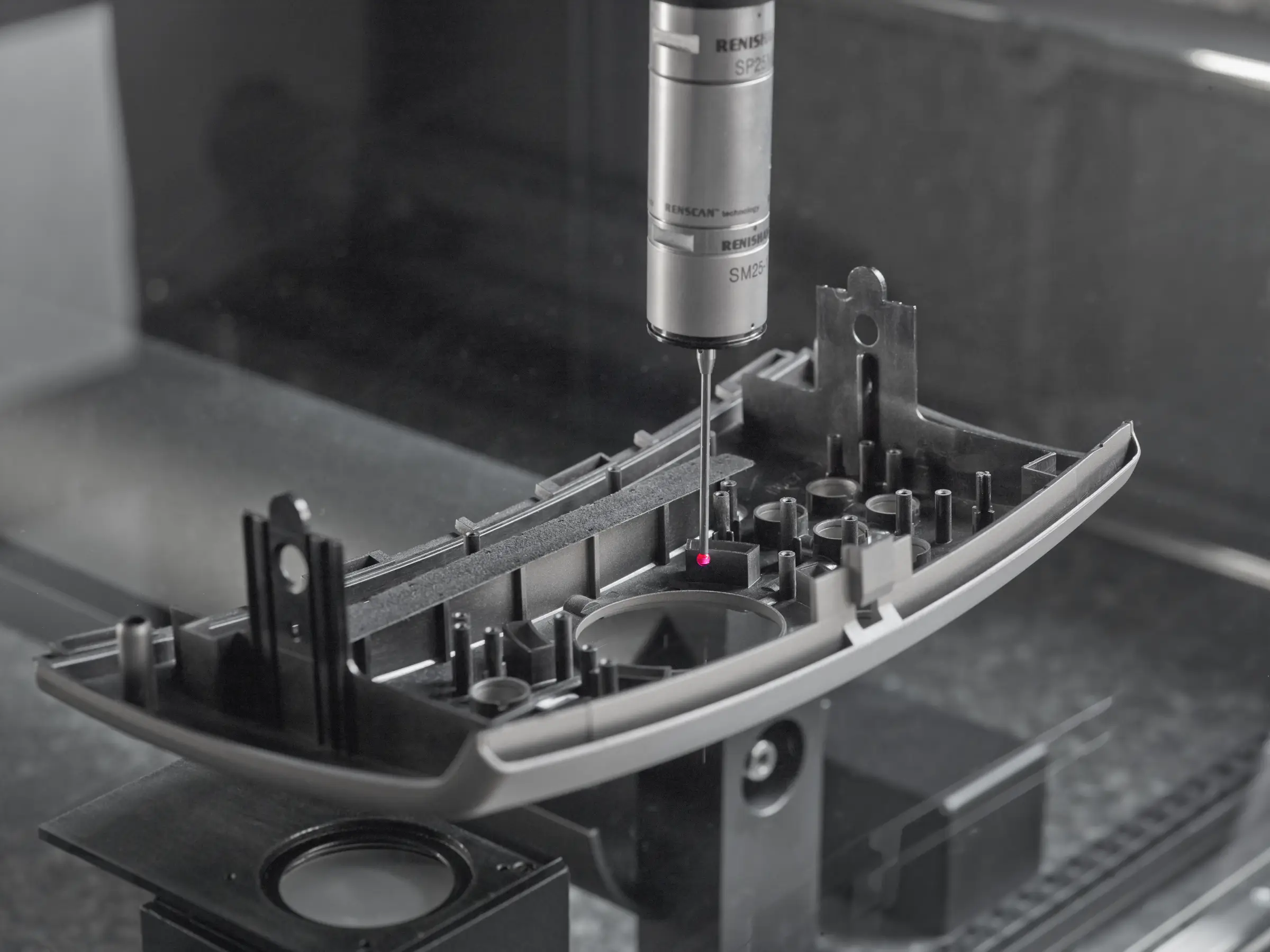

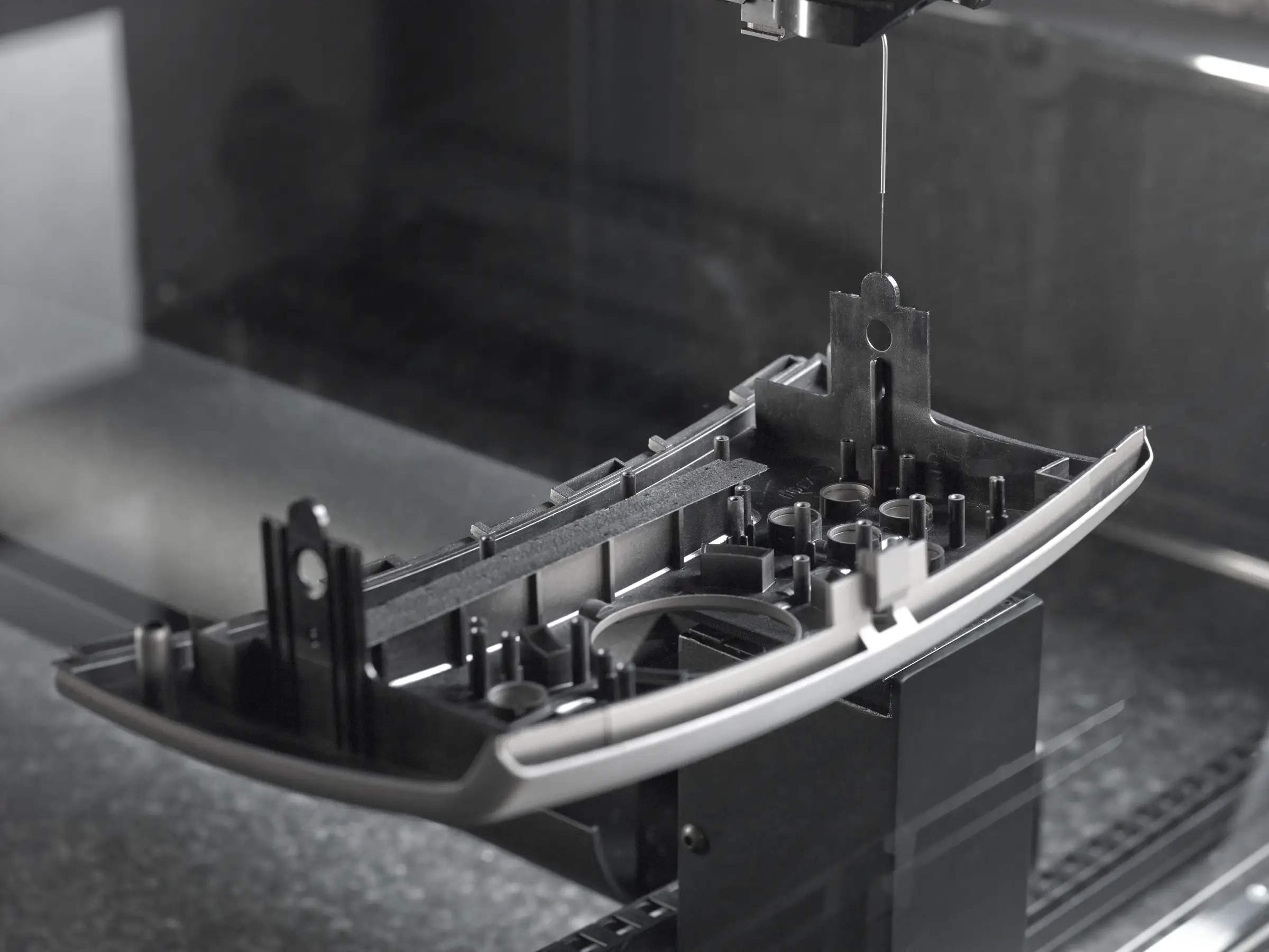

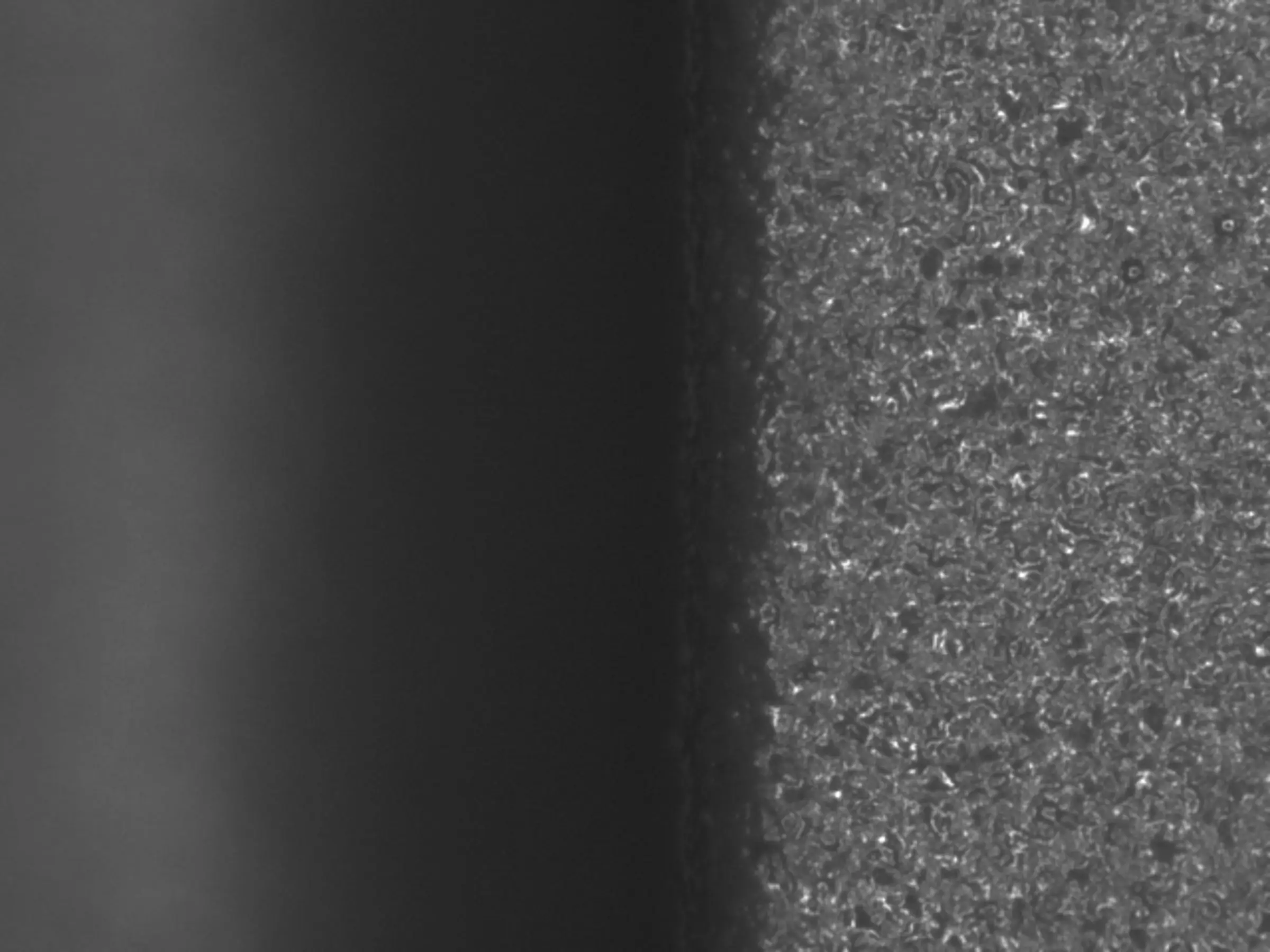

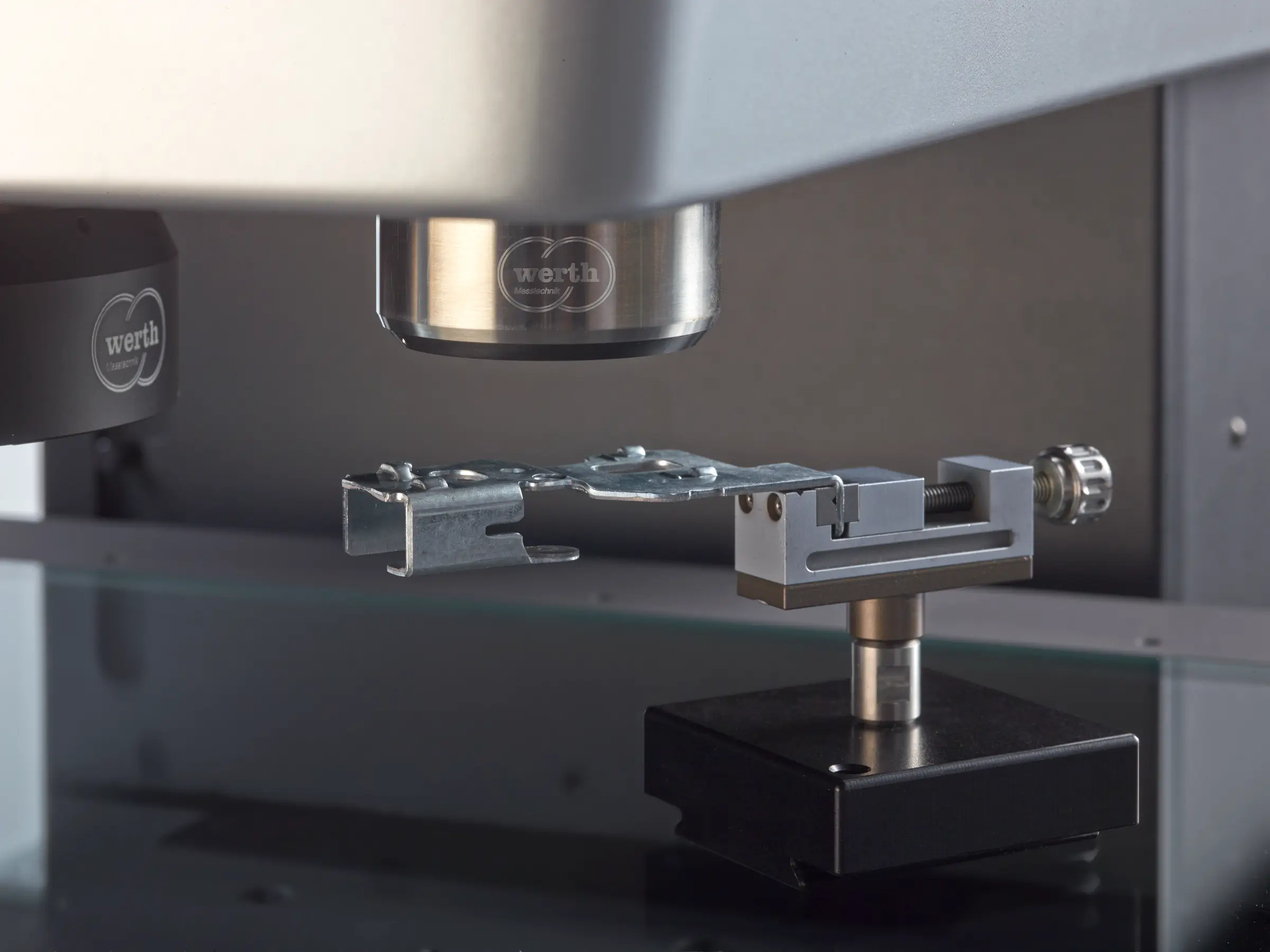

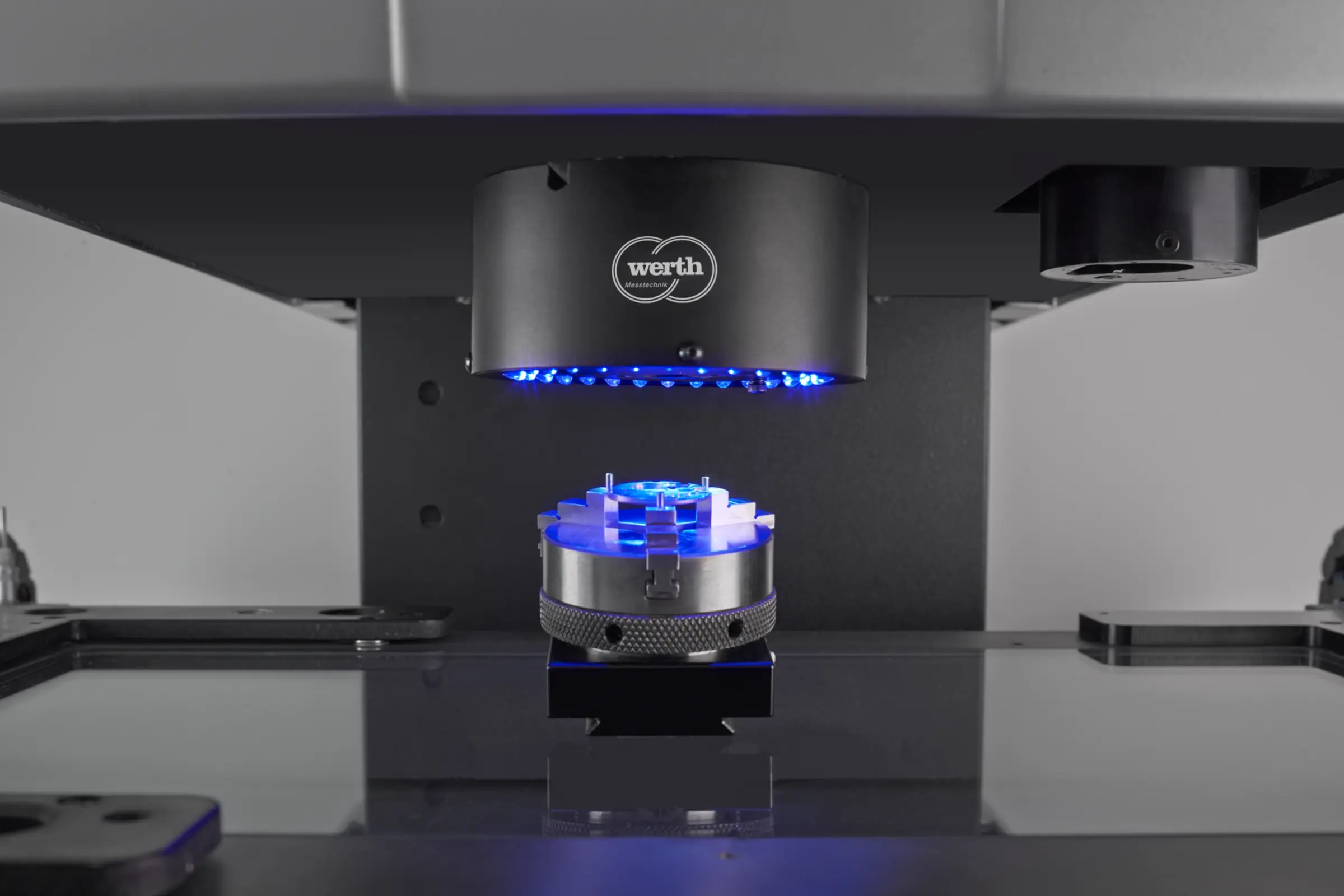

