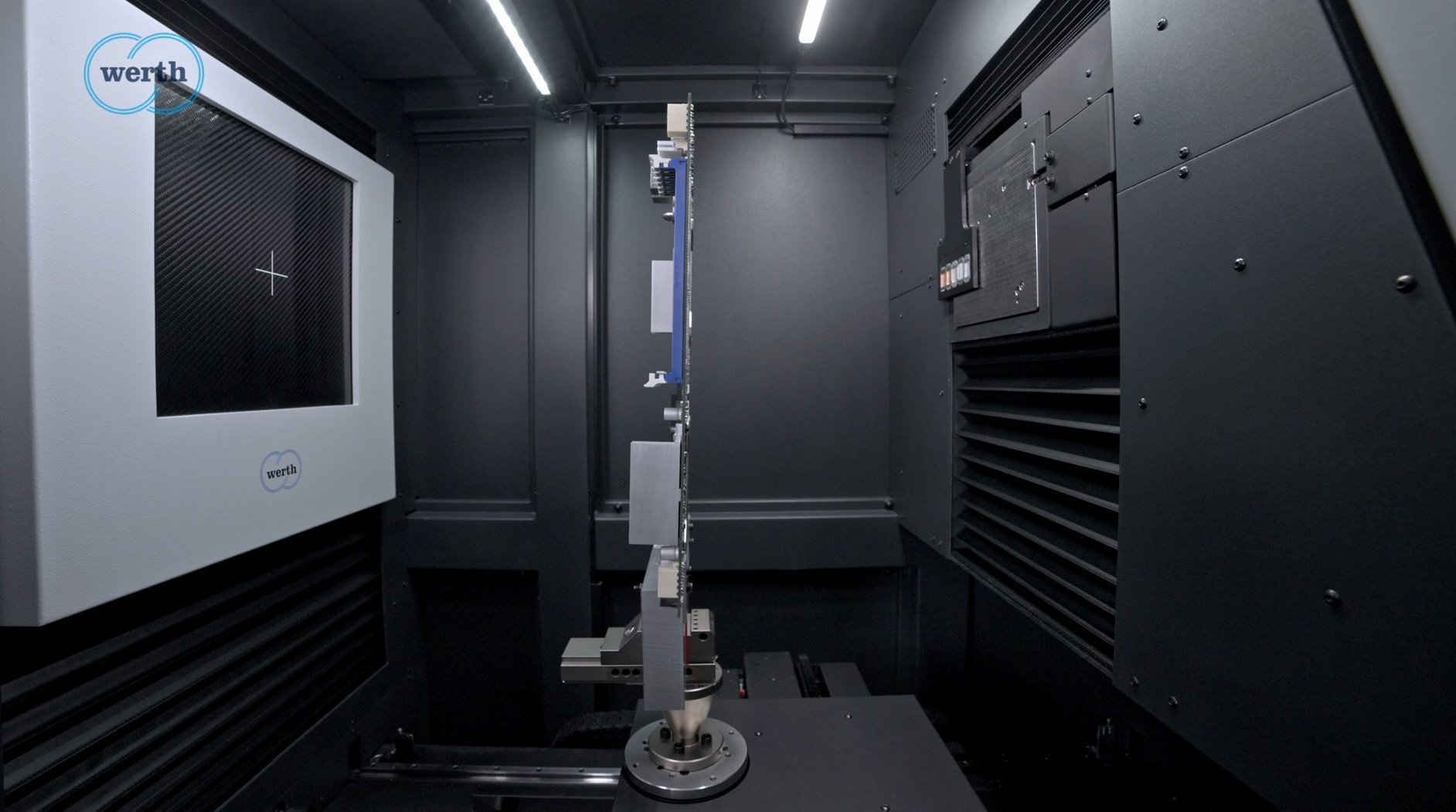

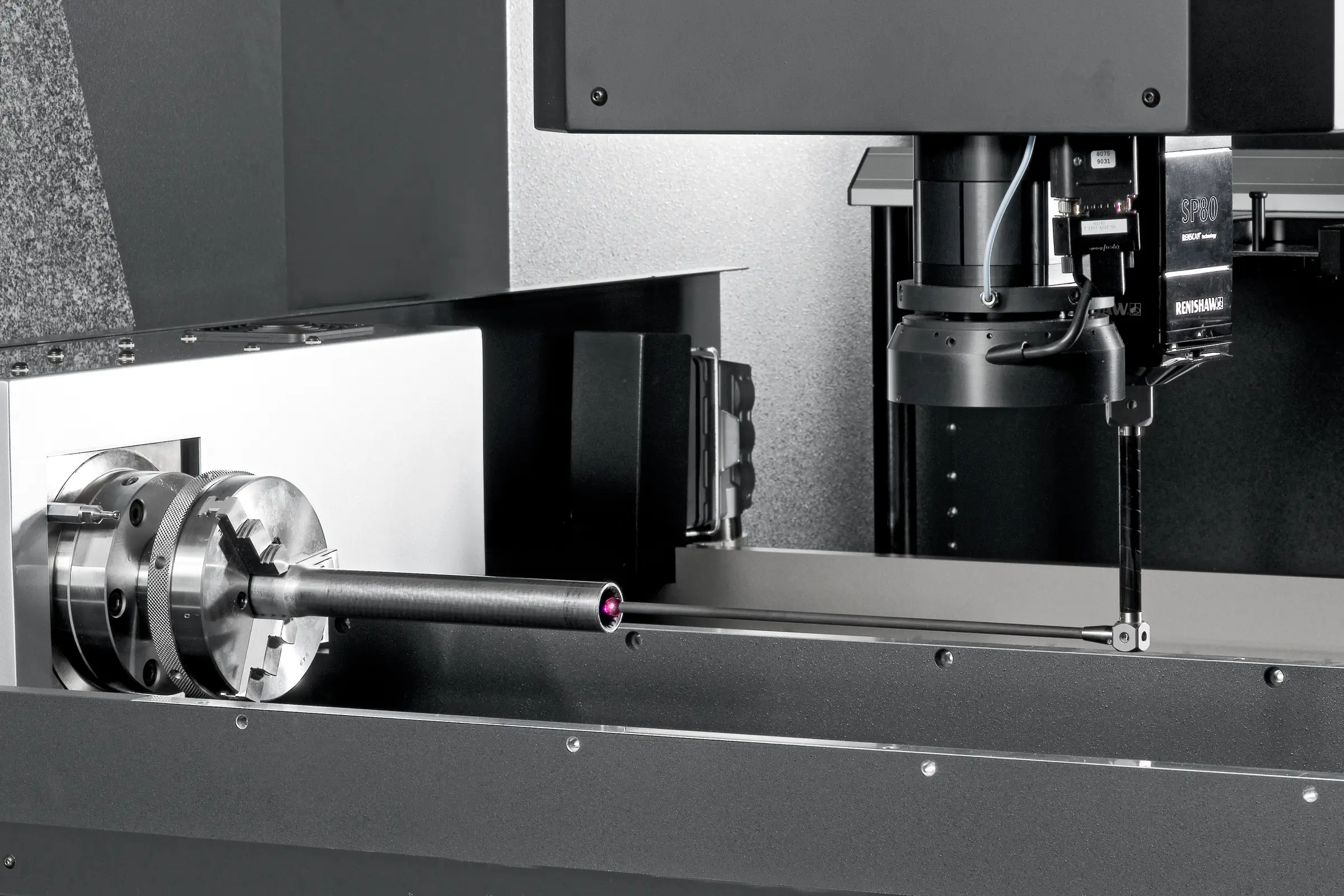

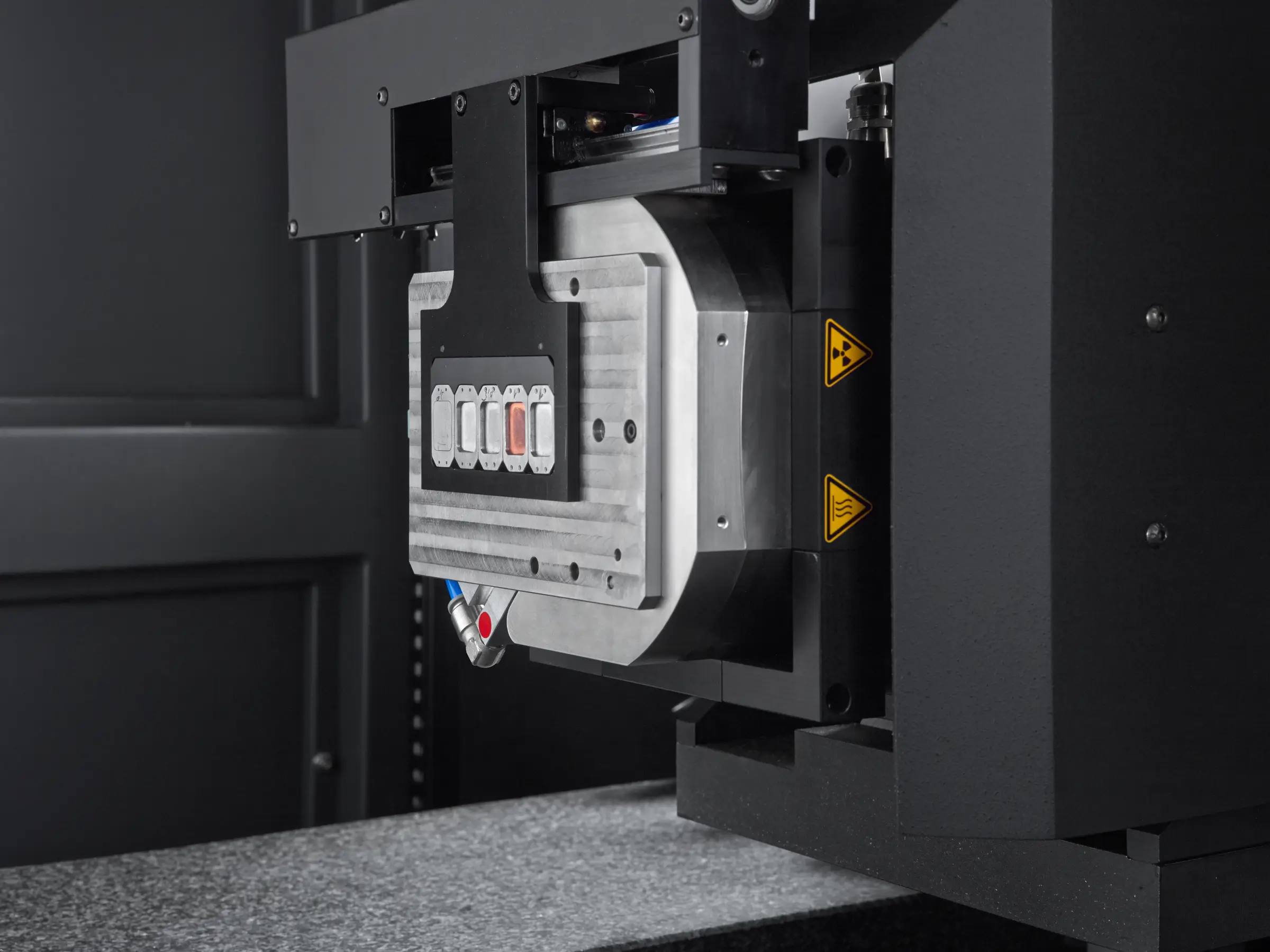

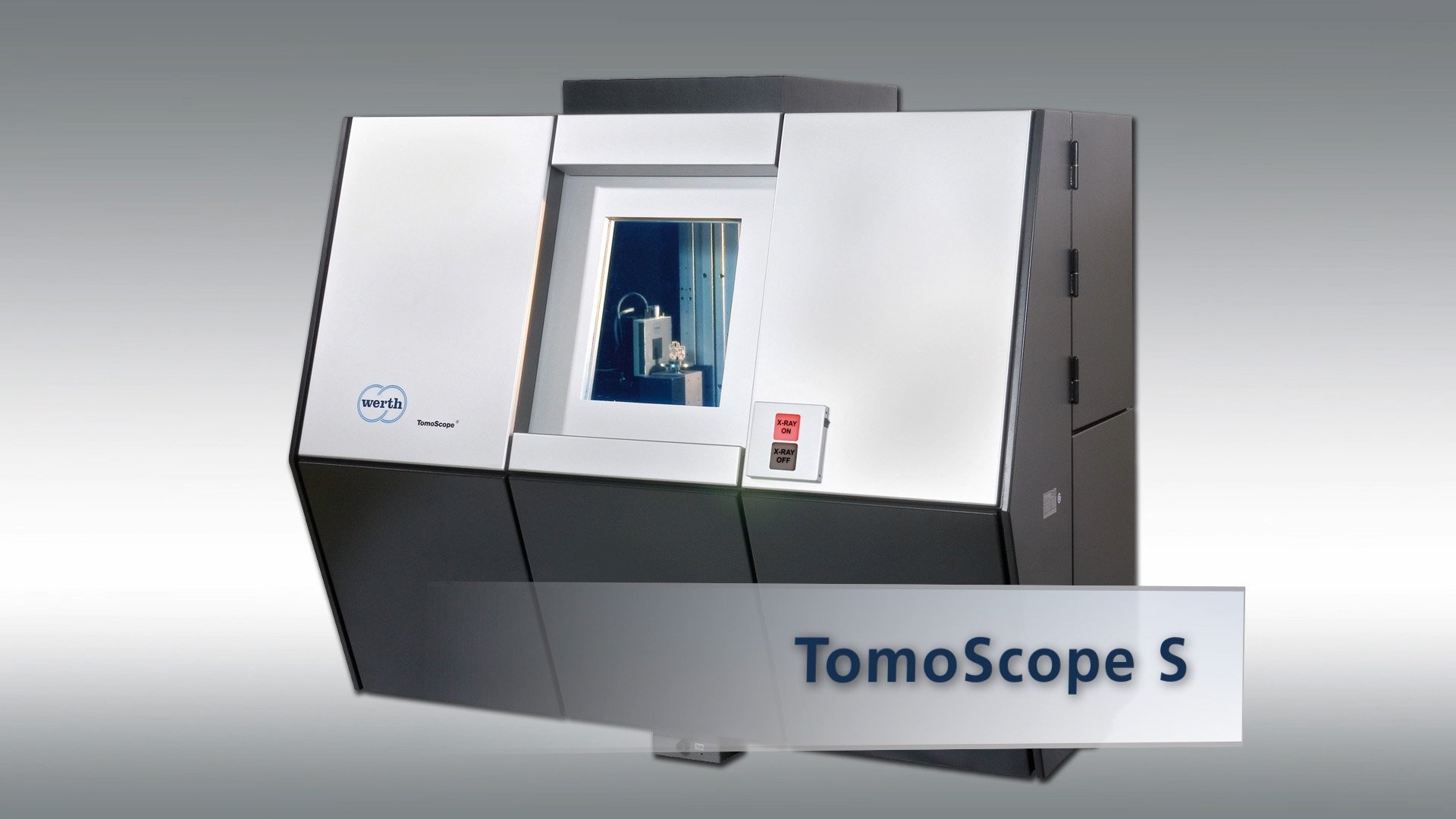

Werth TomoScope® S, makine sınıfında en yüksek doğruluk ve kompakt dış boyutlarla karakterize edilir. Makine, mevcut göreve uyarlanmış ölçüm hacimleri ile üç farklı tasarımda mevcuttur. Geniş ölçüm aralığı ve yüksek tüp voltajları sayesinde, büyük nesneler bile ölçülebilir. Mevcut X-ışını tüpleri, yüksek tüp gücüyle bile çok küçük bir odak noktası sunar ve bu sayede, işbirliği yapmayan iş parçalarında bile yüksek ölçüm hızıyla maksimum çözünürlük sağlar. Uygulama alanları arasında yüksek yoğunluklu iş parçaları (alüminyum, çelik, titanyum, elastomerler, hibrit plastikler (örn. cam elyaf takviyeli), seramikler, çoklu malzemeler (örn. konektörler), montajlar) bulunmaktadır.

