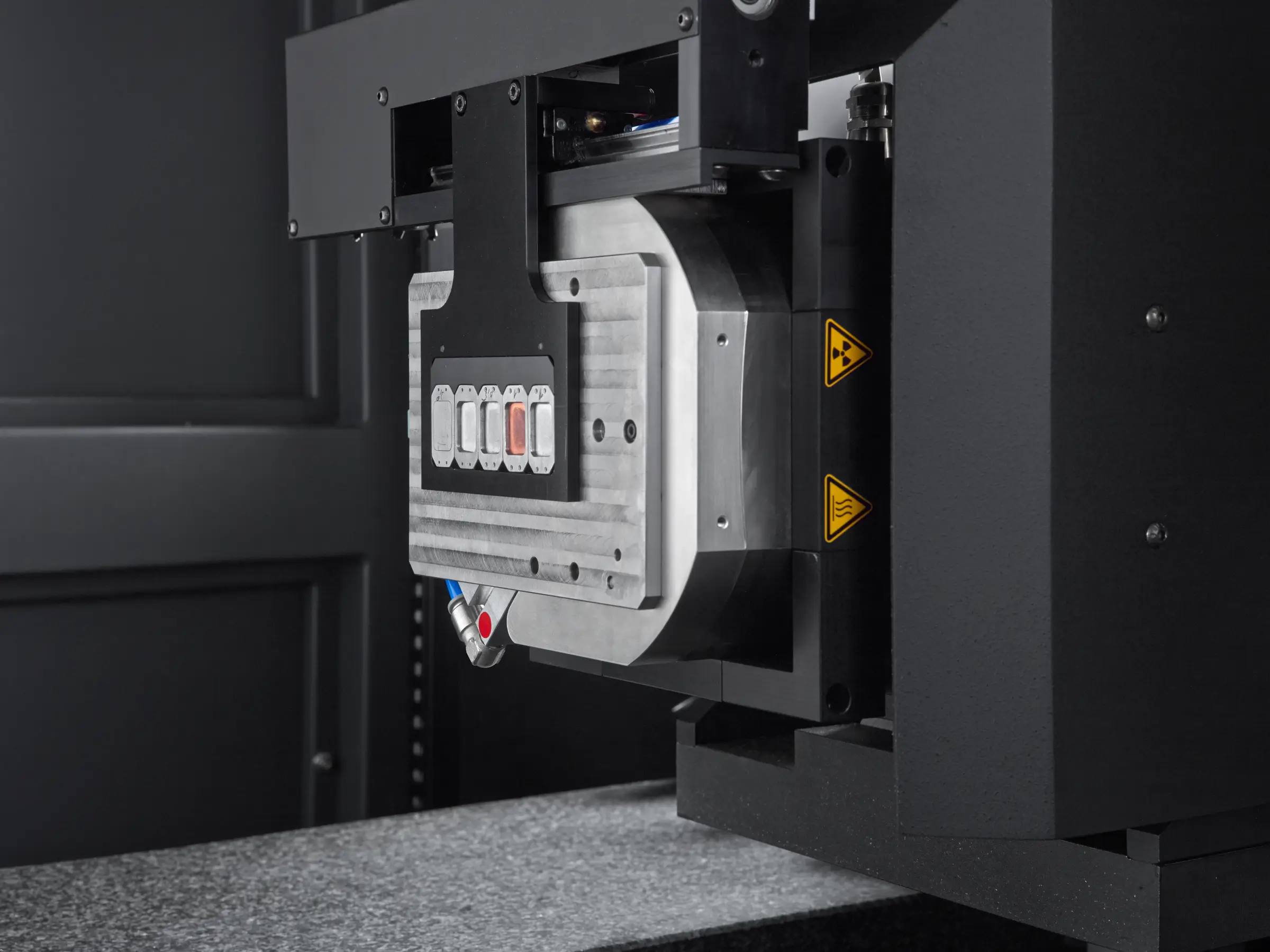

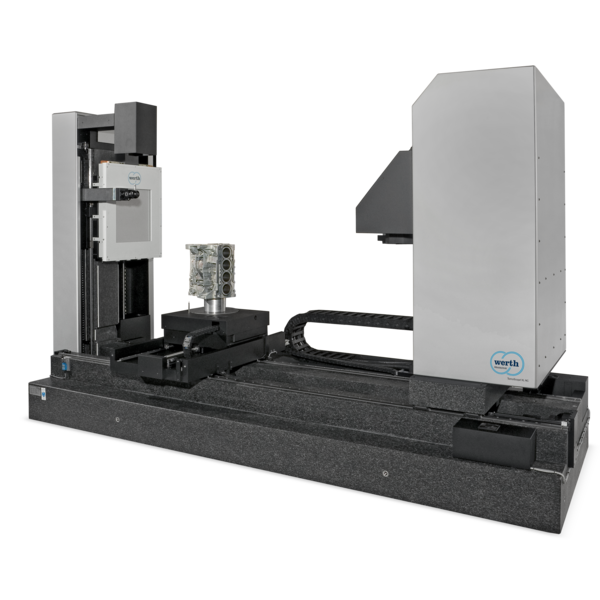

450 kV tüp voltajı sayesinde TomoScope® XL NC, büyük ve masif iş parçalarının ölçüm ve kontrol görevleri için de uygundur. Uygulama alanını genişletmek için, X-ışını tomografisi (CT) özellikli bu çok sensörlü koordinat ölçüm makinesinde otomatik geçişle ikinci bir X-ışını kaynağı kullanılabilir, örneğin en yüksek çözünürlükle küçük bileşenlerin ek ölçümleri için. Uygulama alanları arasında dökümlerin (motor blokları, silindir kafaları) ve seramik iş parçalarının 3D ölçümleri yer almaktadır.

