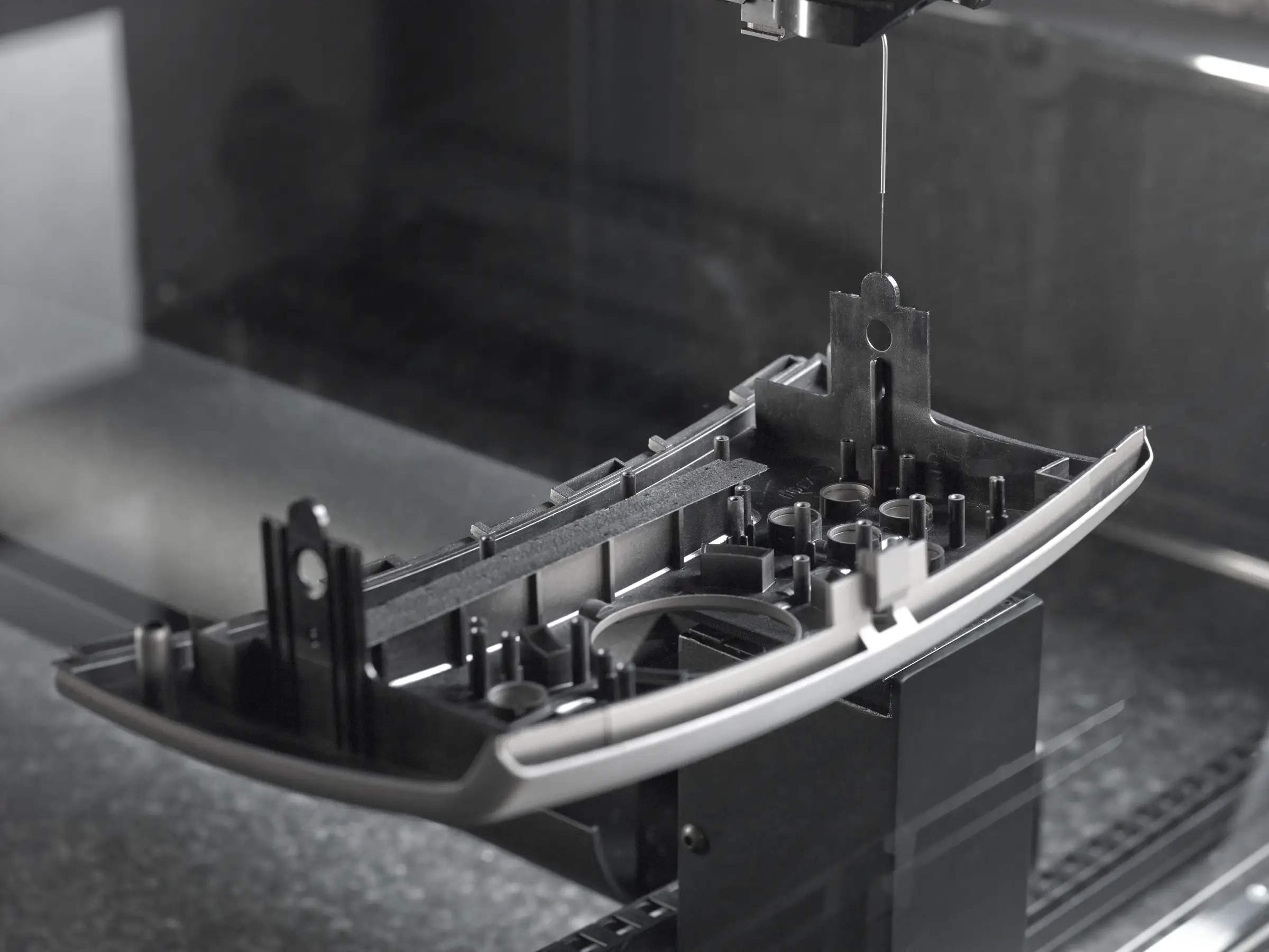

