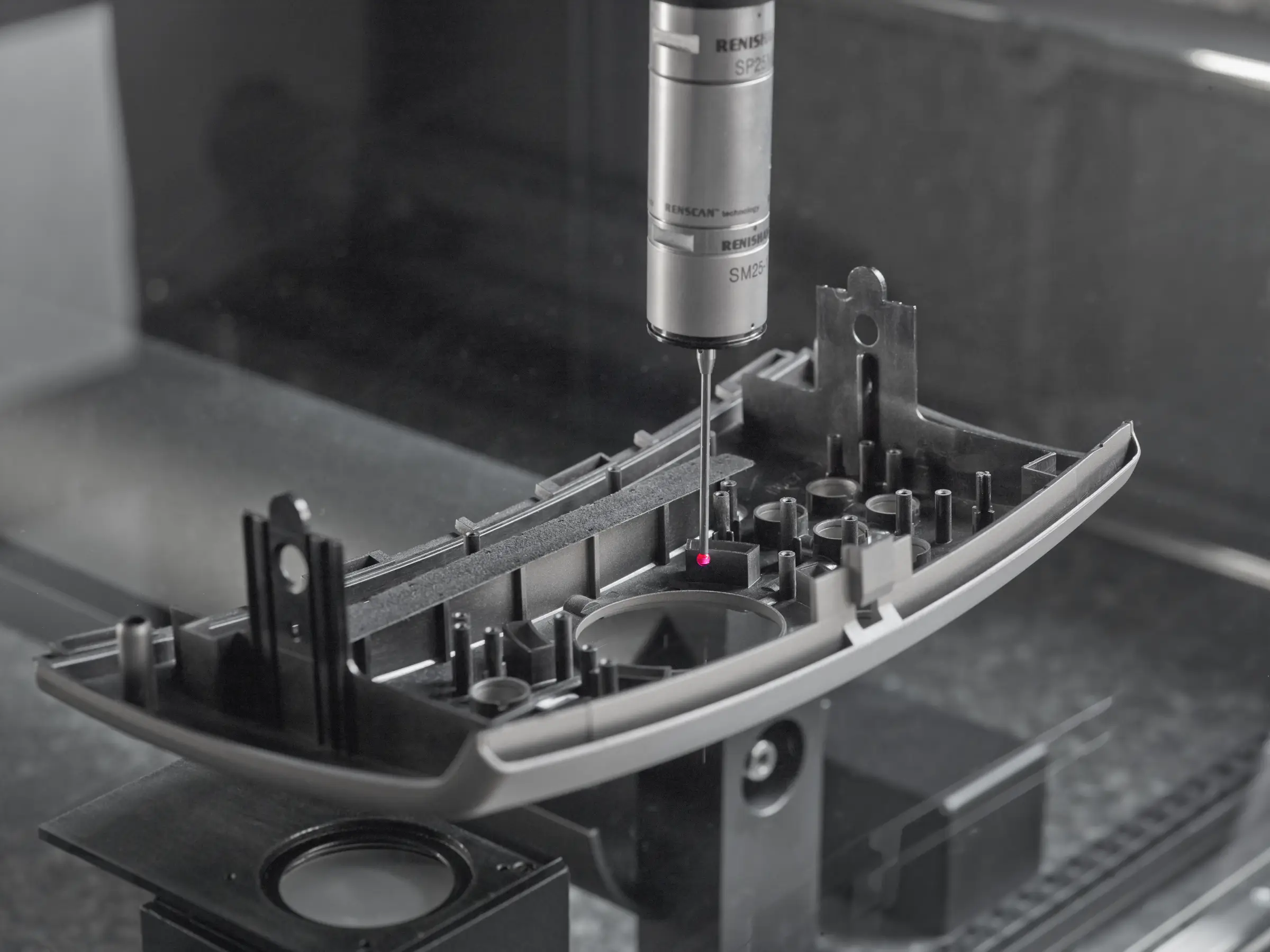

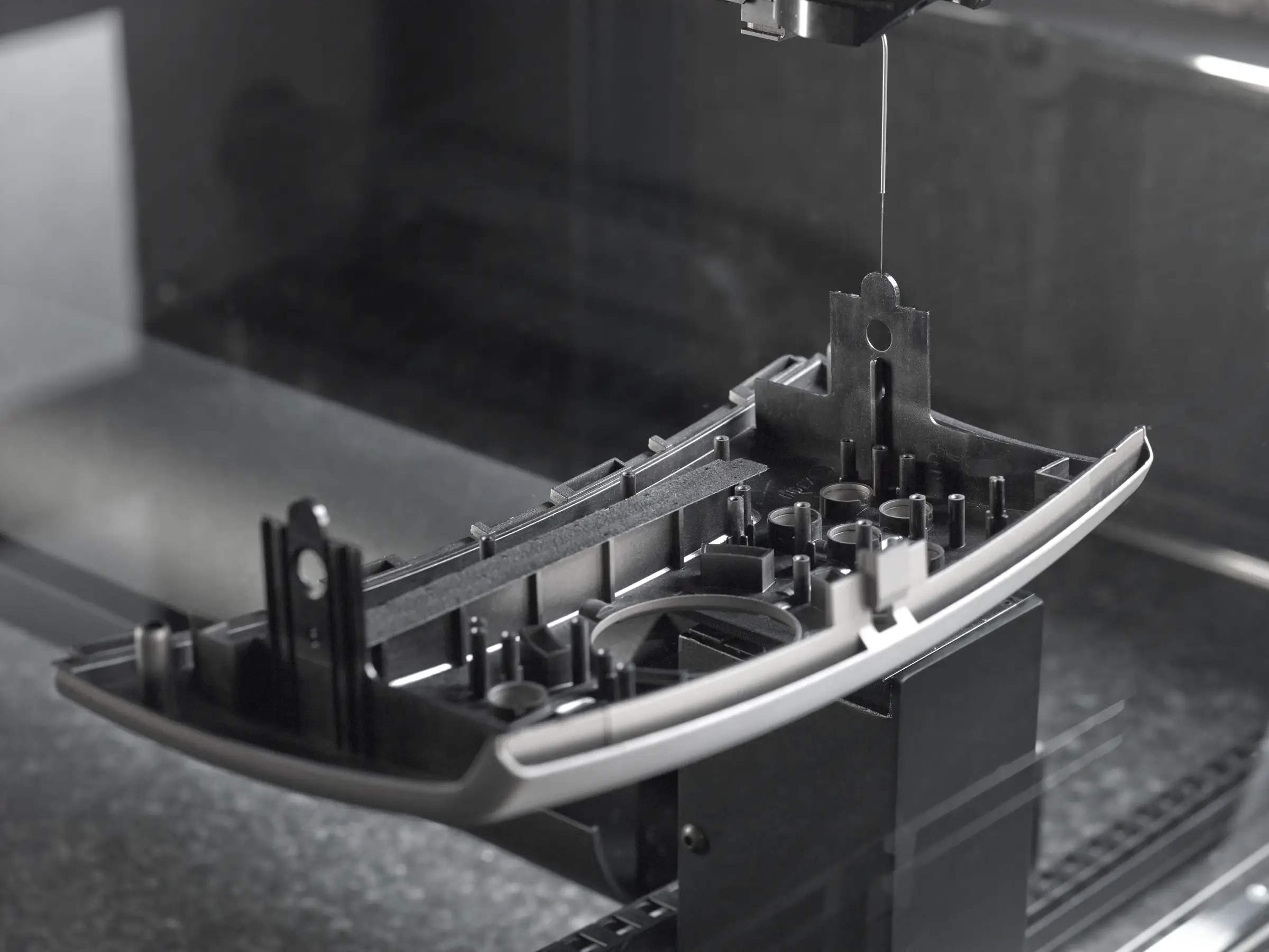

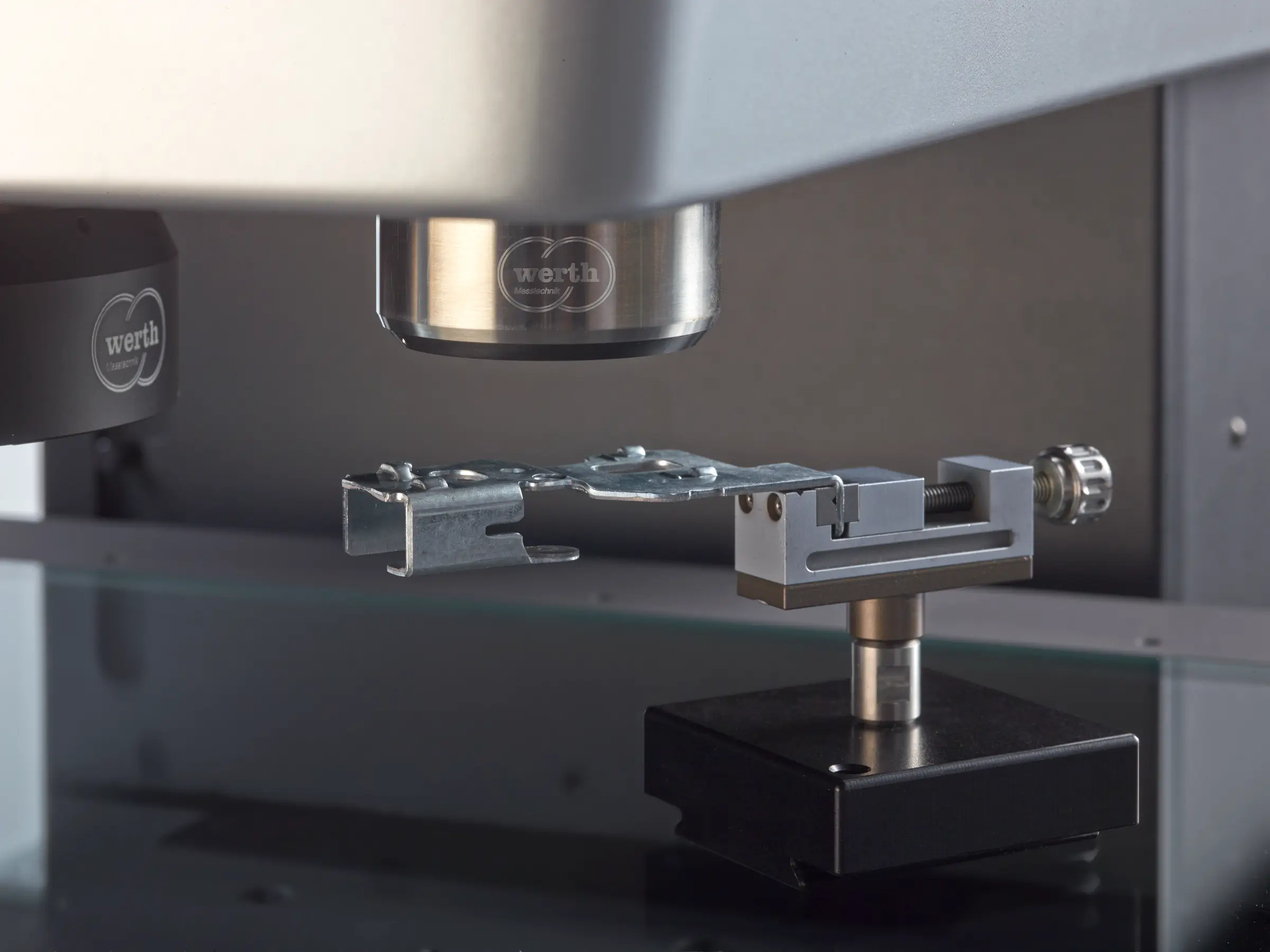

