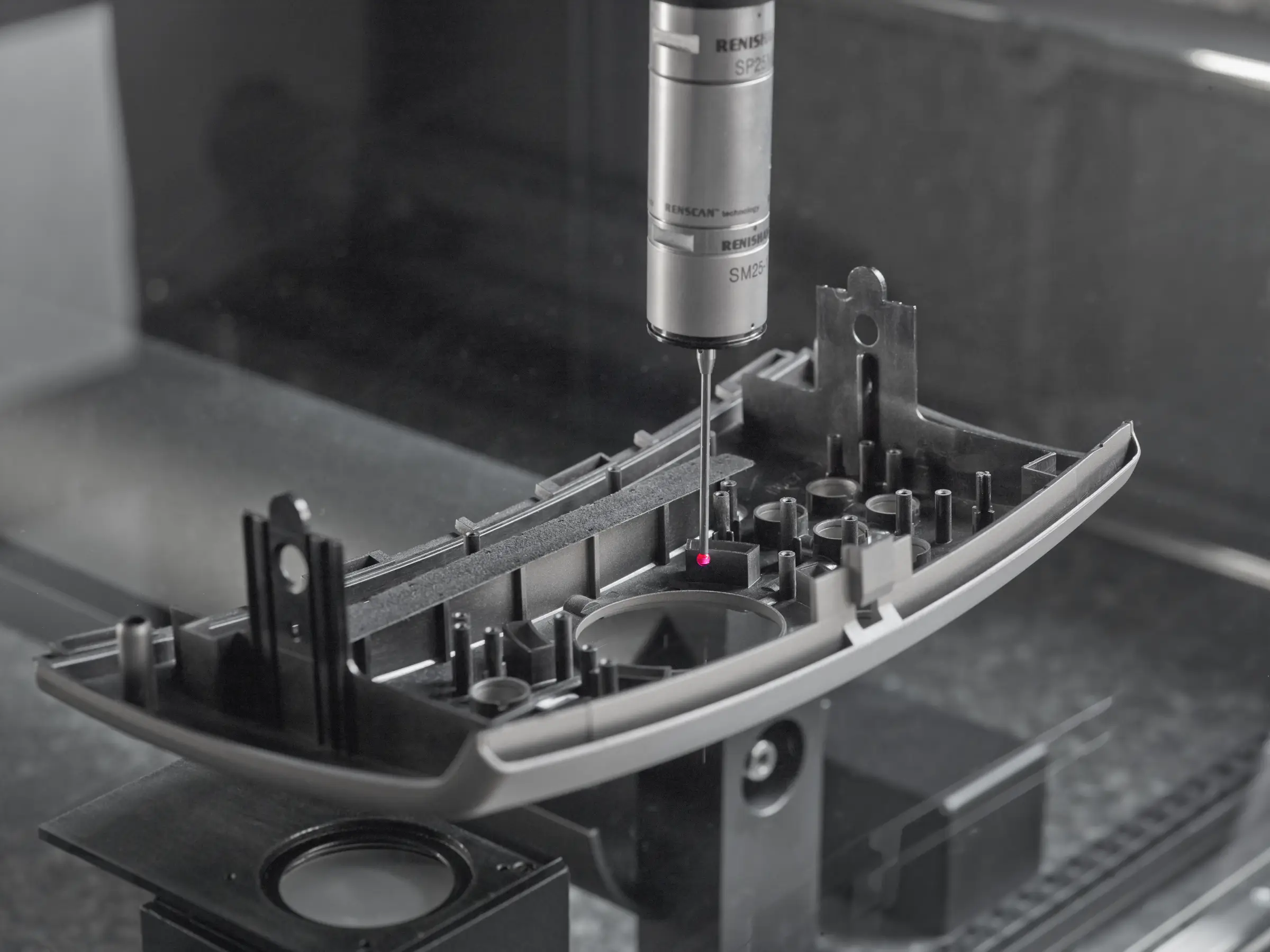

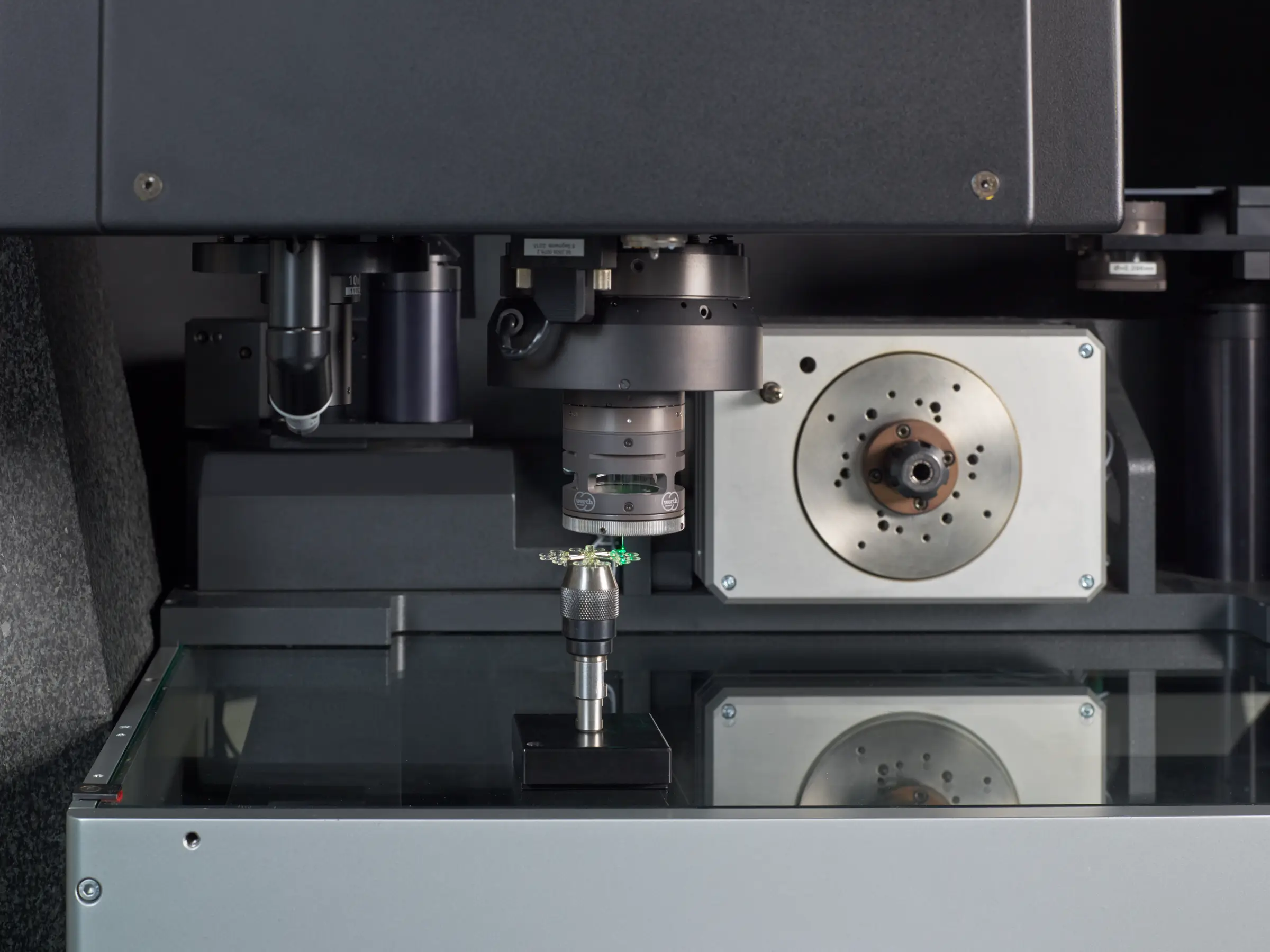

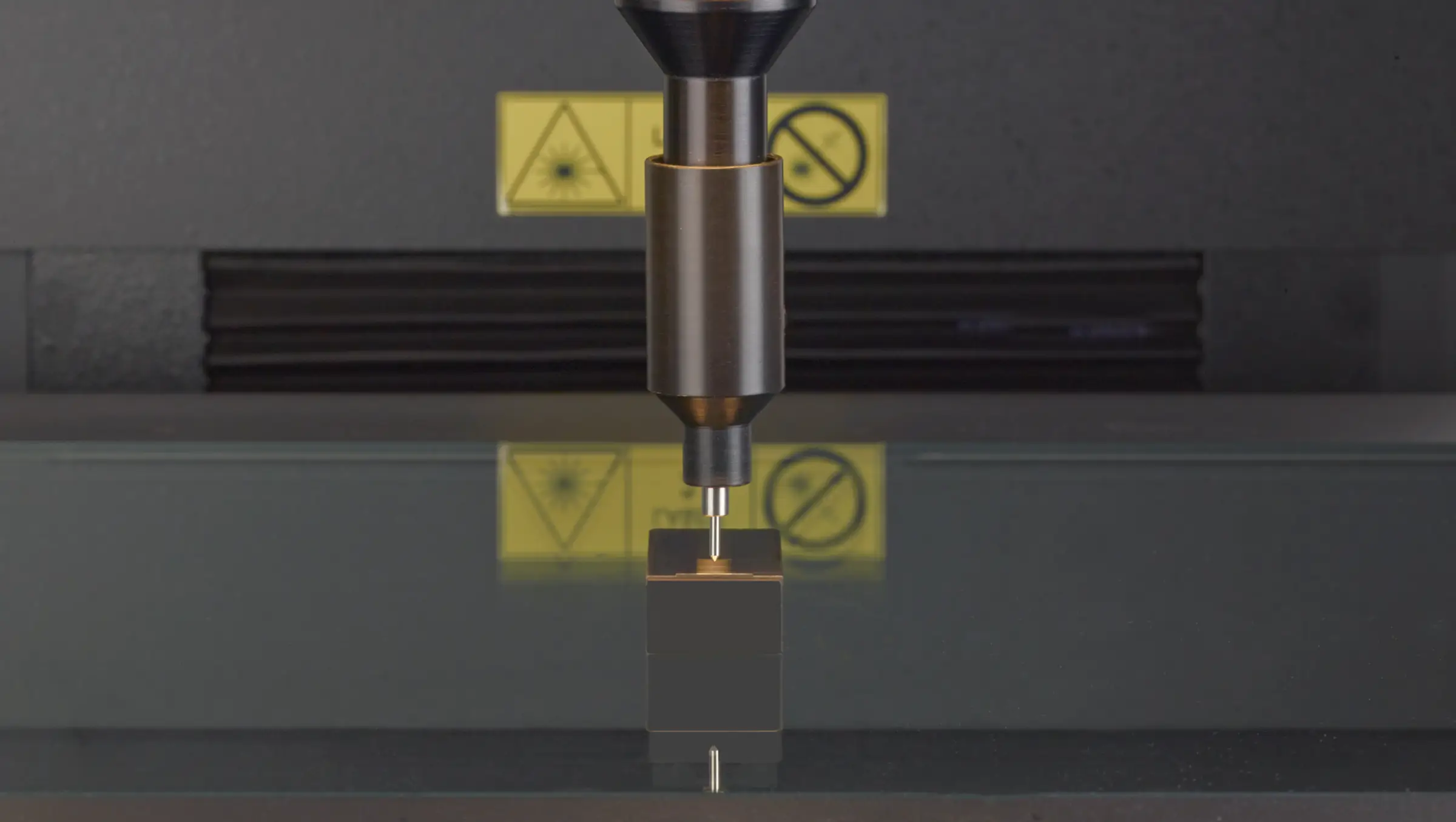

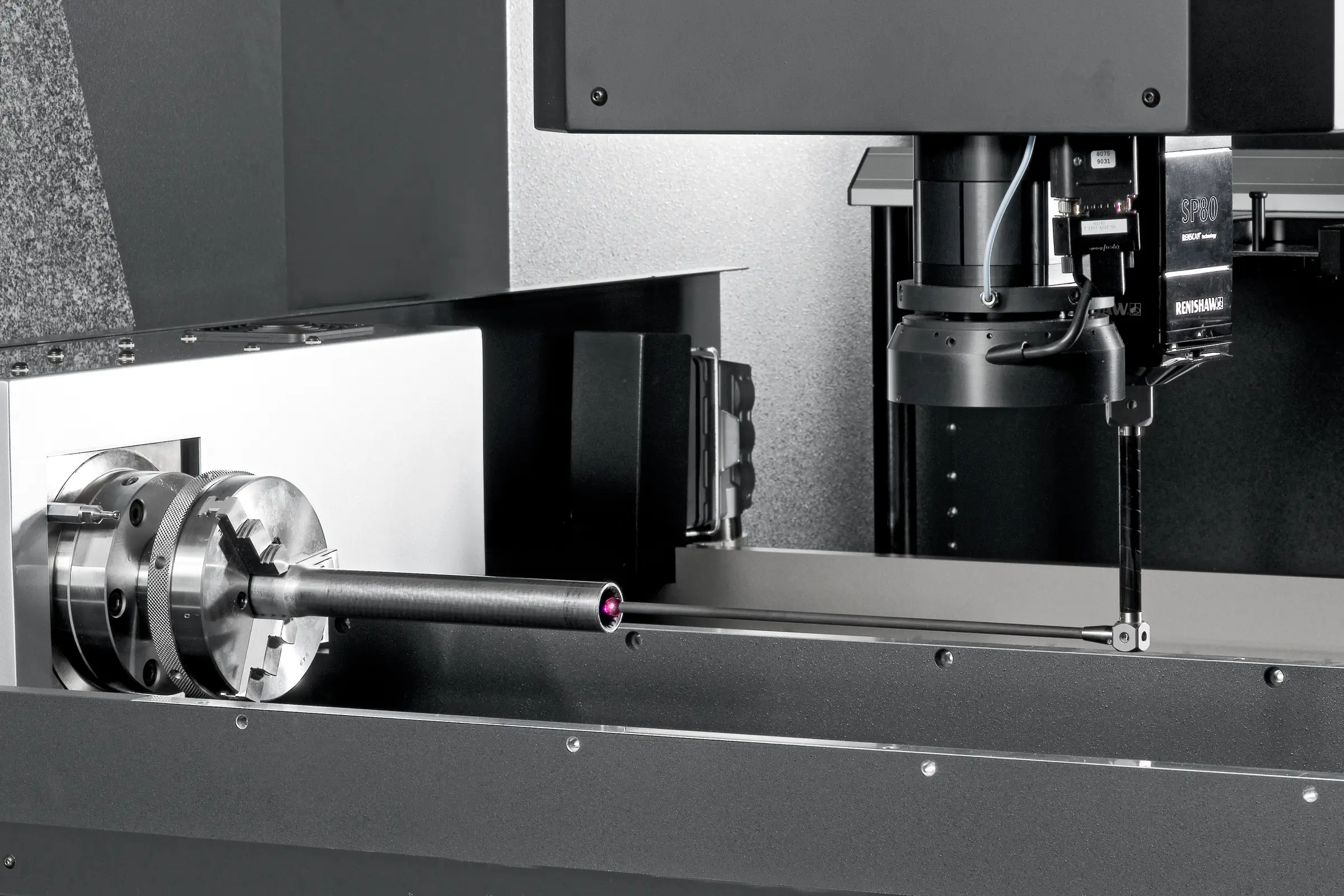

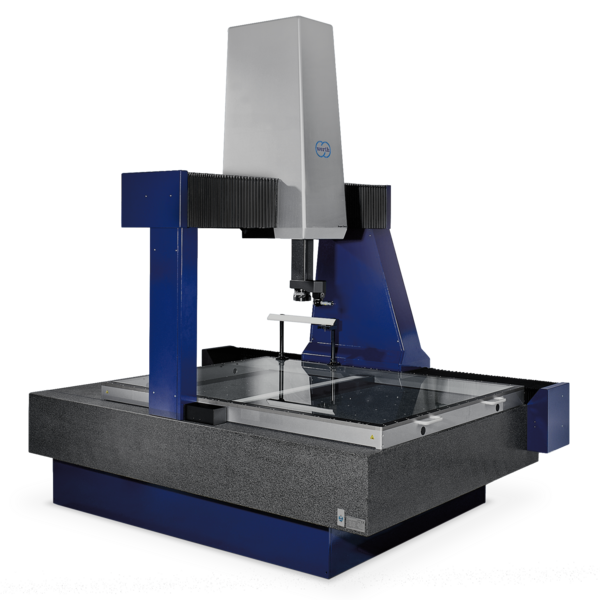

Sensörler, ölçüm sırasında iş parçasının hareket ettirilmesine gerek kalmayacak şekilde hareketli köprü kullanılarak konumlandırılır. X ekseninde 500 mm ile 2.000 mm, Y ekseninde 5.000 mm ve Z ekseninde 1.500 mm arasındaki standart ölçüm aralıkları, otomotiv, makine mühendisliği ve takım imalat endüstrilerinde 5 tona kadar ağırlığa sahip büyük hacimli iş parçalarında ölçüm yapılmasını sağlar. Sıcaklık dengeleme özelliğine sahip hava yataklı çok sensörlü koordinat ölçüm makinesi, üretime yakın bir yere kurulduğunda bile hassas ölçüm sonuçları sunar.

