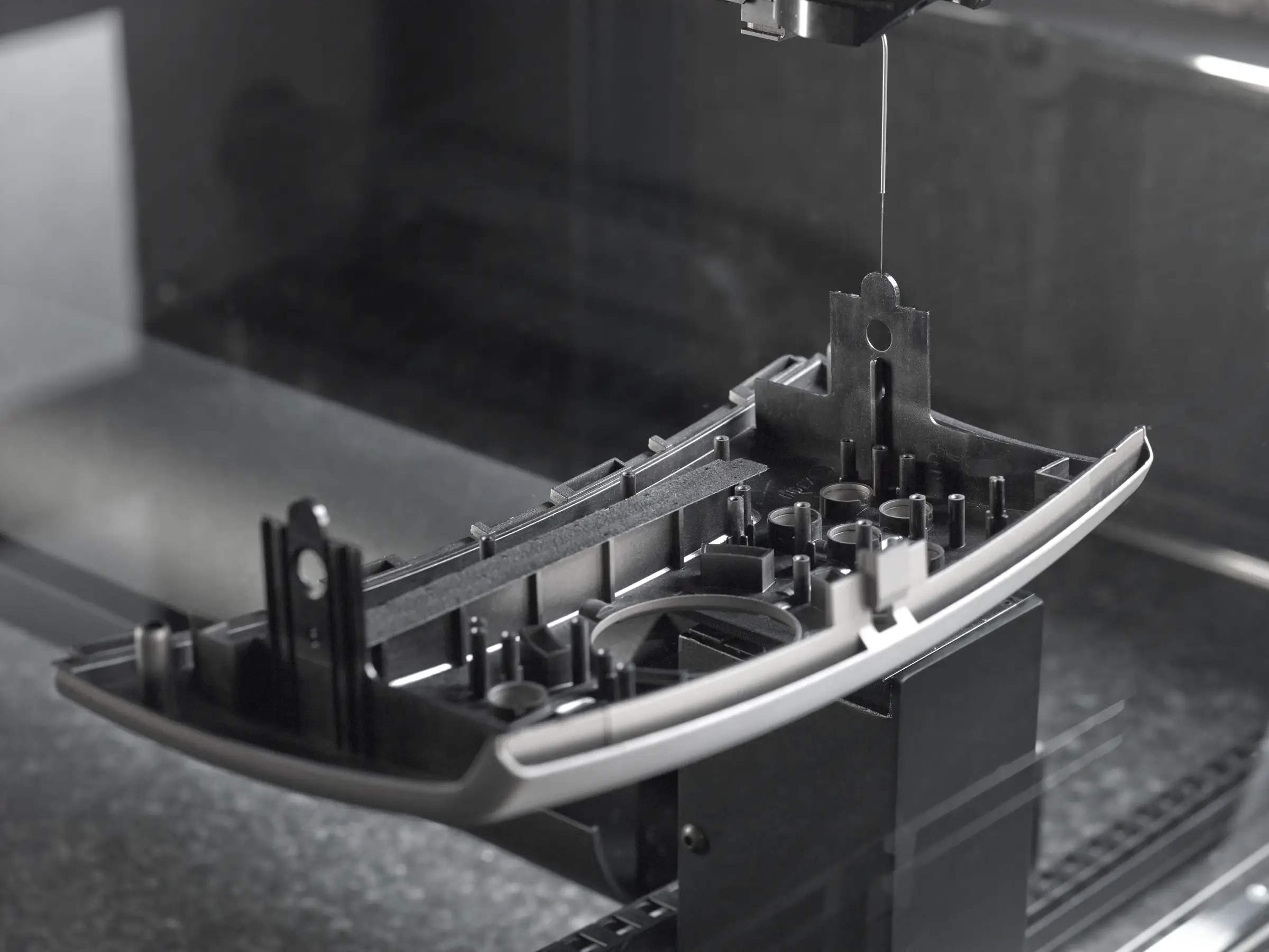

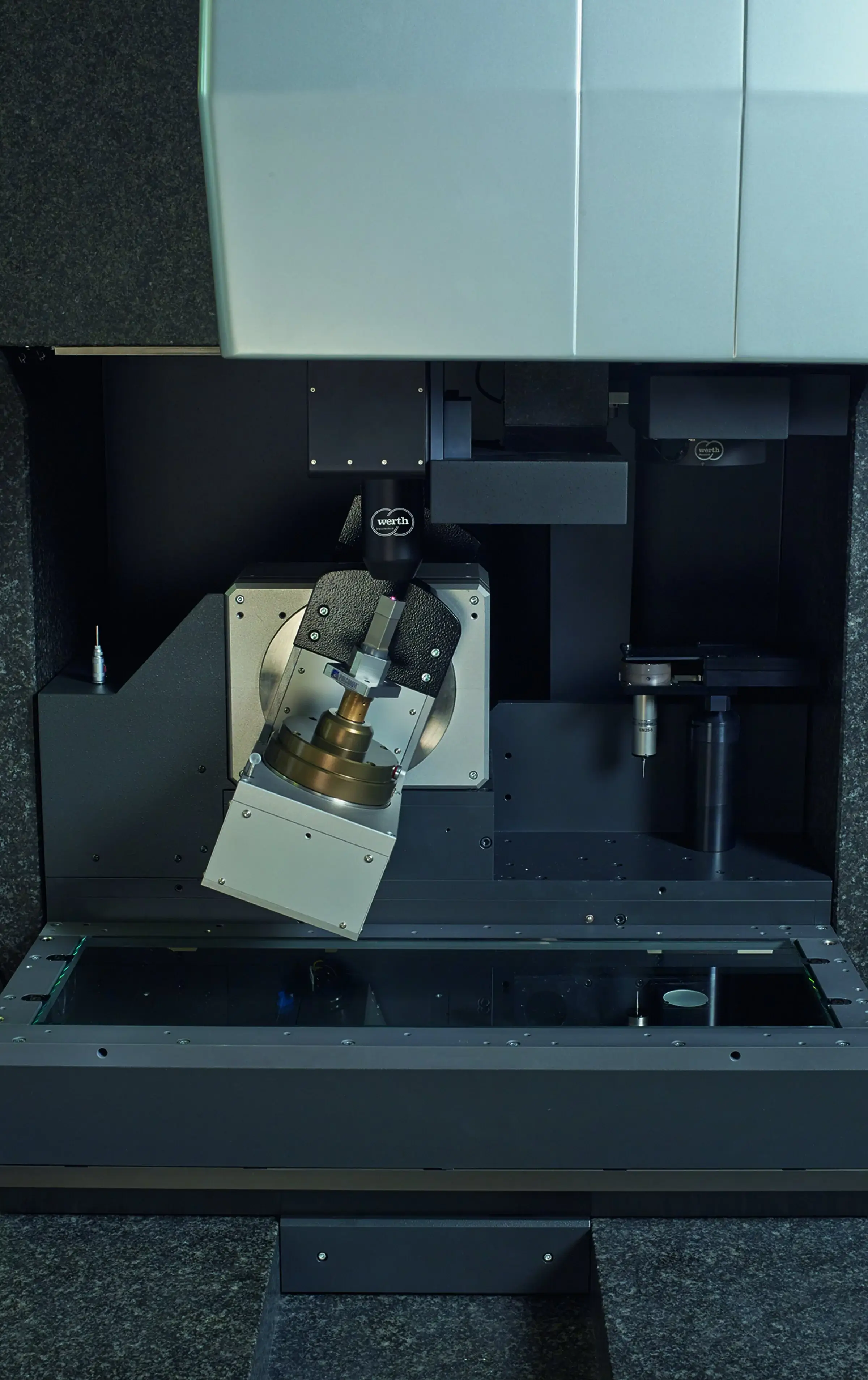

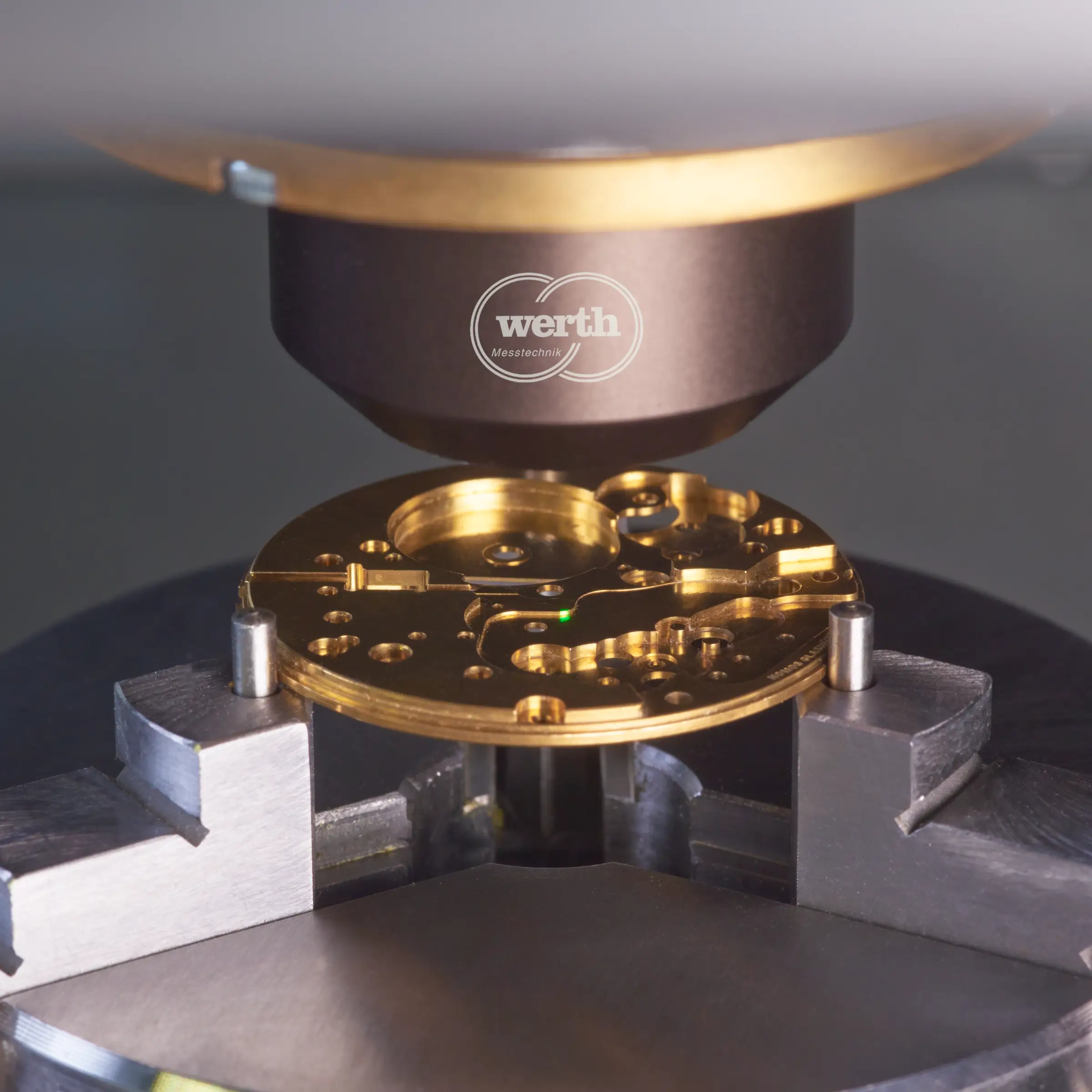

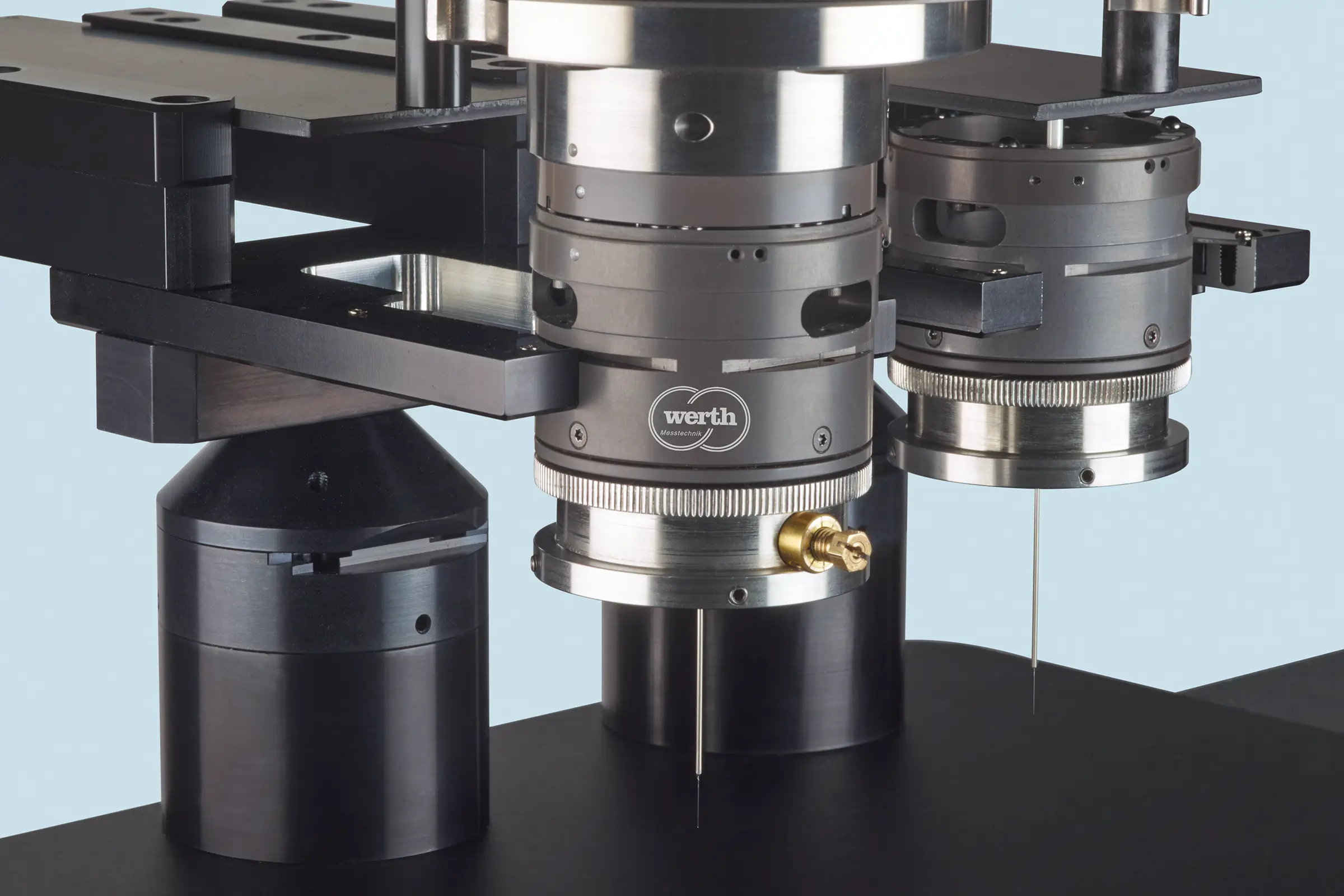

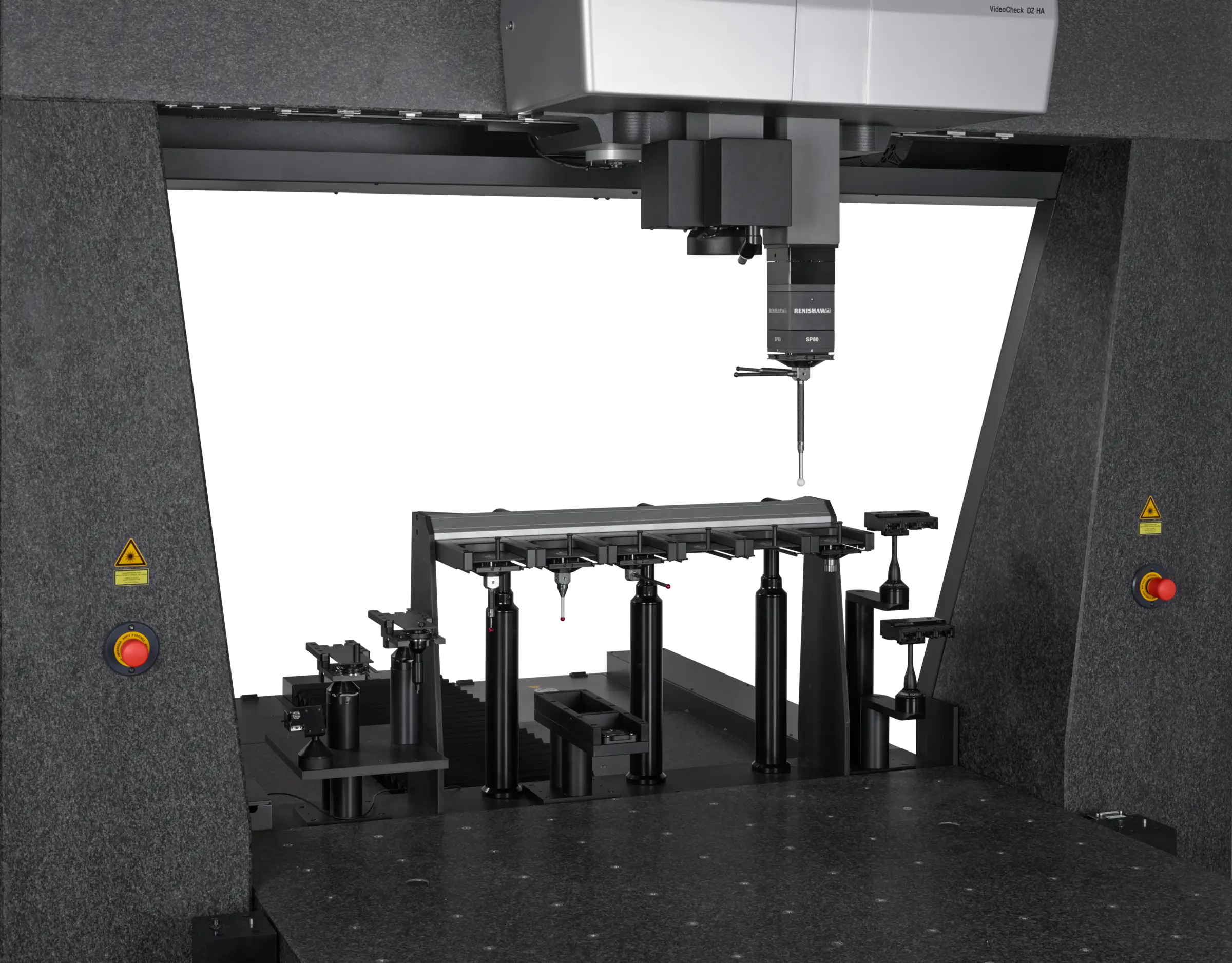

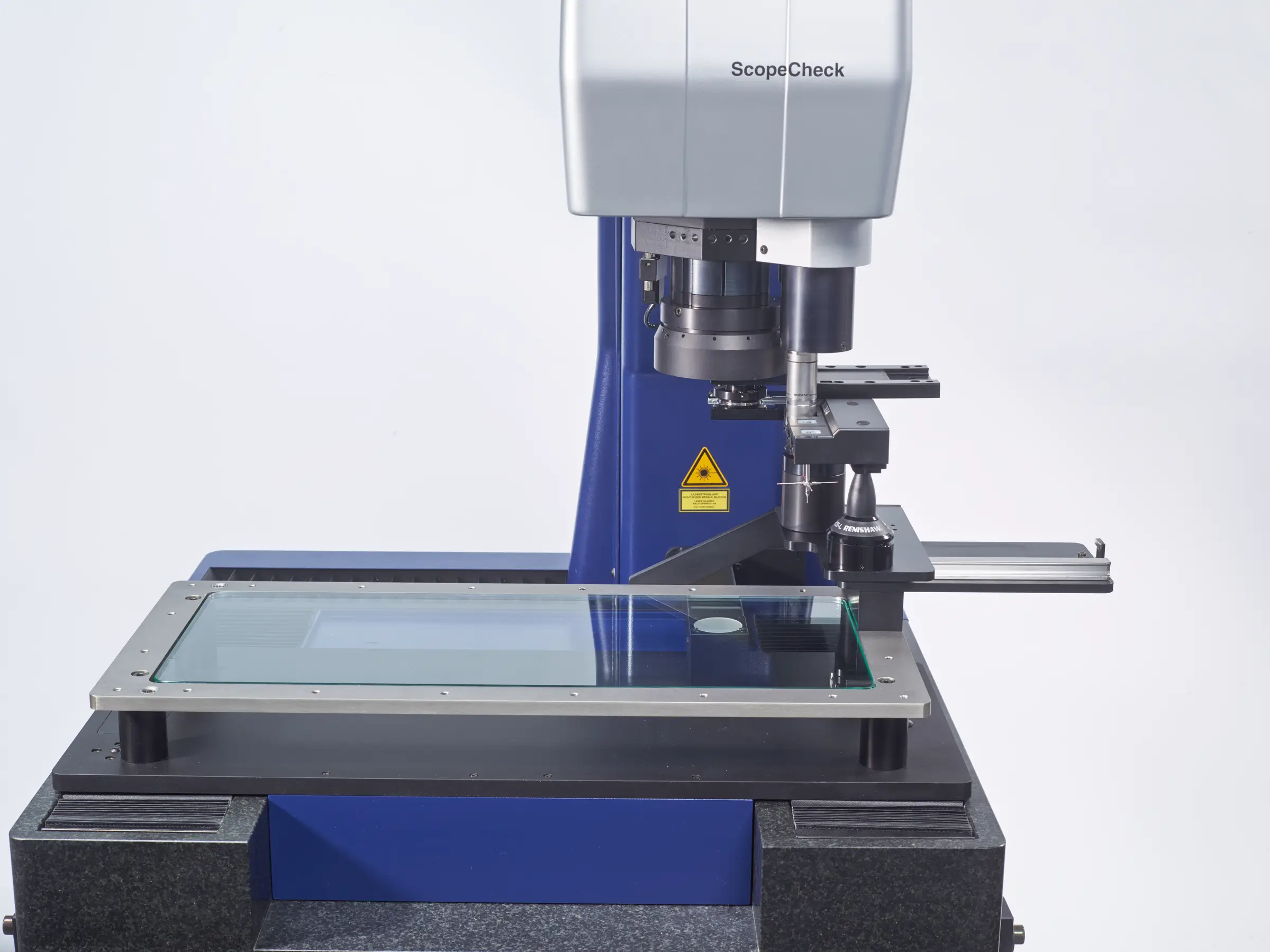