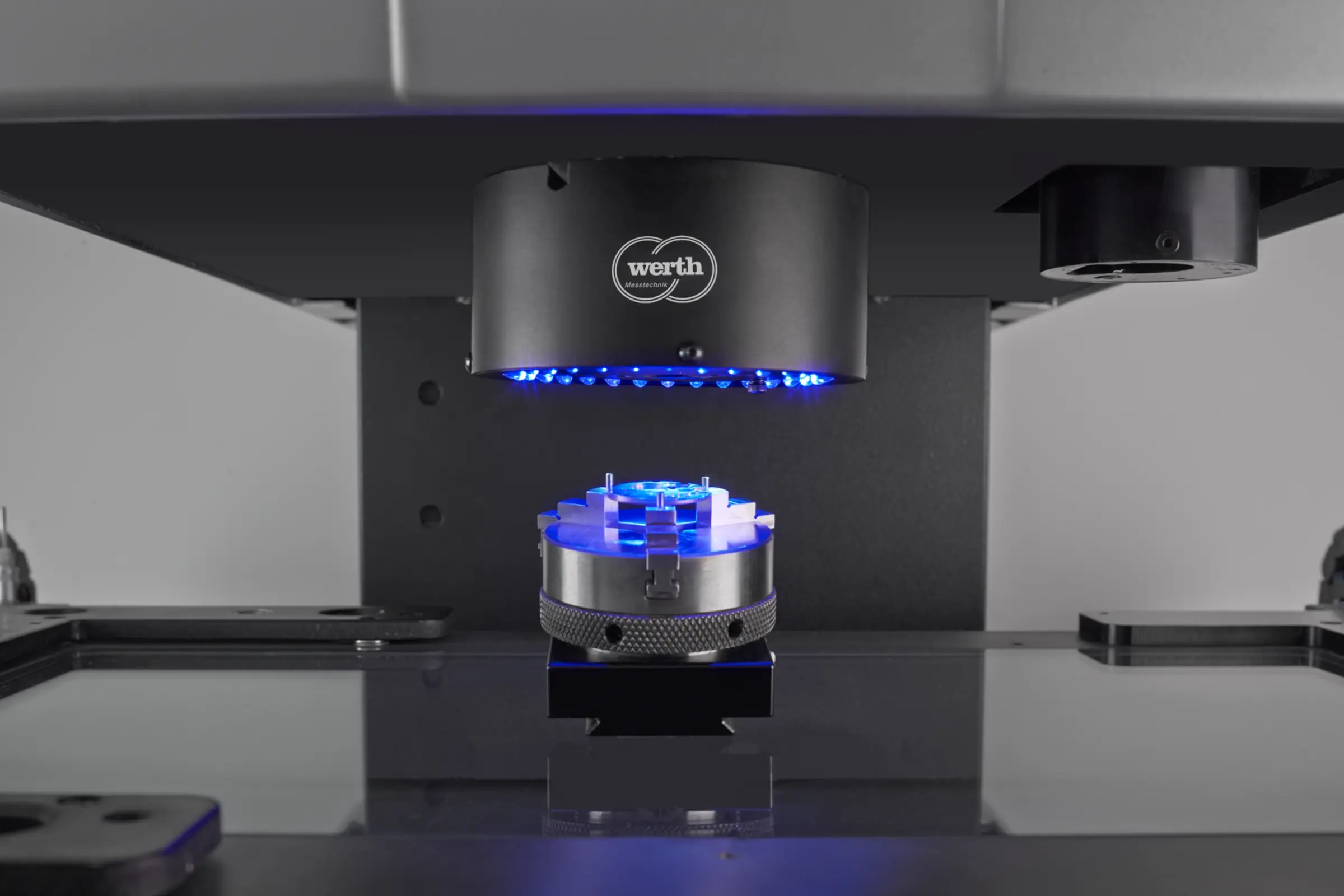

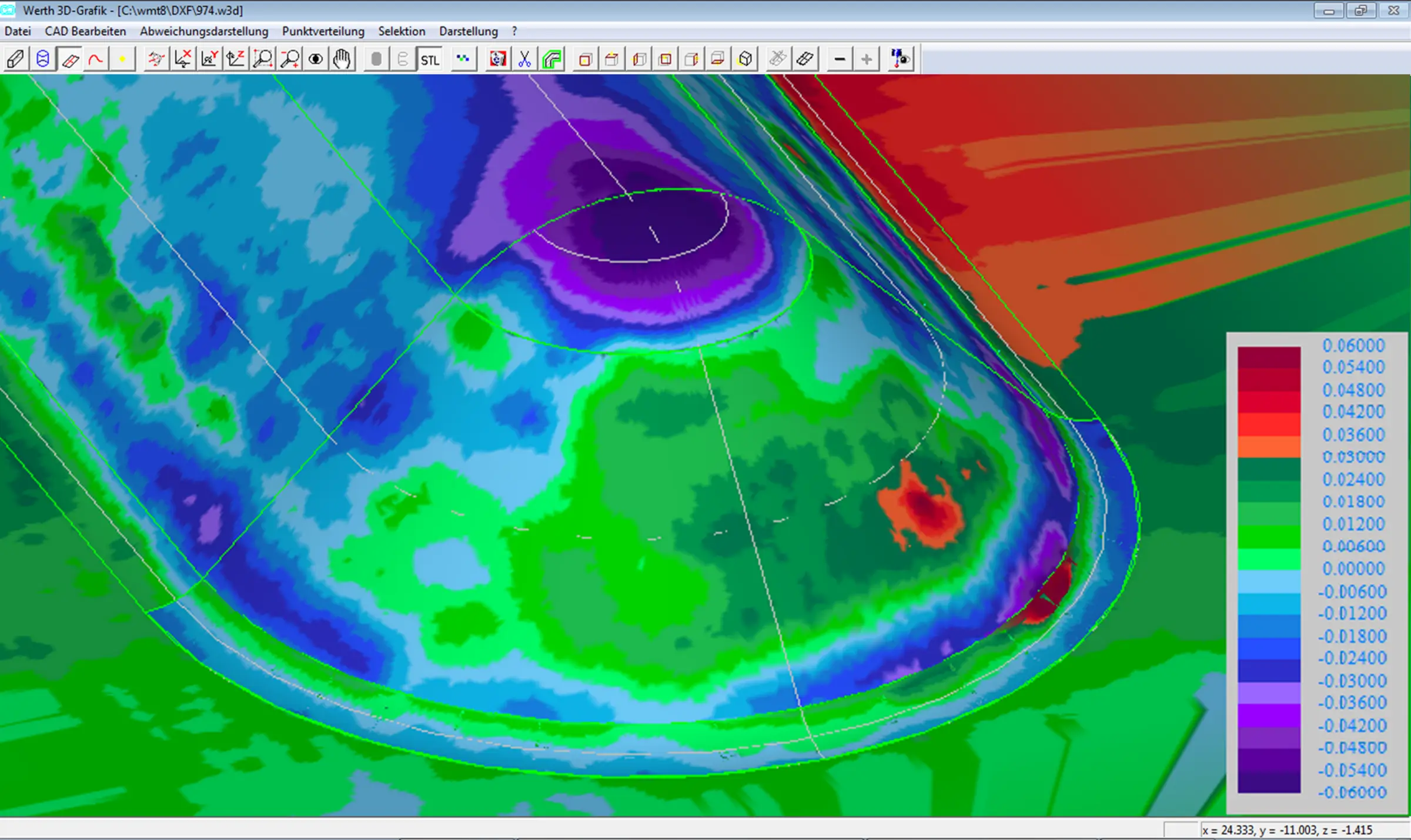

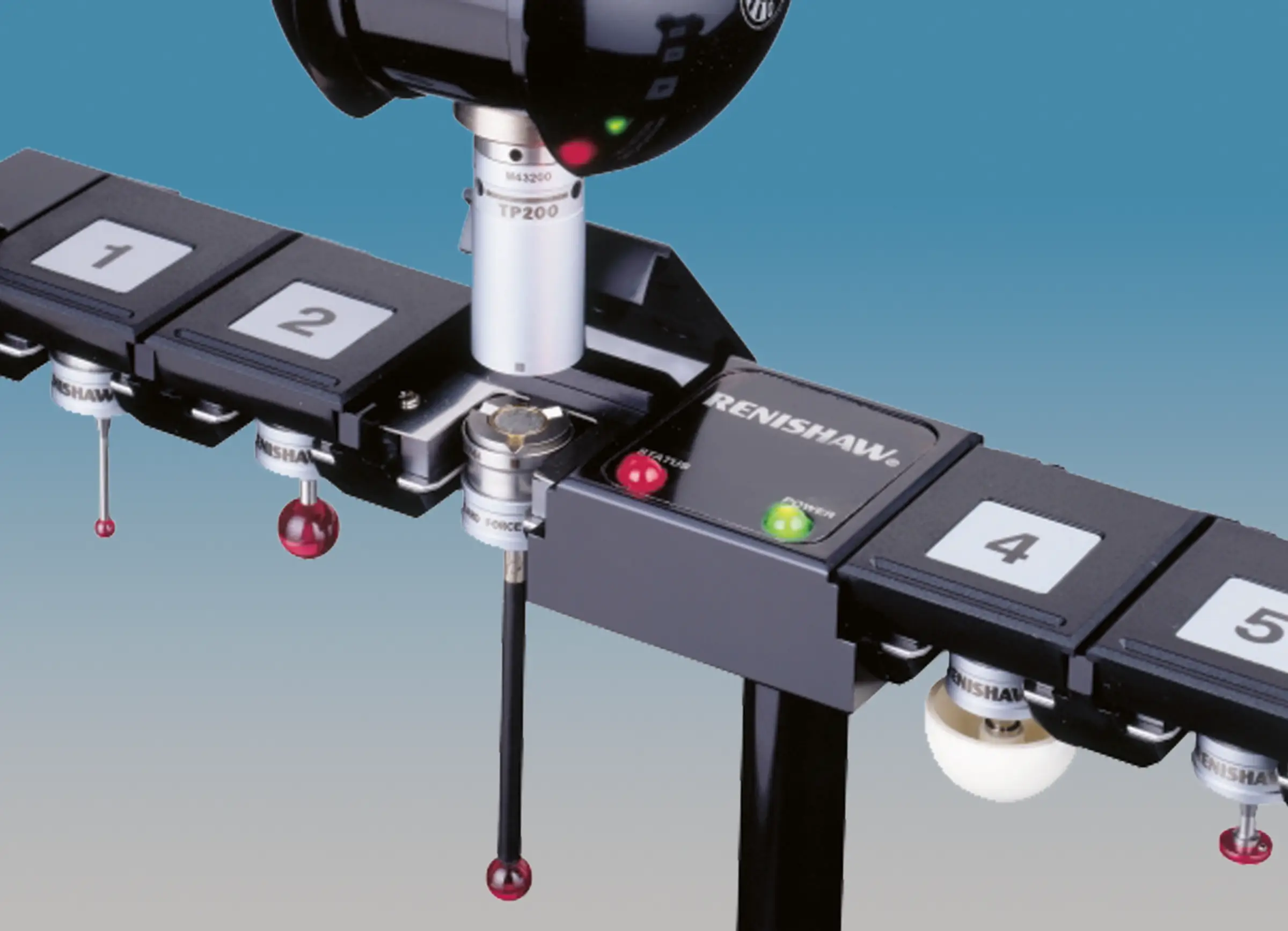