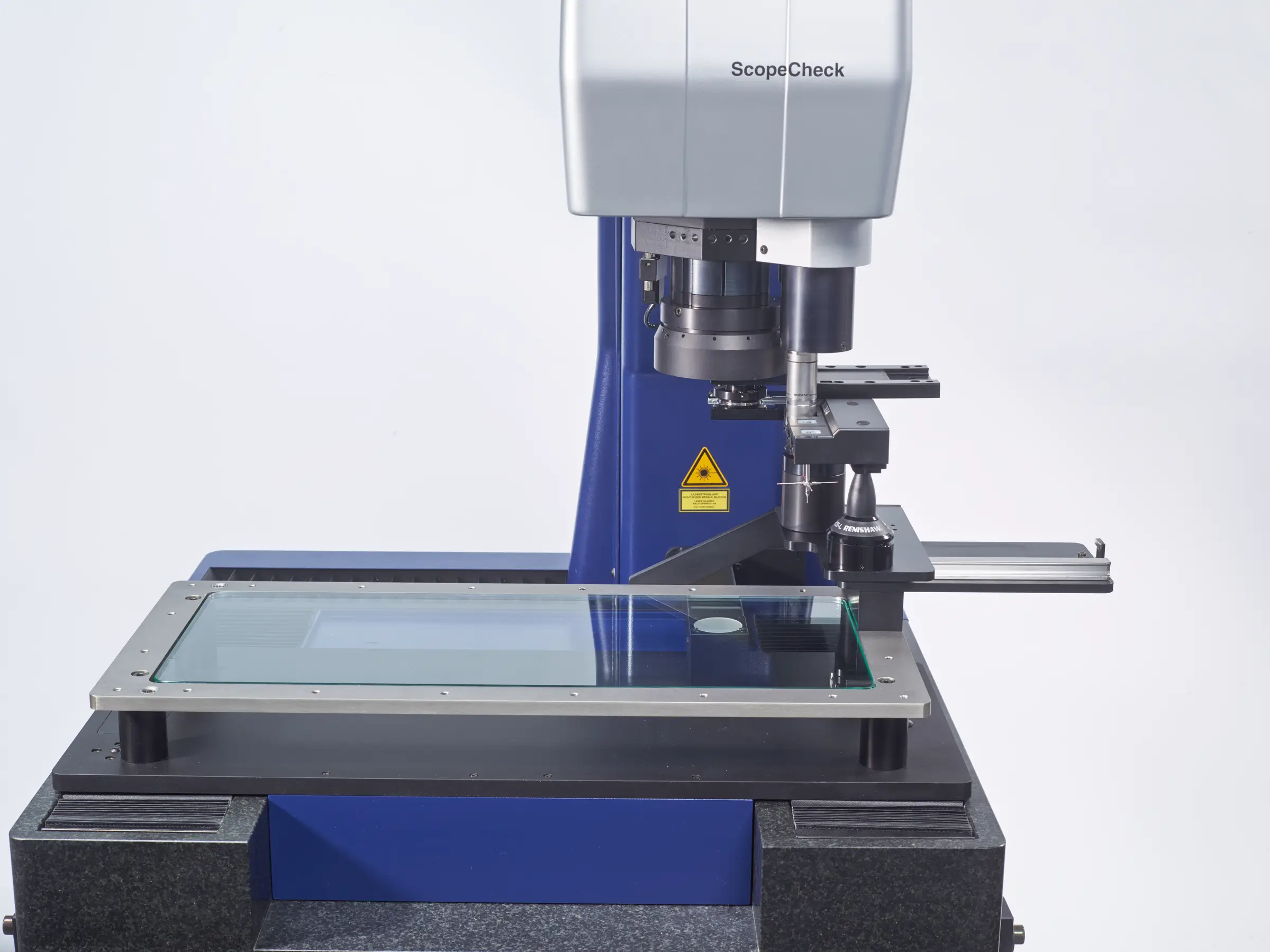

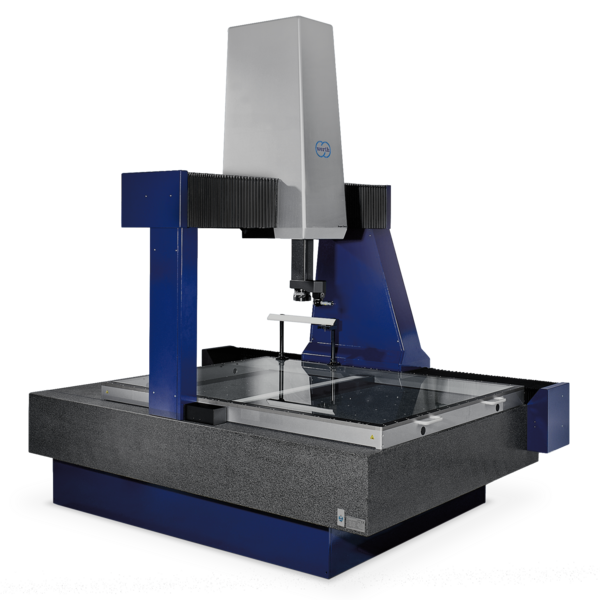

ScopeCheck® MB

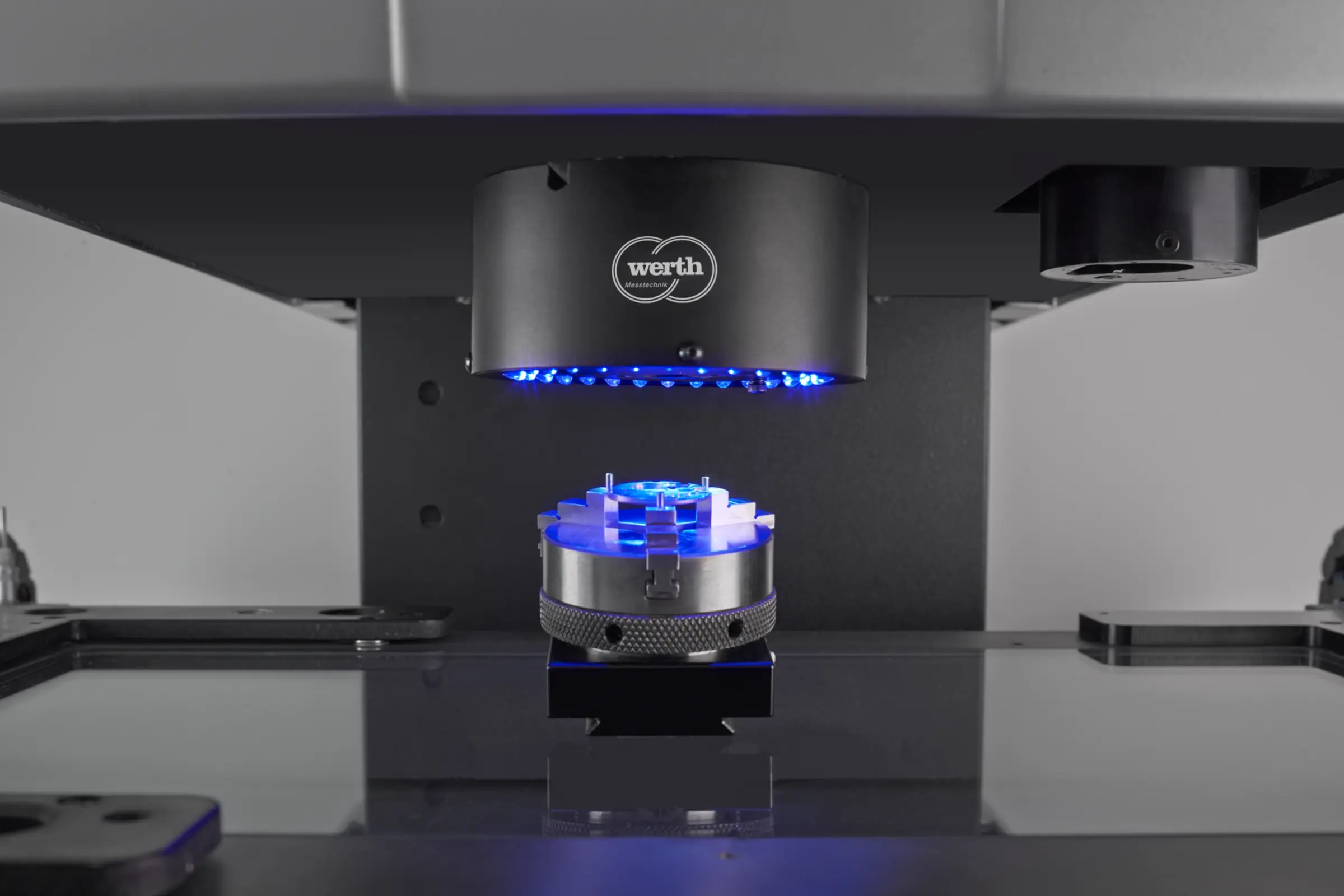

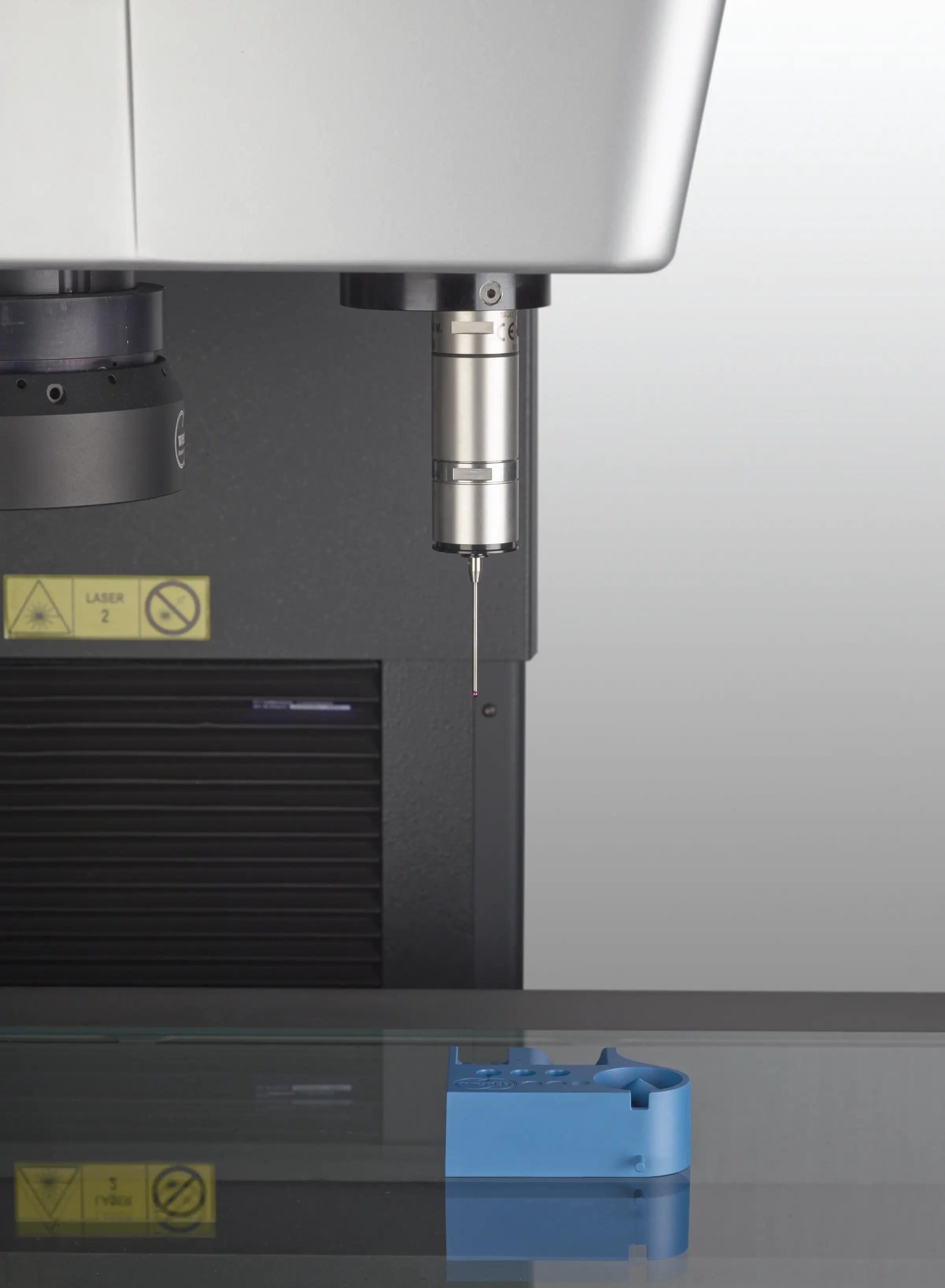

