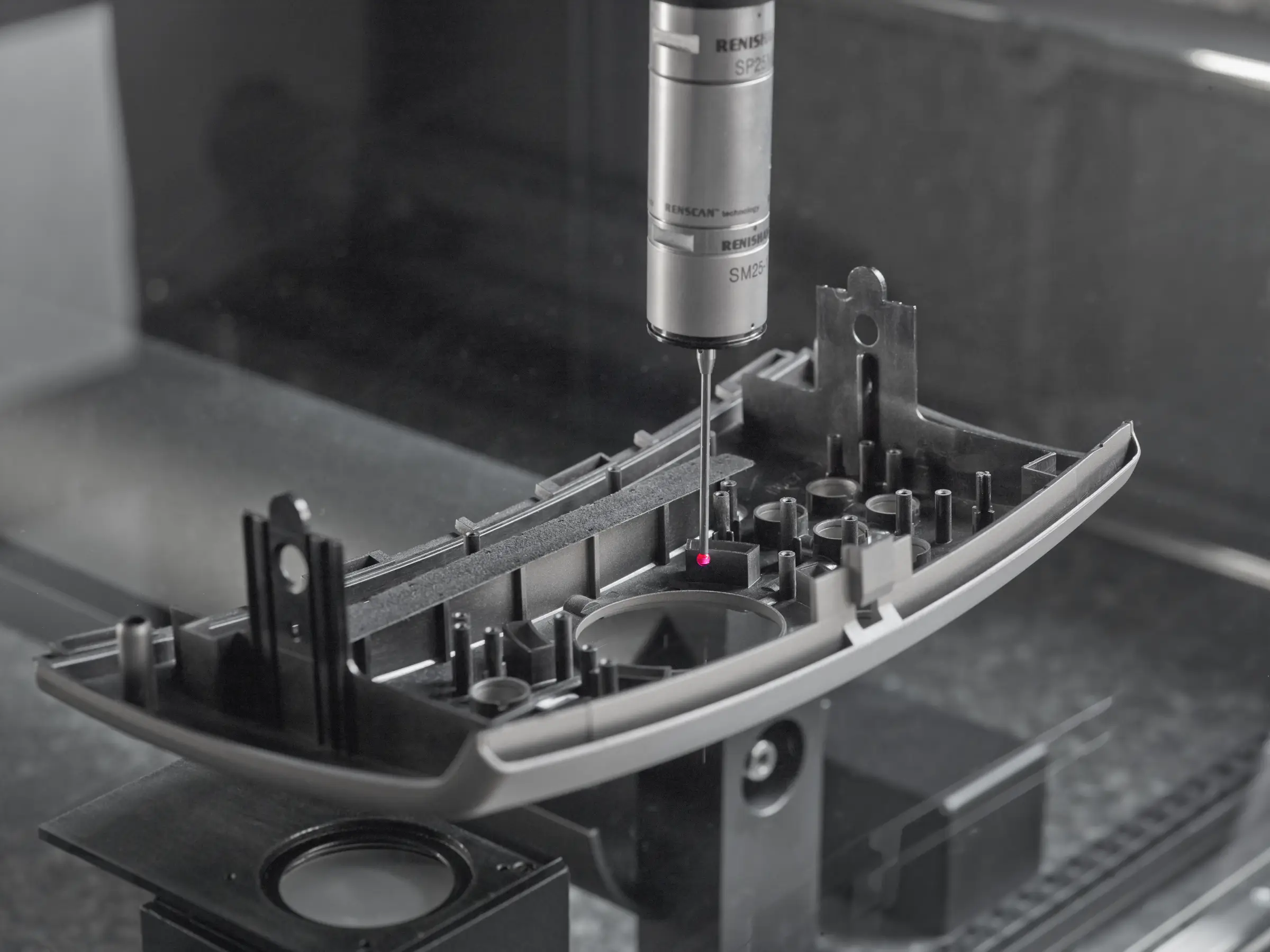

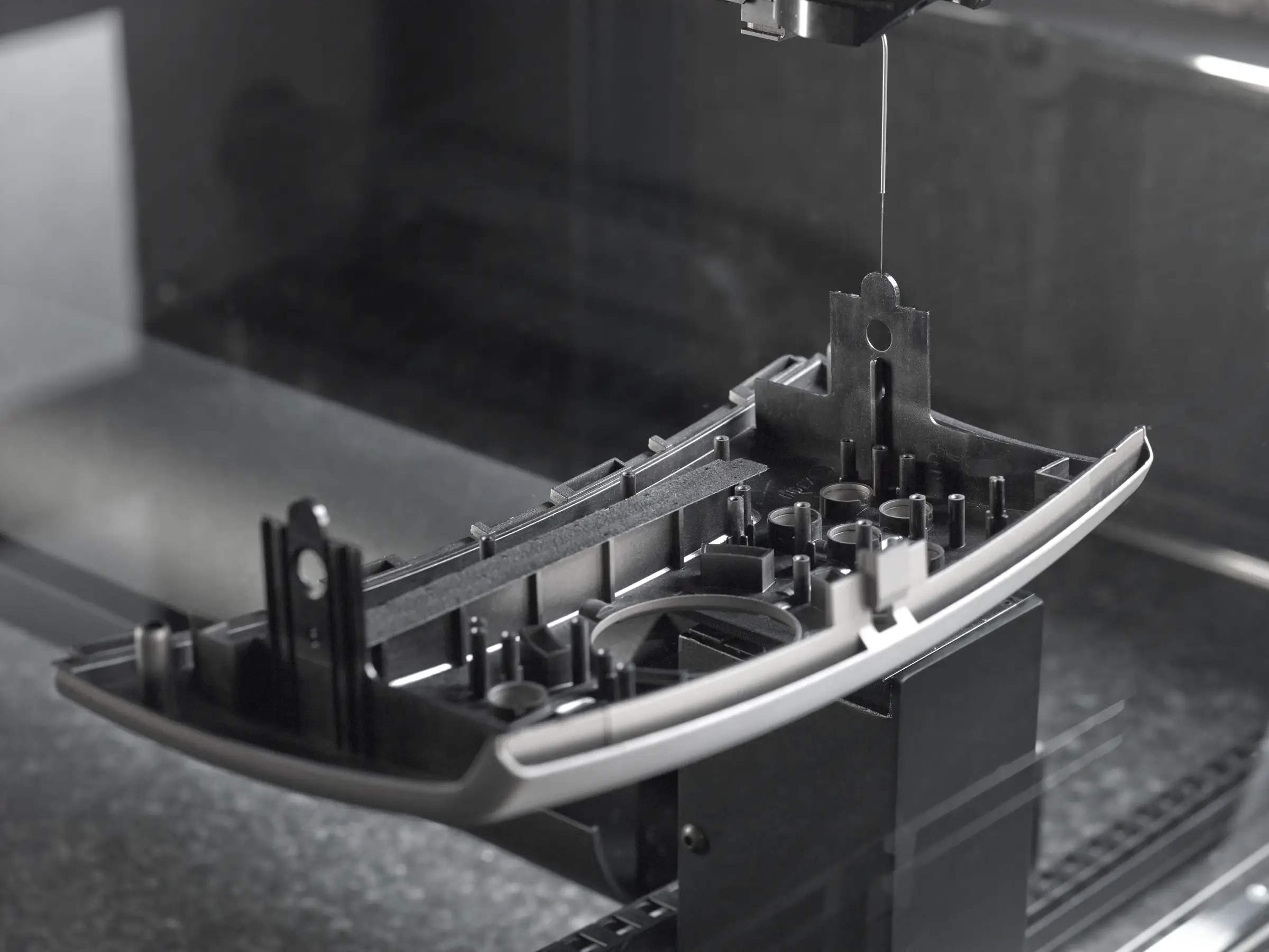

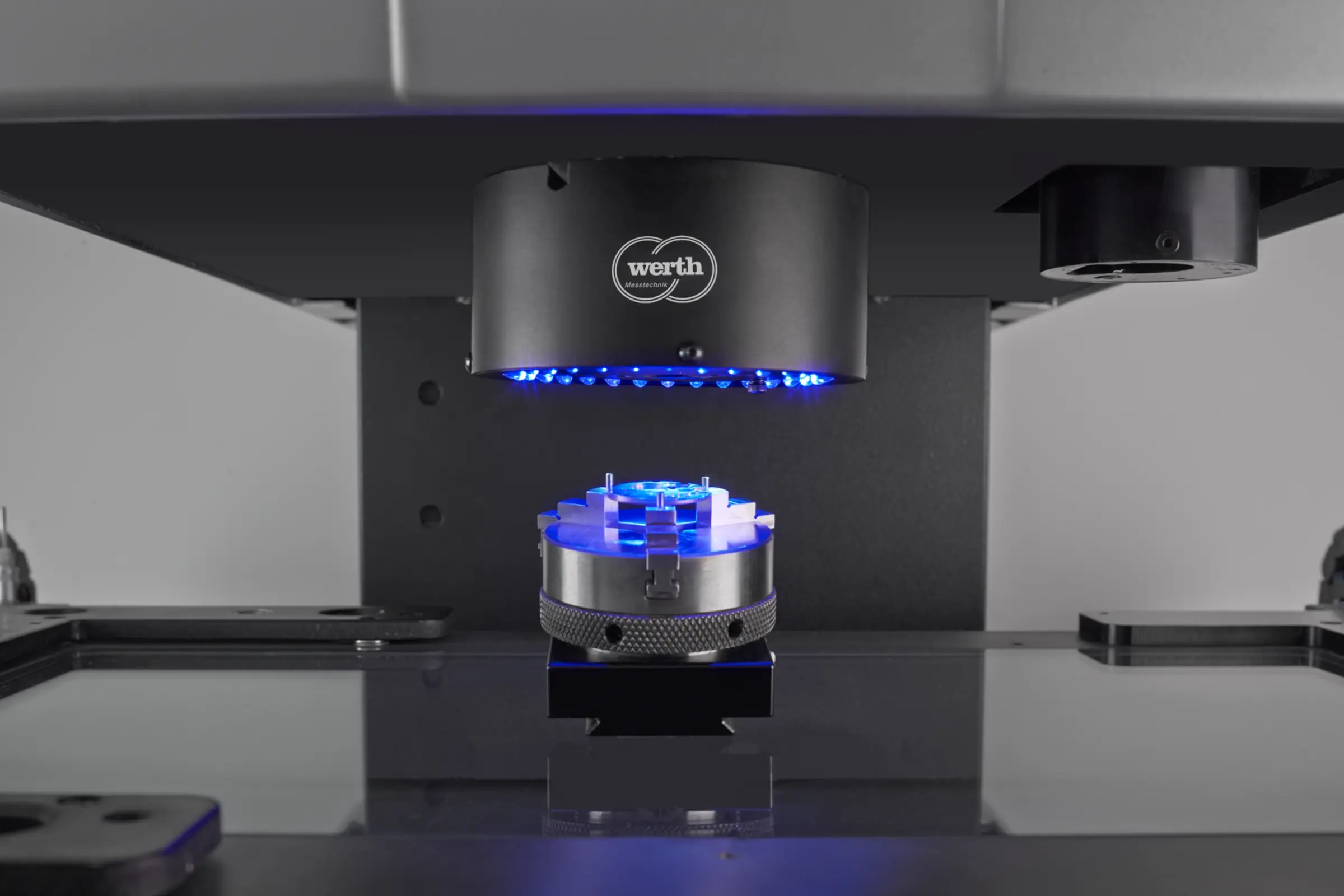

Inspector® FQ, yüksek ölçüm hızı sayesinde, aşırı uzun ölçüm süreleri nedeniyle geleneksel koordinat ölçüm makinelerinin erişemeyeceği uygulama alanlarına olanak tanır. Esnek makine, örneğin büyük sac ve plastik parçaların muayenesinde ölçüm cihazlarının veya manuel tezgah ölçüm cihazlarının yerini alır. Uygulama alanları, yüksek ölçüm hızının gerekli olduğu her yerde bulunur; örneğin elektronik endüstrisi, takım ve makine imalatı veya otomotiv, plastik ve kauçuk endüstrileri.