TomoScope® S FOV / S / S Plus

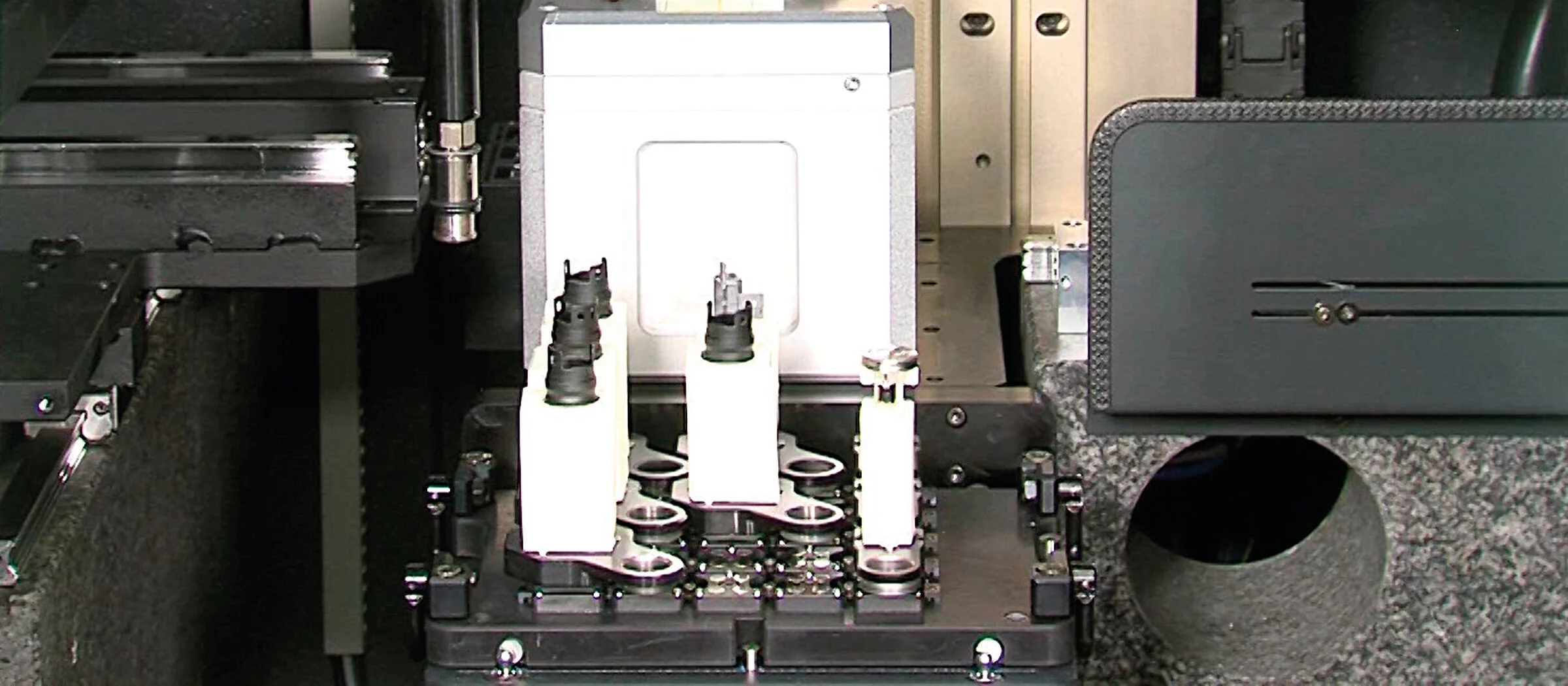

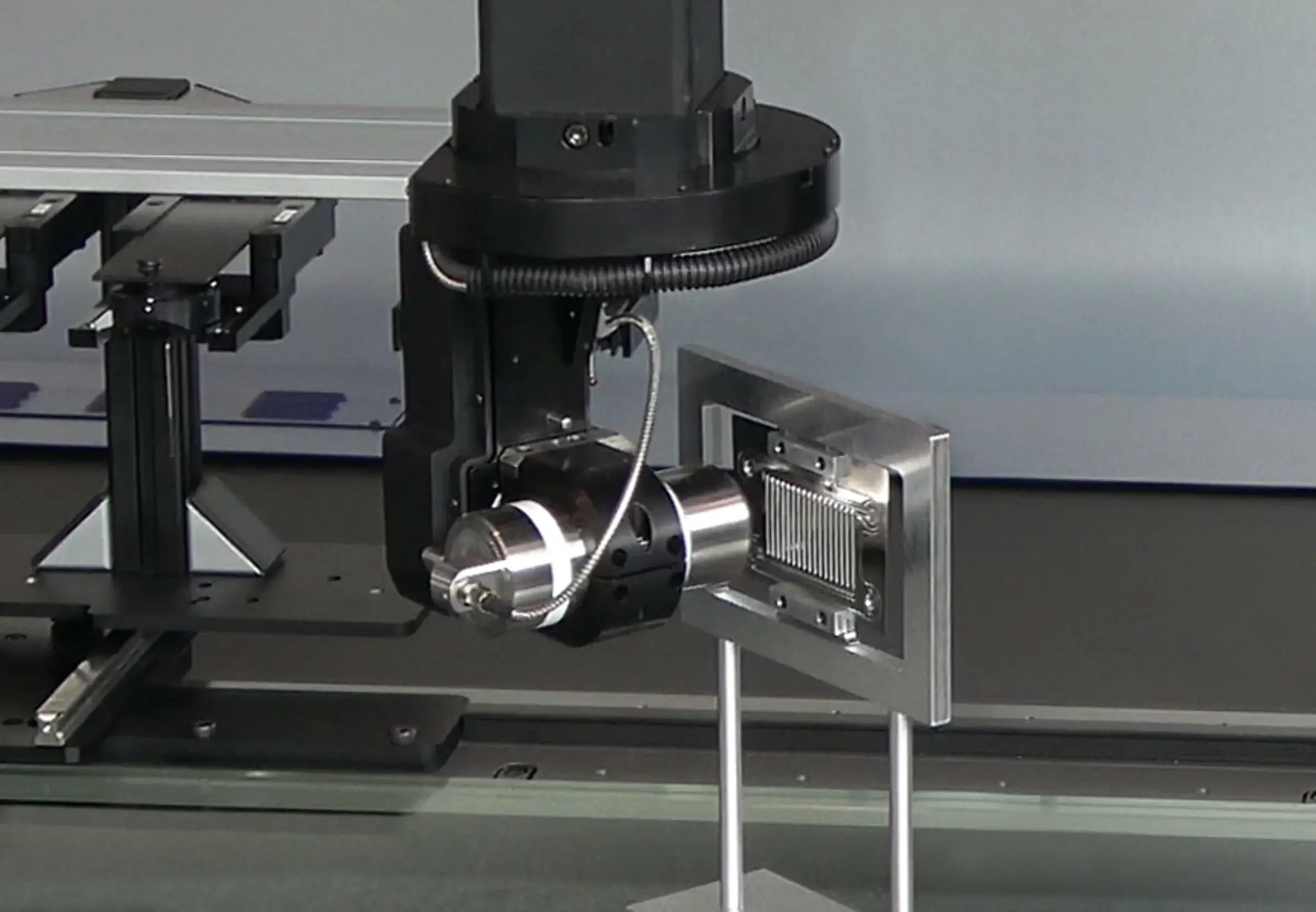

Ölçüm nesnelerinin kolay konumlandırılması için optik iş parçası konumlandırma yardımı

Subvoxeling işlemiyle elde edilebilen doğruluk ve yüksek ölçüm noktası yoğunluğu sayesinde, bu teknoloji enjeksiyon kalıplama için aletlerin düzeltilmesinde de idealdir.

Tüm TomoScope® makinelerinin tasarımı ve yapımı, Radyasyondan Korunma Yönetmeliği'ne göre tam koruma cihazlarına uygundur.

Bir iş parçası değiştirme sistemi cihaz muhafazasına entegre edilebilir ve bilgisayarlı tomografi koordinat ölçüm makinesi gece ve hafta sonları da sürekli ve otomatik olarak kullanılabilir.

Opsiyonel aktif cihaz iklimlendirme sayesinde üretim veya gelen mallarda bile yüksek hassasiyetli 3D ölçümler

Güvenilir ve izlenebilir ölçüm sonuçları için VDI 2617 standardına uygun kalibrasyon, isteğe bağlı olarak DAkkS sertifikası ile birlikte

Tasarım

Bilgisayarlı tomografi sensörlü 3D CNC çoklu sensörlü koordinat ölçüm makinesi

Ölçüm Aralığı

Maks. İş parçası boyutları D = 500 mm / L = 686 mm (iş parçalarının en boy oranına bağlı olarak)

Hassasiyet

İzin verilen uzunluk ölçüm hatası 4,5 µm'ye kadar

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlere sahip makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi ...

Koordinat ölçüm makinesi ile ilgili kapsamlı hizmet

İlk devreye alma, eğitim ve bakımdan yenilemeye kadar tüm hizmetler...