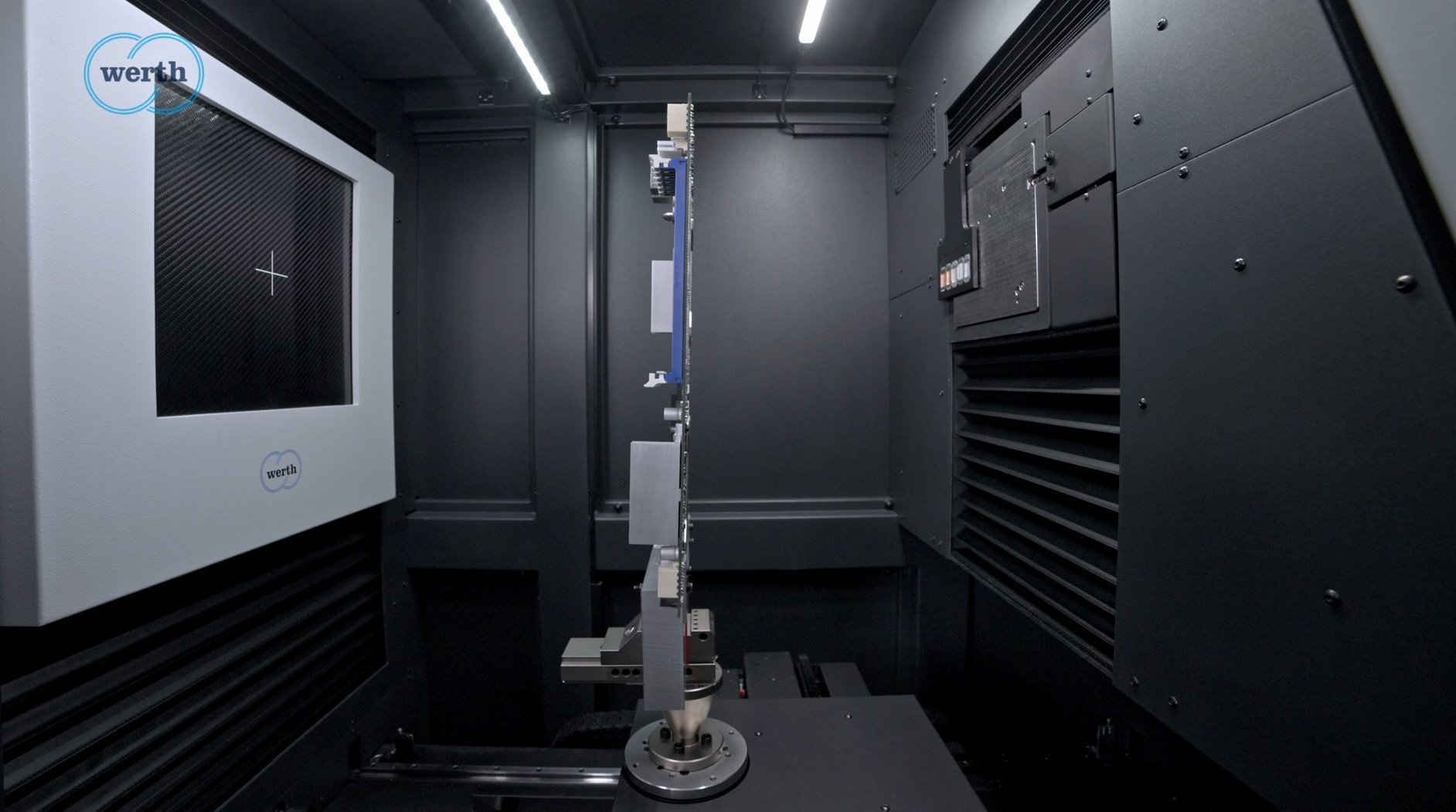

TomoScope® XL NC