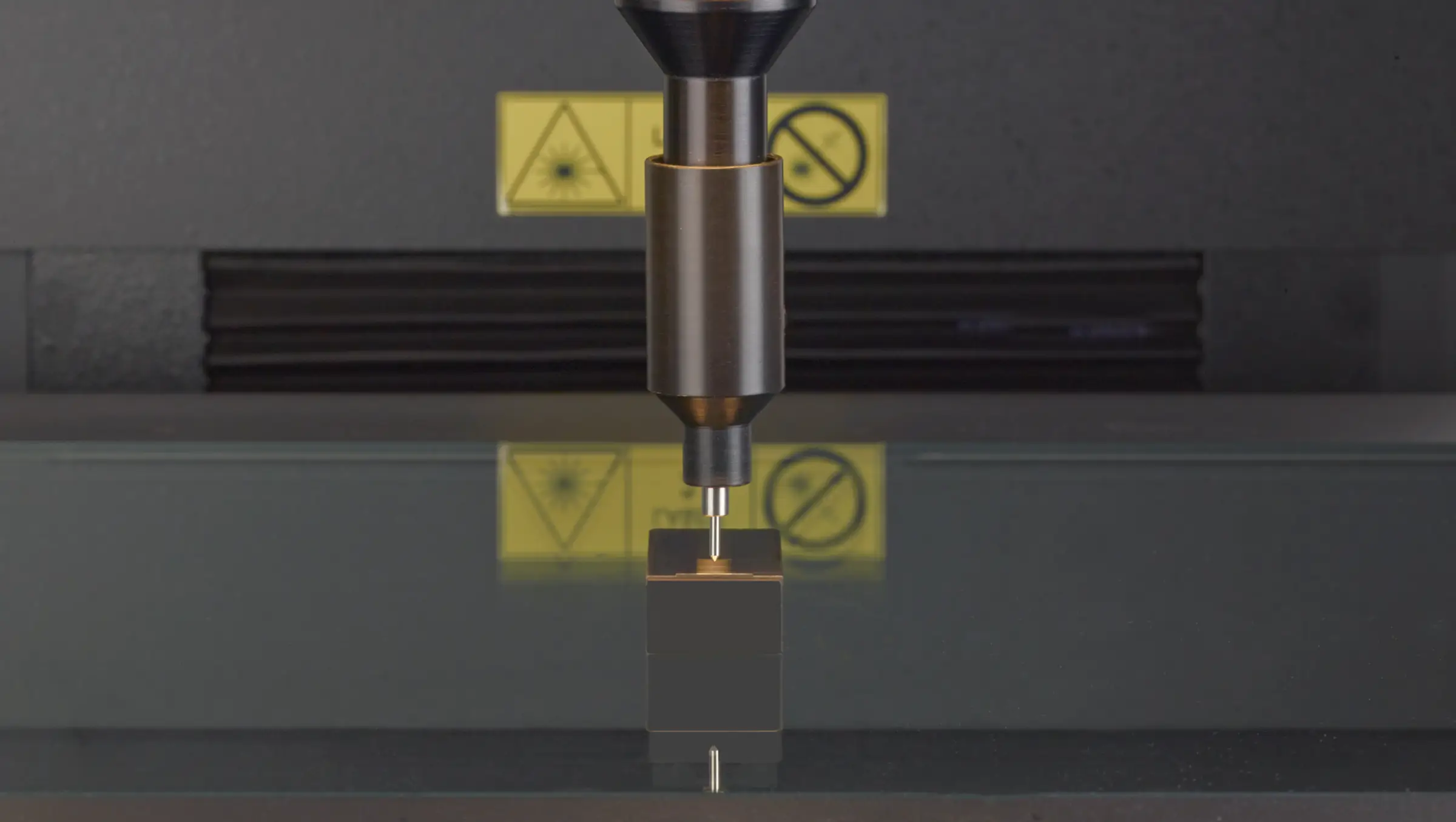

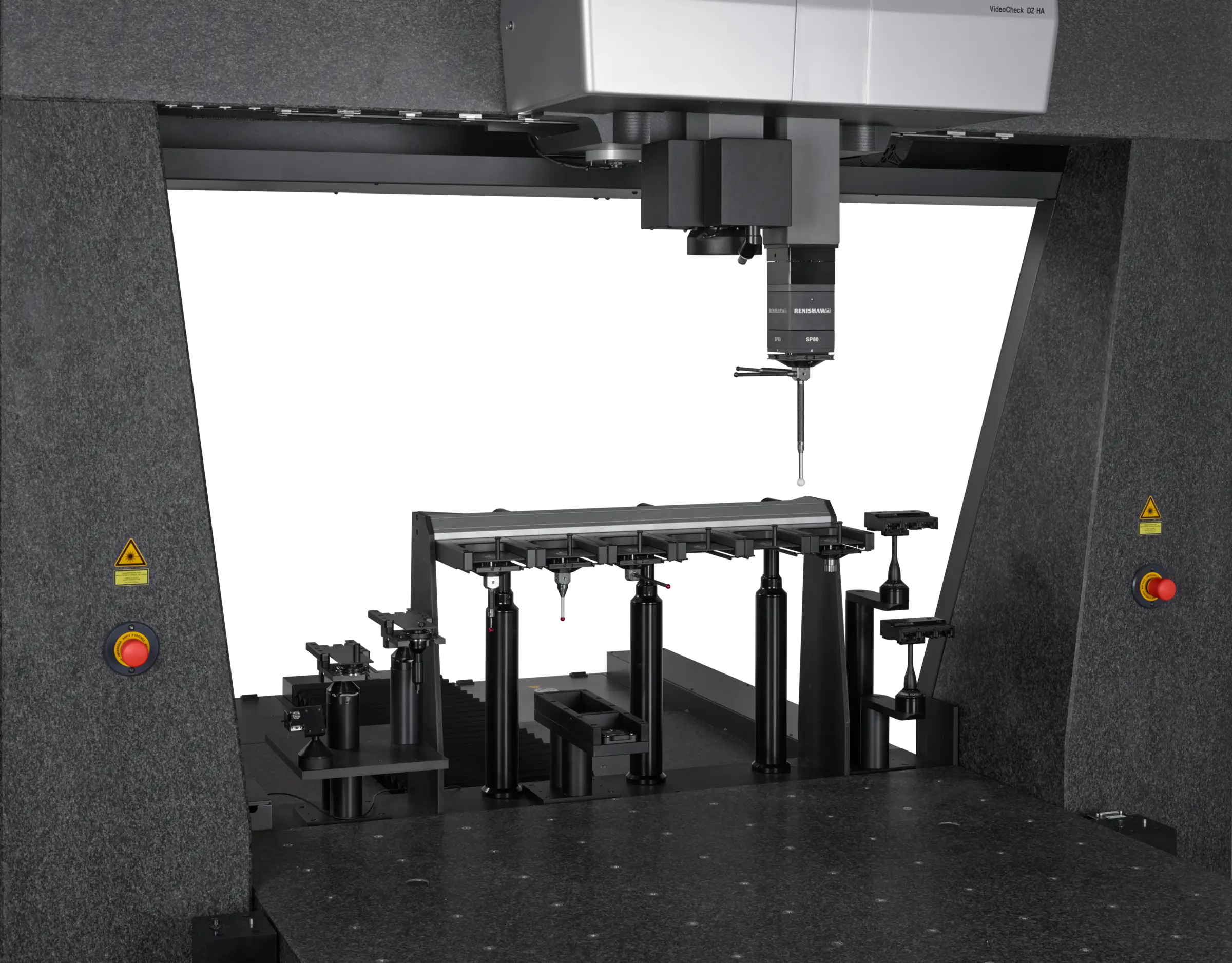

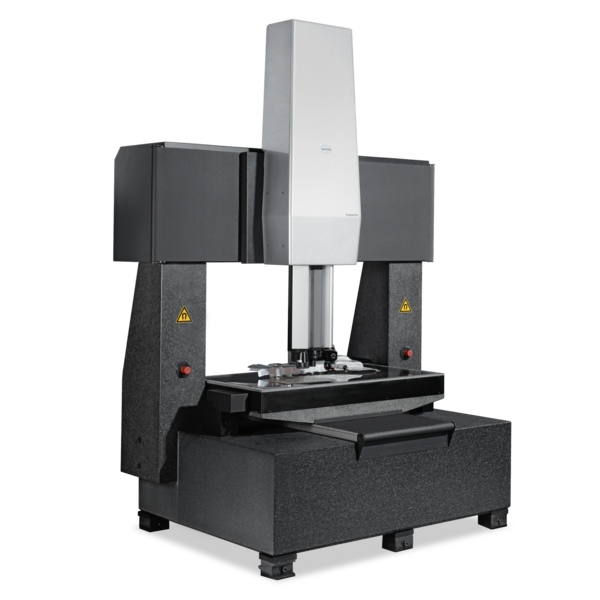

Inspector® FQ