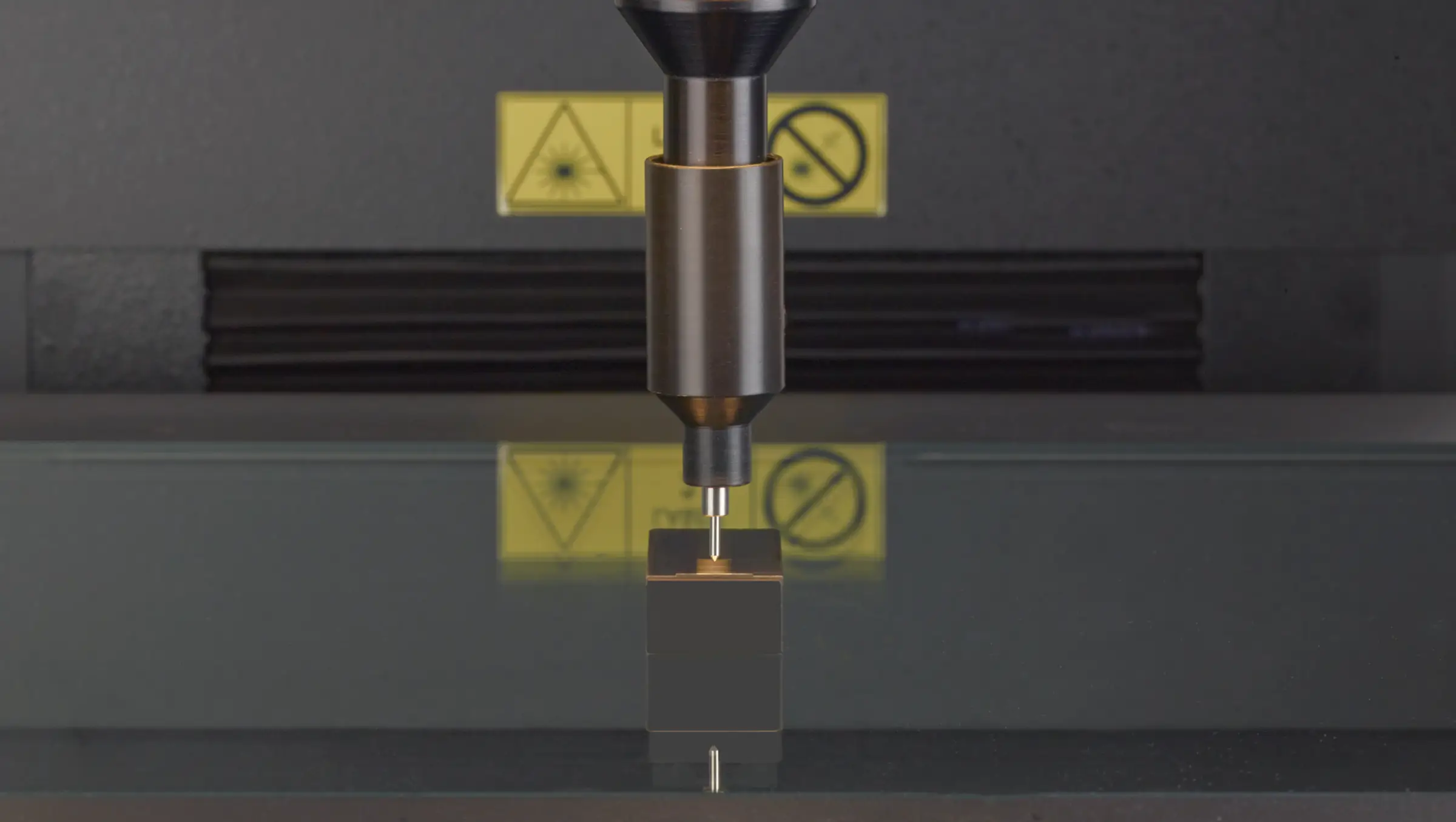

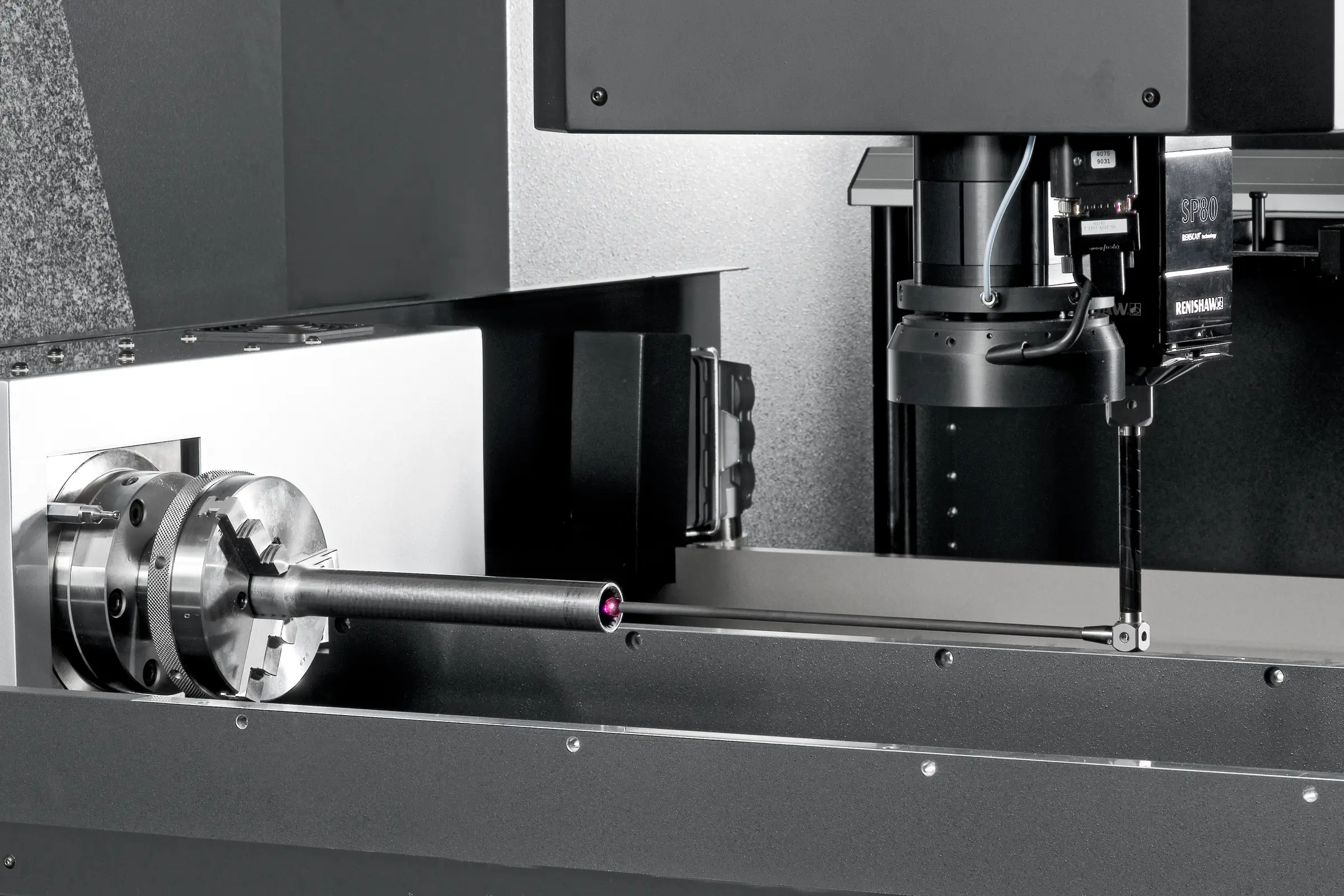

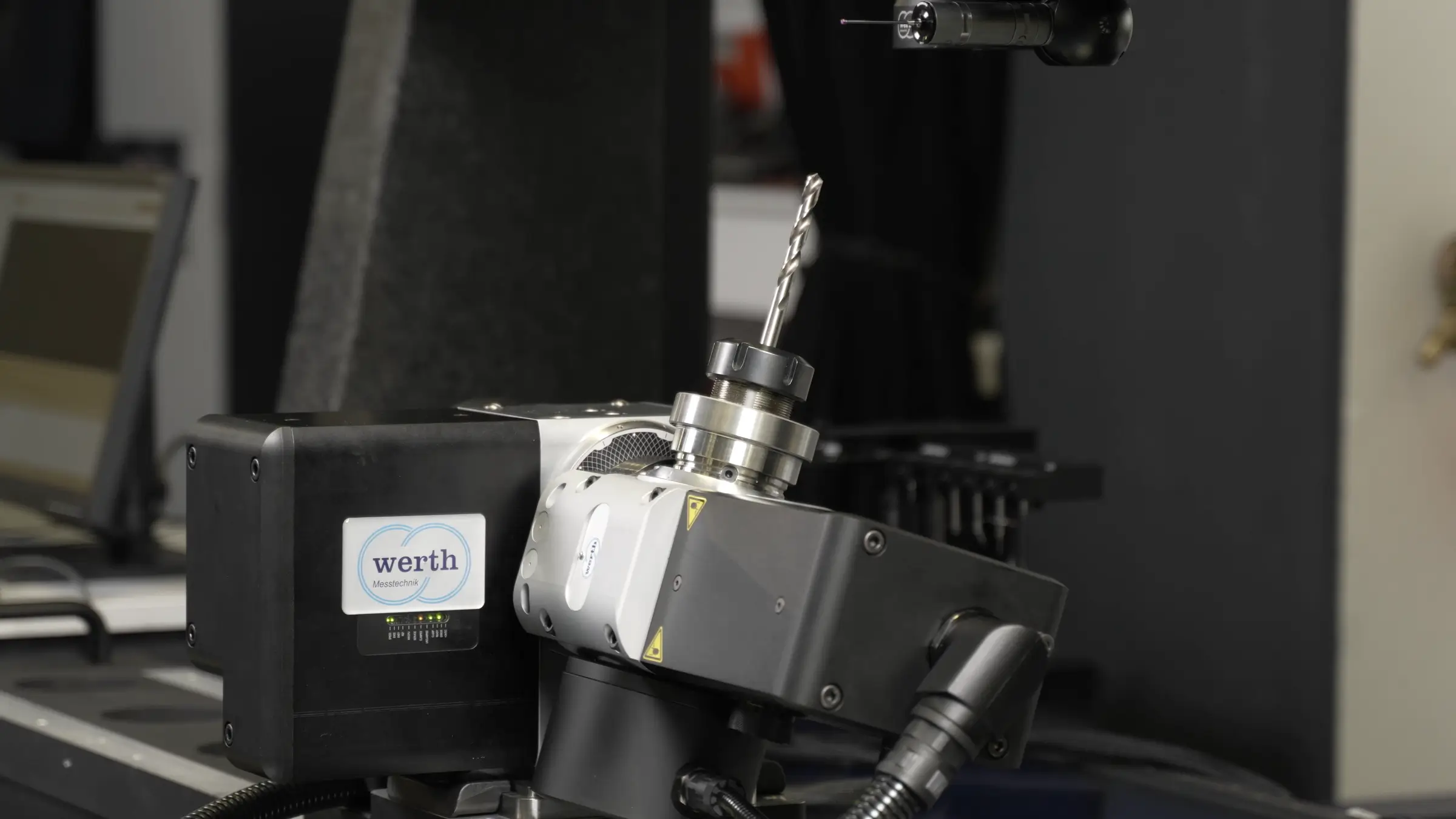

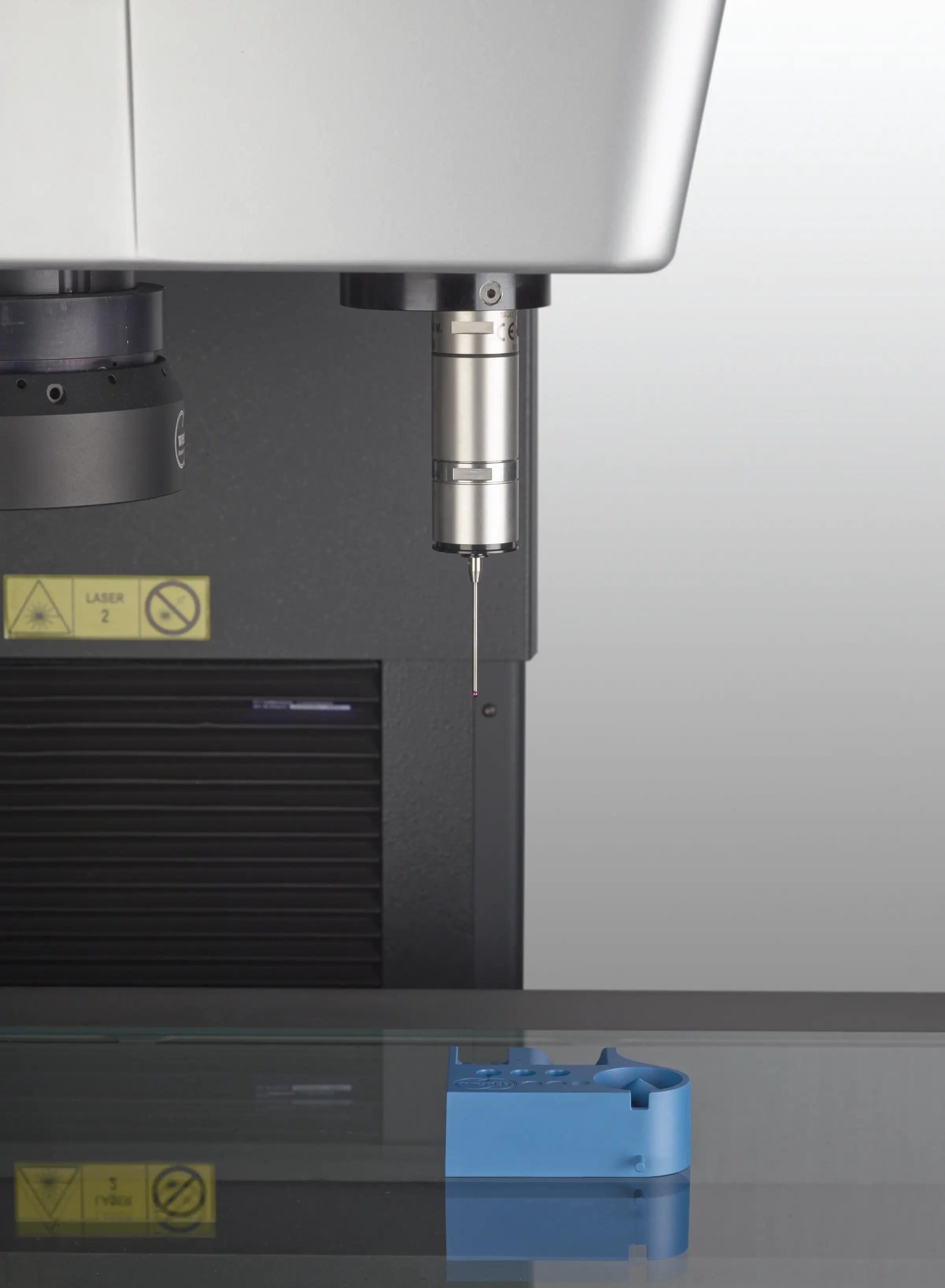

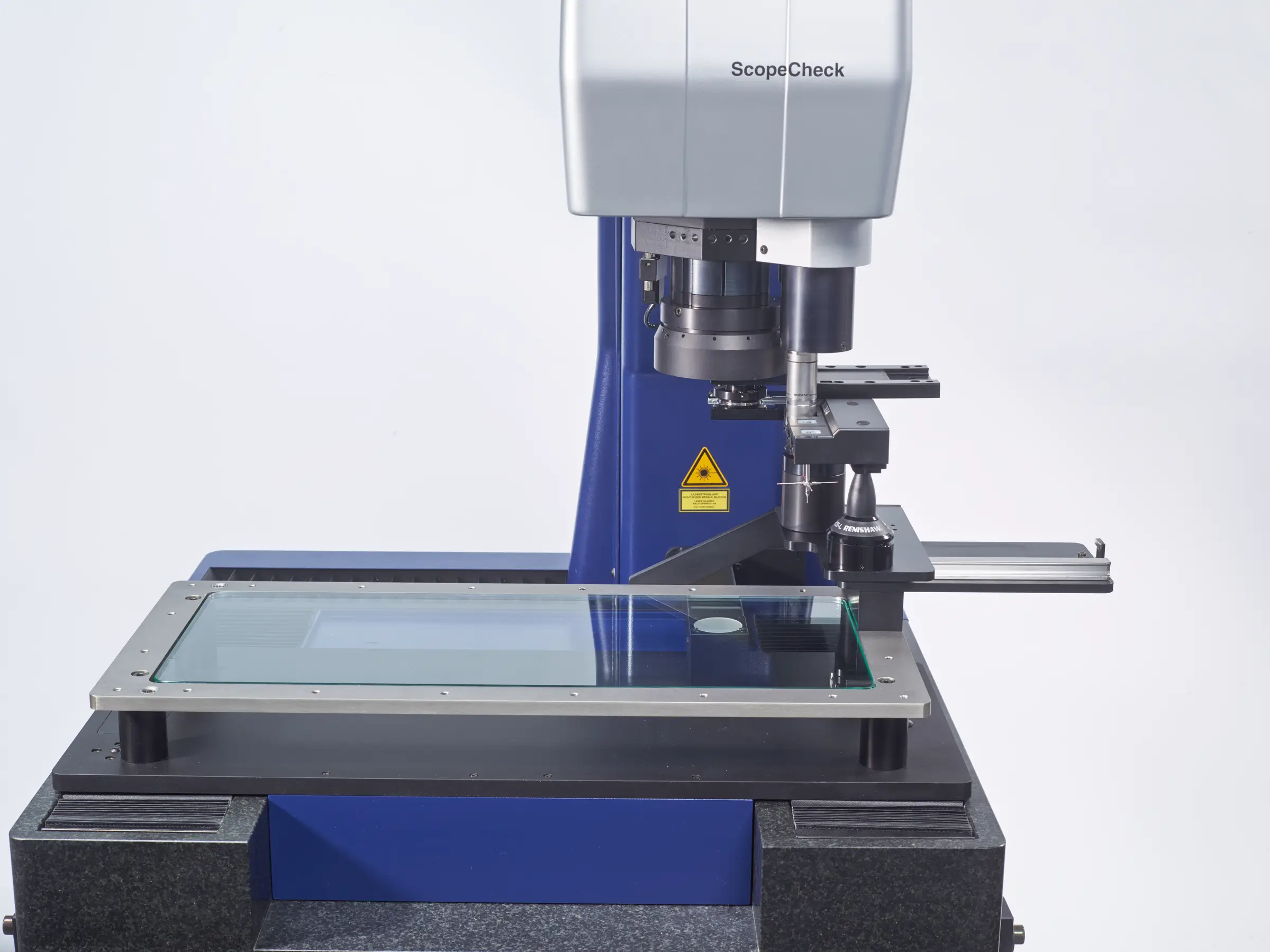

