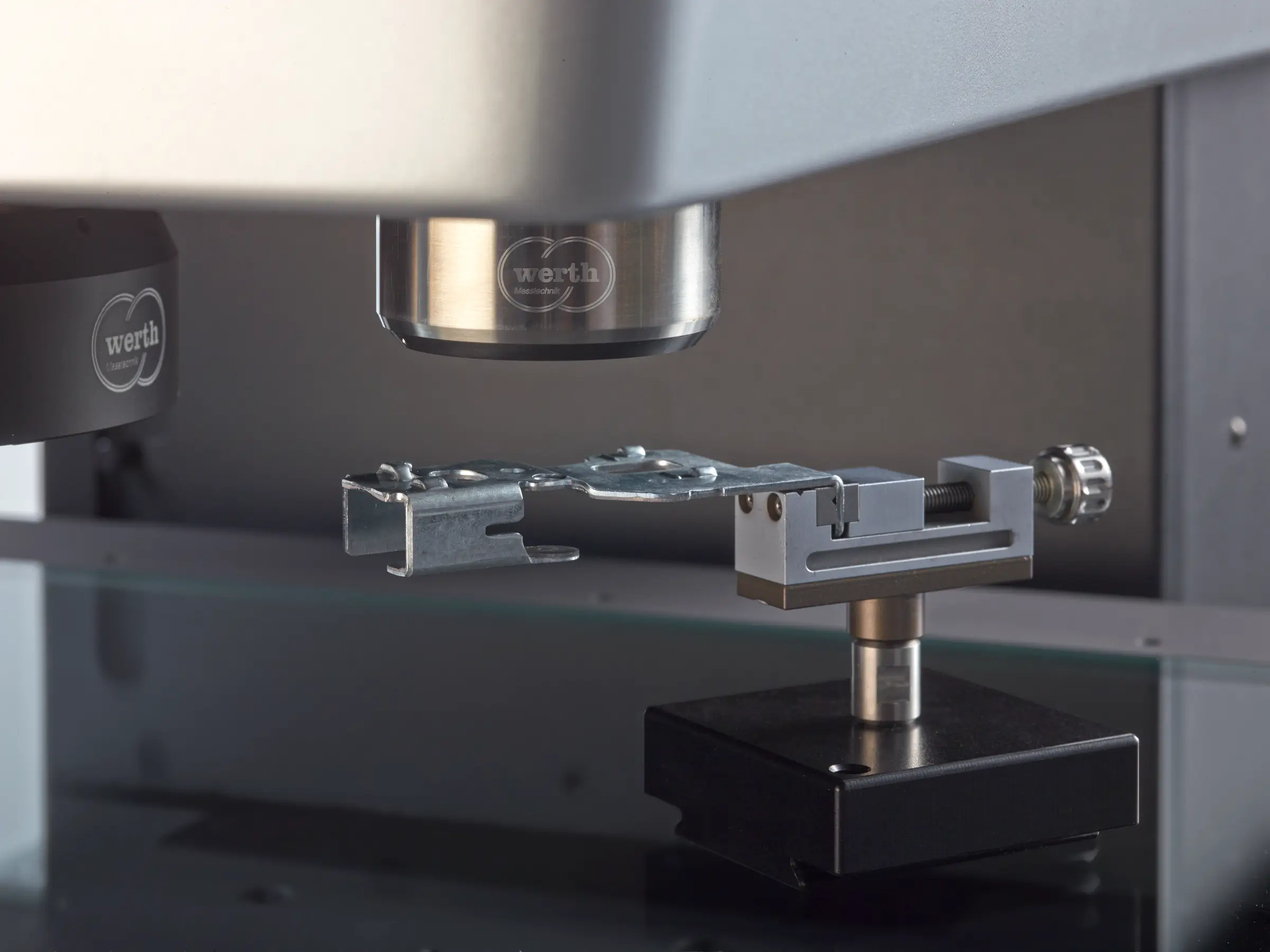

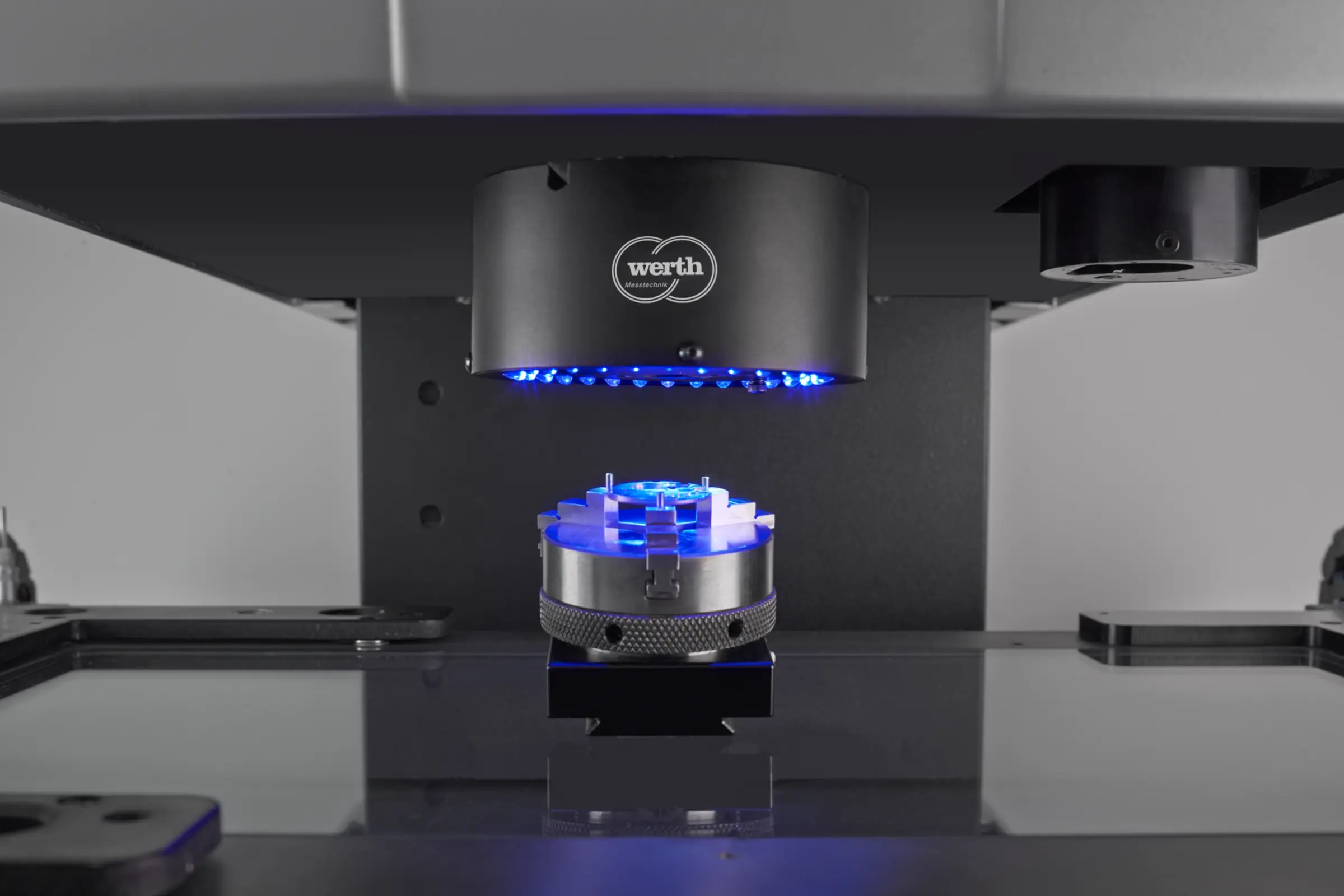

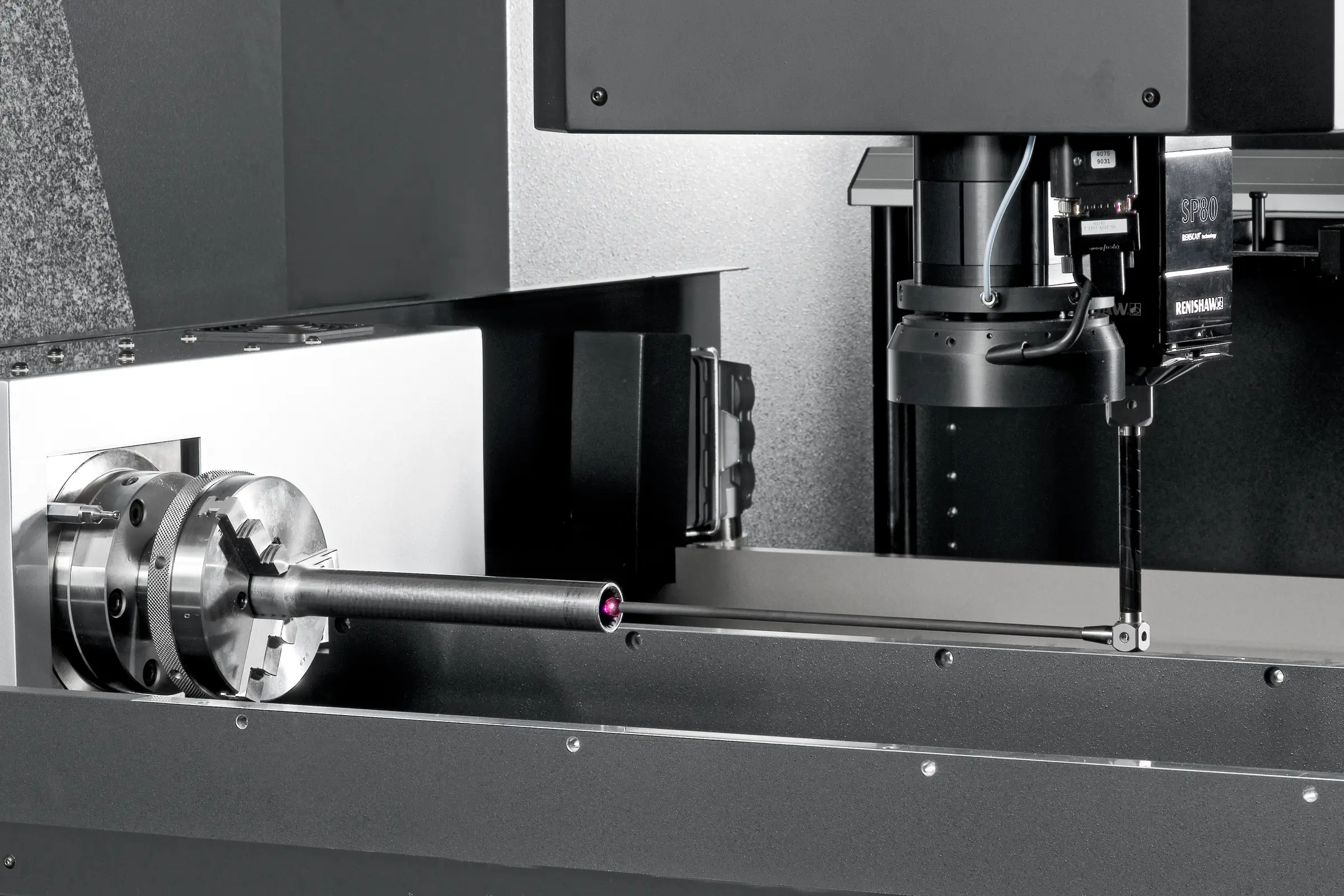

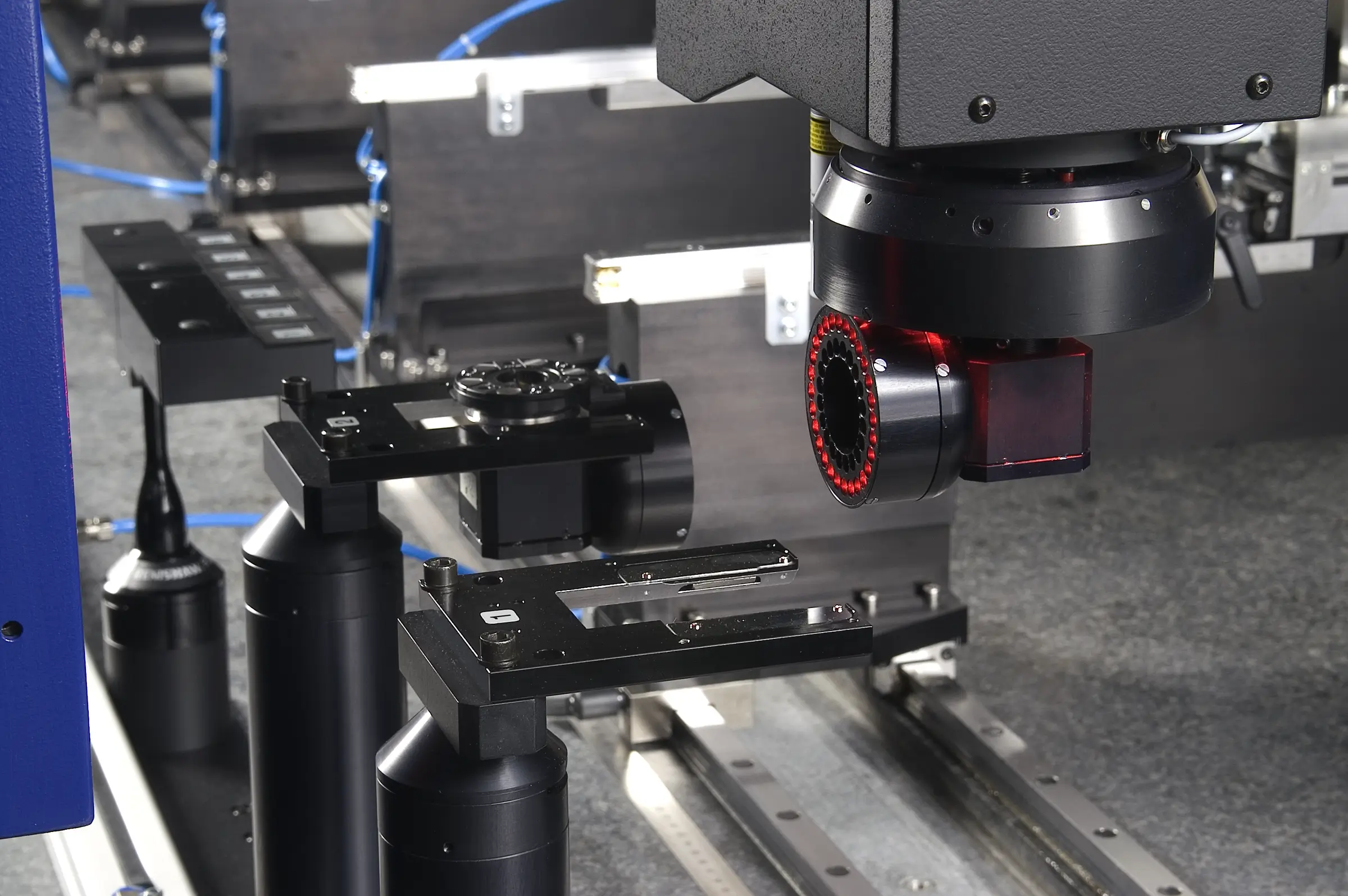

NanoMatic CNC ölçüm makinesi, takımların hızlı üretim takibi için özel olarak tasarlanmıştır. Benzersiz Werth döner aparatı V Pro üzerindeki takım sıkıştırma, en yüksek hassasiyette, sapma hataları olmadan etkin konturun ölçülmesini sağlar. Örneğin, makine yarıçap, çap veya şekil ölçerken mikrometrenin onda biri aralığında tekrarlama doğruluğuna ulaşır.

NanoMatic

Werth Lazer Probu ve salınım telafili hava yataklı döner eksen kombinasyonu, eğim ve boşluk açılarının ölçülmesini de sağlar.