Aşınmayan doğrusal tahrikler sayesinde en yüksek konumlandırma hızı

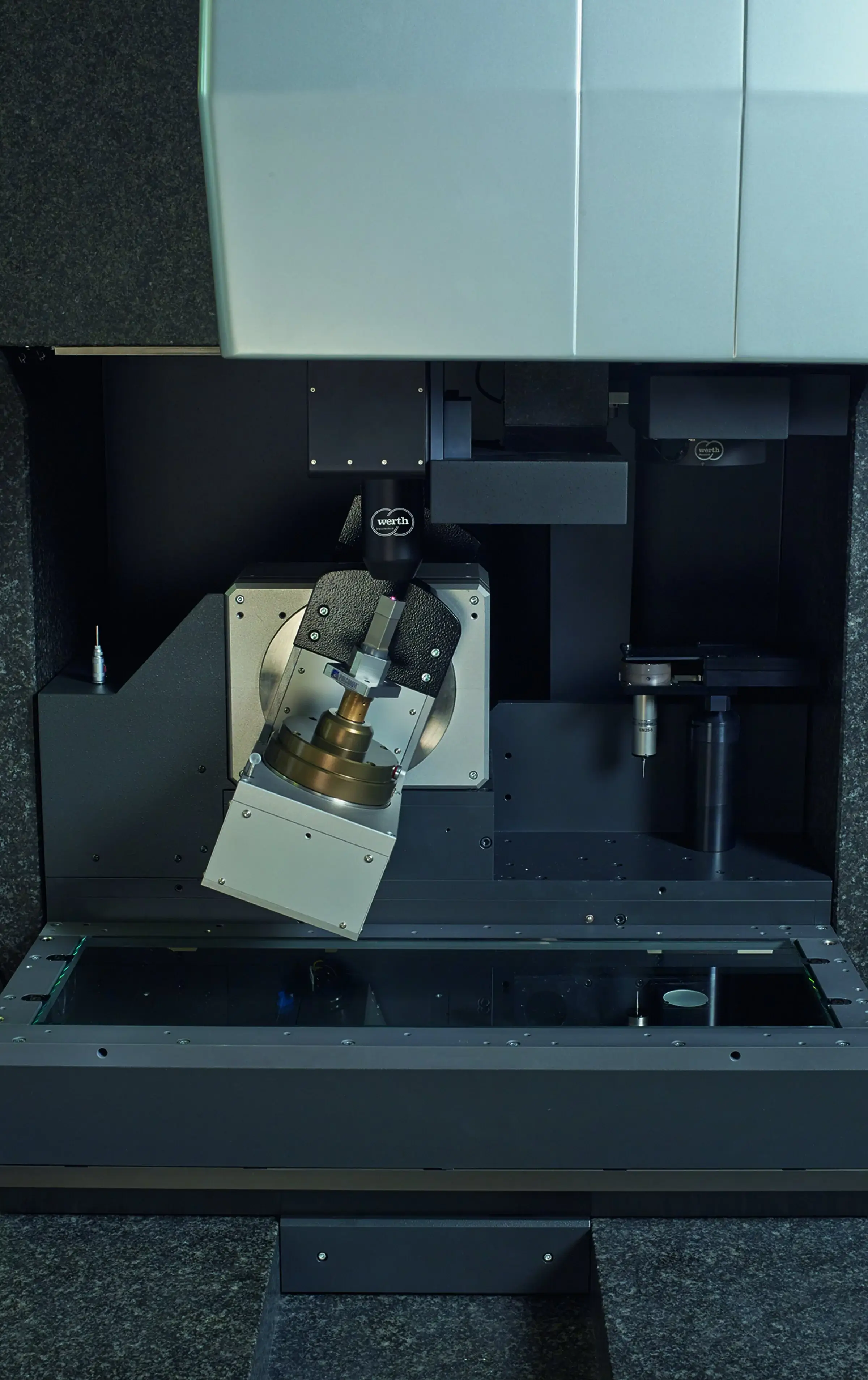

Zorlu çevre koşulları için mekanik olarak monte edilmiş kılavuz raylar