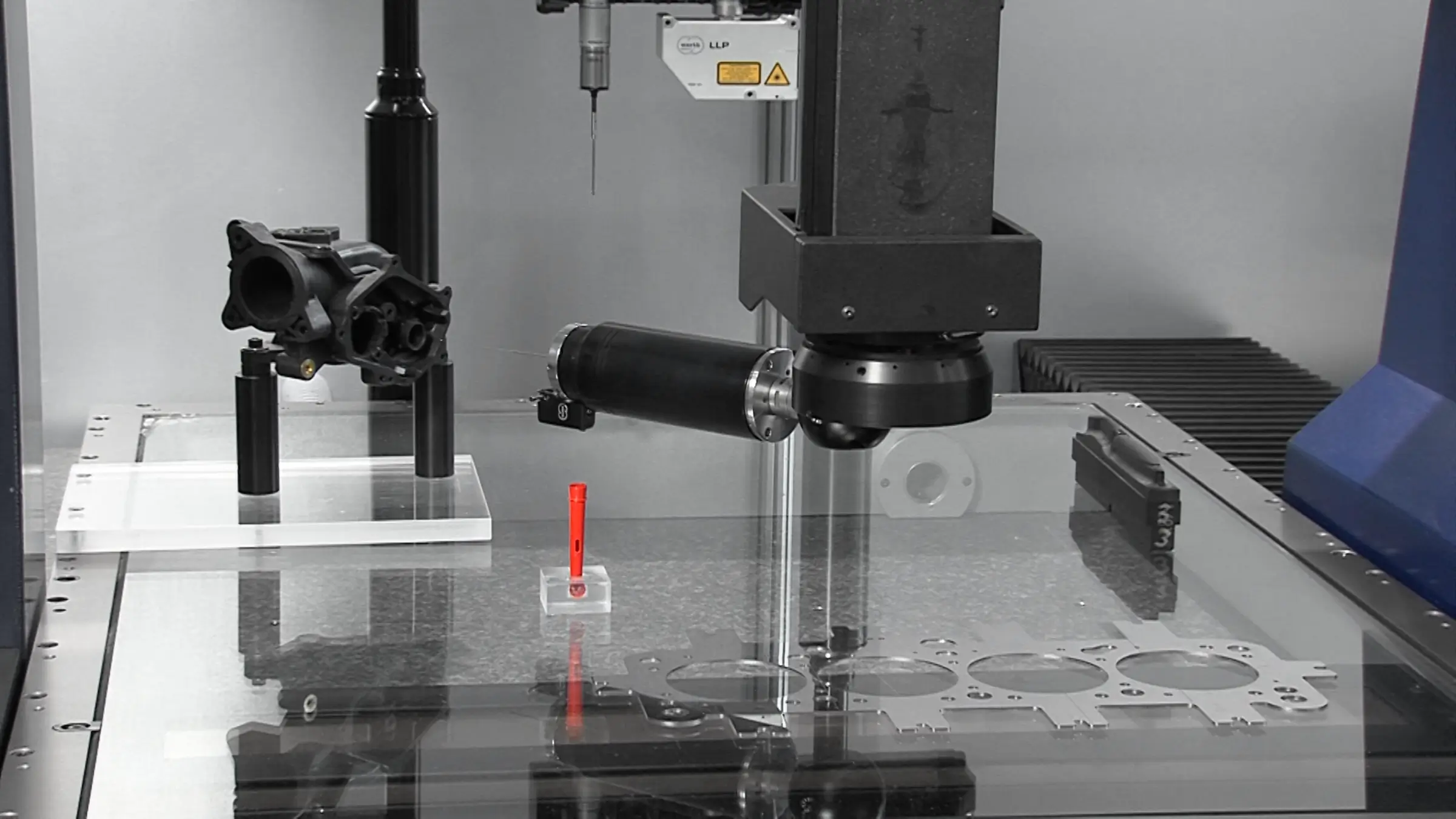

Sabit köprülü VideoCheck® FB, birden fazla bağımsız sensör ekseni (ram) ile donatılabilir. Sabit köprülü tasarım, iki hareket eksenini birbirinden ayırır ve üç eksenin de ölçekleri merkezi olarak düzenlenebilir. Bu, tasarımın yüksek rijitliğiyle birleşerek düşük ölçüm belirsizlikleri sağlar. Ayrıca, makineye kolayca erişilebilir ve dört taraftan besleme yapılabilir. VideoCheck® FB, geniş bir uygulama yelpazesine sahiptir.