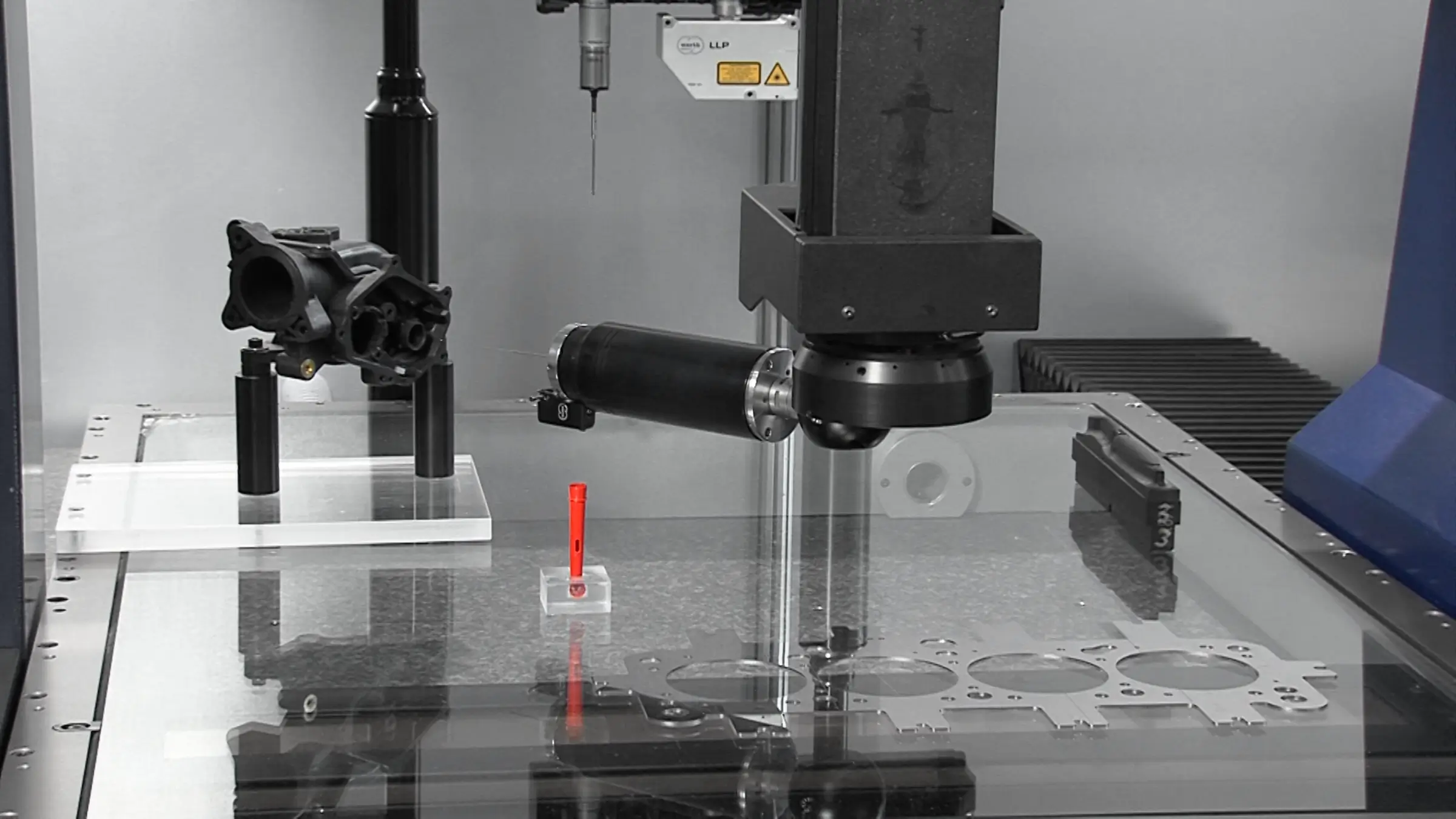

Z-Ekseninde değişken çalışma mesafeli Werth Zoom'un tam entegrasyonu sayesinde iş parçalarının optik 3B ölçümü için sınırsız olanaklar