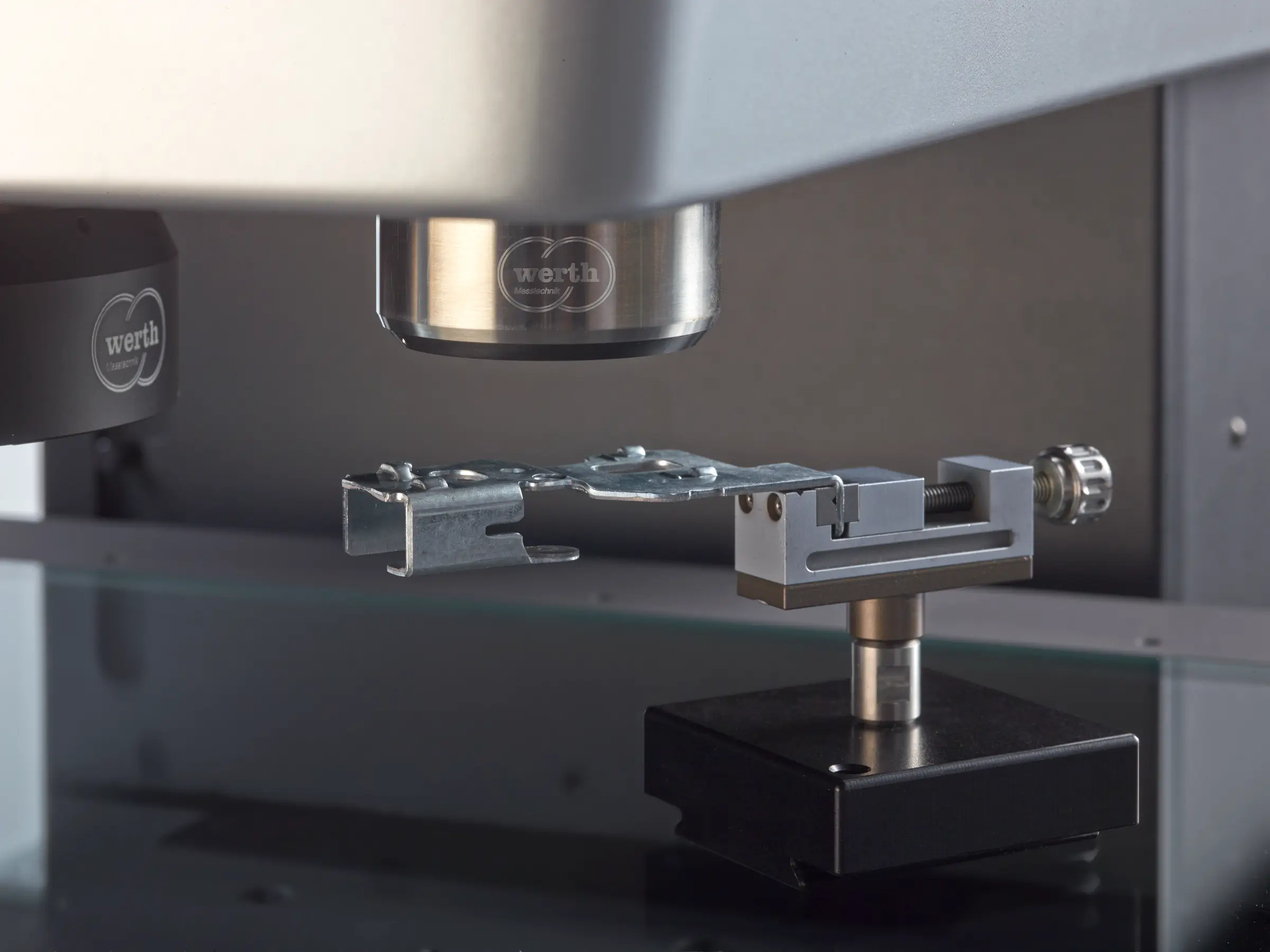

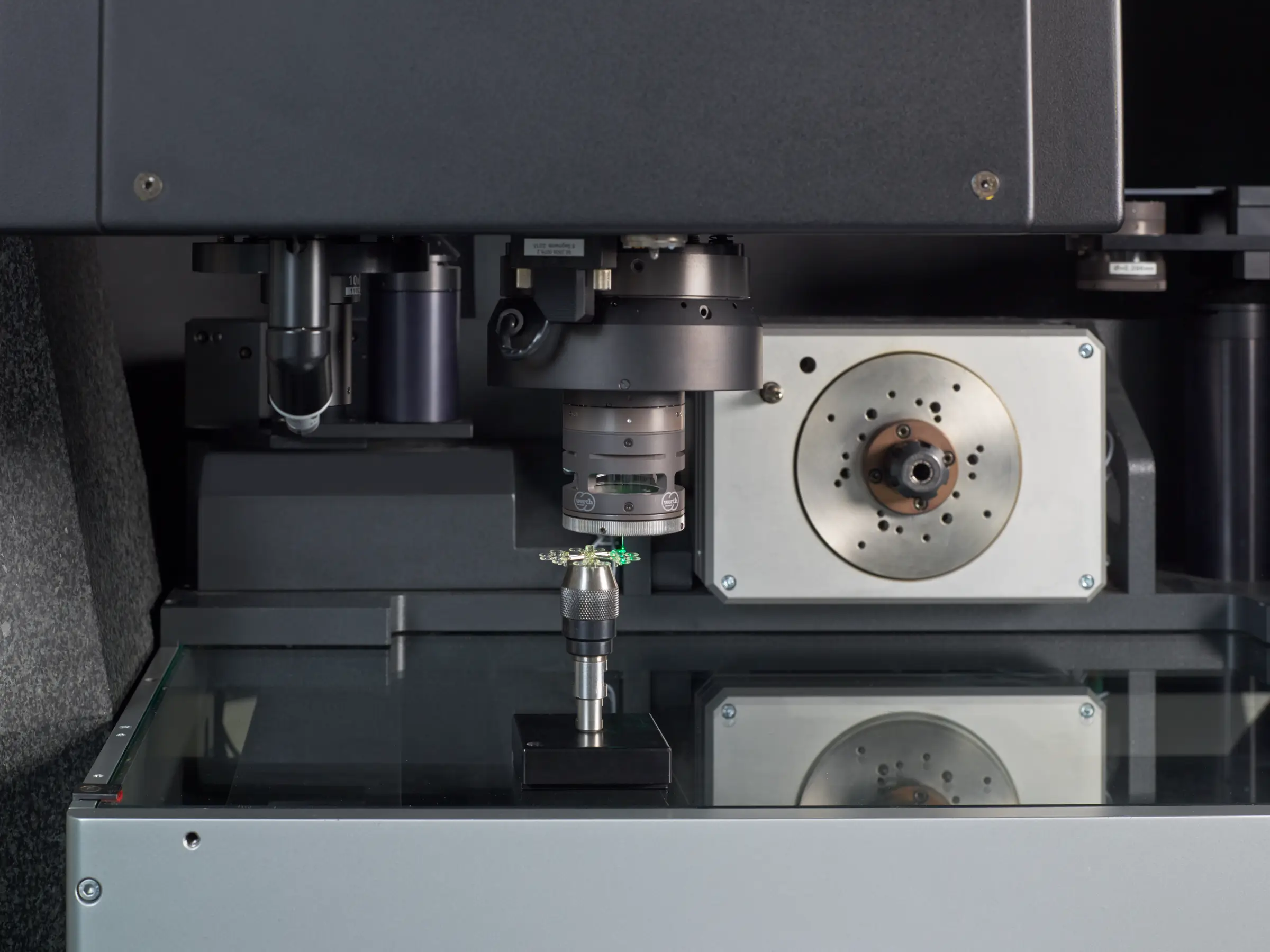

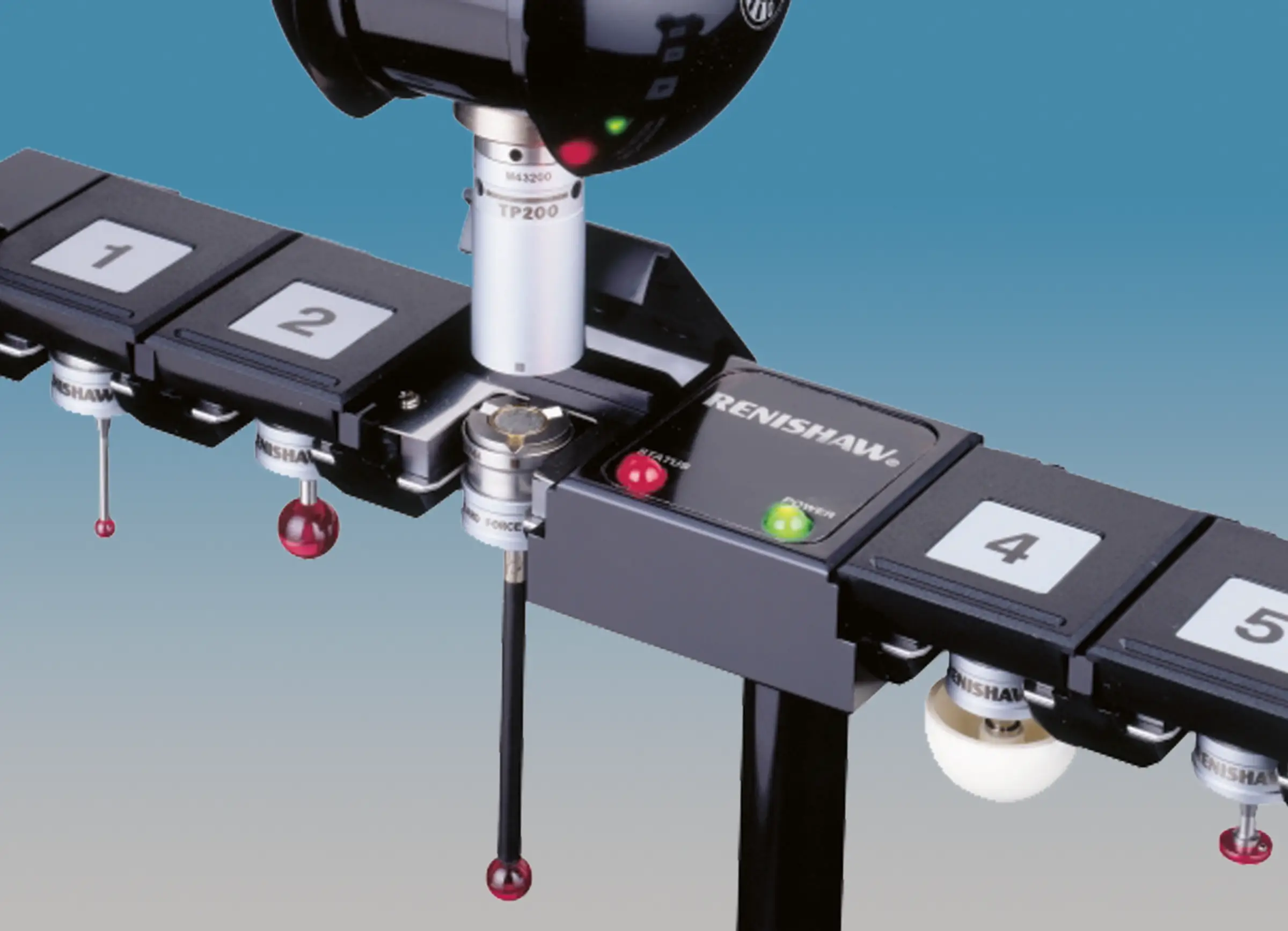

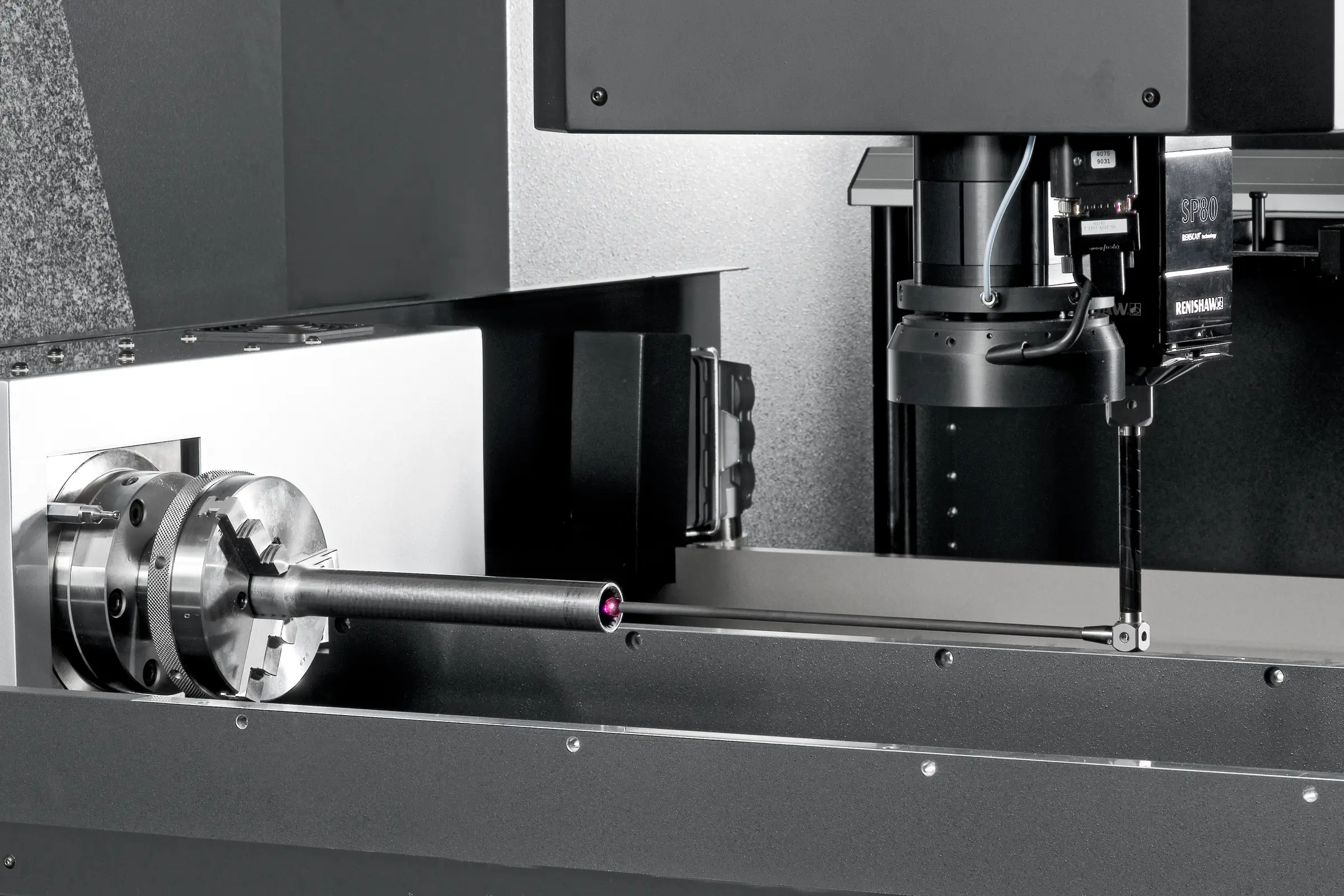