VideoCheck® FB

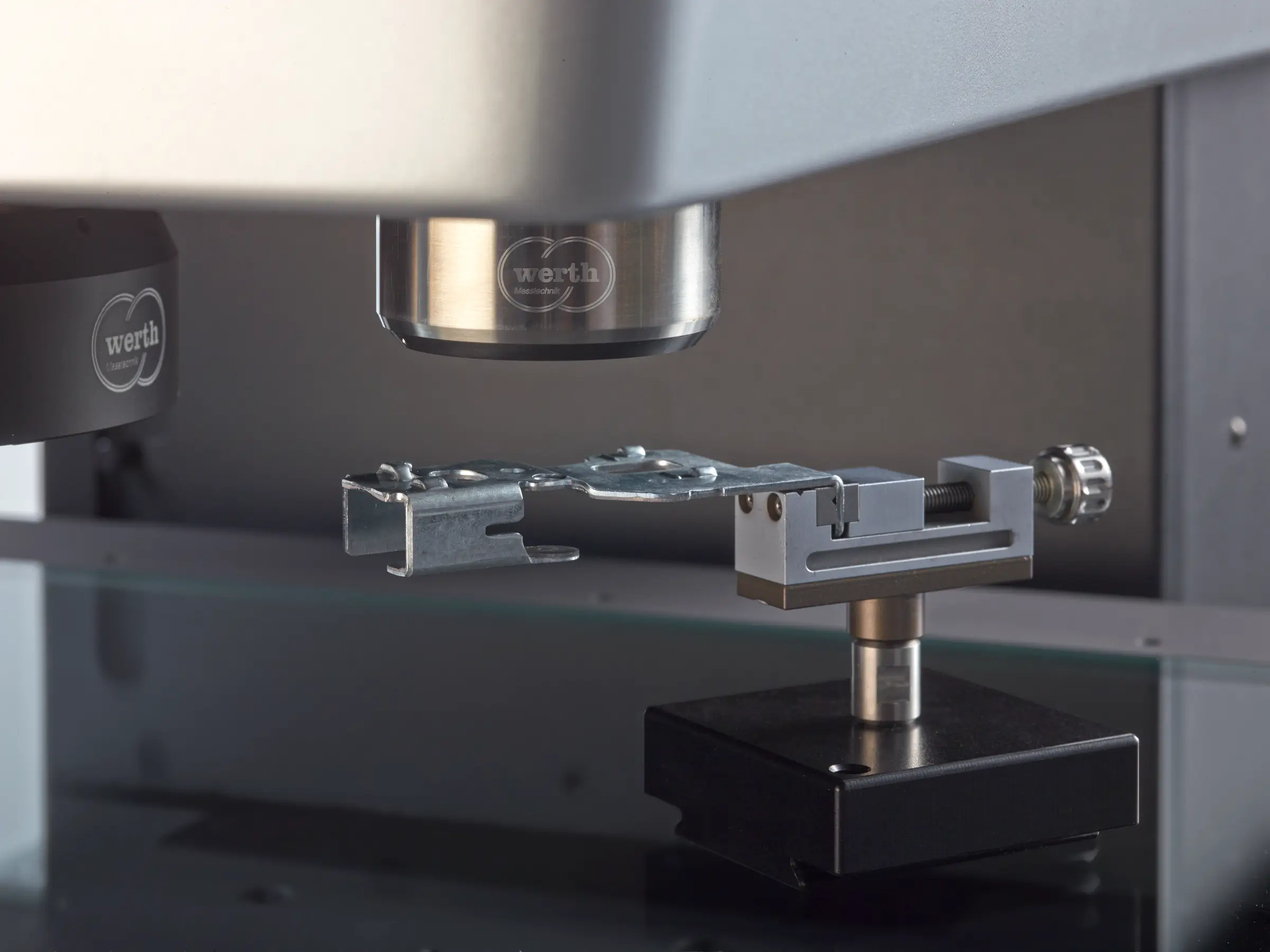

Belirtilen uzunluk ölçüm hatasına uyulması durumunda, hava yataklı granit ölçüm aşaması 100 kg'a kadar veya isteğe bağlı olarak 250 kg ile yüklenebilir.

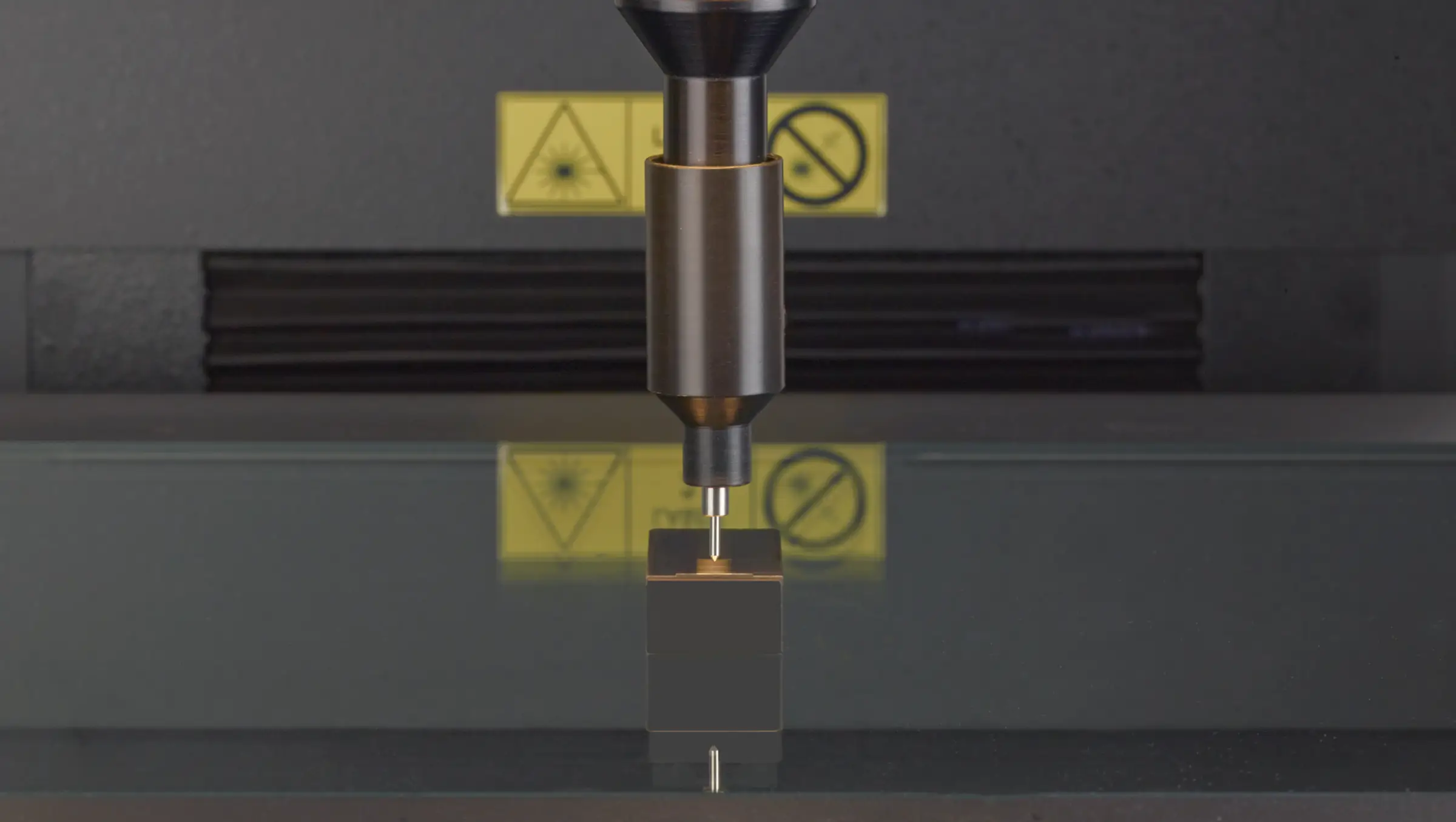

Özellikle ağır iş parçalarındaki ölçümler için, iletilen ışık ünitesini çıkarmak mümkündür

