TomoScope® FQ cihaz ailesi, ölçüm nokta bulutunun hesaplanmasını ve değerlendirilmesini 50 kata kadar hızlandırır. Valf blokları, muhafazalar ve dökümler gibi iş parçaları için geometrik özellikler neredeyse her yarım dakikada bir belirlenir, ana parçanın ölçüm noktası bulutu ile nominal-gerçek karşılaştırması yapılır ve iş parçaları çapak gibi kusurlar açısından test edilir. WinWerth® Scout ölçüm yazılımı, devam eden ve tamamlanan ölçüm süreçleri için net bir durum göstergesi ve tüm ölçüm sonuçlarına bir fare tıklamasıyla erişim sağlar.

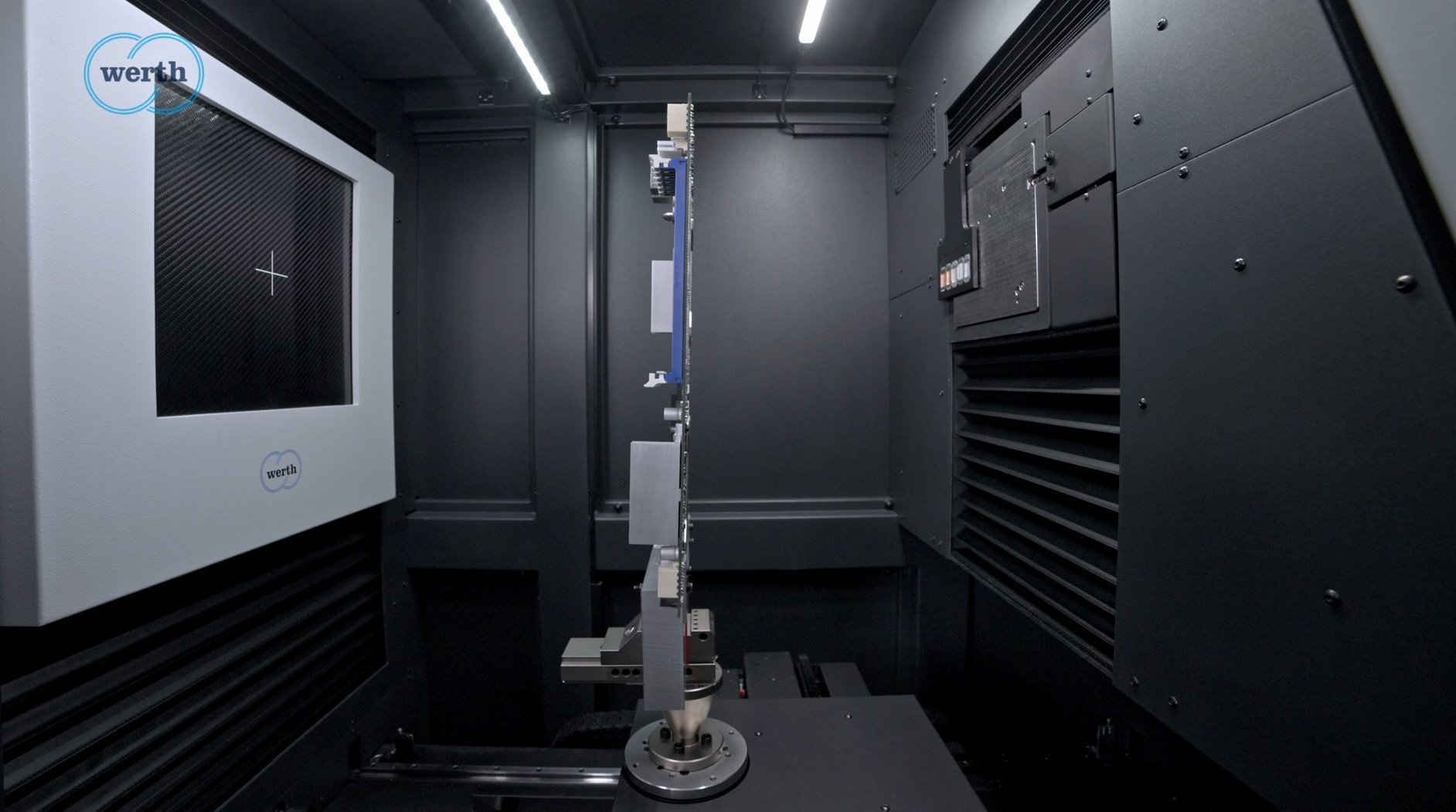

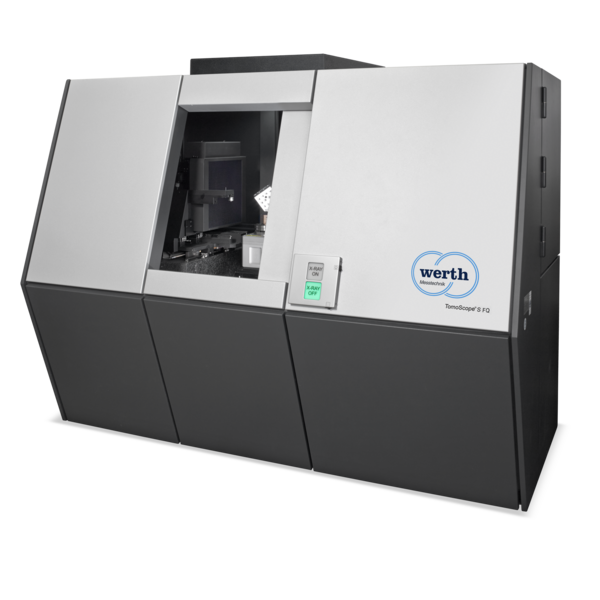

TomoScope® S FQ

Tüm TomoScope® ölçüm makineleri “FQ” versiyonu olarak mevcuttur.