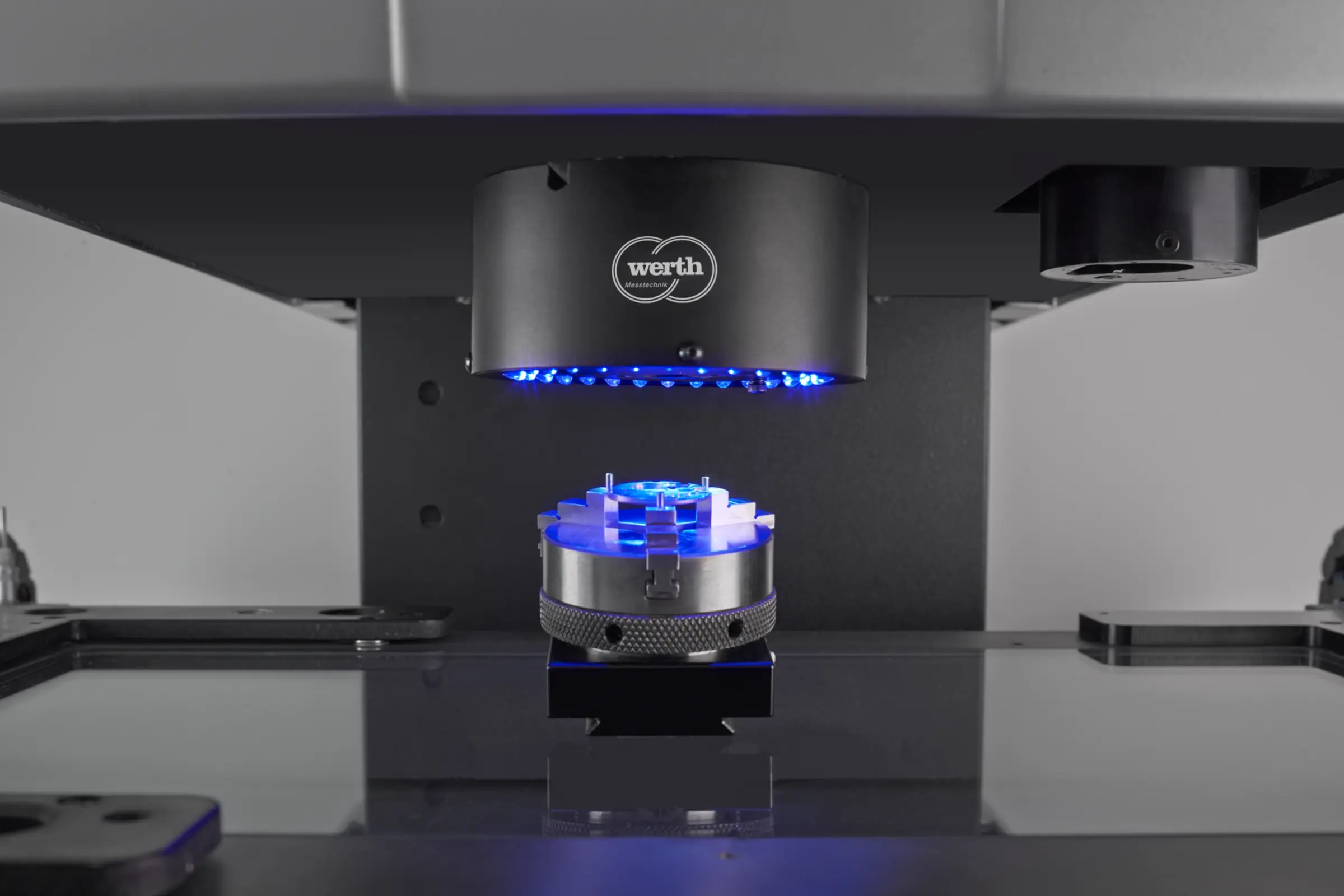