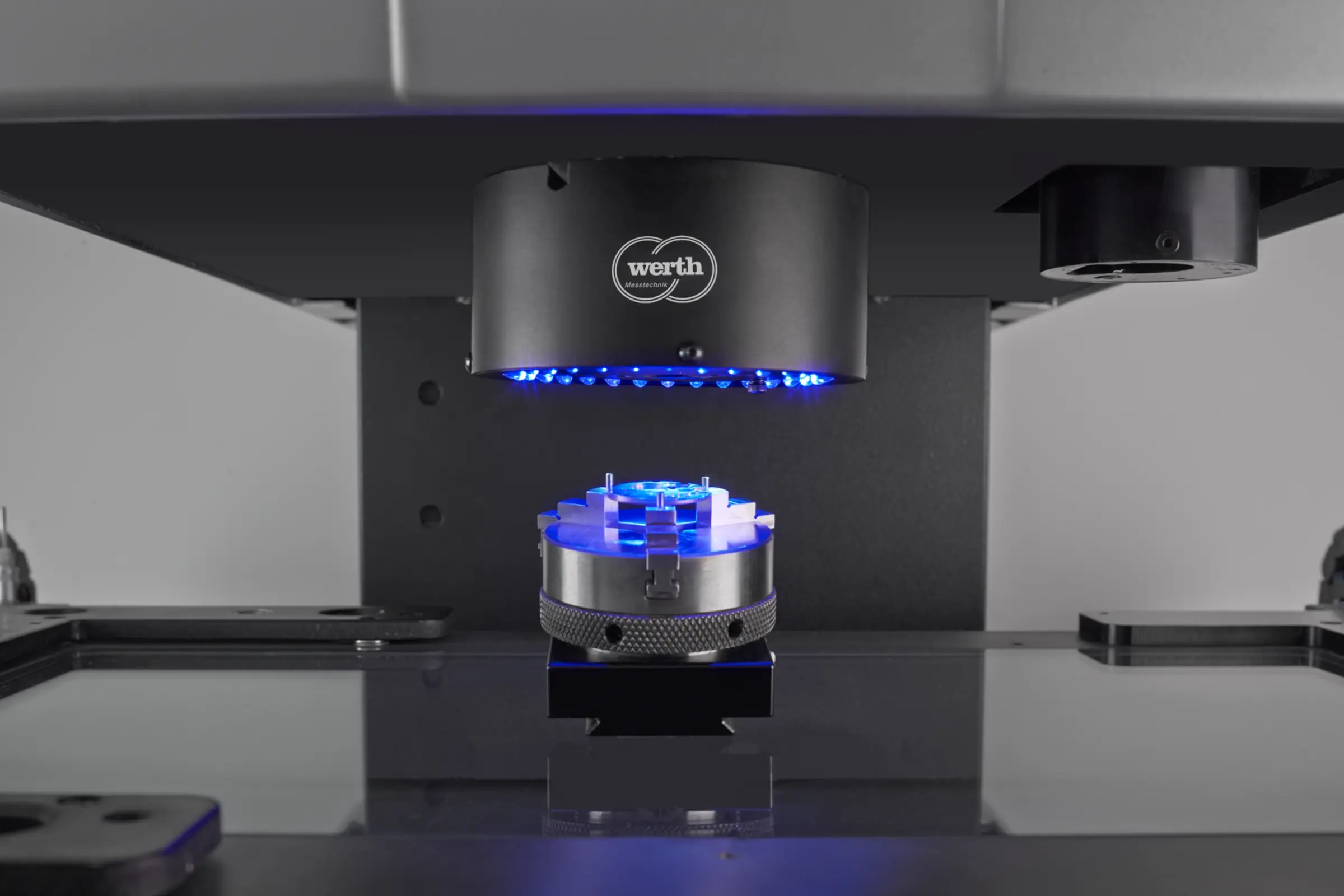

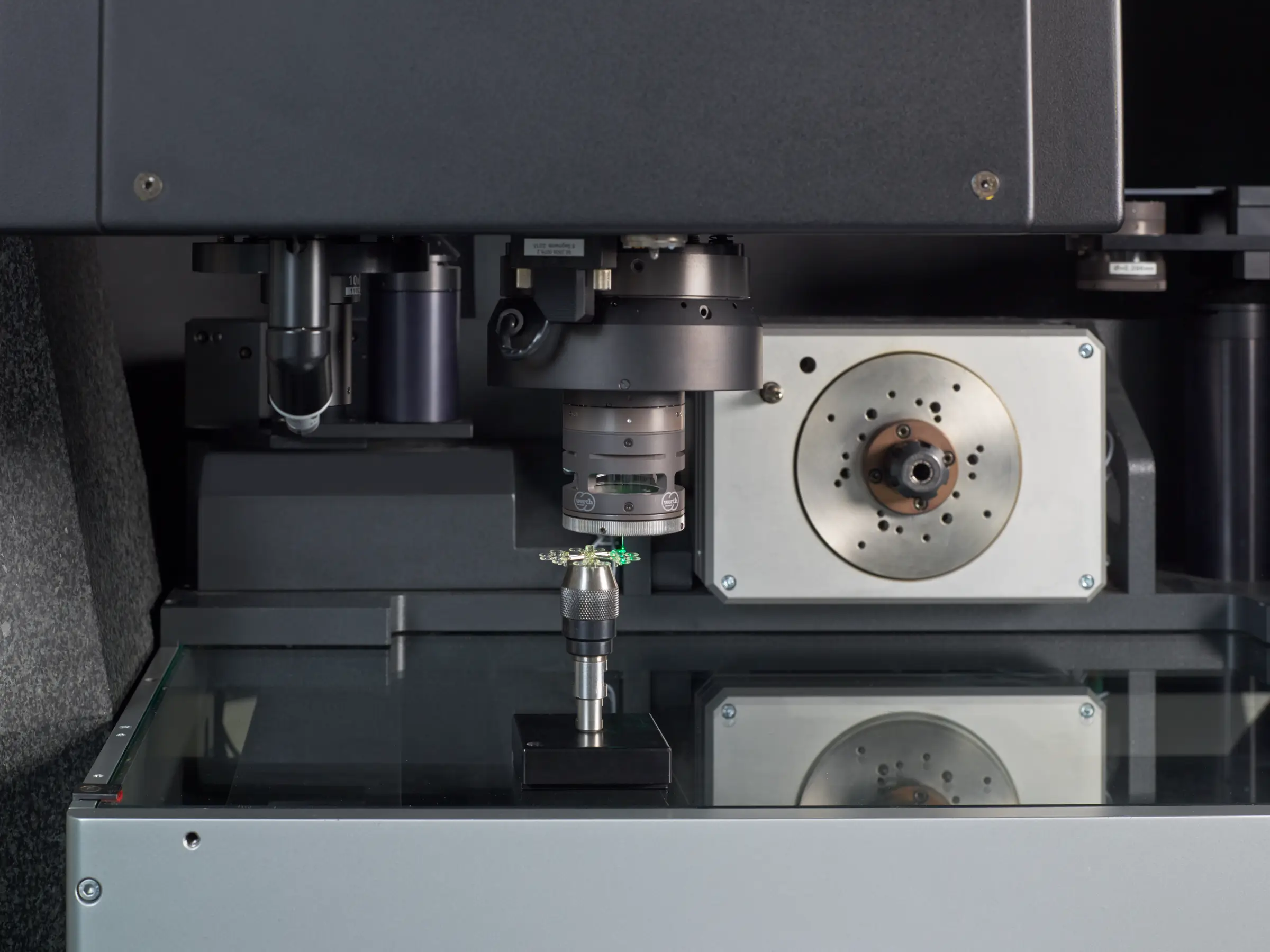

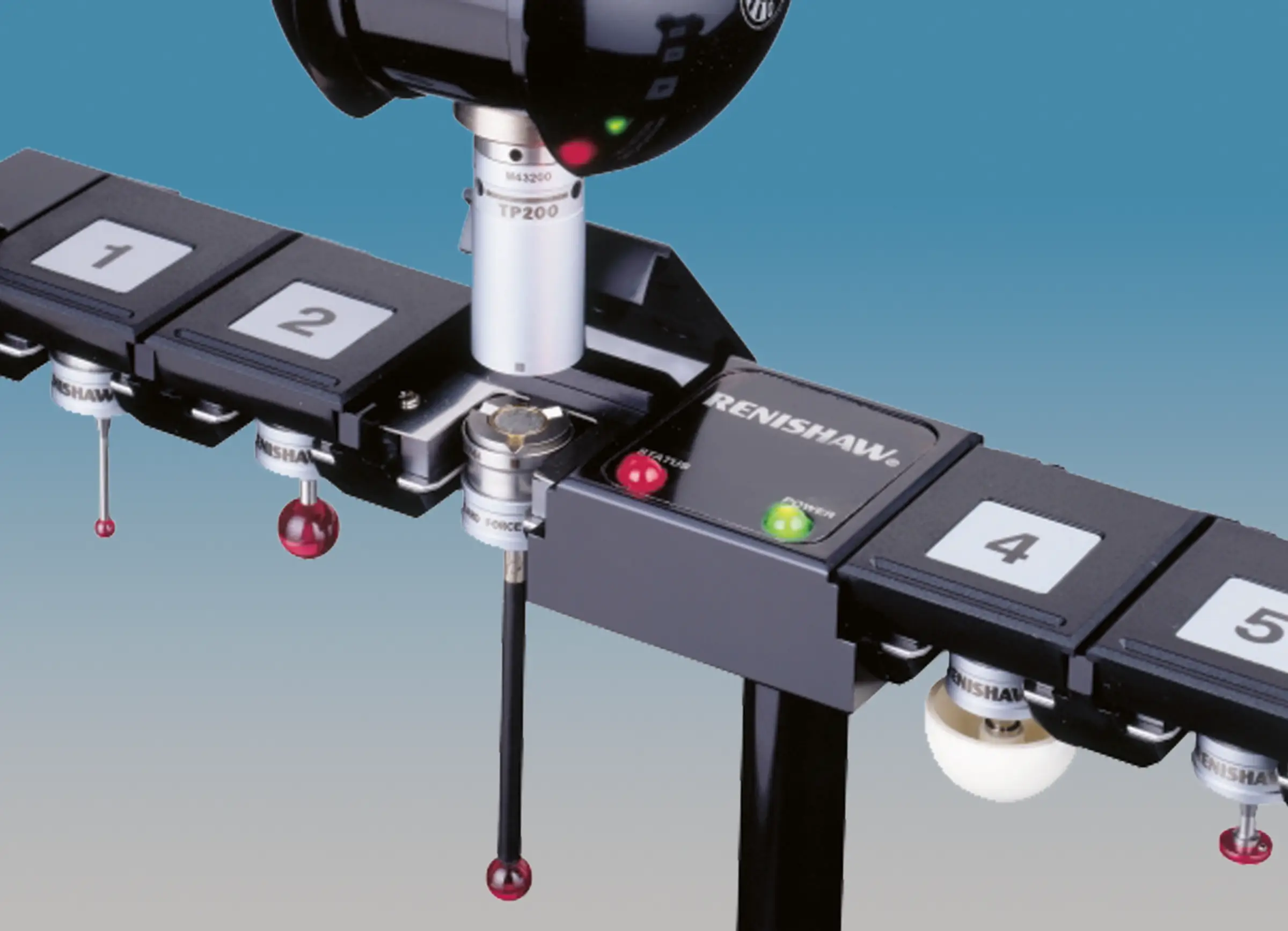

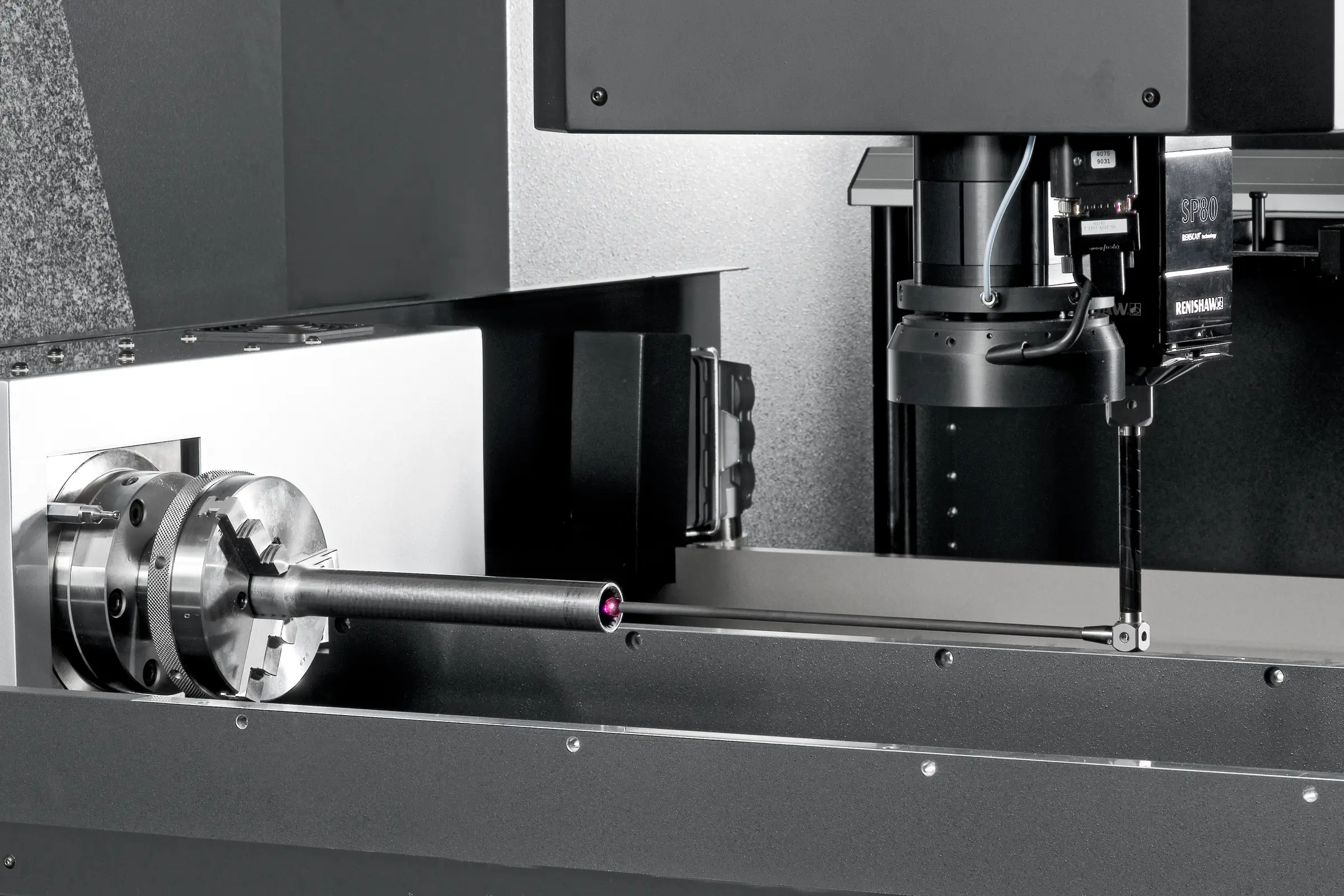

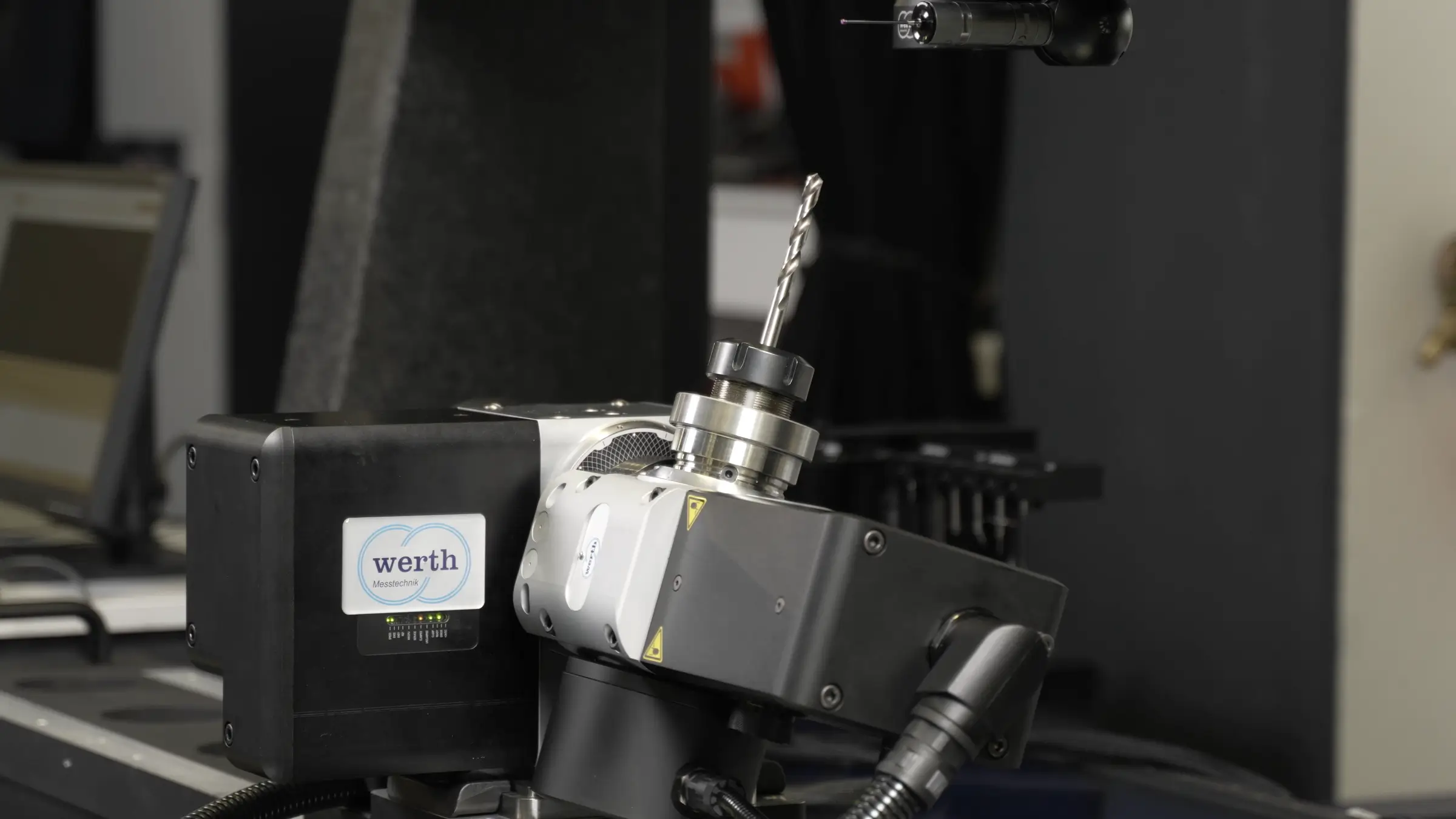

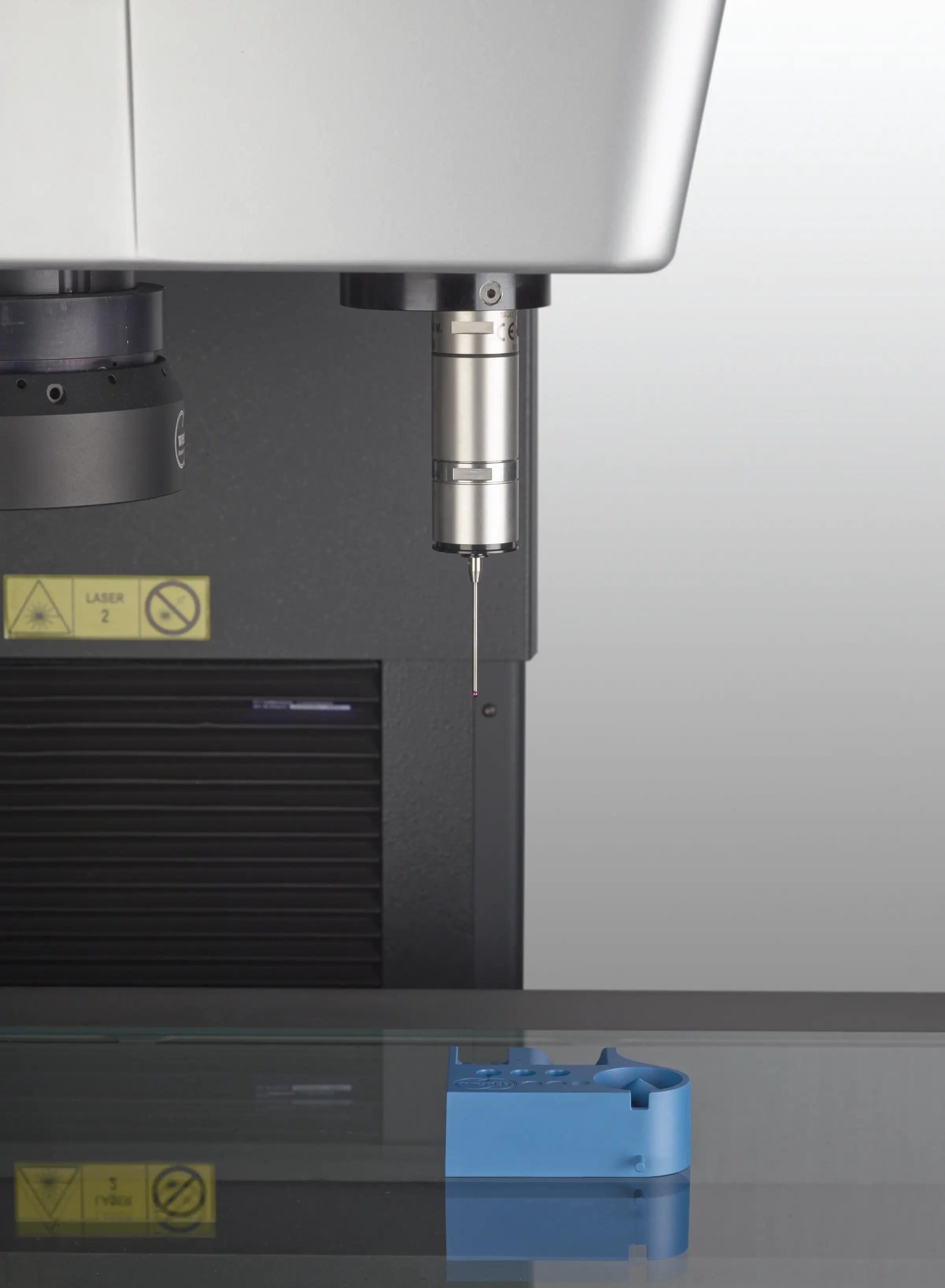

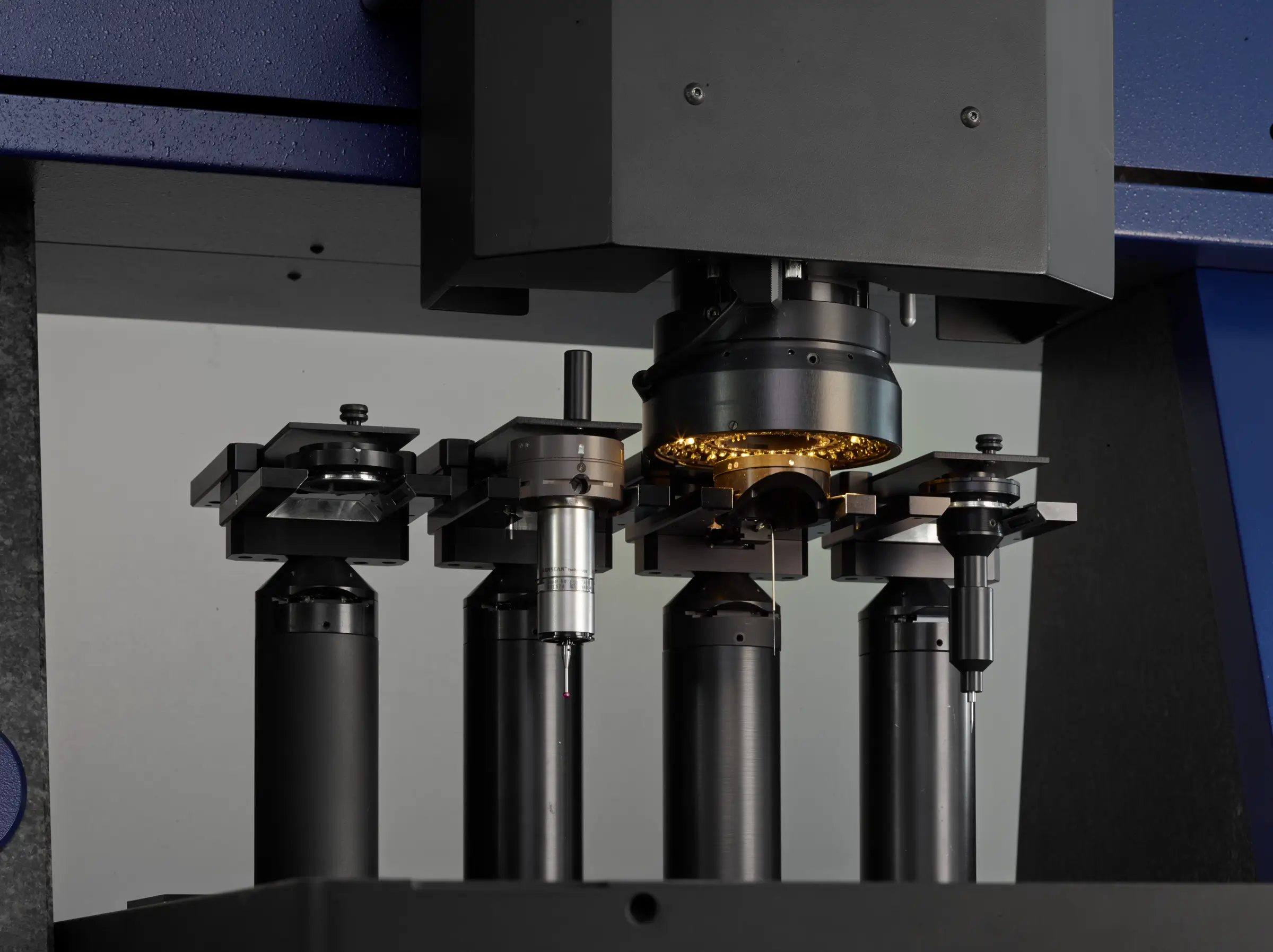