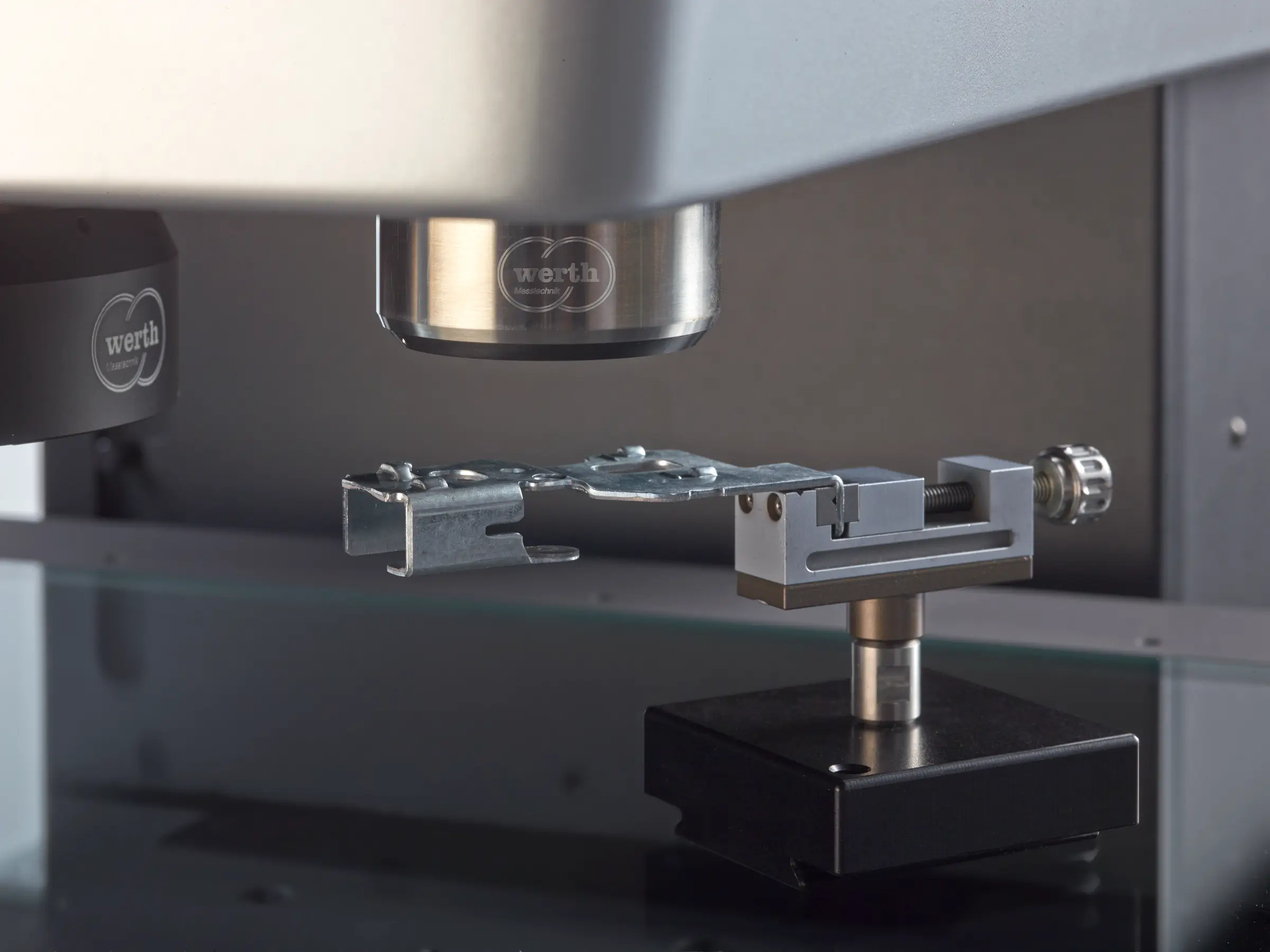

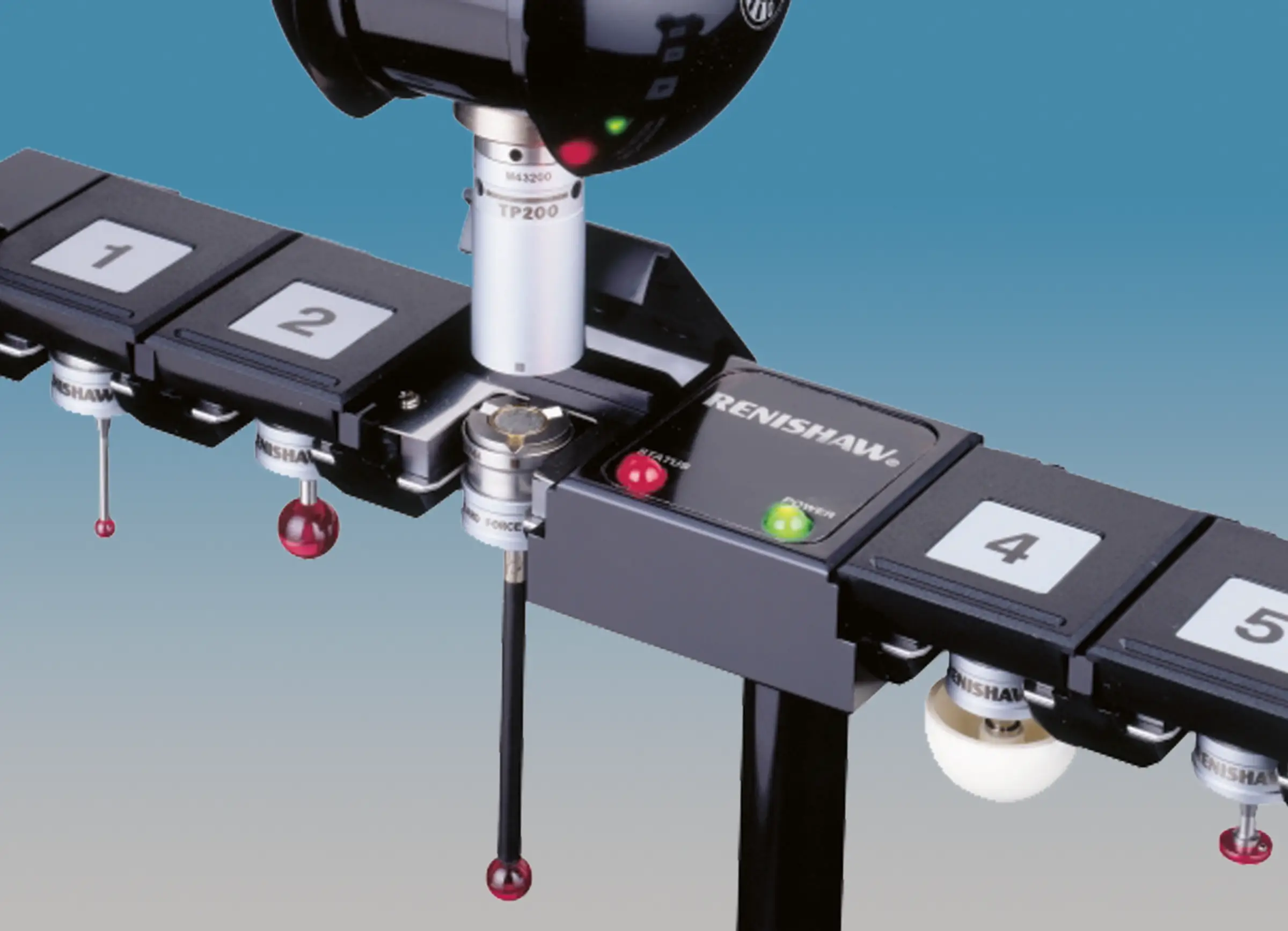

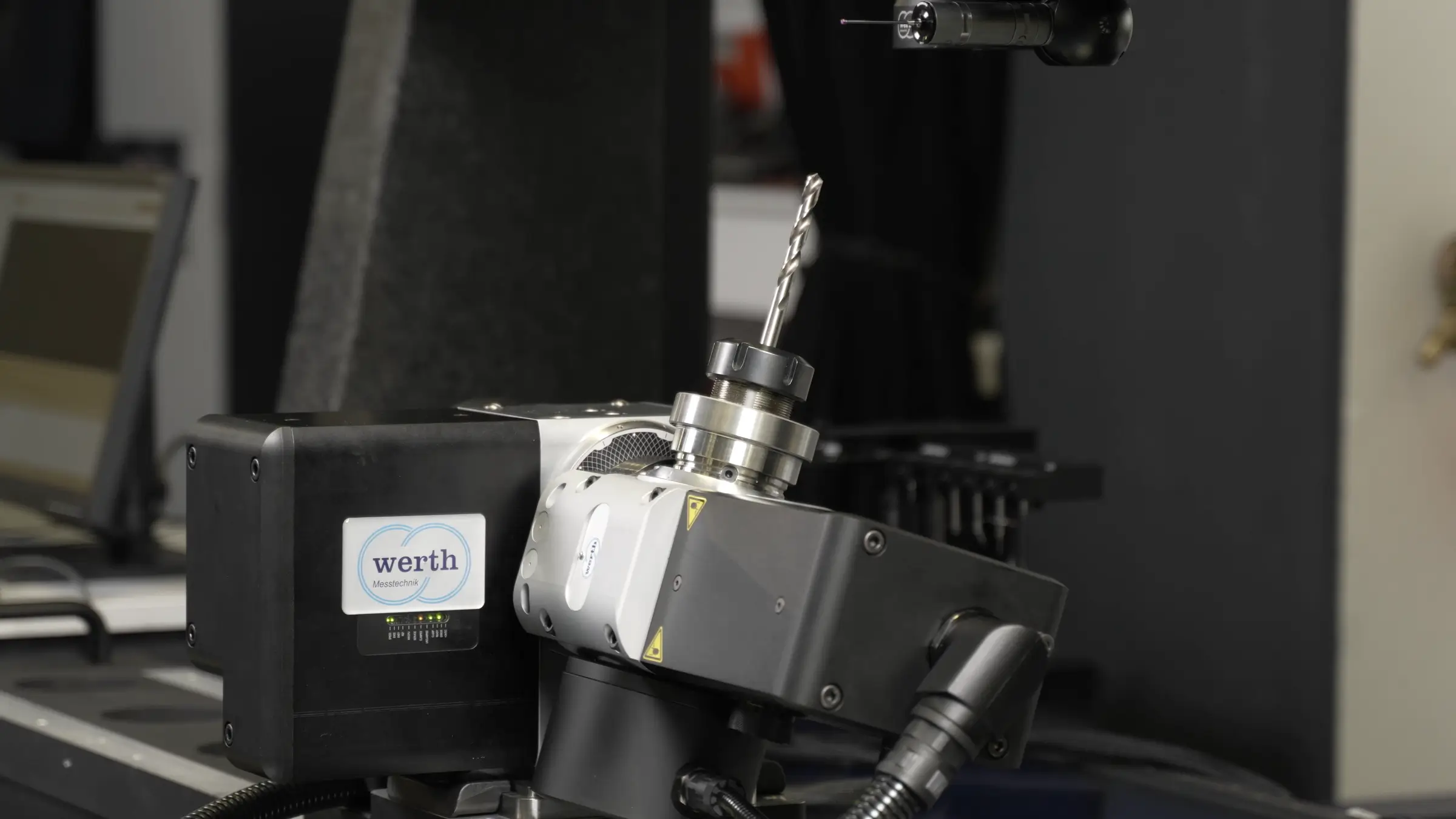

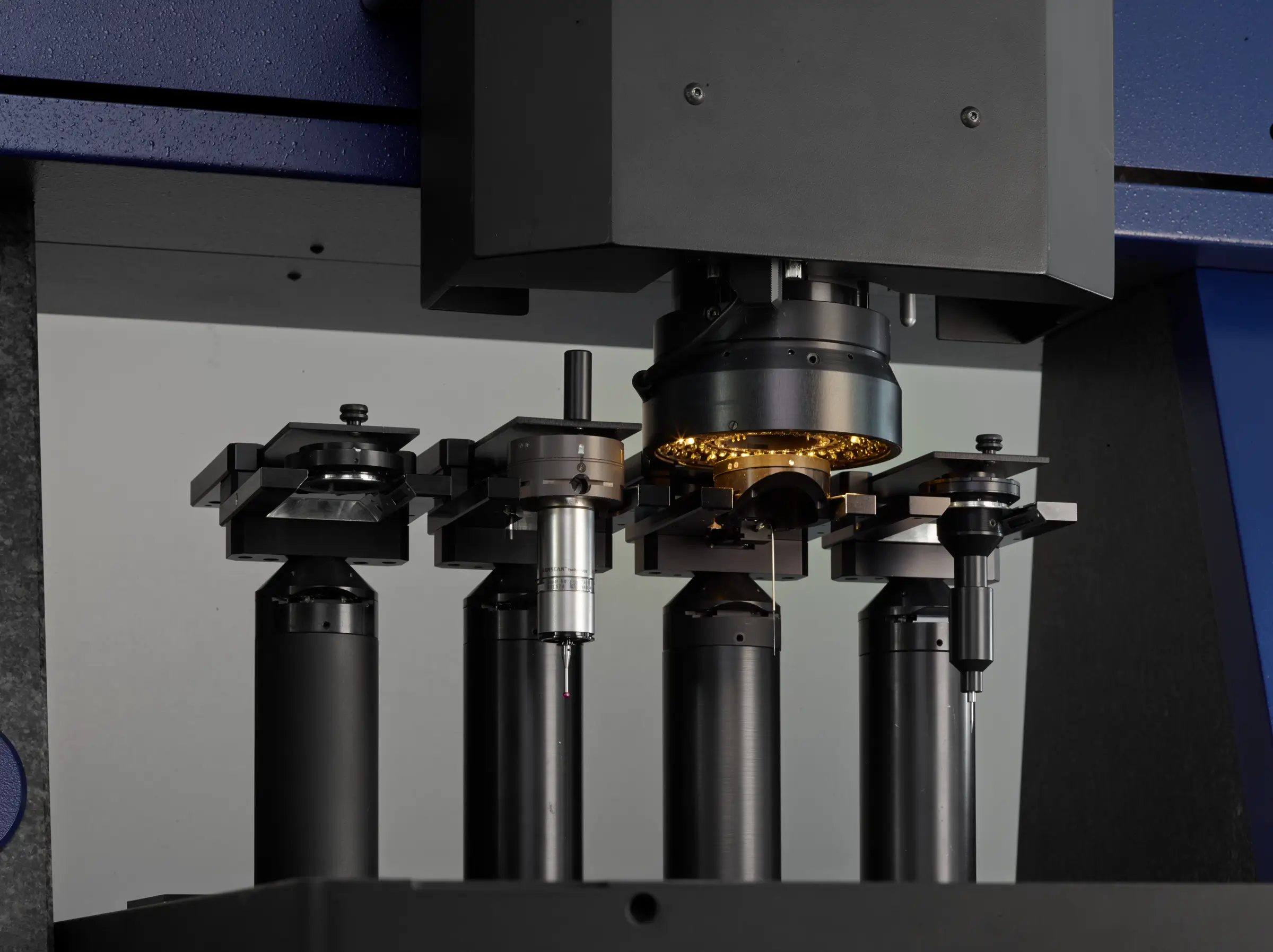

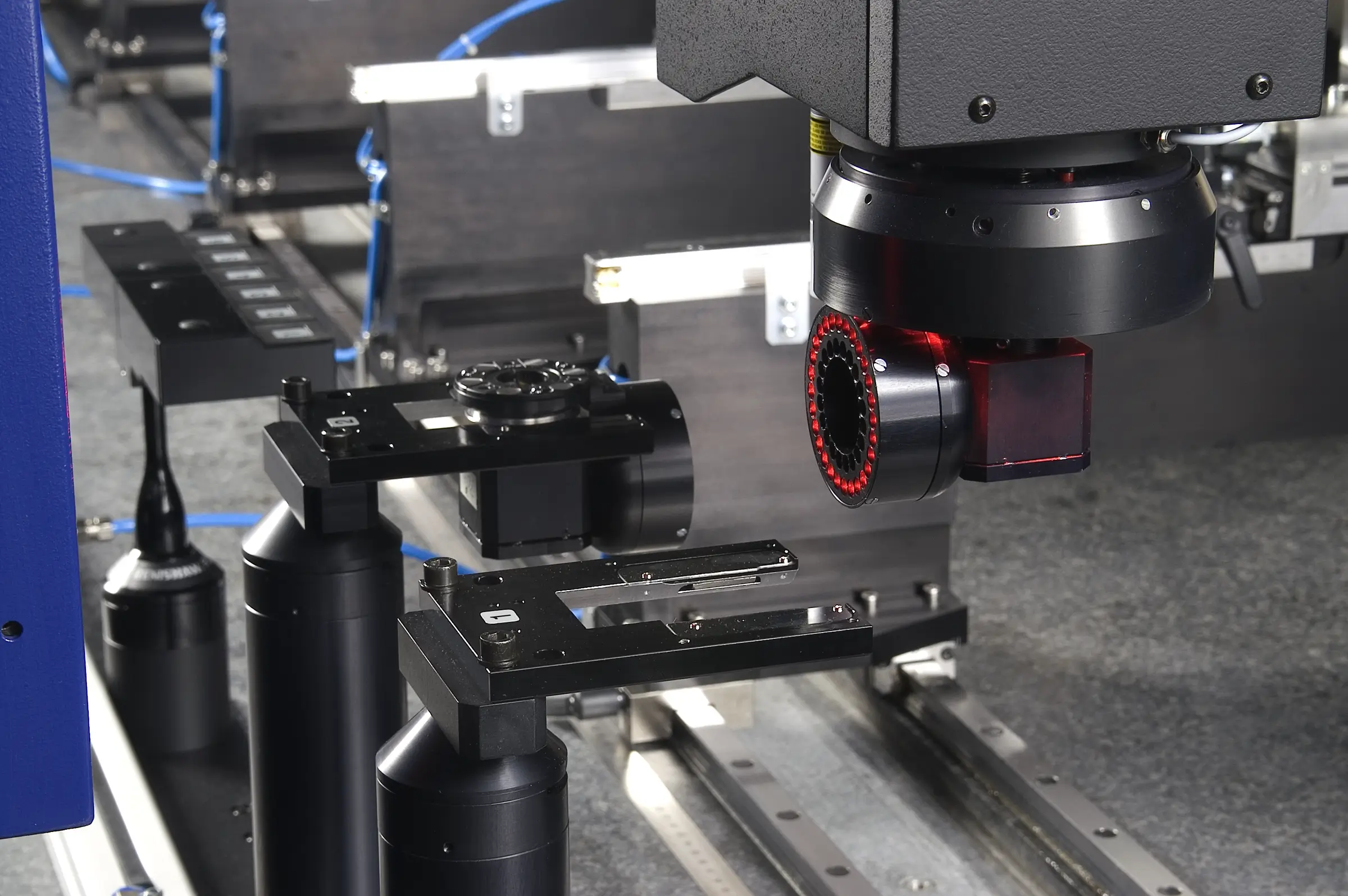

Çoklu sensör sistemlerinin entegrasyonu sayesinde yüksek ölçüm hızında artan esneklik