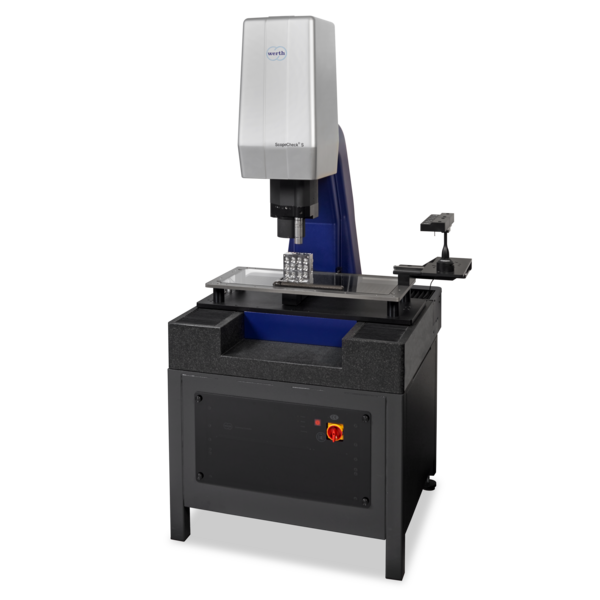

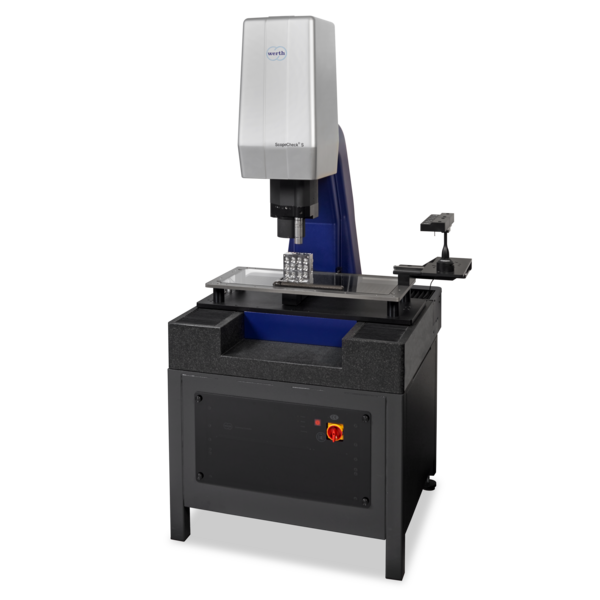

Kompakt ScopeCheck® S, granit ve polimer betondan üretilmiş, korumalı kılavuz yolları ve ölçekleri ile sıcaklık dengeleme özelliğine sahip son derece sağlam bir tasarıma sahiptir ve bu nedenle üretime yakın kullanım için optimize edilmiştir. Temel konfigürasyona dahil olan Werth görüntü işleme sensörü, boyutsal metrolojinin gereksinimlerine özel olarak uyarlanmıştır ve en zorlu kontrast koşullarında bile güvenilir Kenar Bulucu sağlar. Farklı odak değişimi yöntemleri optik 3B ölçümlere olanak tanır. Tipik uygulama alanları tornalanmış, frezelenmiş, plastik, delinmiş ve bükülmüş parçalardır.