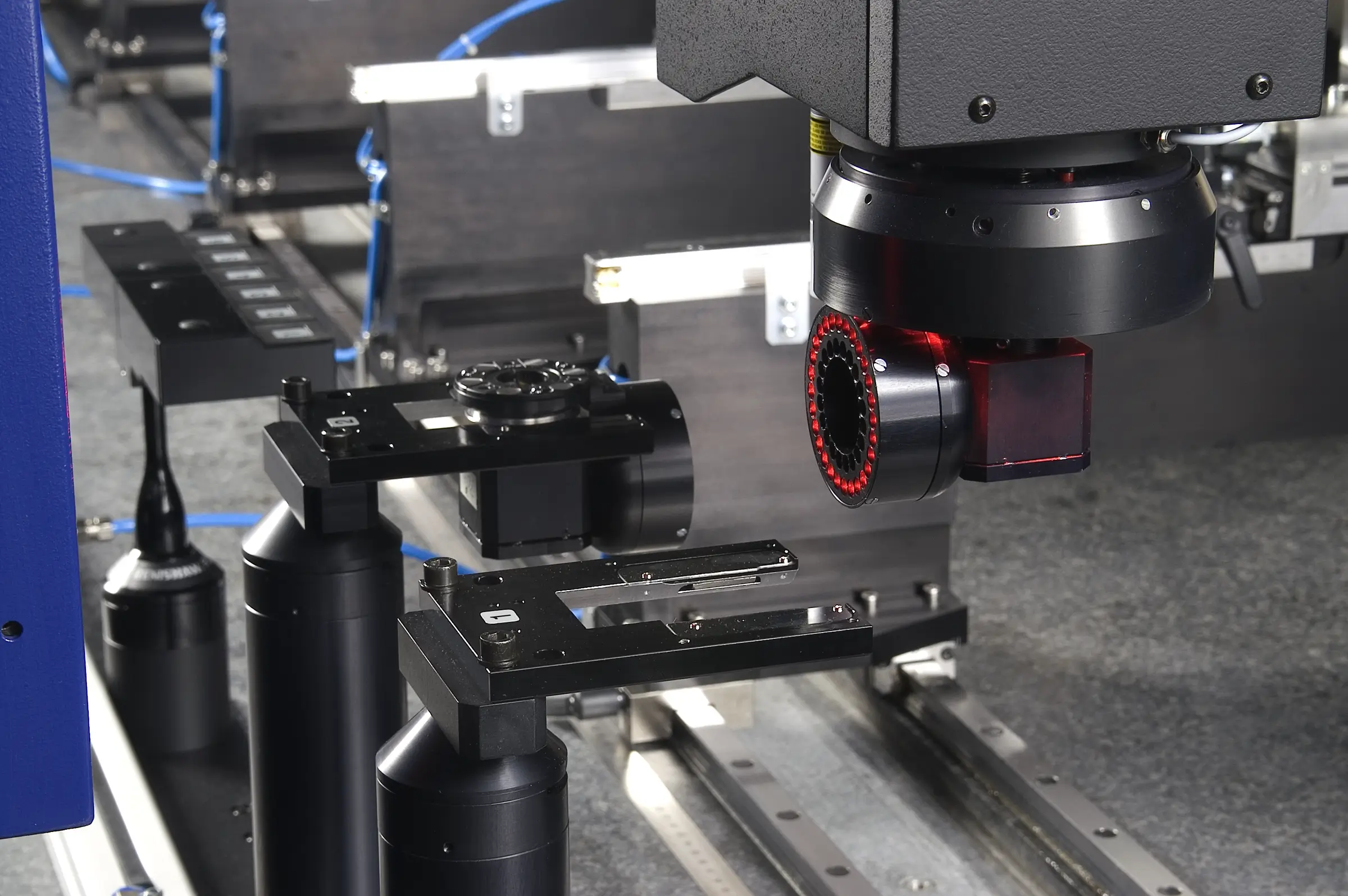

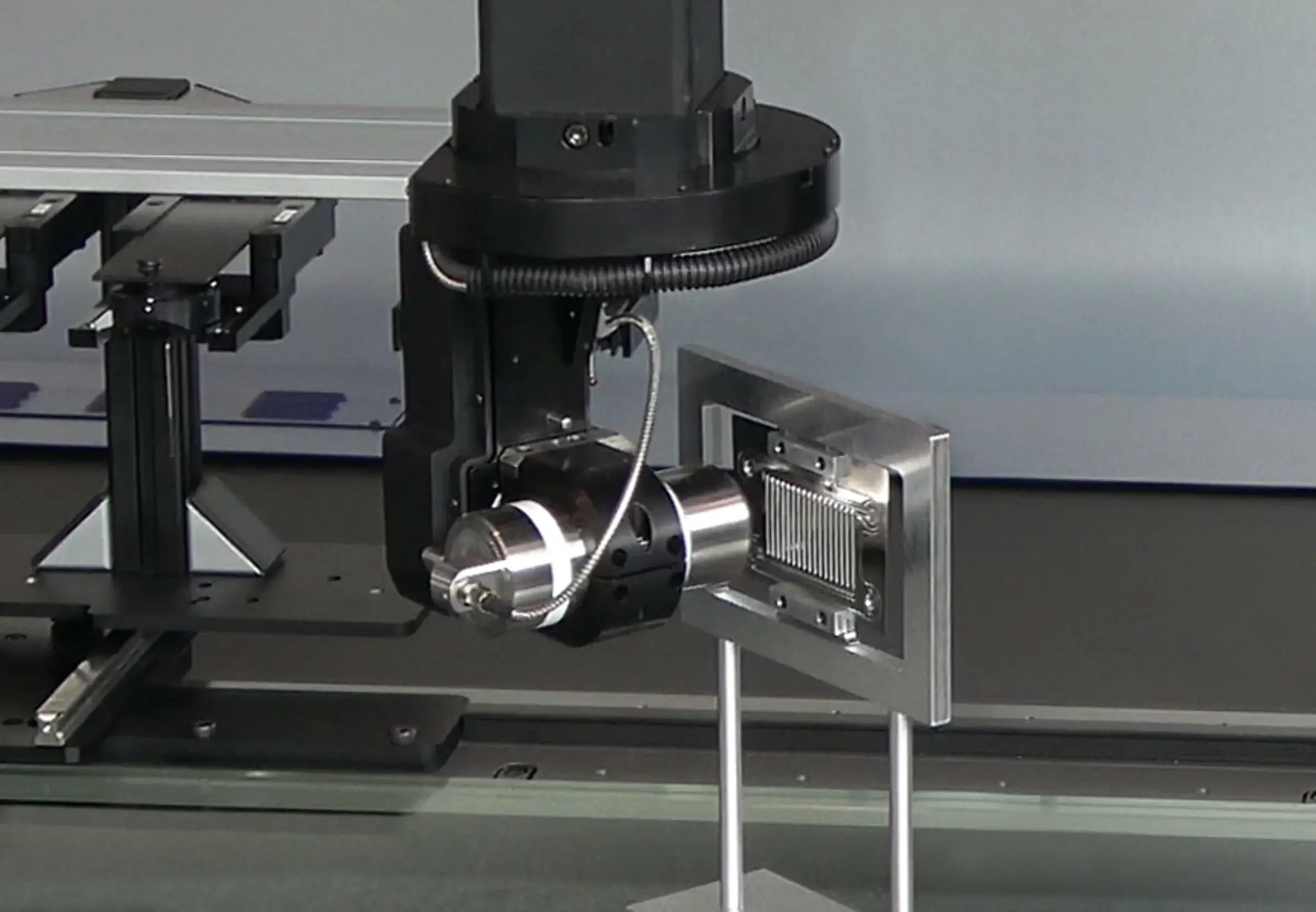

Bağımsız sensör eksenleri, ölçüm aralığının en iyi şekilde kullanılmasını sağlar; örneğin, SP80 dokunsal sensörler ve döner/eğimli kafa, aynı ram üzerinde SP25 3D tarama