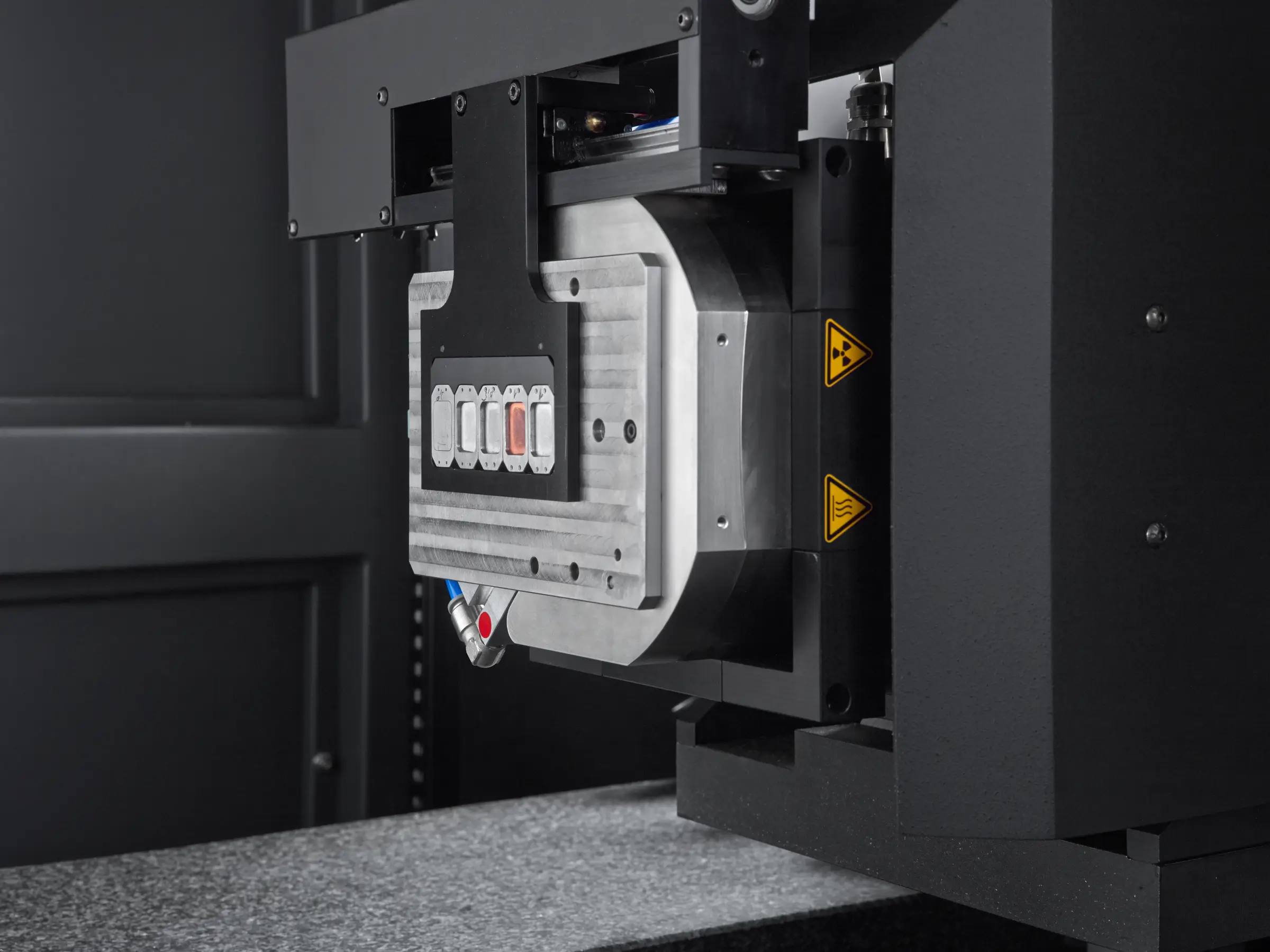

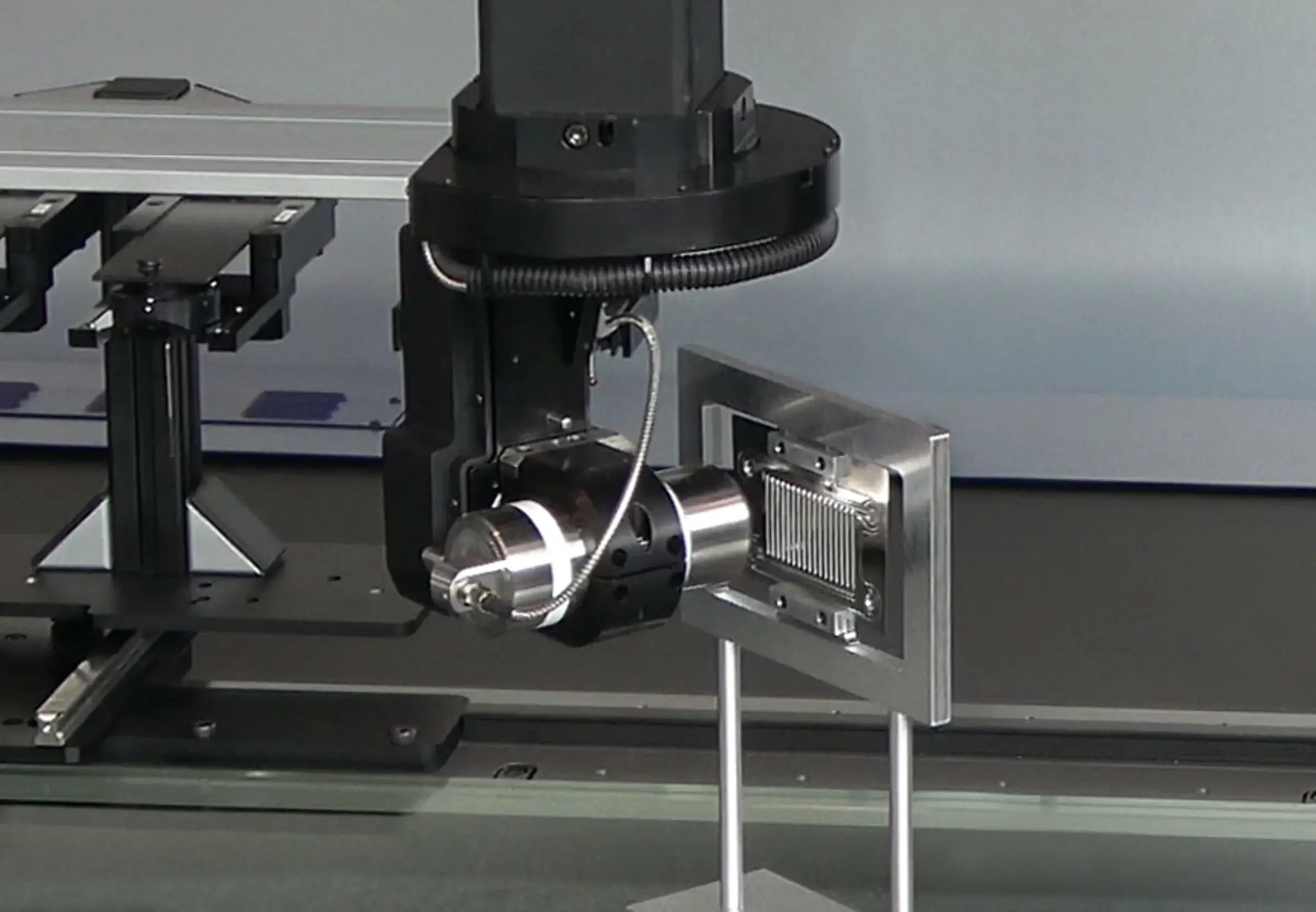

Yoğun malzemelerin ve büyük iş parçalarının hızlı ölçümü için bakım gerektirmeyen kapalı yüksek performanslı X-ışını tüpü