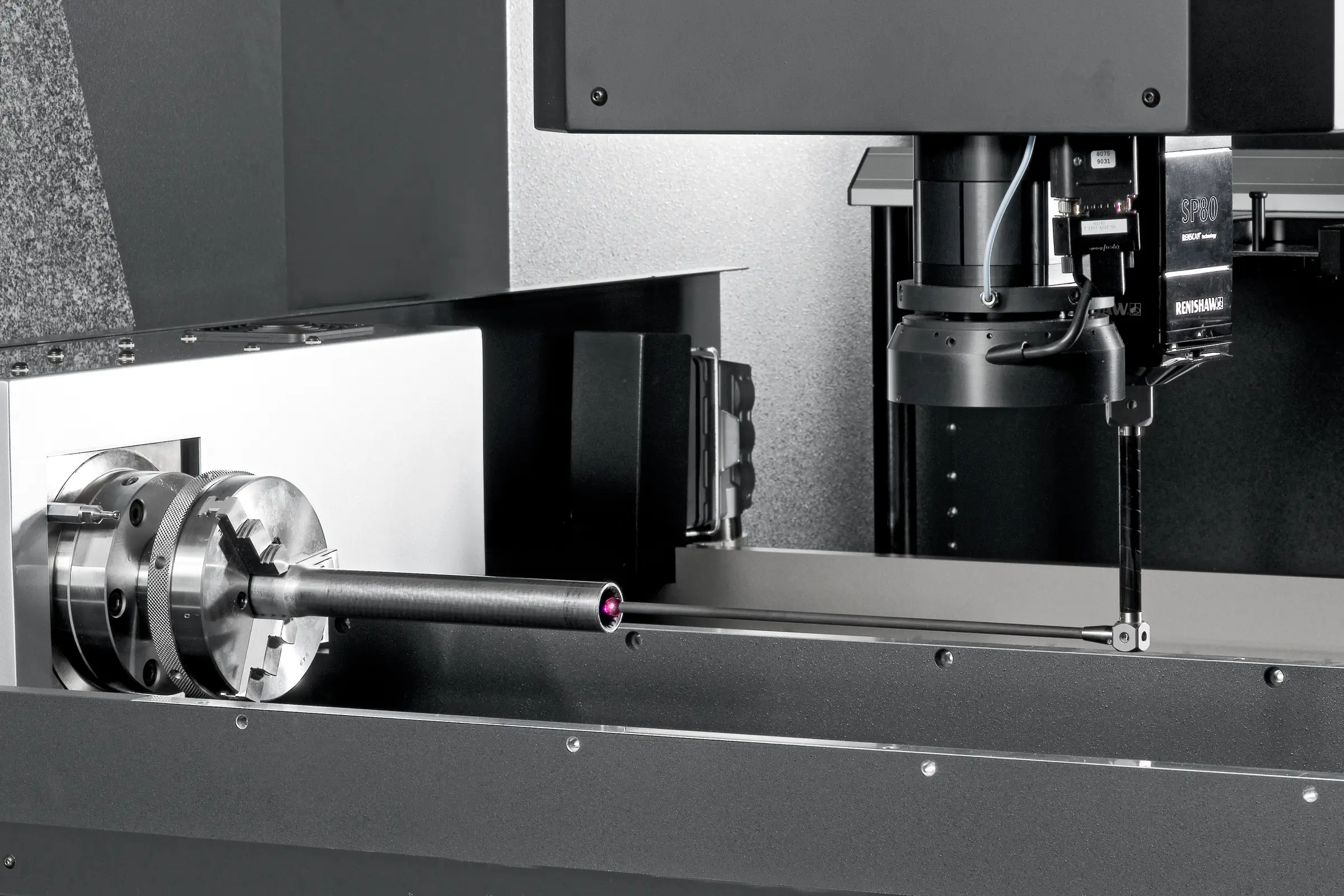

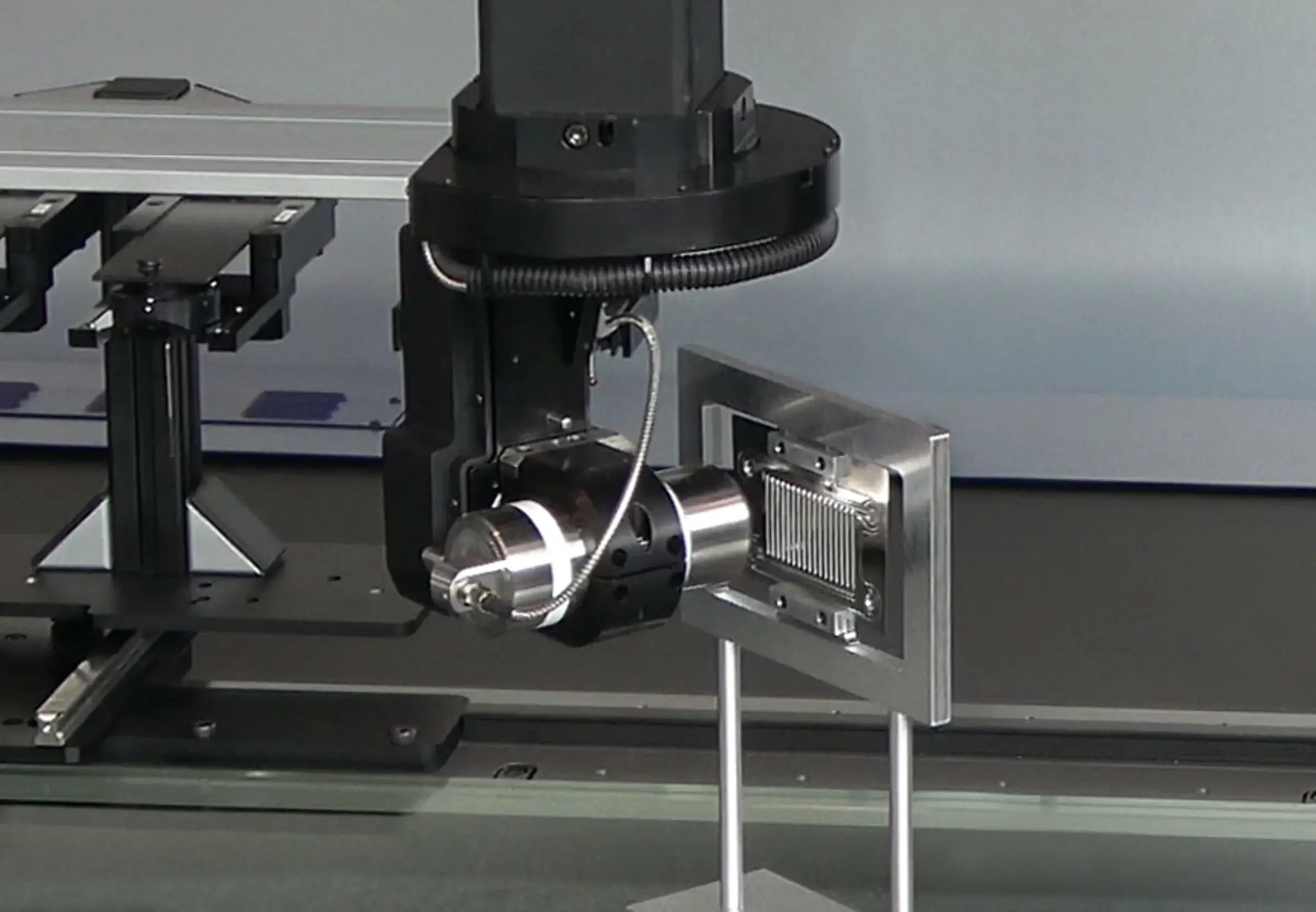

Küçük koni açıları ile hassas ölçüm için X-ışını tüpü ile dedektör arasında geniş mesafe