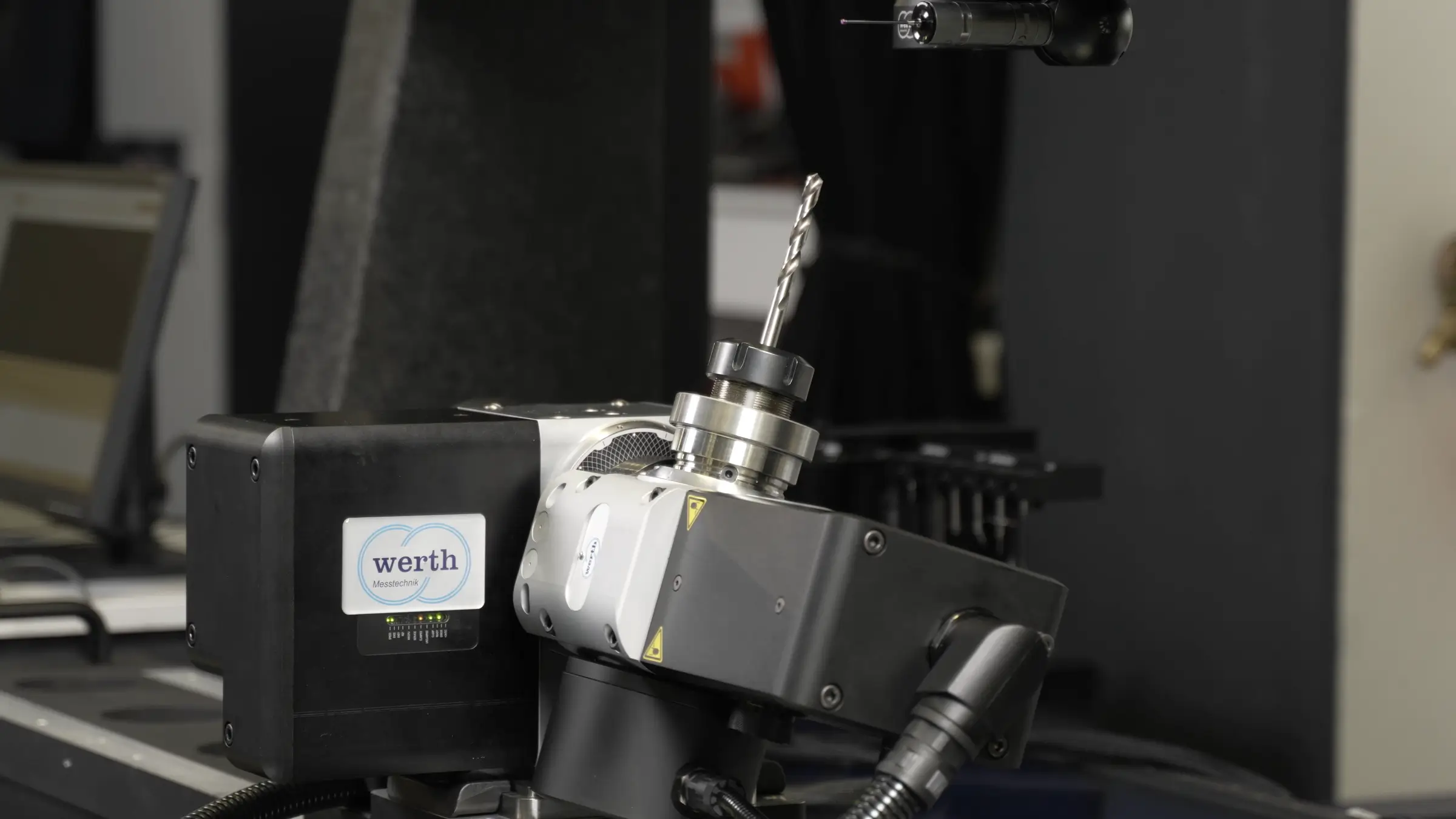

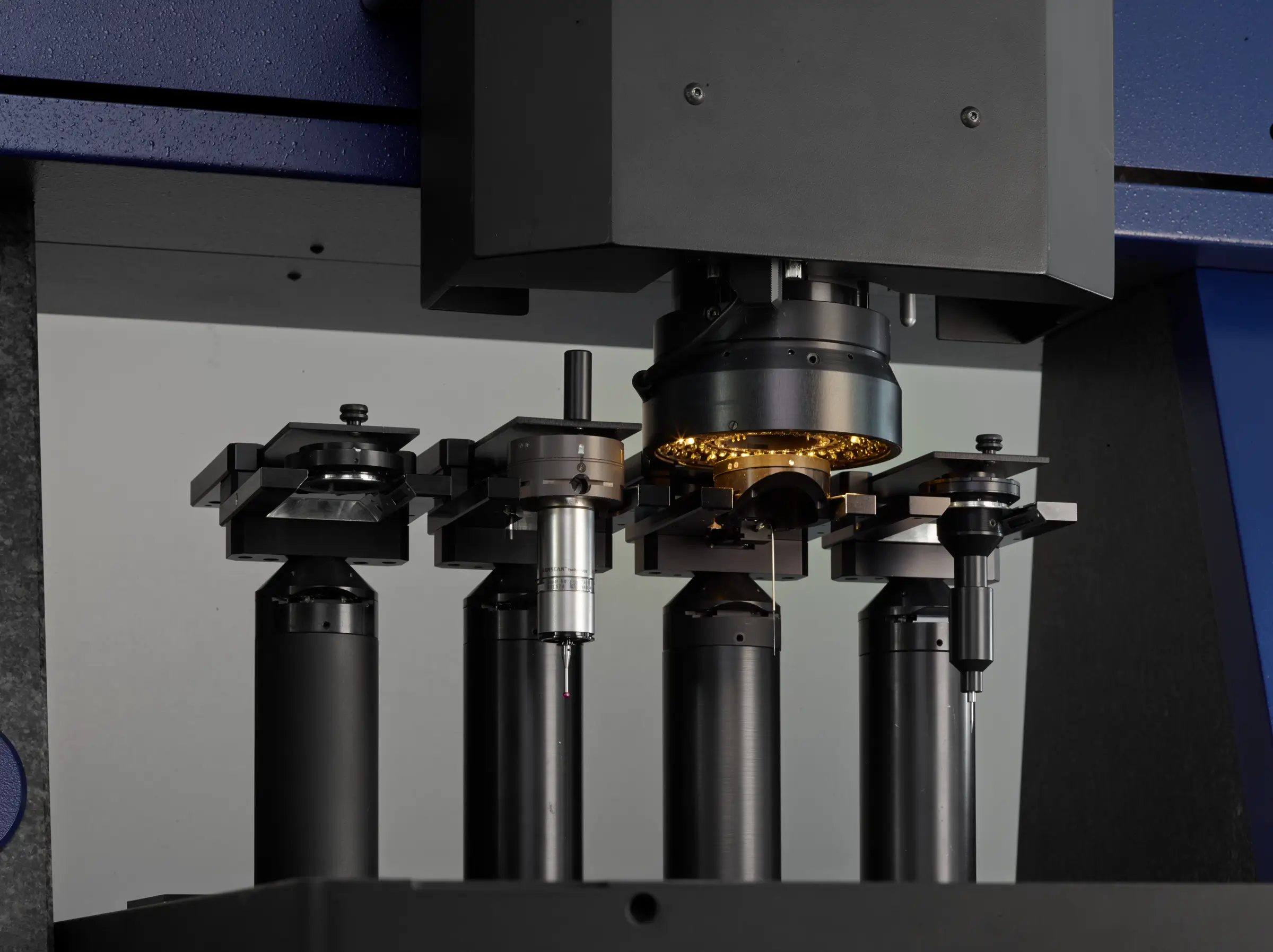

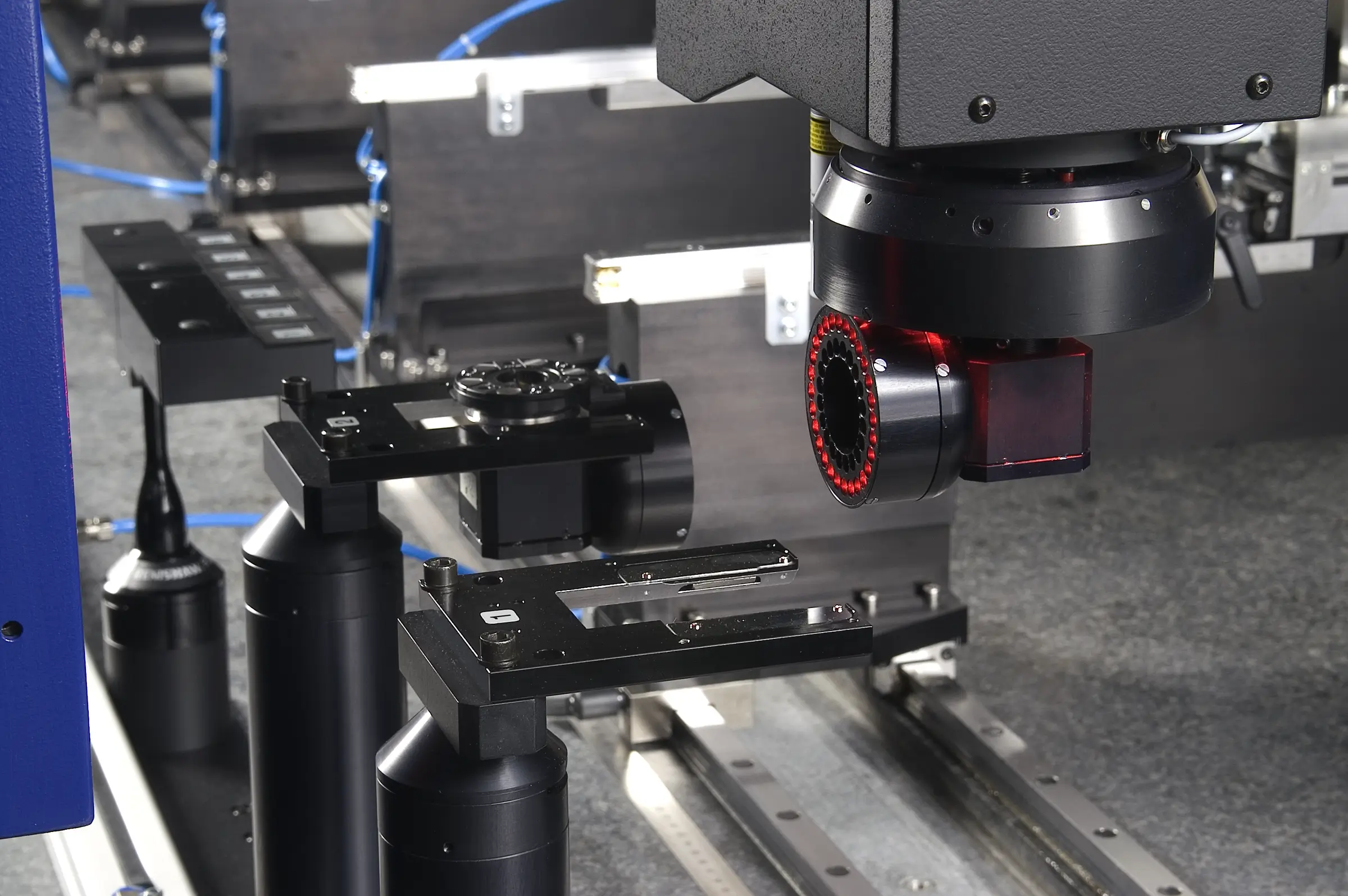