ScopeCheck® S

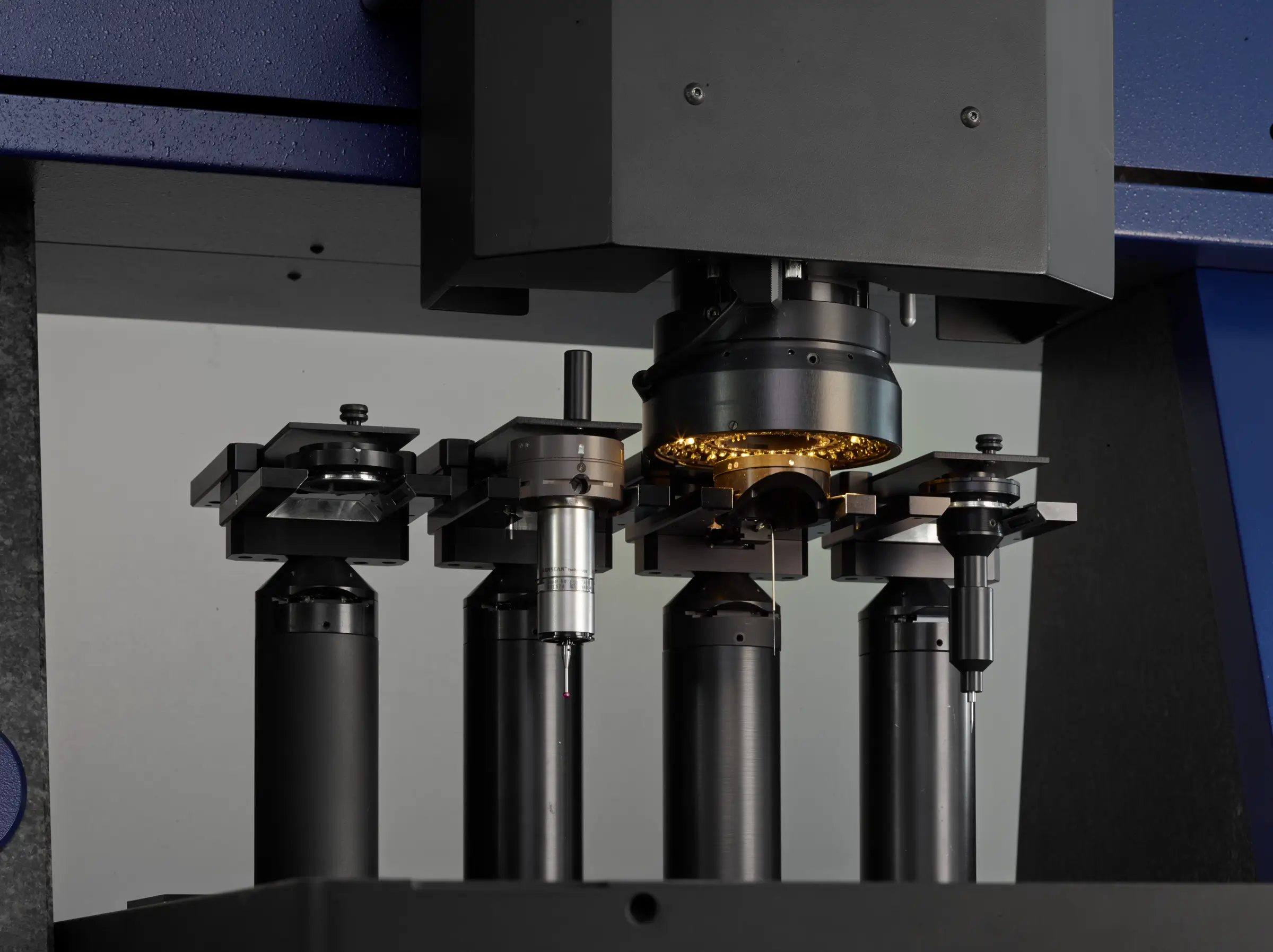

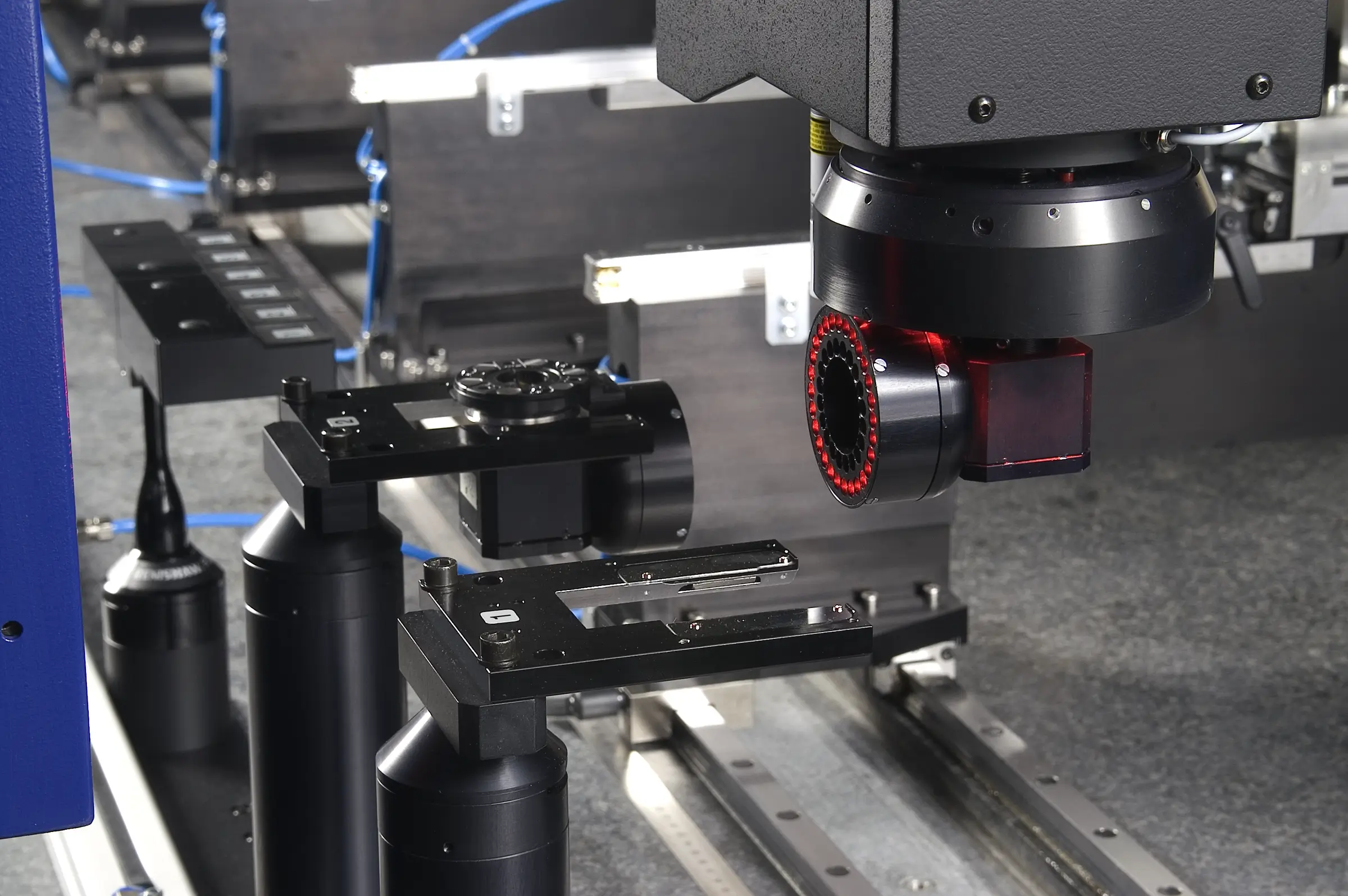

0,9x ila 4,3x entegre motor yakınlaştırma optiği veya 1x ila 100x değiştirilebilir optikler.

