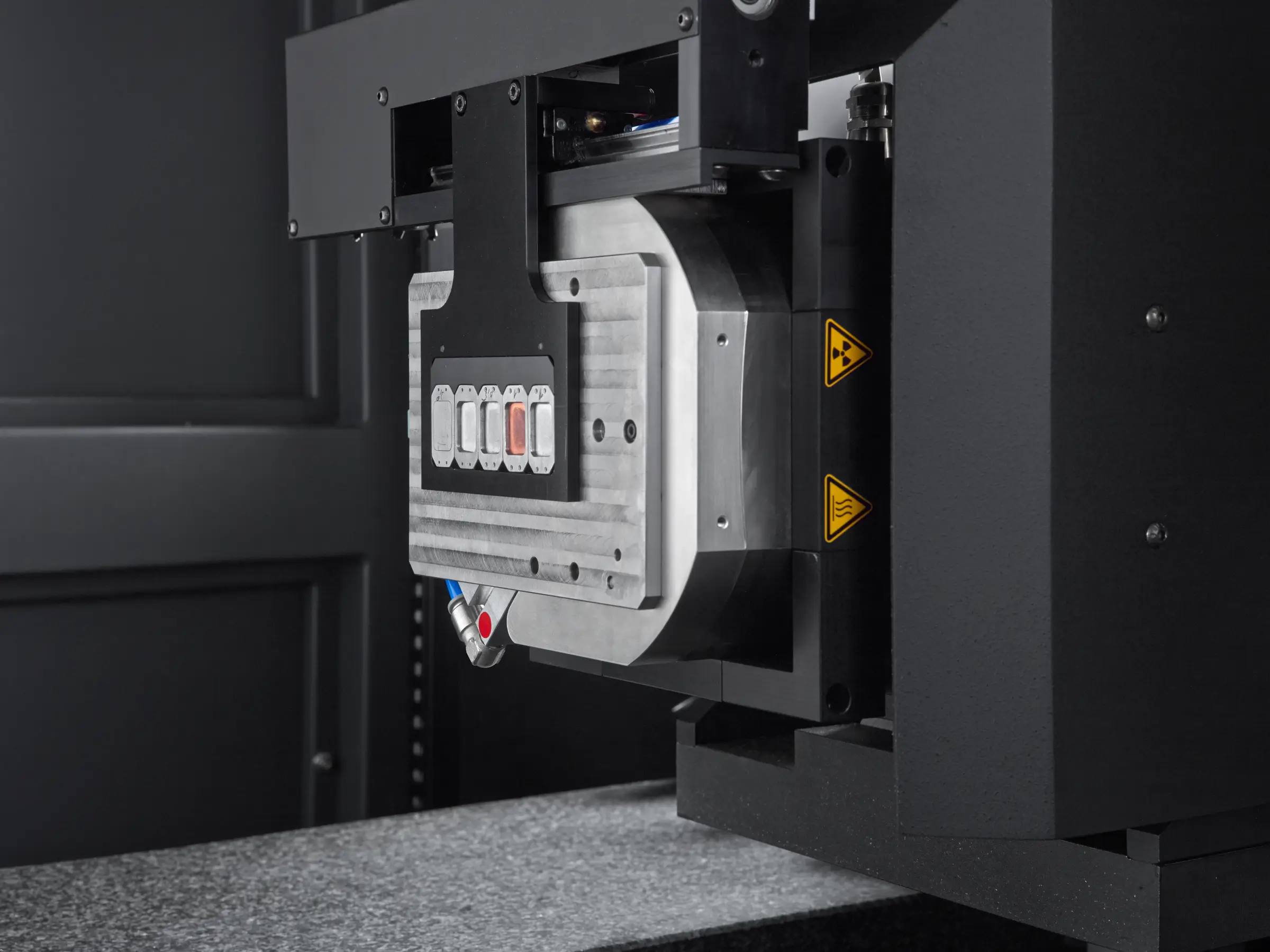

225 kV hızlanma voltajına sahip iletim tüpleri ile büyük, yüksek çözünürlüklü dedektörleri bir araya getiren TomoCheck® S HA (Yüksek Hassasiyet), çok malzemeli montajların yanı sıra büyük hacimli iş parçalarının 3D ölçümlerini yüksek çözünürlük ve benzeri görülmemiş bir hassasiyetle gerçekleştirir. Granit temel tasarım, yüksek hassasiyetli mekanik, hava yastığı teknolojisi ve yüksek performanslı kontrol, mikrometre altı aralıkta uzunluk ölçüm hataları sağlar. Uygulama alanları arasında plastik, hafif metal ve grafitten yapılmış mikro parçalar ve iş parçaları bulunur.