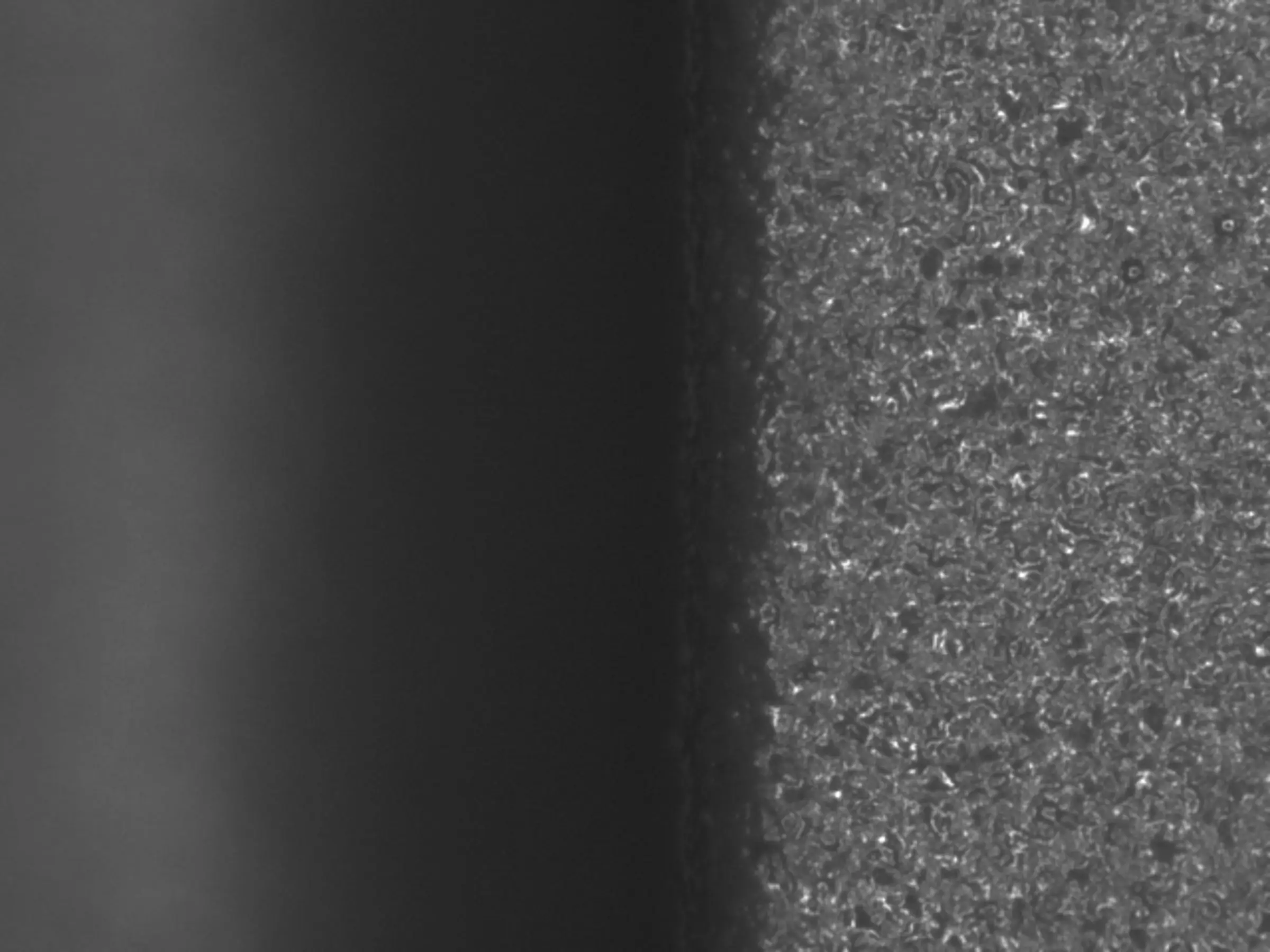

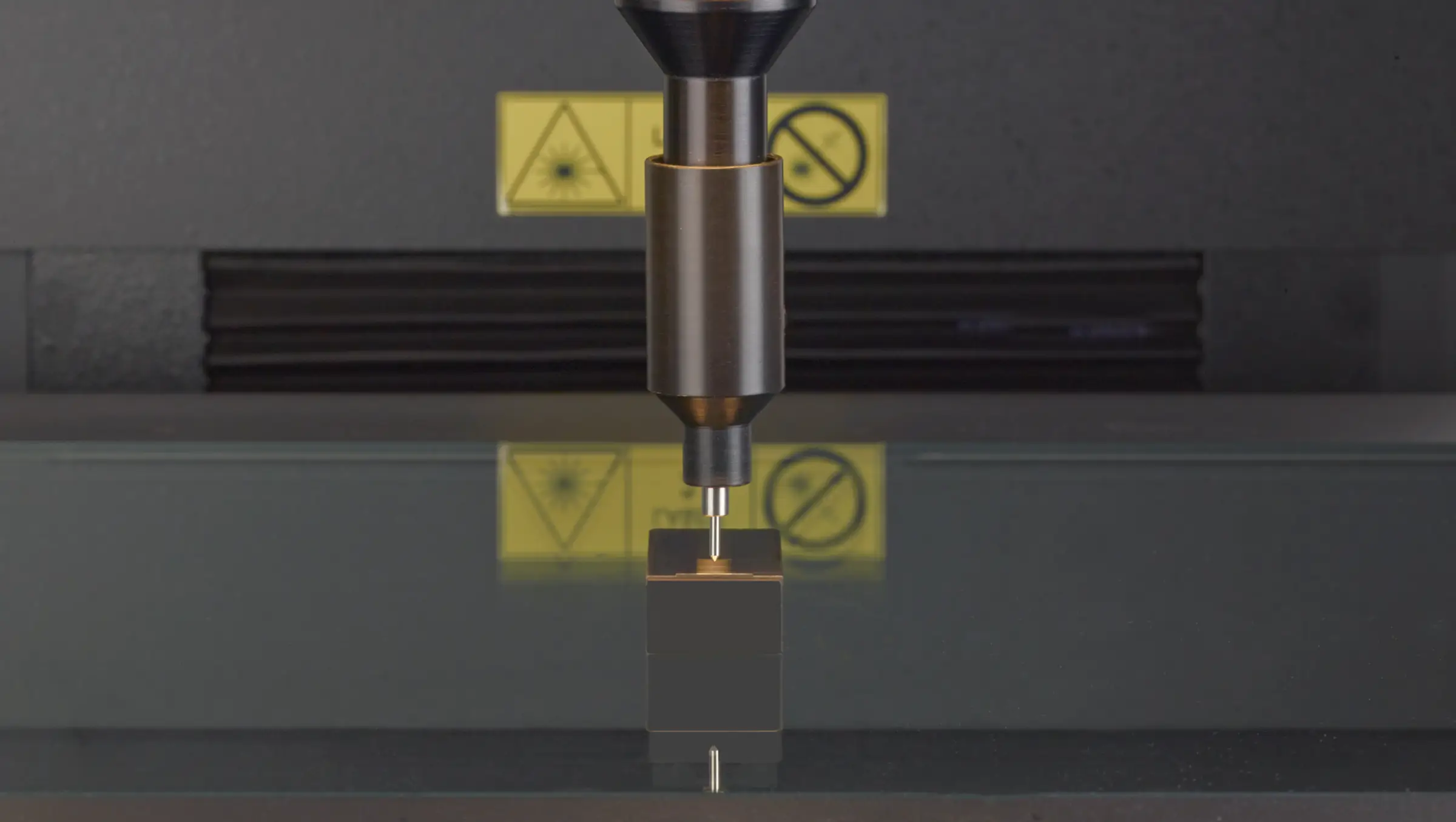

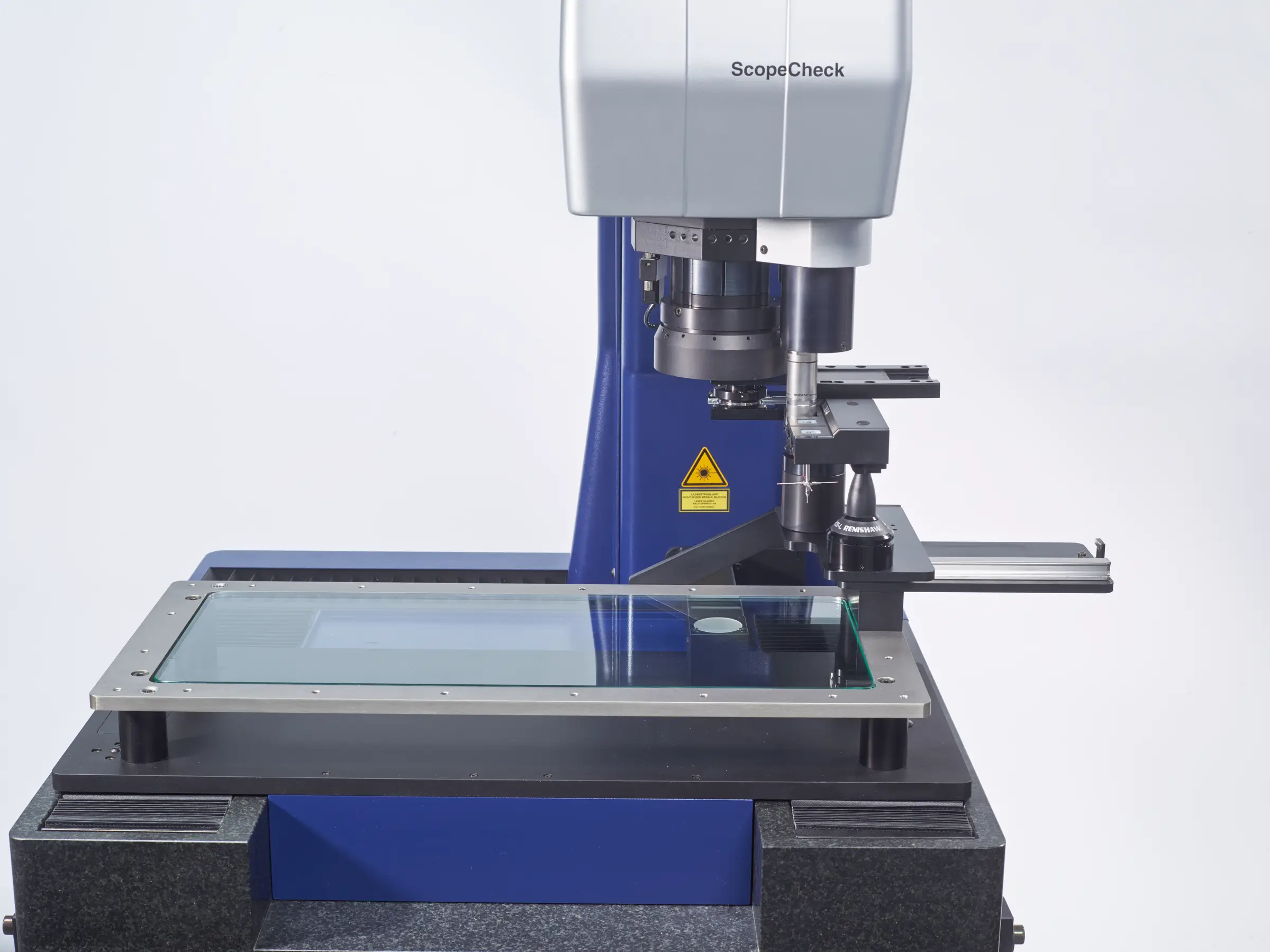

Entegre motor yakınlaştırma optiği sayesinde en yüksek çözünürlükte kesme kenarlarının optimum tespiti sağlanır.