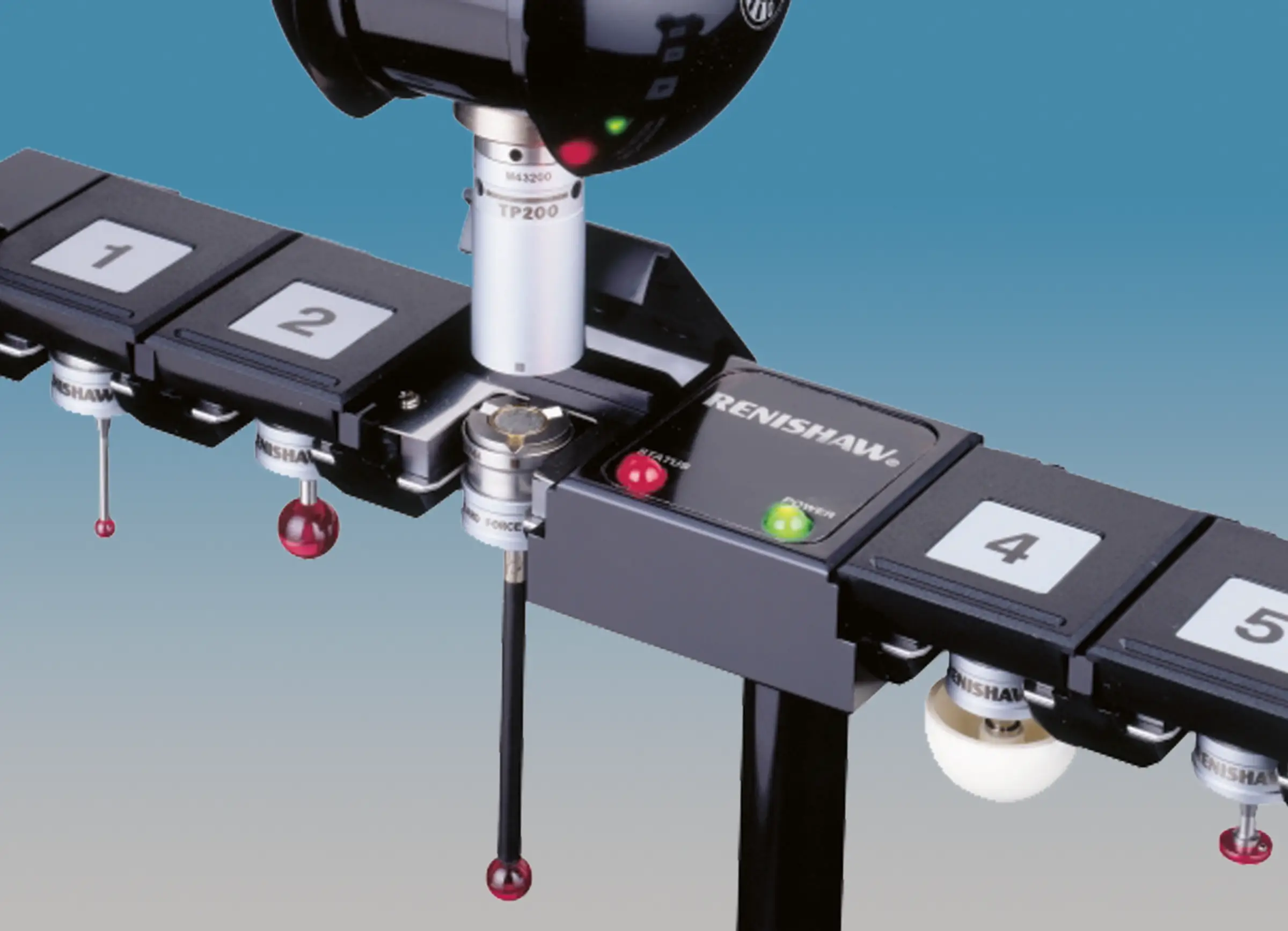

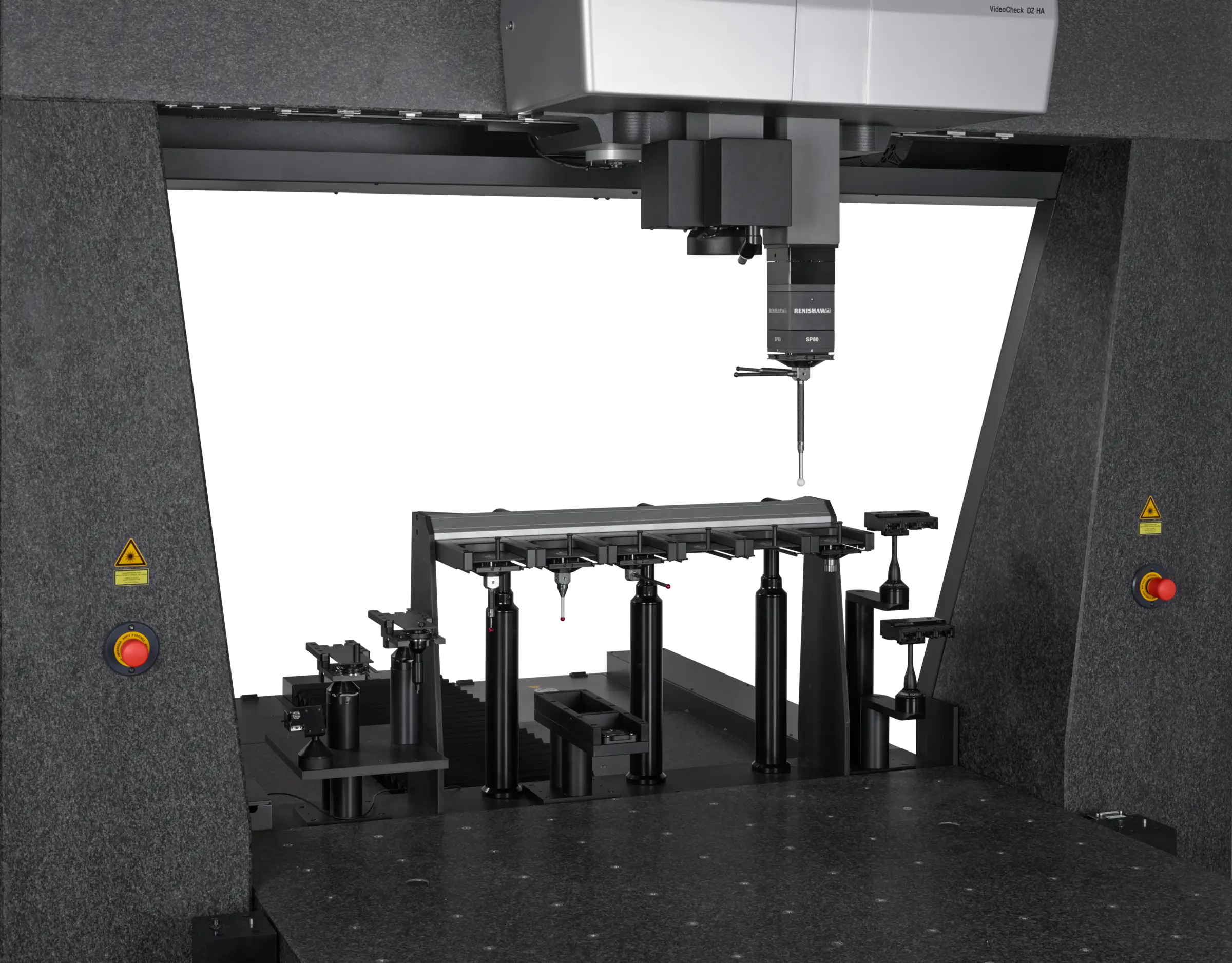

Ek sensörlerin, döner veya döner/eğimli eksenlerin entegrasyonu sayesinde artırılmış esneklik.

Gelen ve iletilen ışıkta düzenli ve serbest biçimli geometrilerin otomatik ölçümü için kontur görüntü işleme.

ISO 10360'a göre belirtilen uzunluk ölçümü ve ölçüm hataları.