Uzun ömürlü, zaman alıcı tüp açma ve kapama işlemlerini önleyen entegre kapak

OnTheFly modunda hızlı görüntü elde etme özelliğine sahip, yüksek performanslı ölçümler için üst düzey dedektör

Ön kapı veya üst yükleme açıklığından robotla iş parçası besleme

Çevrimdışı iş istasyonlarında uzaktan programlama

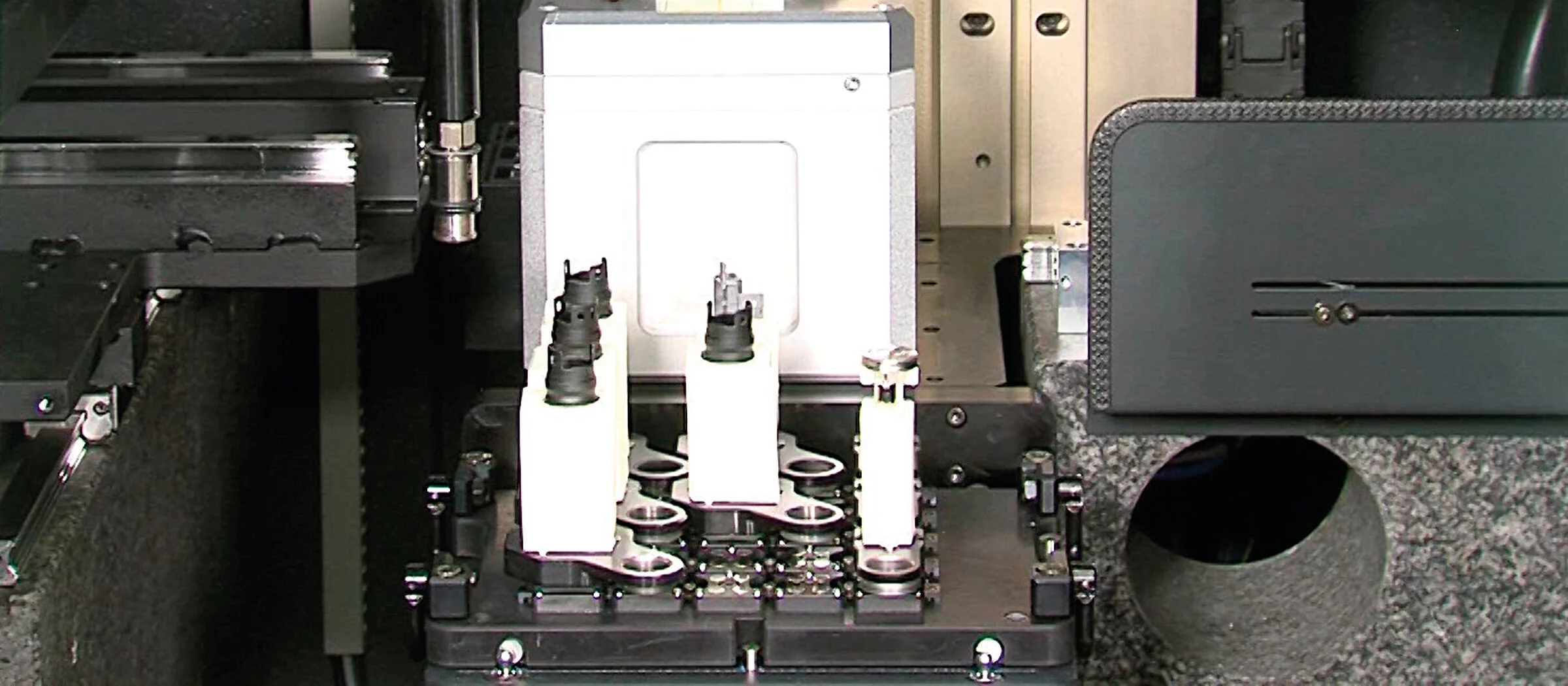

Ölçüm sürecinin başlatılması, örneğin QR kodu veya RFID çipi aracılığıyla, böylece iş parçaları ve partiler açıkça tanımlanabilir.