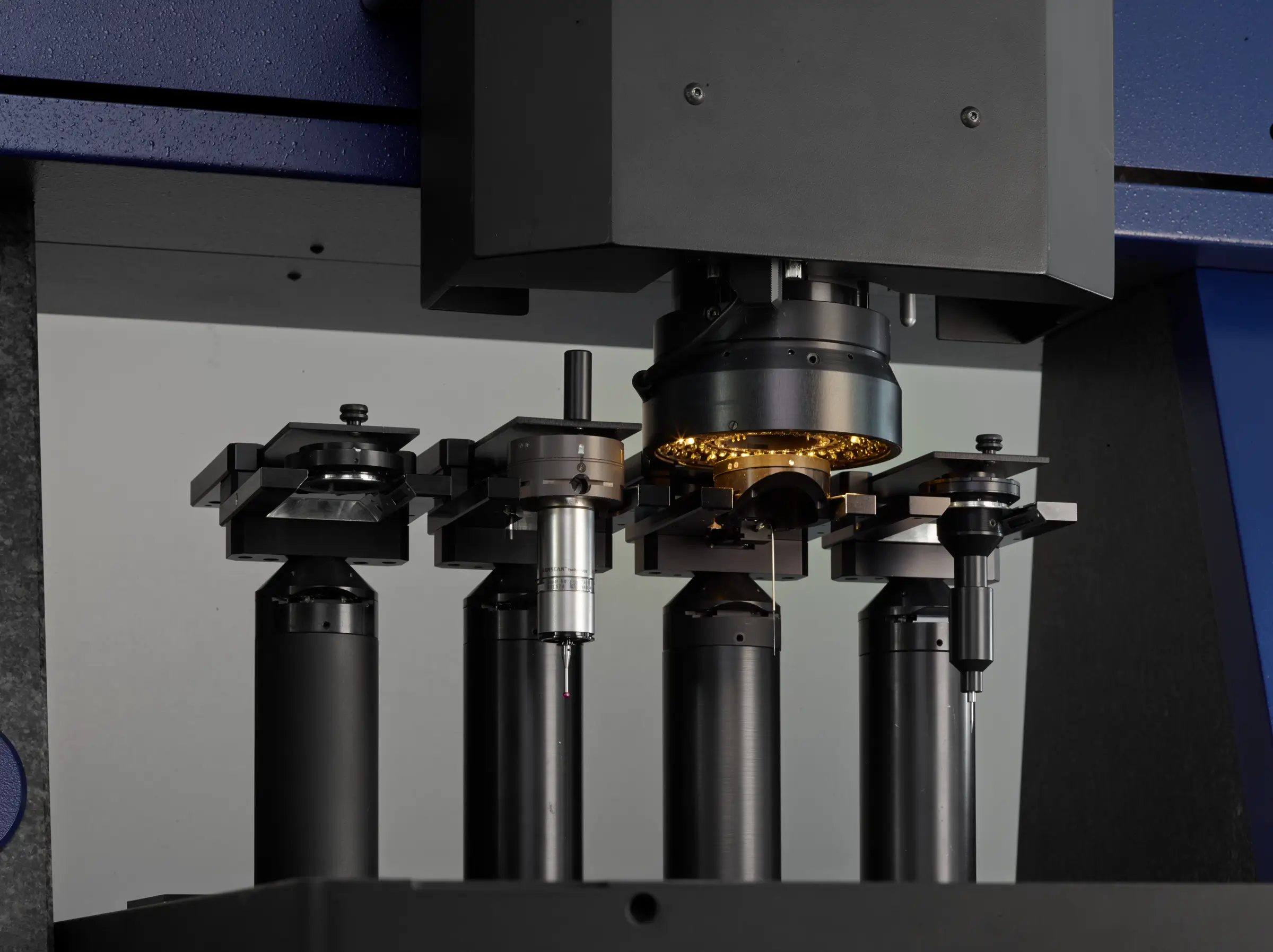

Yüksek ölçüm hızı sayesinde %100 denetim için de kullanılabilir.

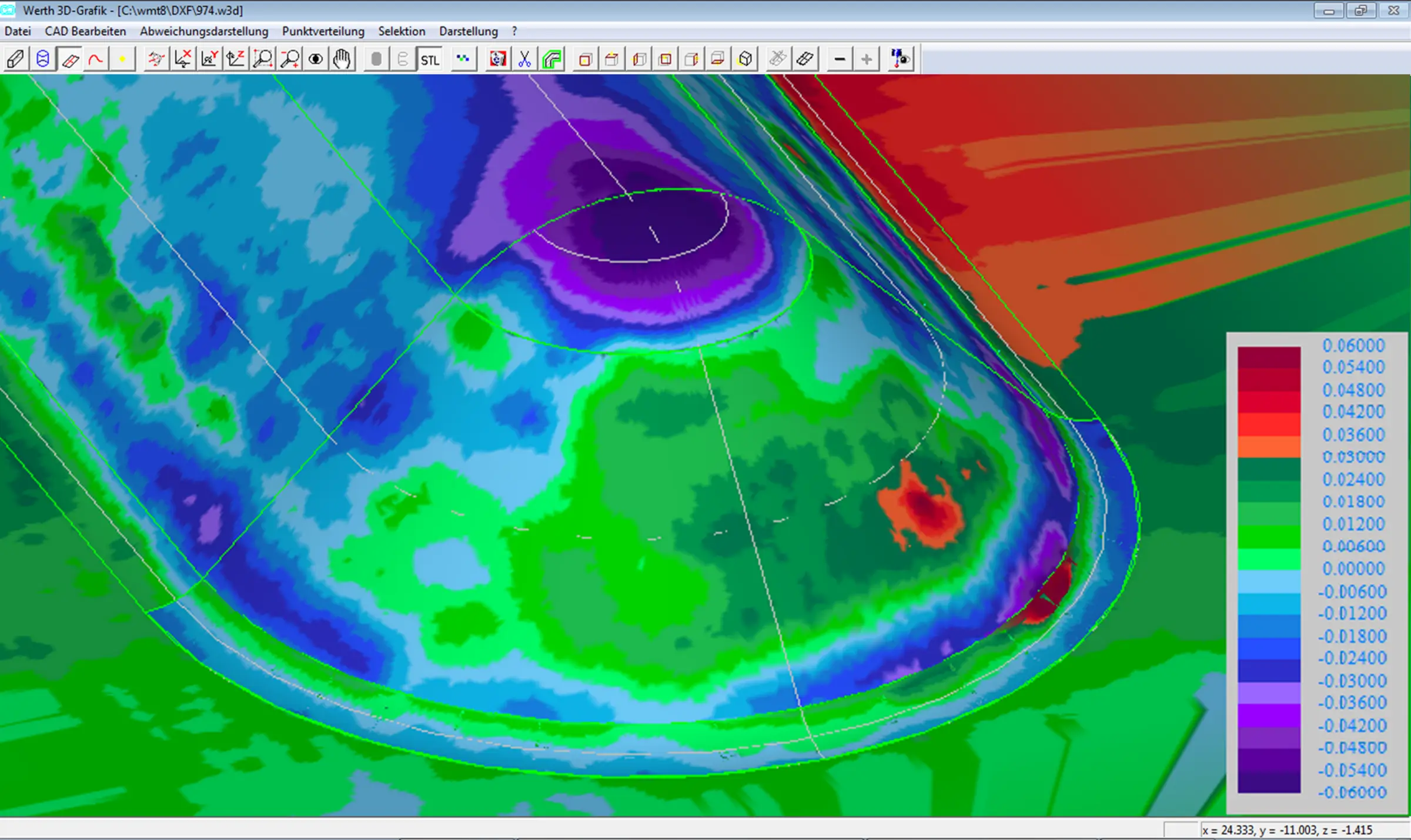

Kullanışlı kullanıcı arayüzüne sahip, atölye uyumlu grafik etkileşimli ölçüm yazılımı WinWerth®