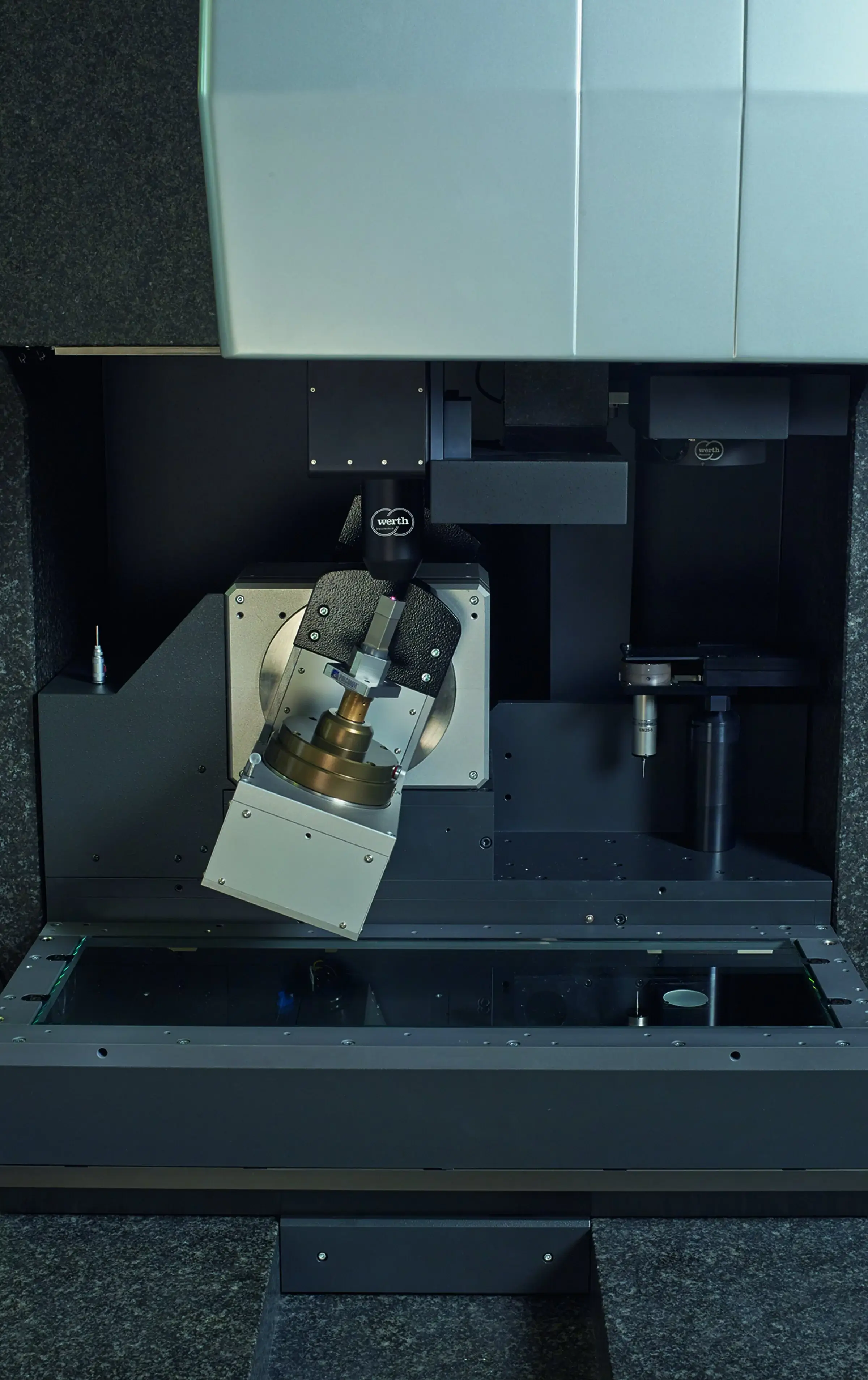