probu ile değiştirilebilirken, ikinci eksen optik ve dokunsal-optik çoklu sensör sistemleriyle donatılmıştır.

Sensörler ile iş parçası arasındaki çarpışma riskinin azaltılması

Daha sonra ikinci bir z ekseni de takılabilir

Tip

Sabit köprülü 3D CNC çok sensörlü koordinat ölçüm makinesi

Ölçüm aralığı

X = 400 (530) mm to 1000 (1130) mm, Y = 400 mm to 2000 mm, Z = 300 mm to 600 mm

Hassasiyet

İzin verilen uzunluk ölçüm hatası 0,75 µm'ye kadar

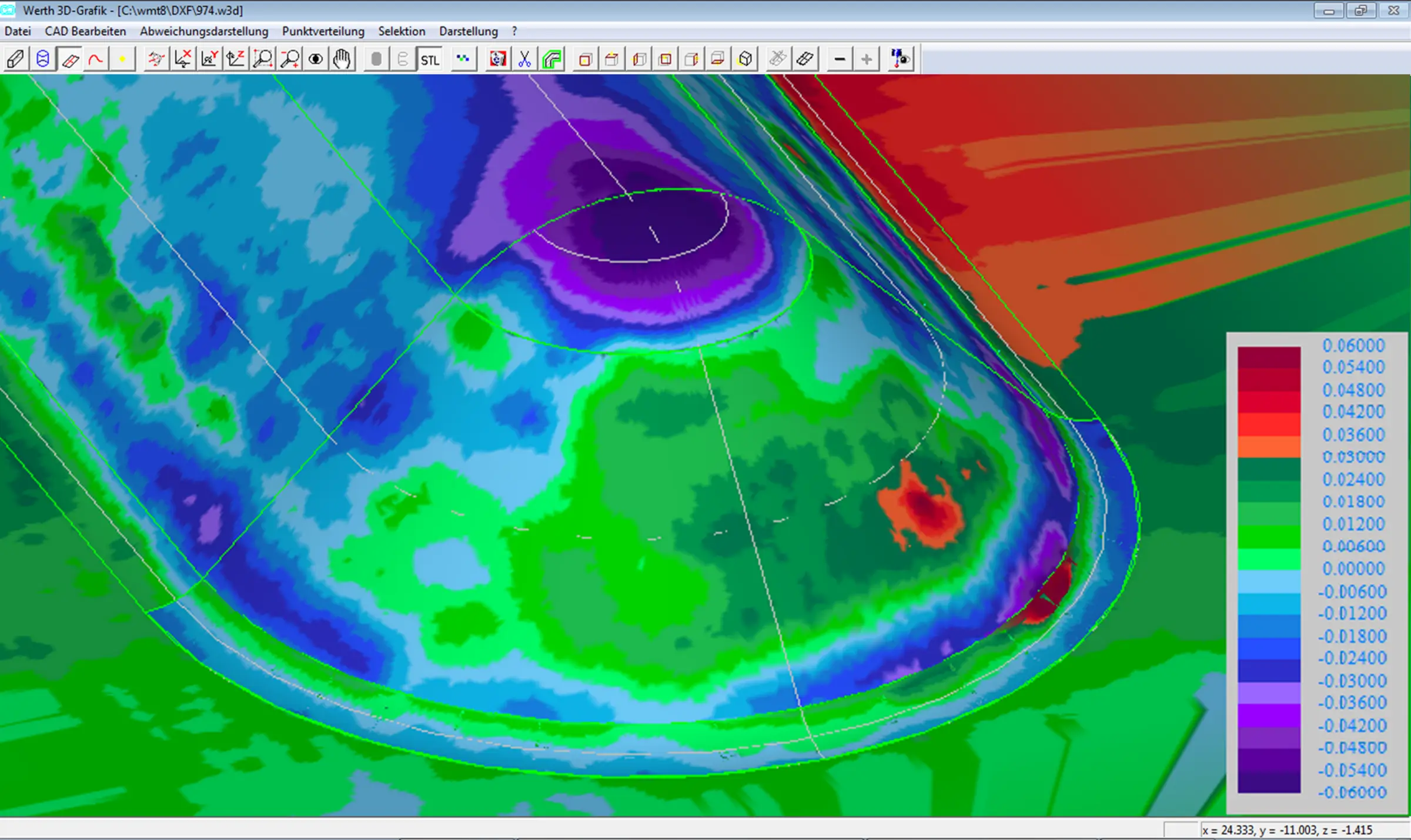

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...