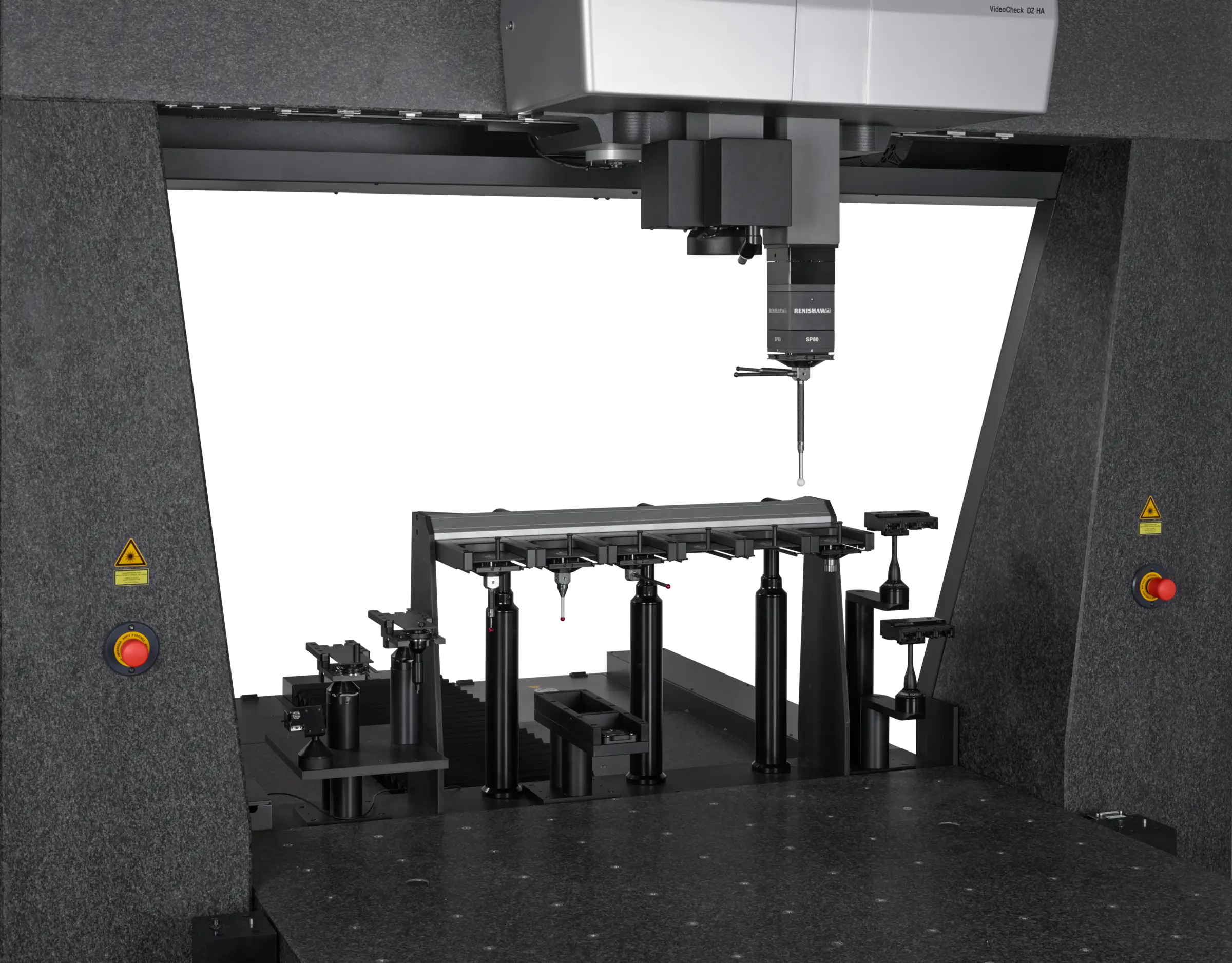

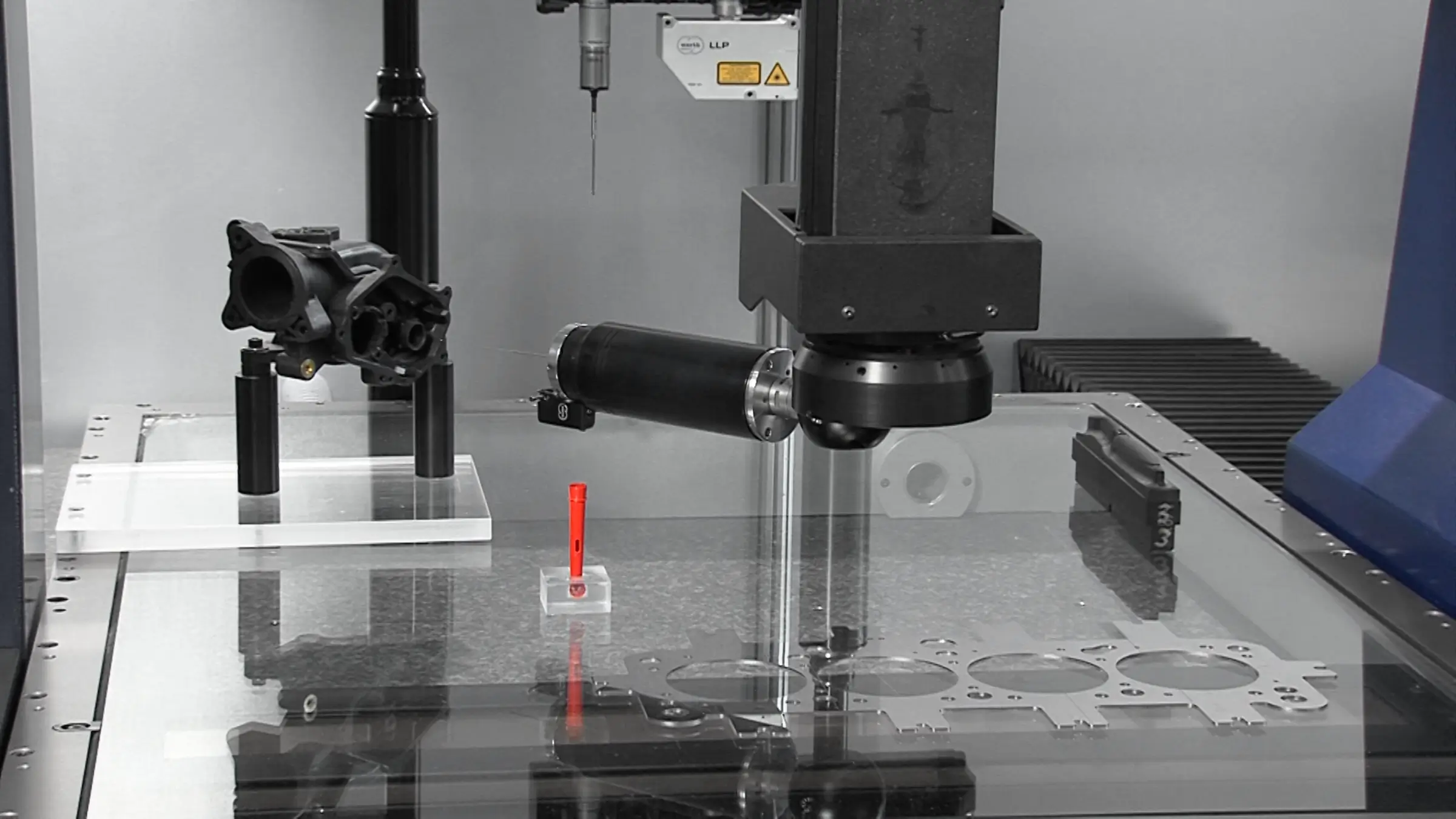

Frezeler, matkaplar, kalıp ve basamak takımları ile raybalar gibi takımlar kolayca ve çok hızlı bir şekilde ölçülebilir.

Çapı 20 mm'ye kadar olan takımların ölçümü, talep üzerine daha geniş ölçüm aralıkları mevcuttur.