Ölçüm nesnelerinin kolay konumlandırılması için optik iş parçası konumlandırma yardımı

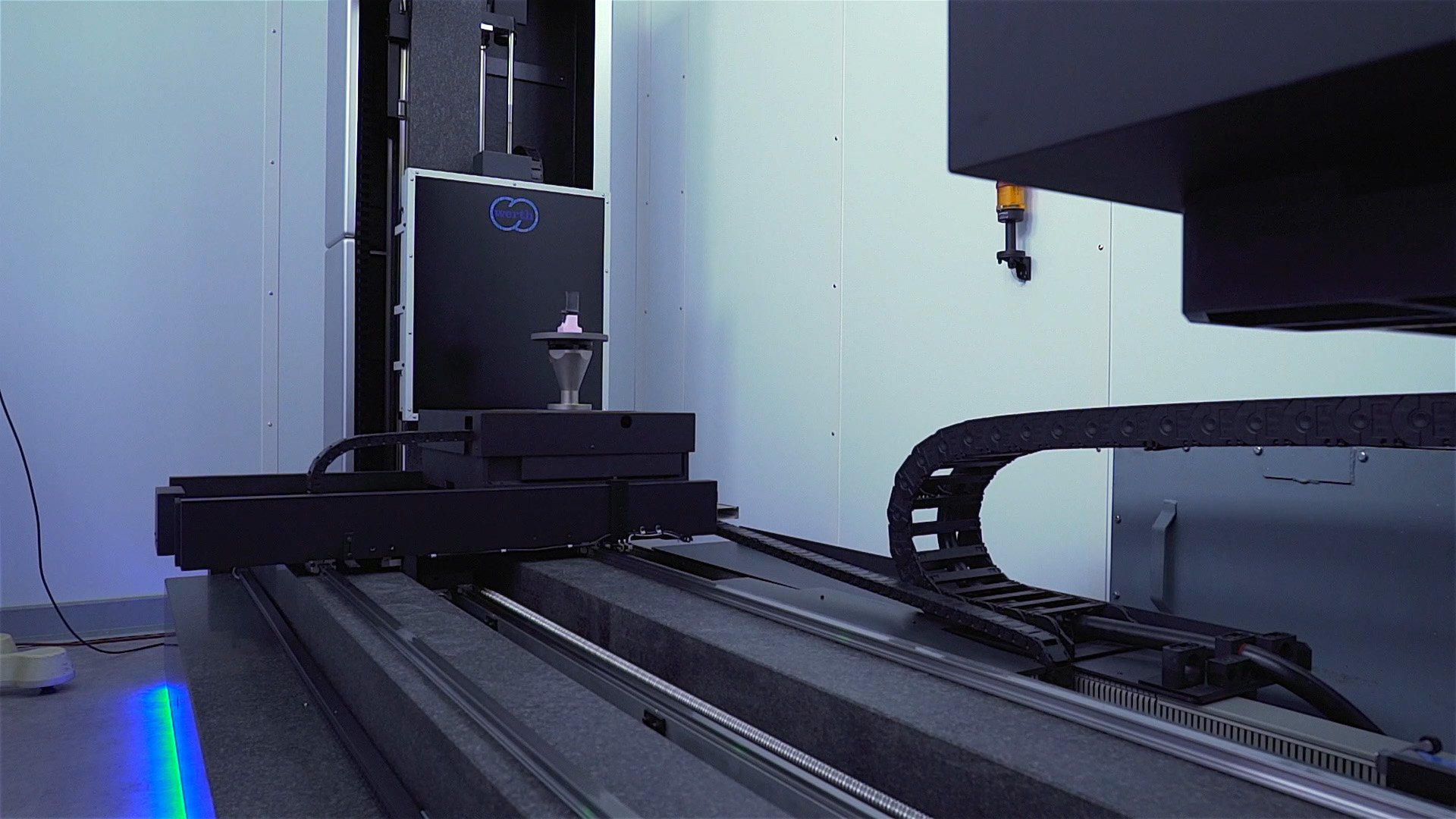

Örneğin, X-ışını yönetmeliğine göre tam koruma cihazlarına uygun tasarım ve yapıya sahip, içeri girilebilir radyasyondan korunma odası (isteğe bağlı) ile uyumludur.