TomoCheck® S HA

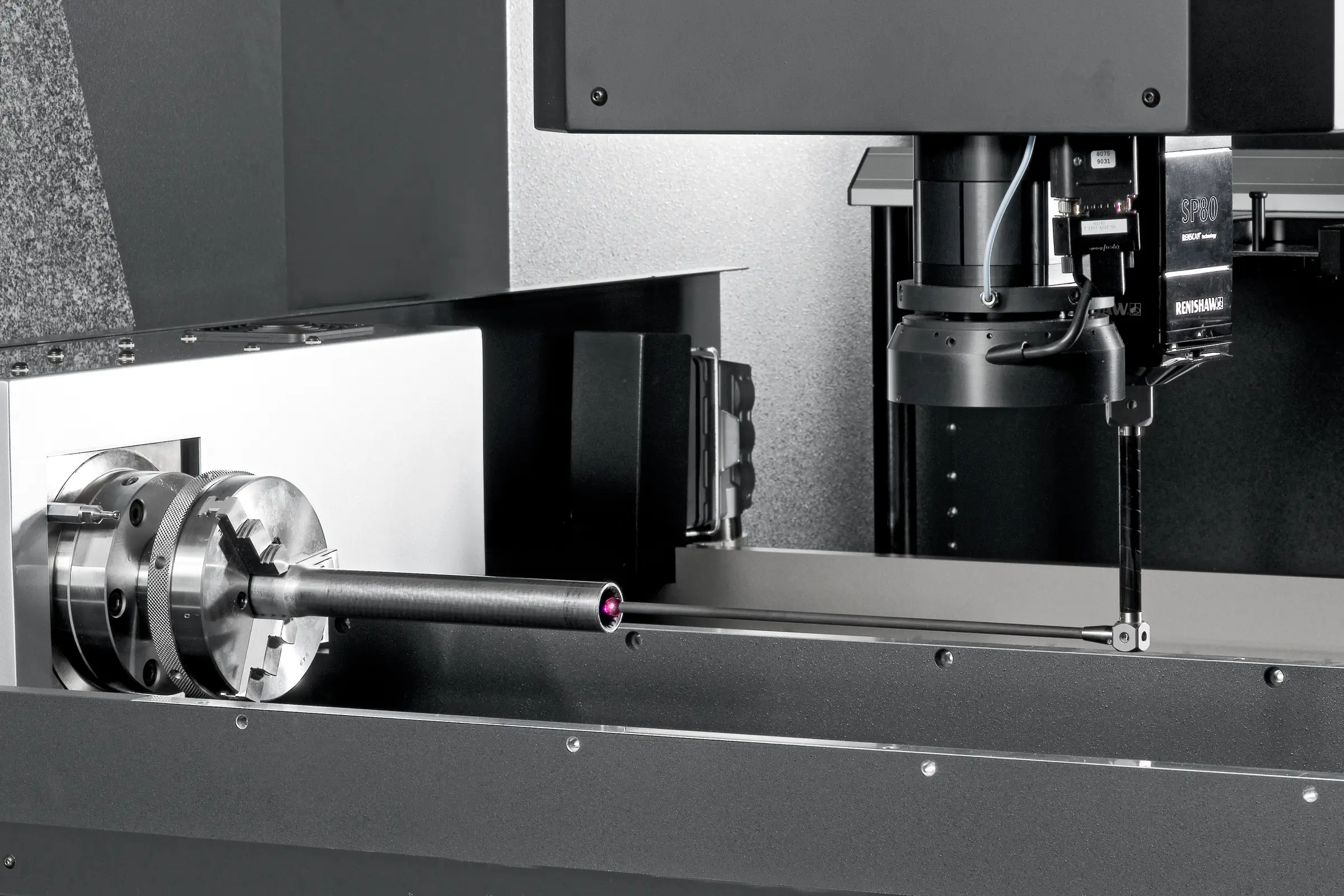

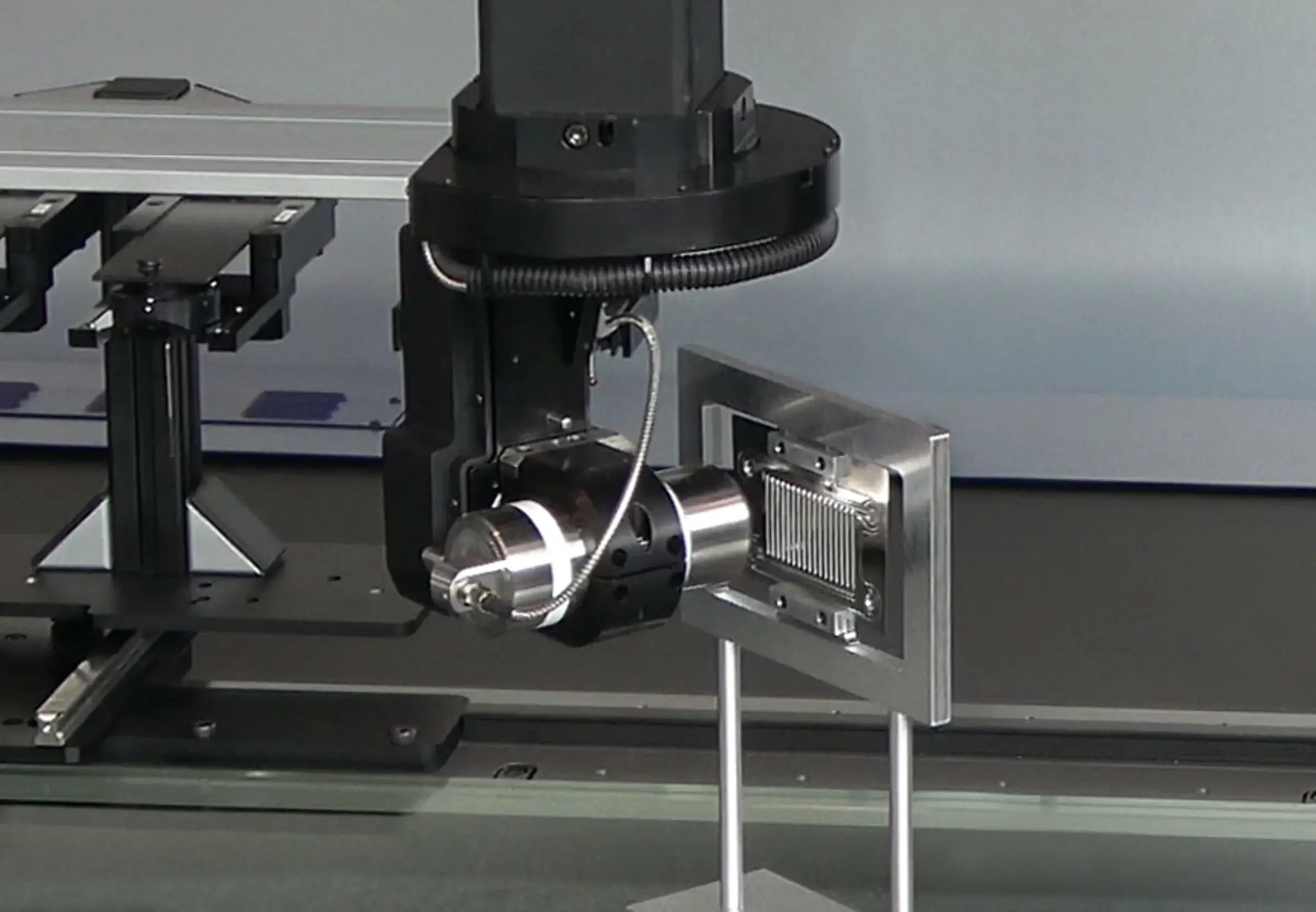

Patentli bir işlemle X-ray sensörünün prob hatasının en aza indirilmesi

Elmas hedef tüpü ve yüksek piksel sayısına sahip dedektör sayesinde 1/10 µm aralığında çözünürlük

Radyasyondan Korunma Yönetmeliği'ne uygun tam koruma cihazı tasarımı

Diğer uygulamaya özel sensörler sonradan takılabilir

VDI 2617'ye göre standartlara uygun kalibrasyon, isteğe bağlı olarak DAkkS sertifikası ile

Tip

Bilgisayarlı tomografi sensörlü yüksek hassasiyetli 3D CNC koordinat ölçüm makinesi

Ölçüm aralığı

Maks. İş parçası boyutları D = 204 mm / L = 434 mm (iş parçalarının en boy oranına bağlı olarak)

Hassasiyet

İzin verilen uzunluk ölçüm hatası 2,5 µm'ye kadar

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlere sahip makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi ...

Koordinat ölçüm makinesi ile ilgili kapsamlı hizmet

İlk devreye alma, eğitim ve bakımdan yenilemeye kadar tüm hizmetler...