Tip

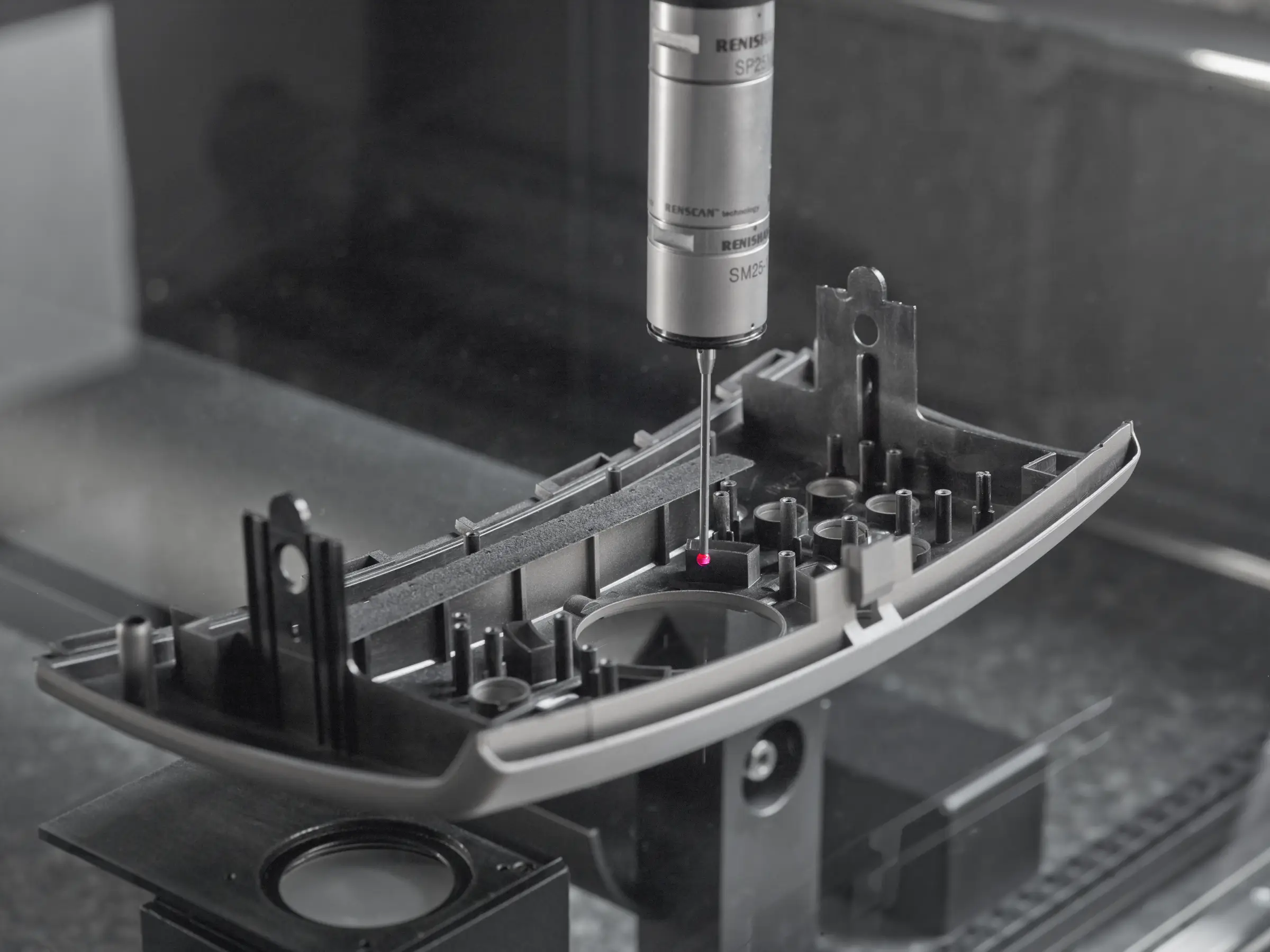

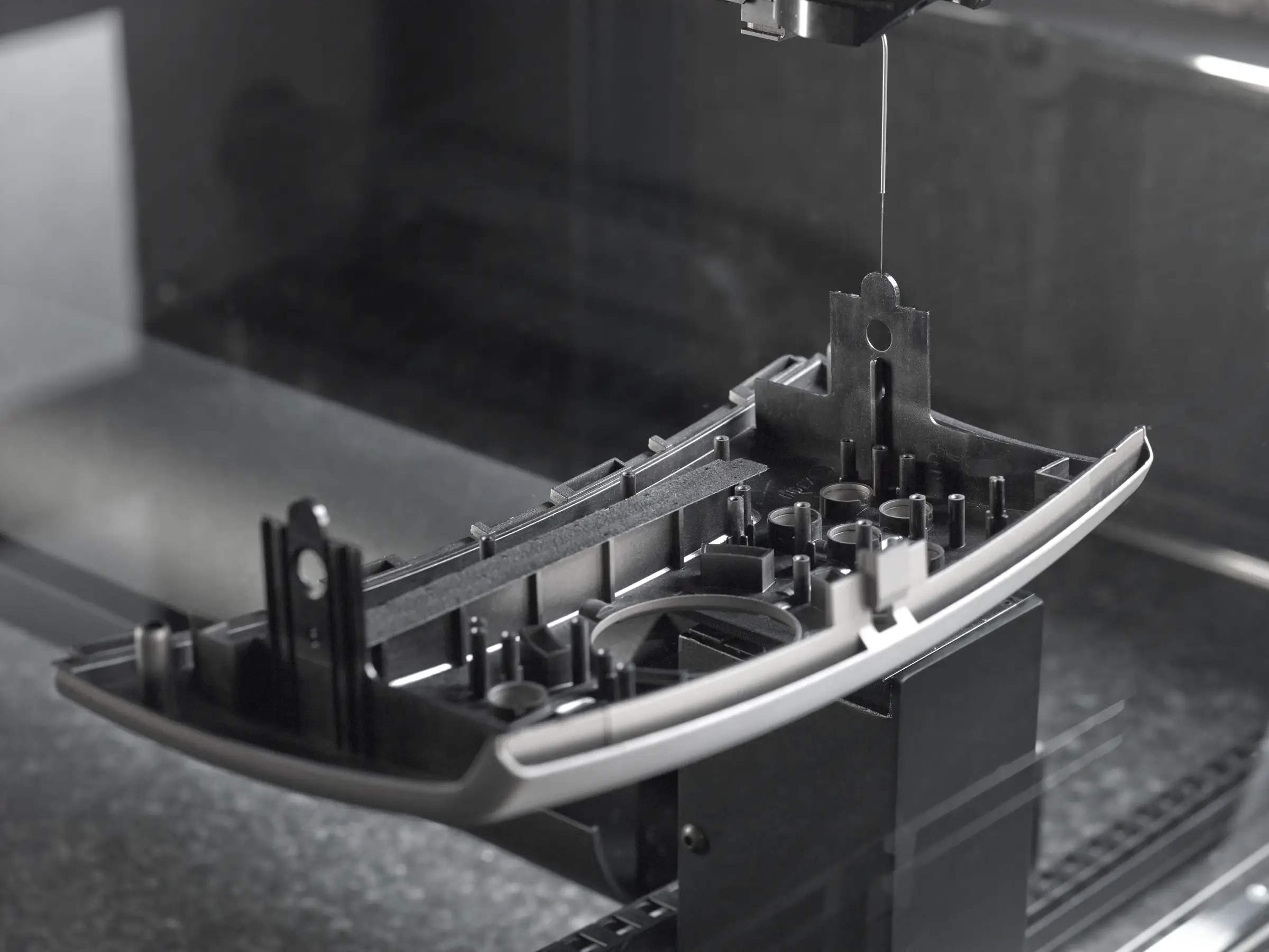

Şaft döner aparatlı takım ölçümü için 3D CNC görüntü işleme ölçüm makinesi V Pro

Ölçüm aralığı

X = 200 mm, Y = 200 mm, Z = 200 mm