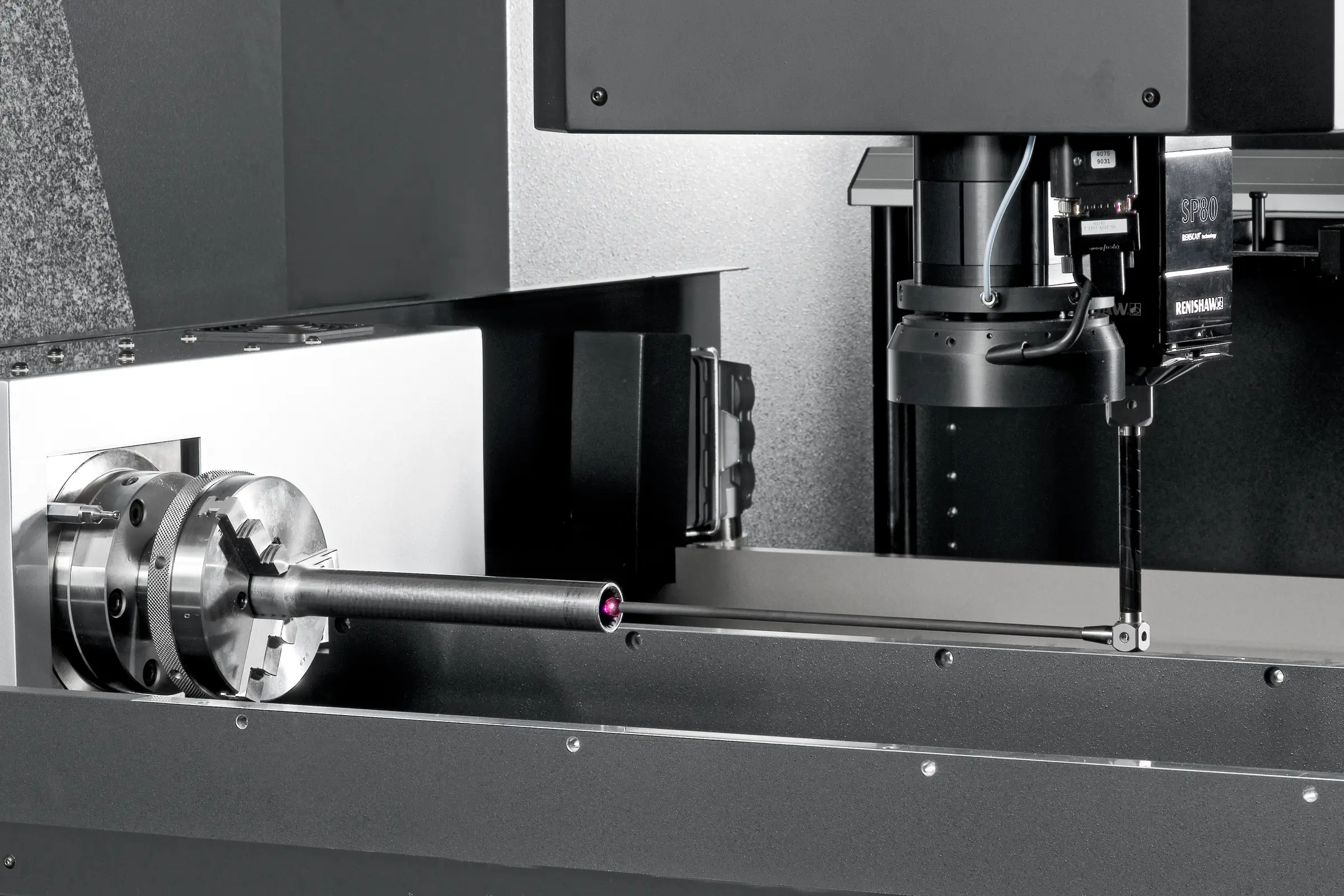

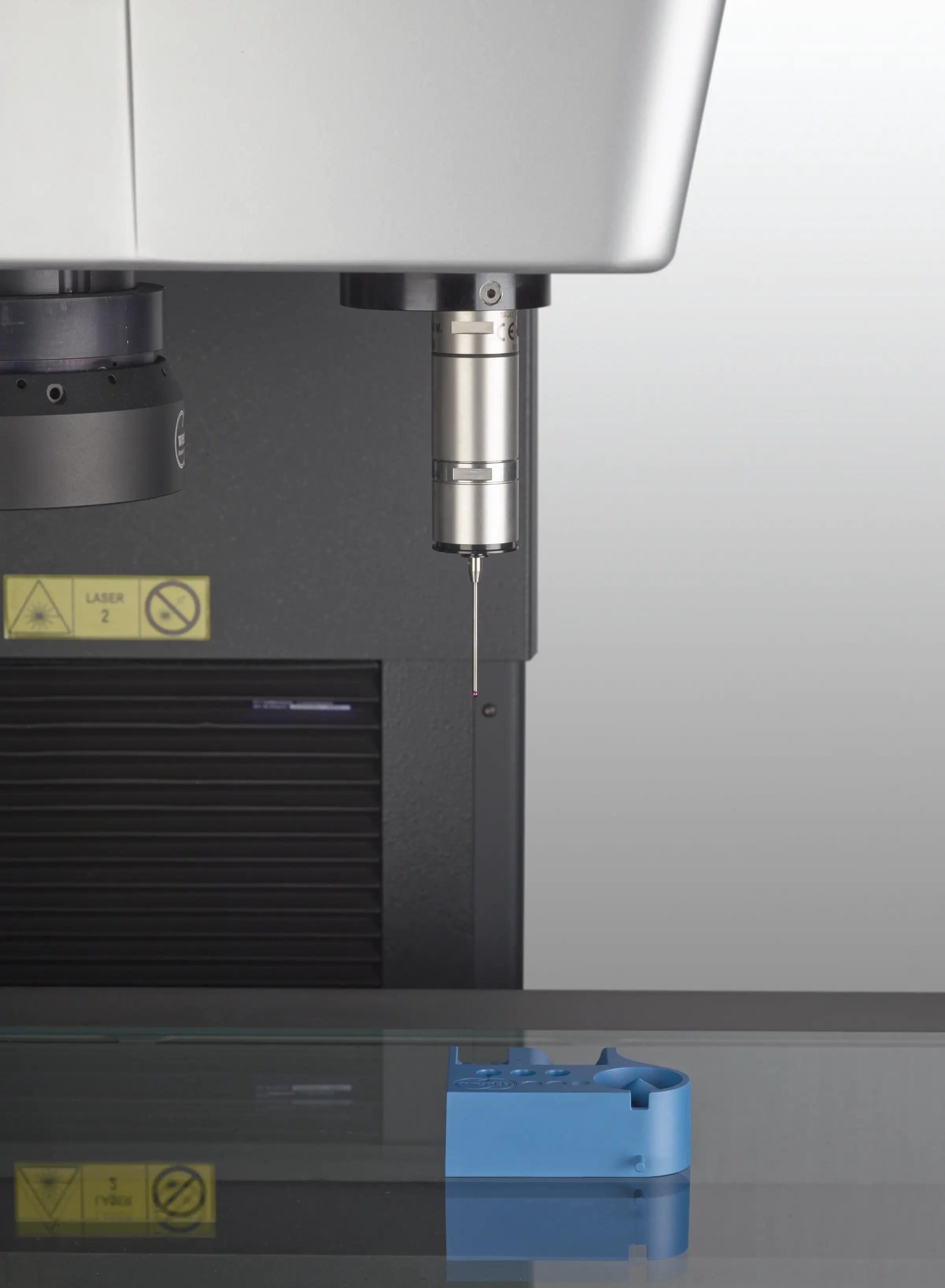

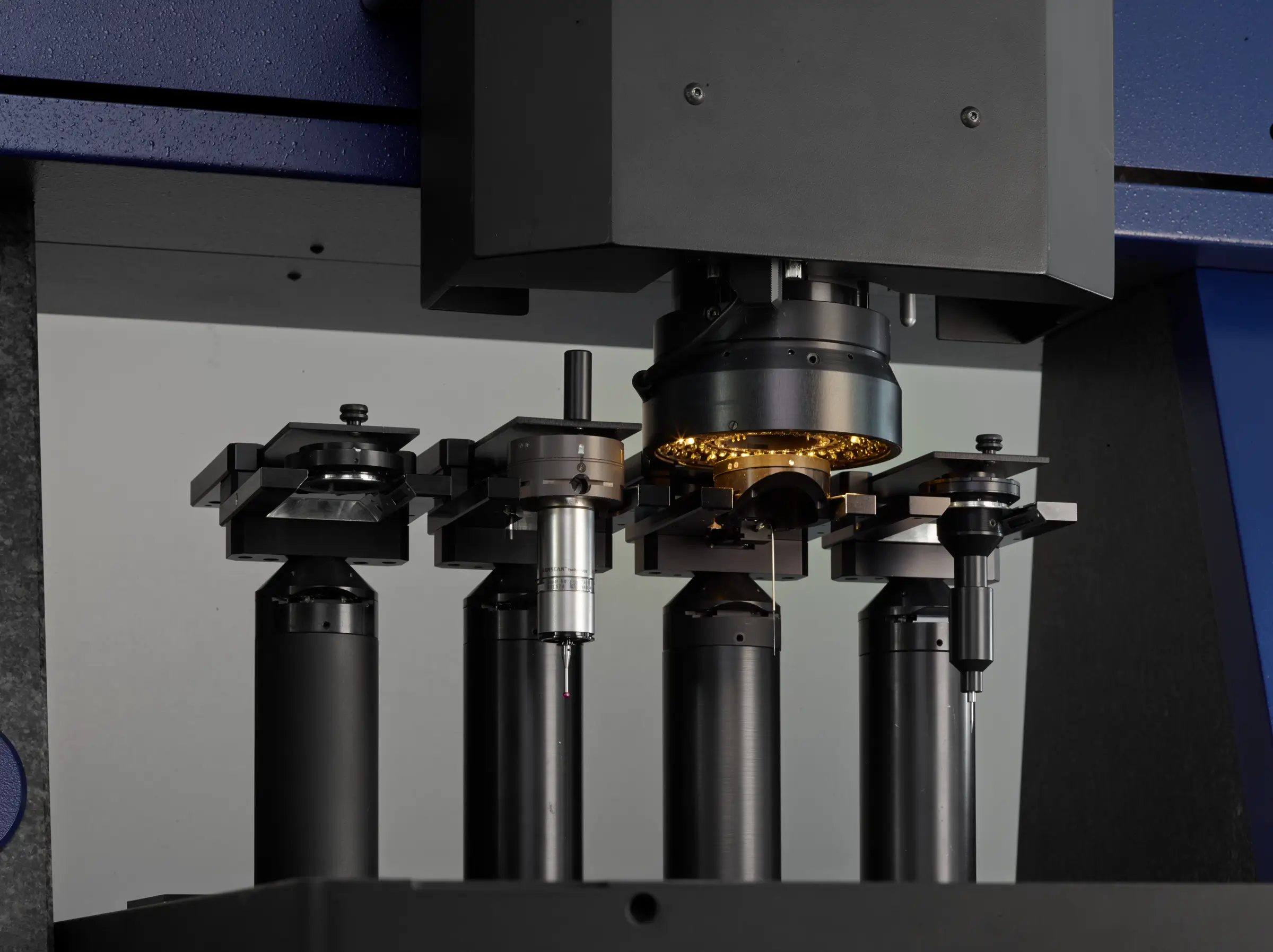