Tasarım

Tek bir düzlemde kılavuz yollara sahip 3D CNC çok sensörlü koordinat ölçüm makinesi

Ölçüm aralığı

X = 300 mm / 400 mm, Y = 200 mm, Z = 200 mm

Hassasiyet

İzin verilen uzunluk ölçüm hatası 1,5 µm'ye kadar

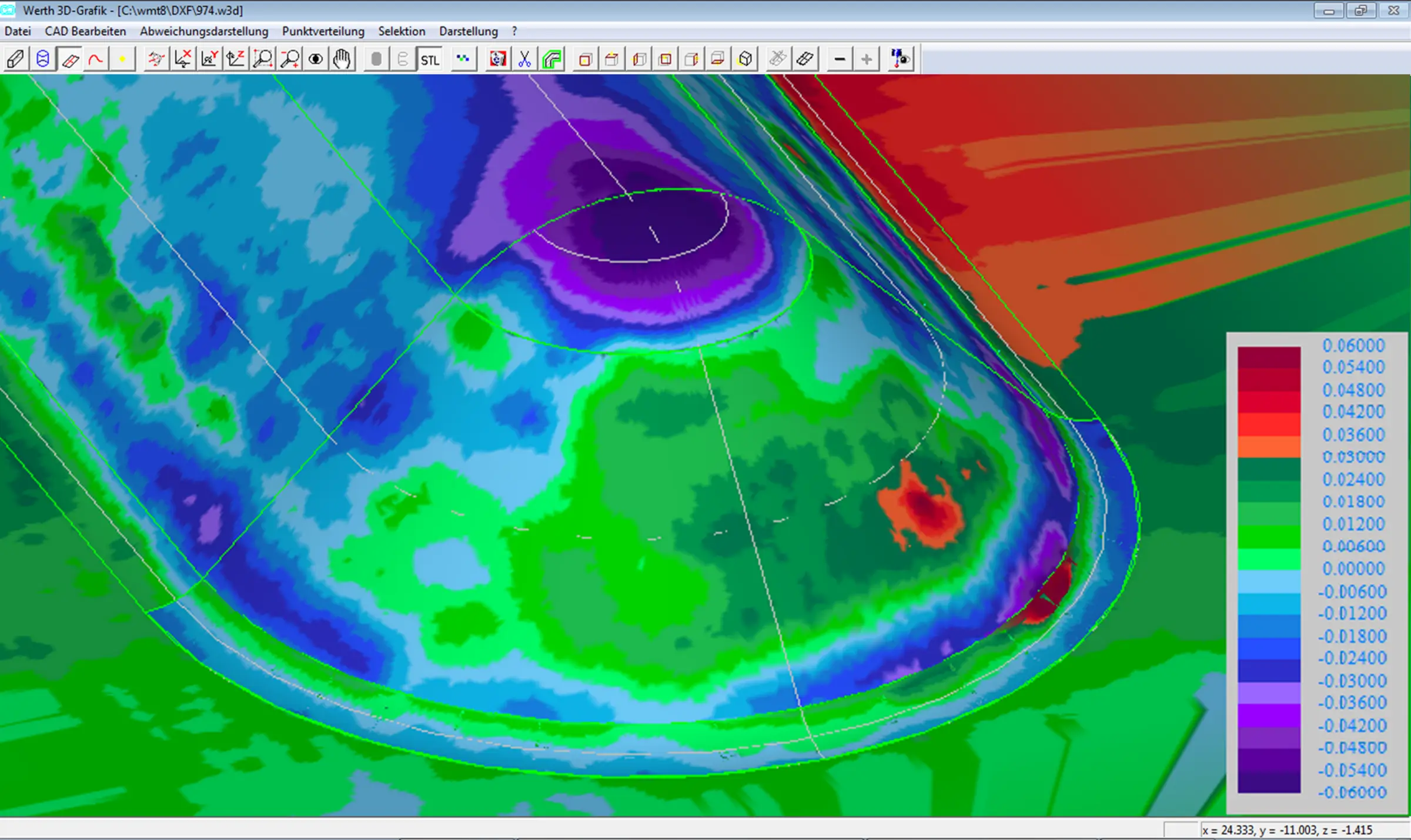

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...