Hassasiyet

İzin verilen uzunluk ölçüm hatası 1,8 µm'ye kadar

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

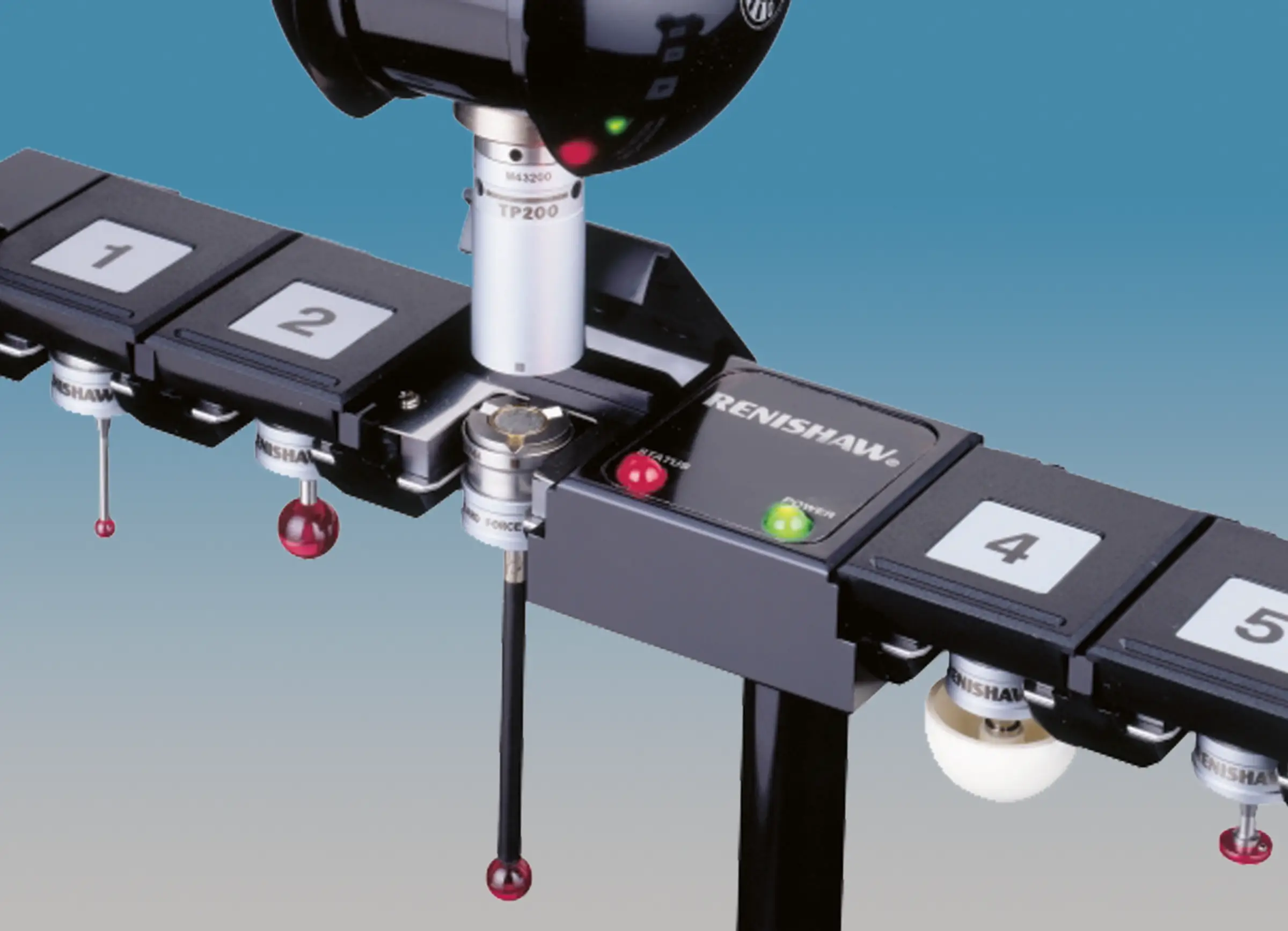

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...