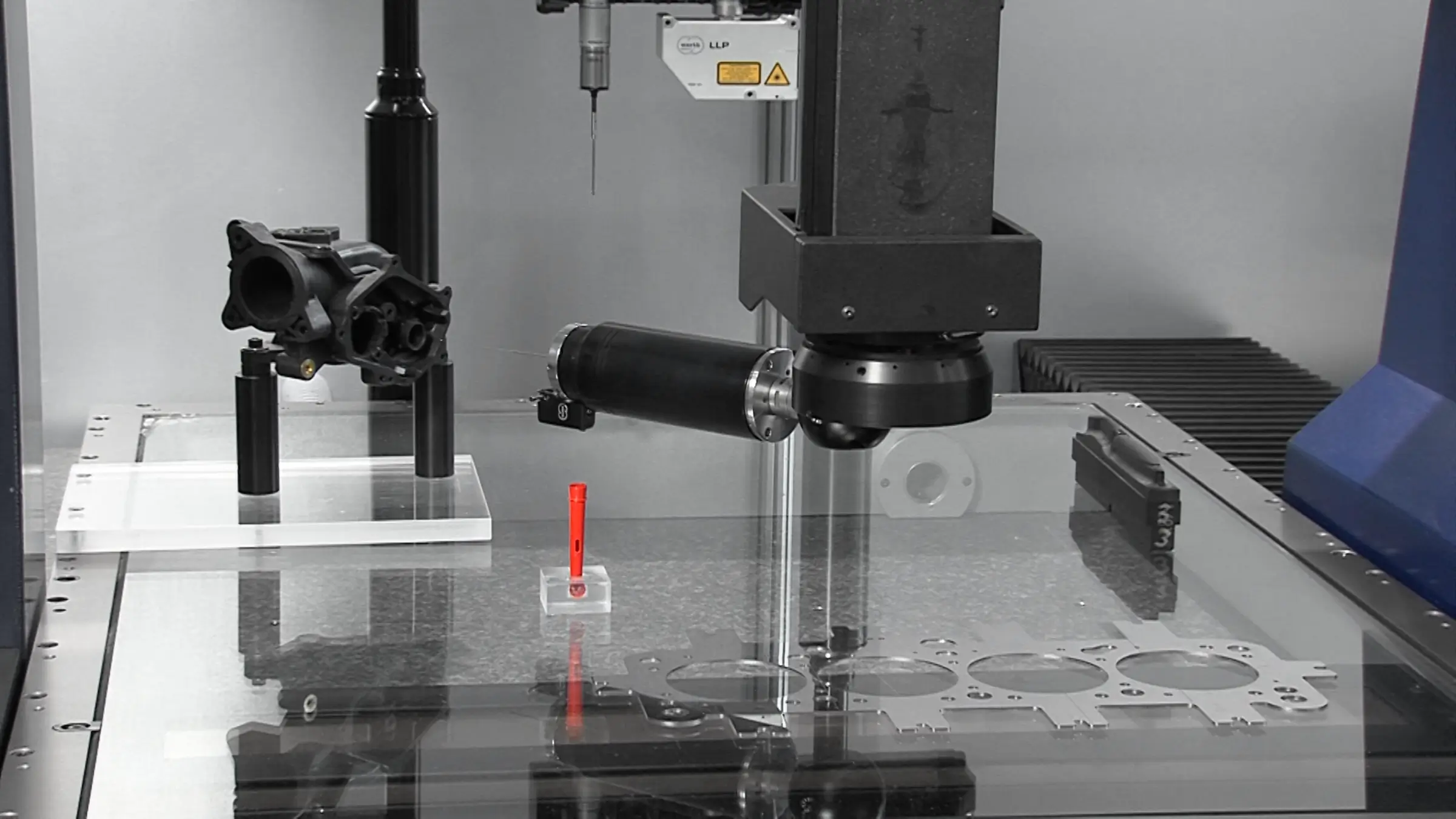

Çok sensörlü bir koordinat ölçüm makinesine daha fazla sensörün entegre edilmesi ve böylece yüksek ölçüm hızında daha fazla esneklik