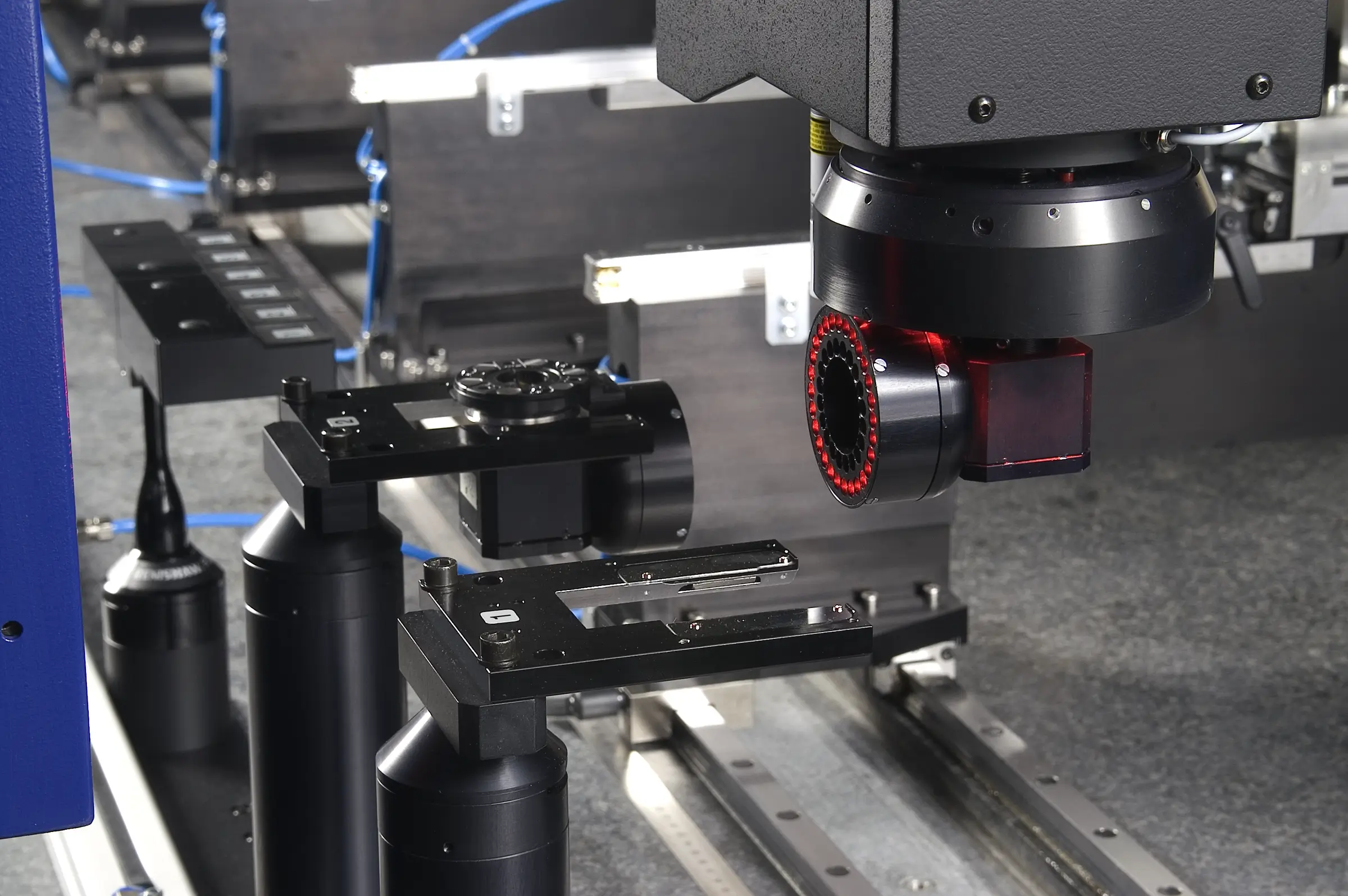

ScopeCheck® V serisi, zorlu yuvarlak iş parçalarının hassas ölçümü için mükemmel bir çözüm sunar. İletilen ışıkla sadece 2 boyutlu boyutların belirlendiği klasik şaft ölçüm makinelerinin aksine, bu koordinat ölçüm makineleri, çoklu sensör konsepti sayesinde örneğin spline'ların, olukların, kontrol kamlarının ve soğutma deliklerinin geleneksel dokunsal sensörler, patentli Werth Fiber Probe® mikro prob veya Werth Lazer Prob ile tek bir kurulumda ölçülmesini de sağlar.