Değişken aydınlatma üniteleri sayesinde yüksek esneklik

Mümkün olan tüm ölçüm aralığında homojen aydınlatma ile damgalı ve bükülmüş parçaların, folyoların ve profillerin hızlı optik ölçümü için ayarlanabilir CNC iletimli ışıklı bağlantı çerçevesi

Tip

Hareketli köprülü 3D-CNC çok sensörlü koordinat ölçüm makinesi

Ölçüm aralığı

X = 800 mm ila 2000 mm, Y = 1200 mm ila 3000 mm, Z = 700 mm ila 1500 mm

Hassasiyet

İzin verilen uzunluk ölçüm hatası 1,8 µm'ye kadar

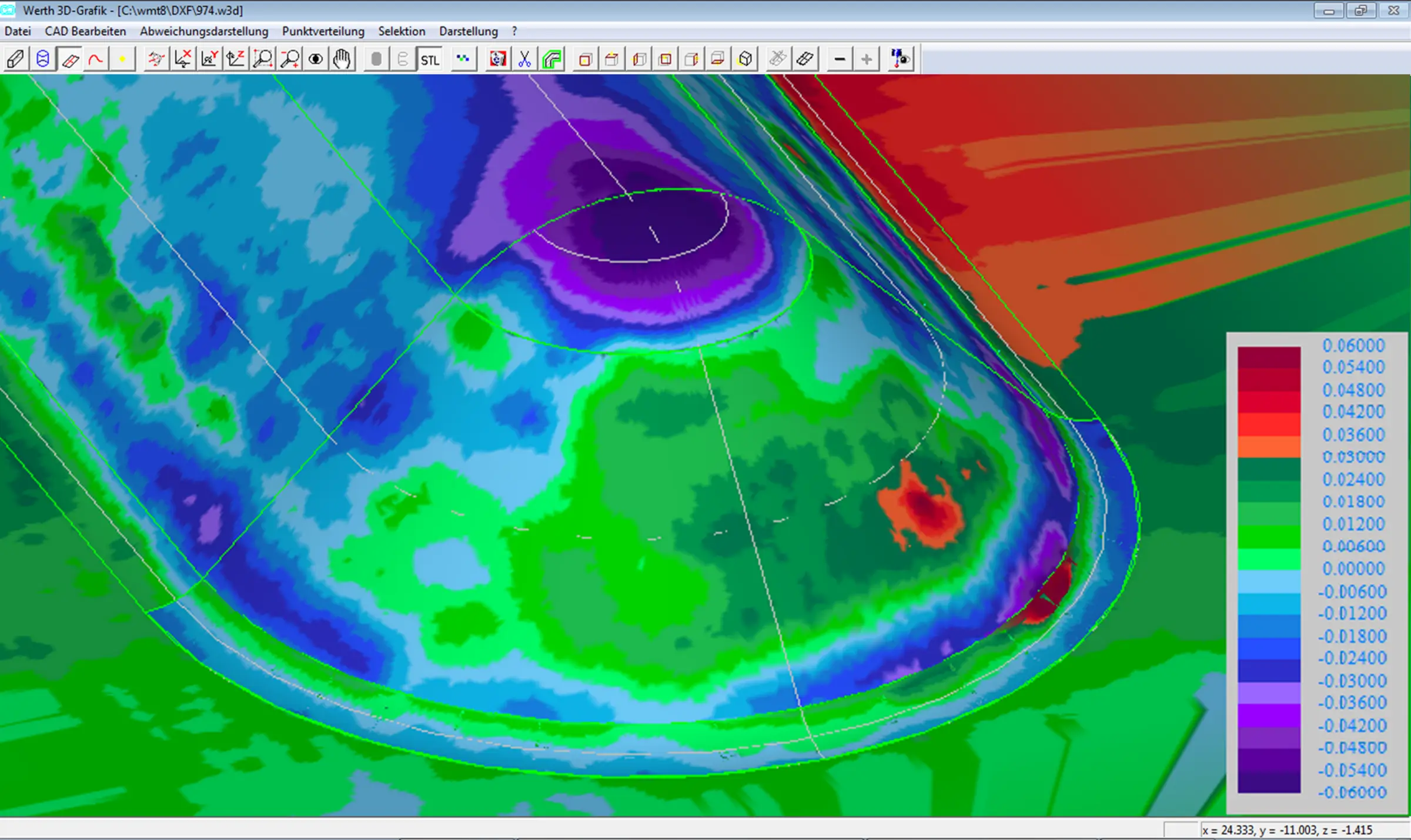

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...