Tip

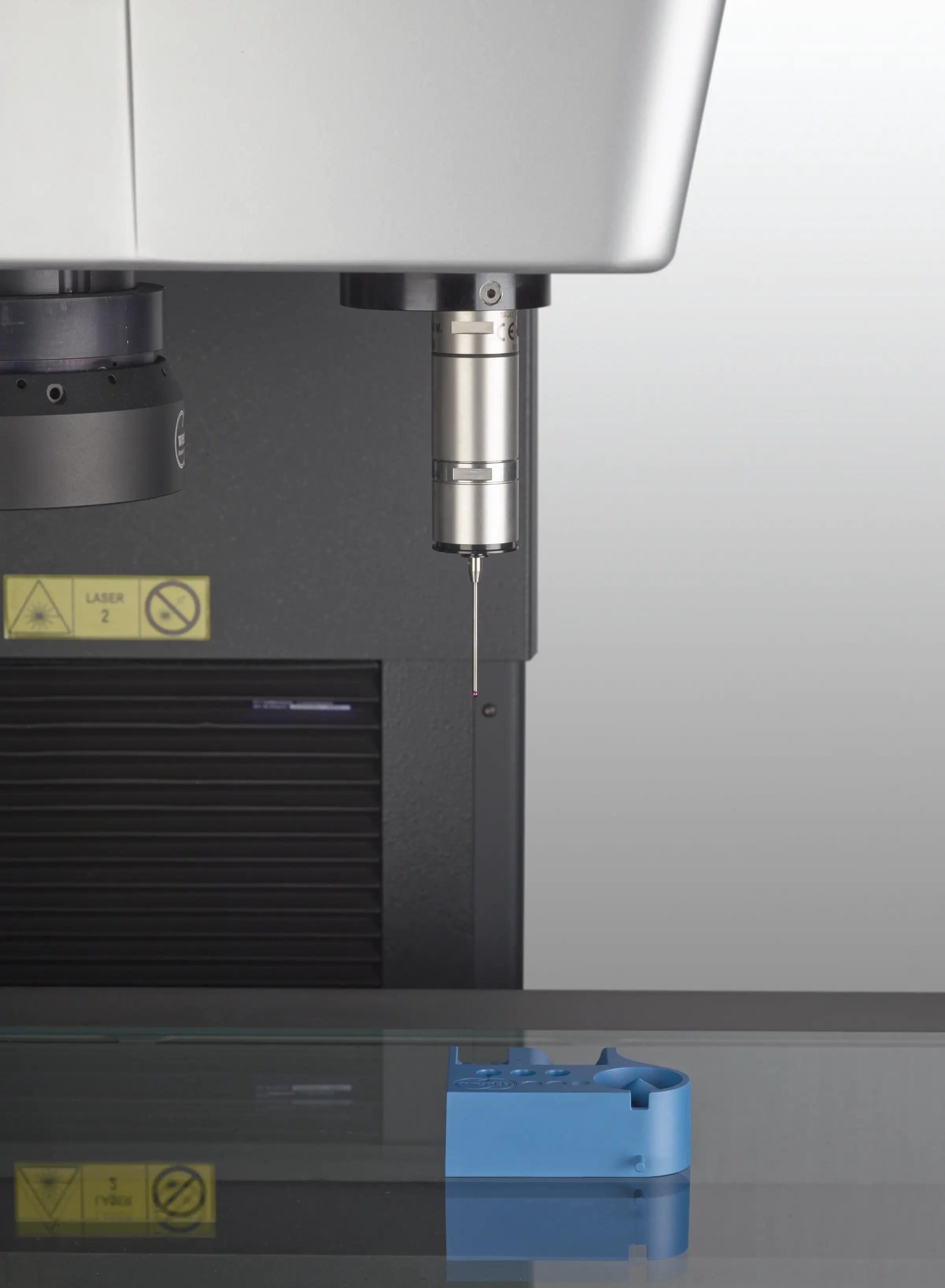

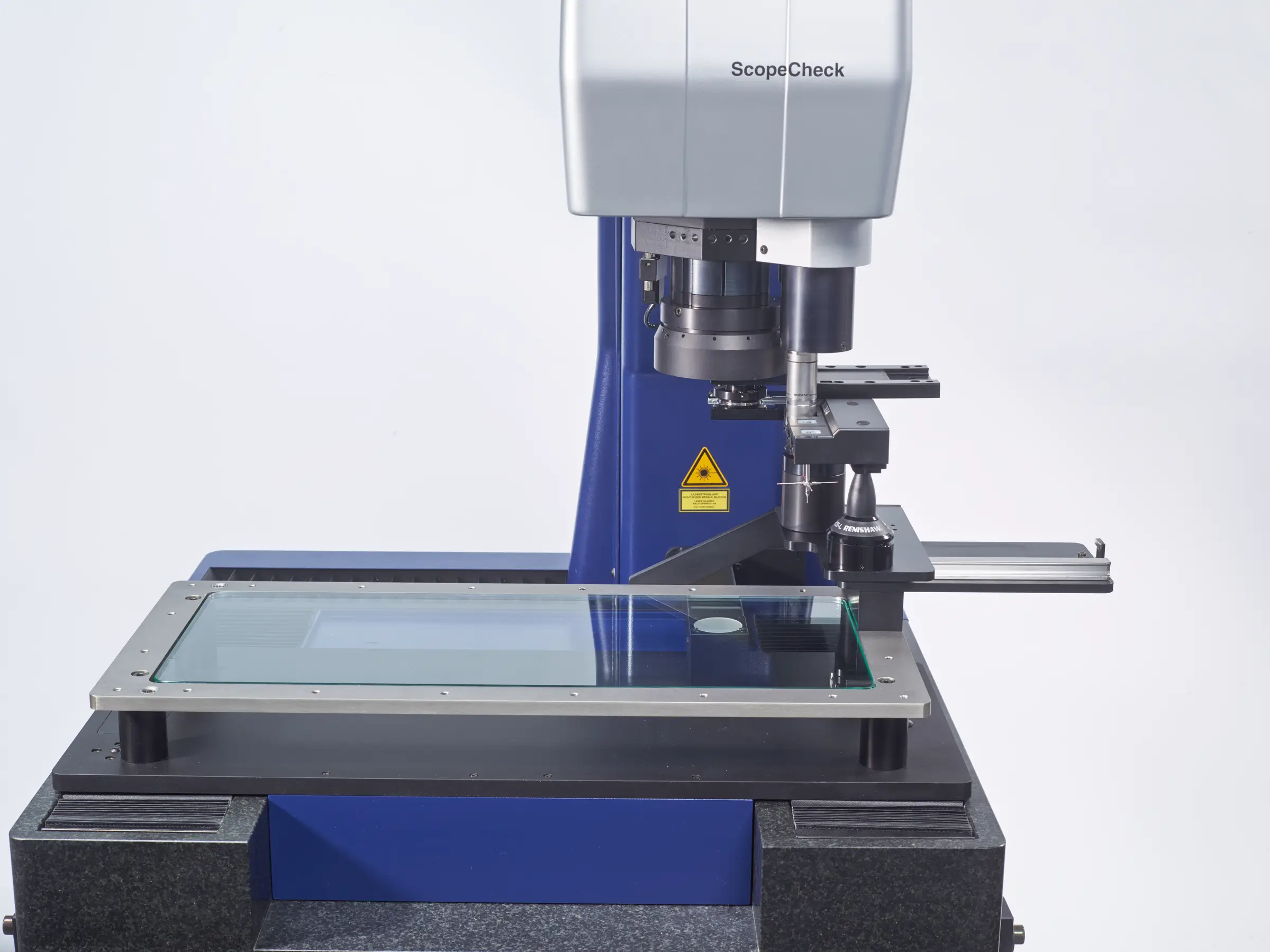

Sabit köprülü 3D CNC çok sensörlü koordinat ölçüm makinesi

Ölçüm aralığı

X = 400 mm to 1000 mm, Y = 400 mm to 1000 mm, Z = 200 mm to 300 mm

Hassasiyet

İzin verilen uzunluk ölçüm hatası 2,5 µm'ye kadar

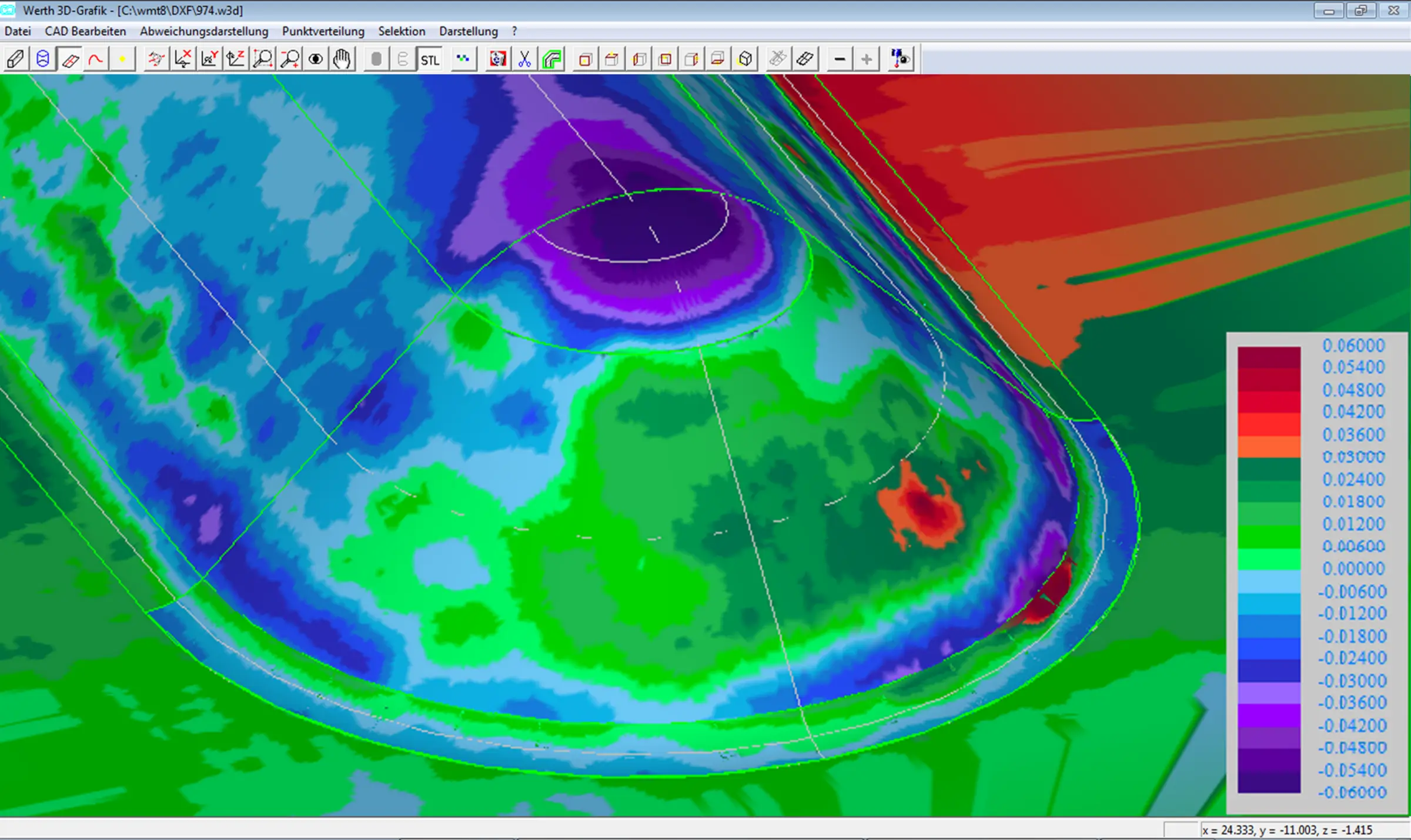

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...