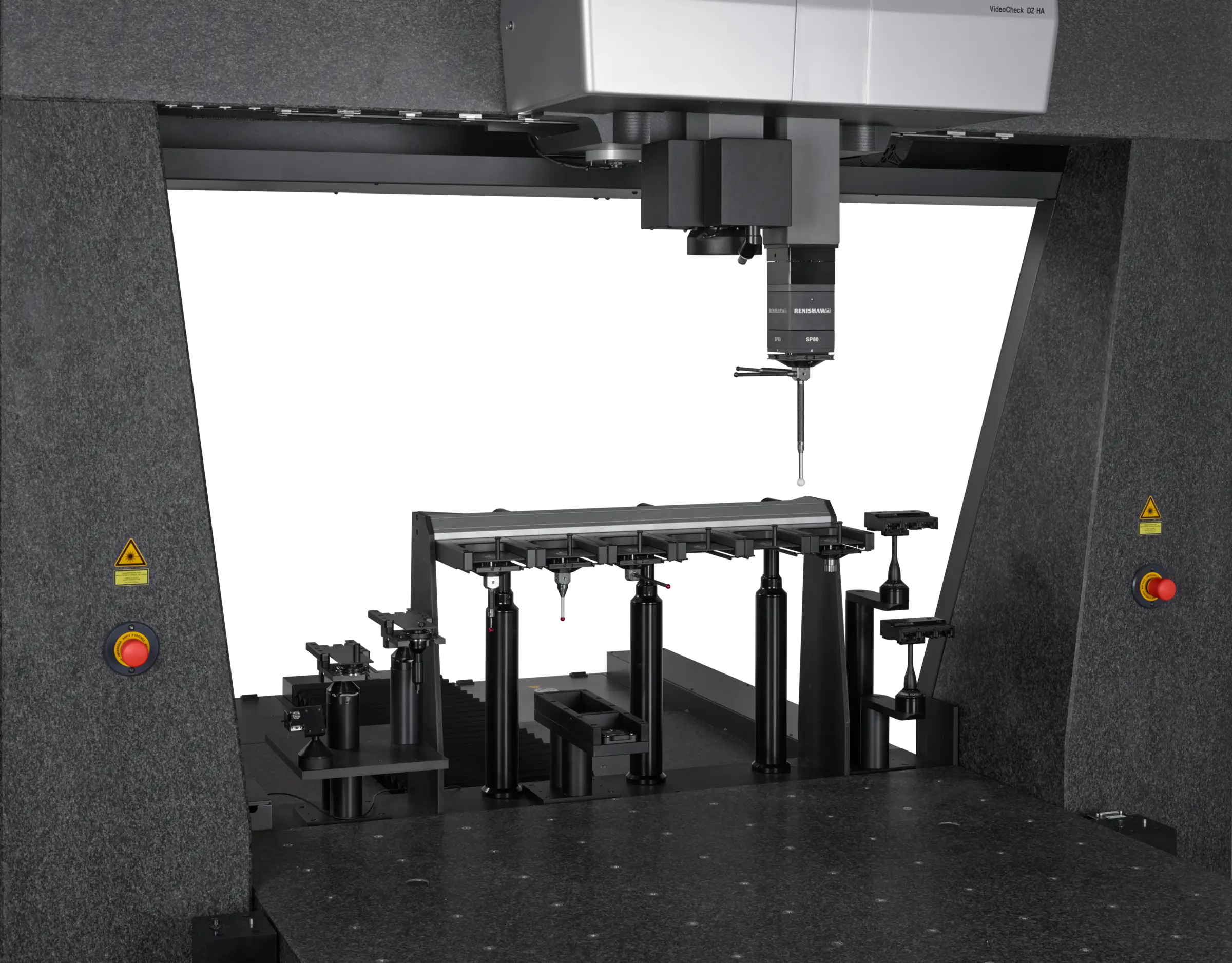

ScopeCheck® V

Tüm yaygın sıkıştırma sistemleri, esnek iş parçası montajı için kullanılabilir

Çarpışmasız çoklu sensör çalışması için ikinci bir sensör ekseni de daha sonra takılabilir

Sallantı hataları (yalpalama), iş parçası eksenini belirlemek için matematiksel yöntemlerle telafi edilir

Takım yazılımına standartlaştırılmış arayüzler, otomatik ölçümlere olanak tanır

Ölçüm makinesinin ISO 10360'a göre eksiksiz özellikleri

Tip

Dikey döner eksenli 3D-CNC çok sensörlü koordinat ölçüm makinesi

Ölçüm aralığı

Maksimum iş parçası boyutları L = 200 mm / 500 mm / 800 mm, D = 140 mm / 250 mm / 250 mm

Hassasiyet

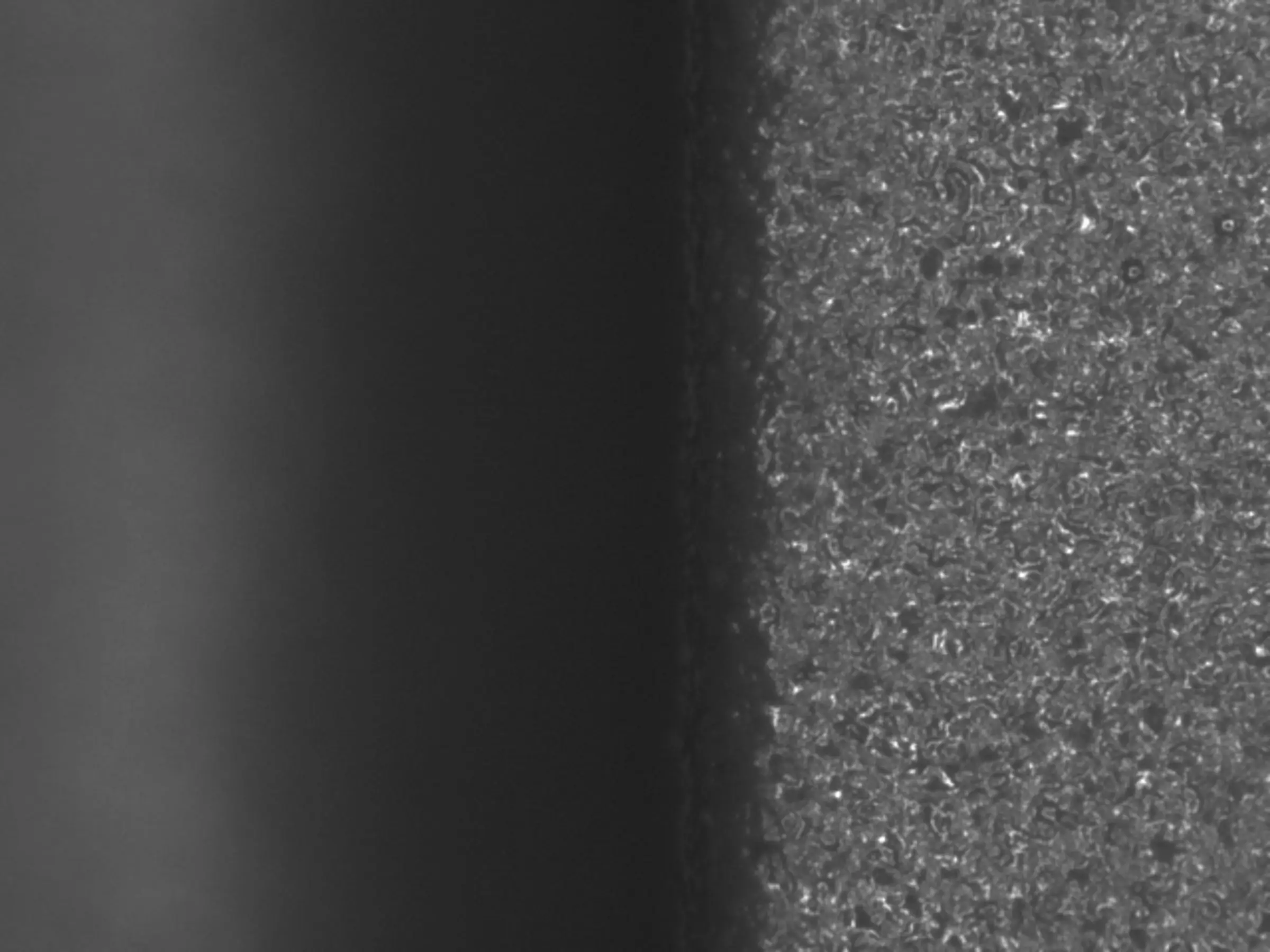

İzin verilen uzunluk ölçüm hatası 1,5 µm'ye kadar

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...