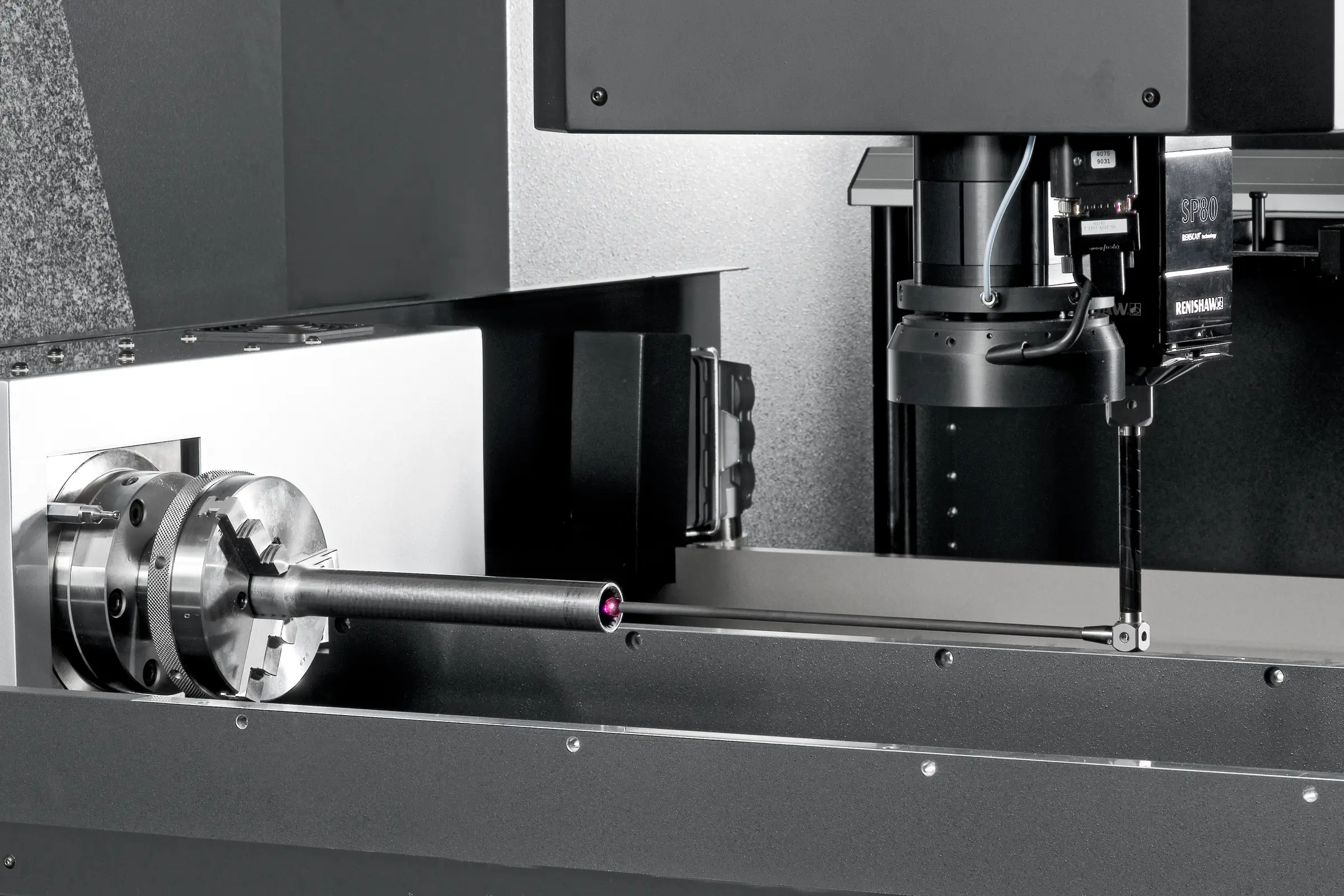

Bilgisayarlı tomografi ve çok sensörlü koordinat ölçüm makineleri arasında görev paylaşımı

Tip

Bilgisayarlı tomografi sensörlü 3D CNC koordinat ölçüm makinesi

Ölçüm aralığı

Maks. İş parçası boyutları D = 260 mm / L = 393 mm (iş parçalarının en boy oranına bağlı olarak)

Hassasiyet

4,5 µm'ye kadar izin verilen prob hatası

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlere sahip makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi ...

Koordinat ölçüm makinesi ile ilgili kapsamlı hizmet

İlk devreye alma, eğitim ve bakımdan yenilemeye kadar tüm hizmetler...