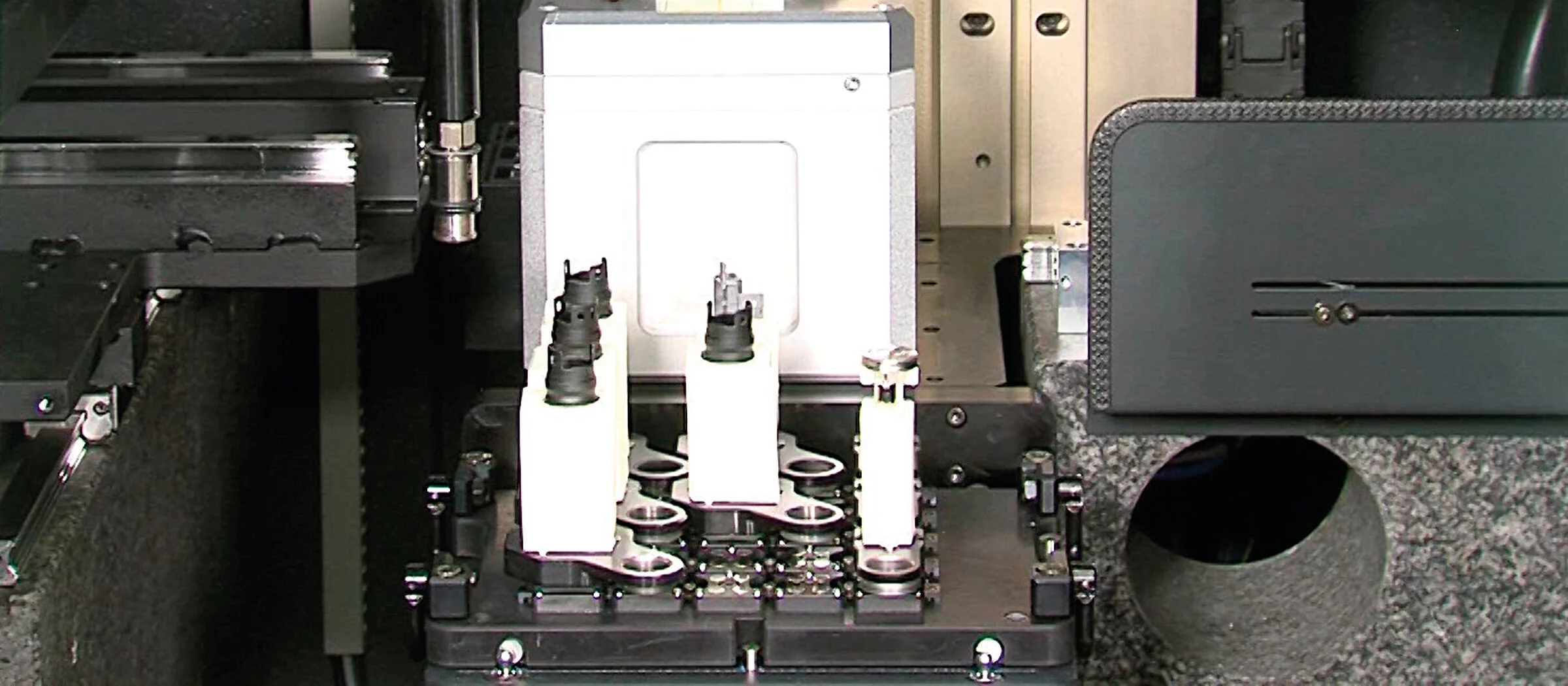

Subvoxeling ve yüksek nokta yoğunluğu, enjeksiyon kalıplama için takım düzeltmesini mümkün kılar.

Bir iş parçası değiştirme sistemi entegre edilebilir; gece ve hafta sonları “ışıklar kapalı” çalışma mümkündür.

VDI 2617'ye göre standartlara uygun kalibrasyon, isteğe bağlı olarak DAkkS sertifikası ile

Tip

Bilgisayarlı tomografi sensörlü 3D CNC koordinat ölçüm makinesi

Ölçüm aralığı

Maks. İş parçası boyutları D = 500 mm / L = 1010 mm (iş parçalarının en boy oranına bağlı olarak)

Hassasiyet

İzin verilen uzunluk ölçüm hatası 4,5 µm'ye kadar

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlere sahip makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi ...

Koordinat ölçüm makinesi ile ilgili kapsamlı hizmet

İlk devreye alma, eğitim ve bakımdan yenilemeye kadar tüm hizmetler...