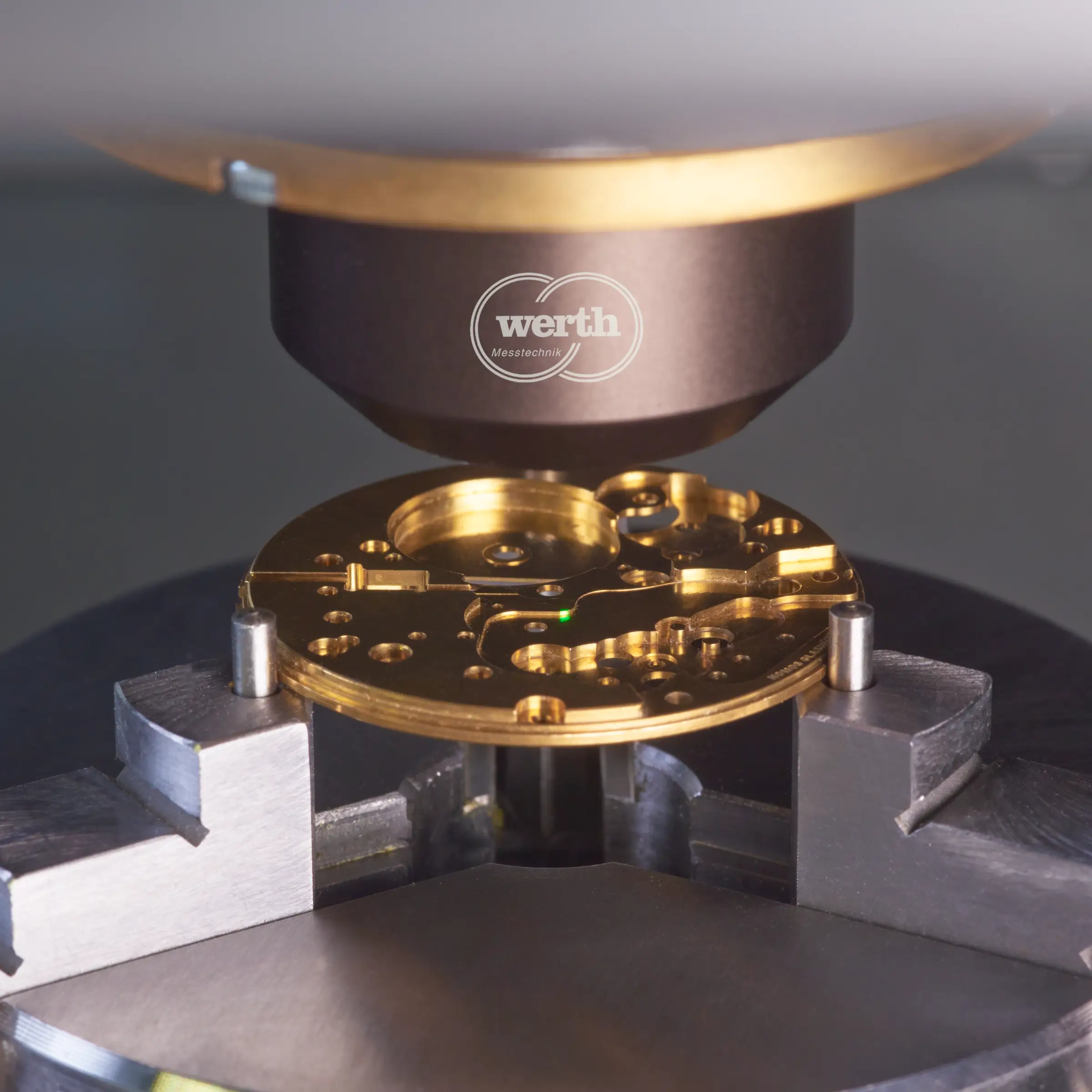

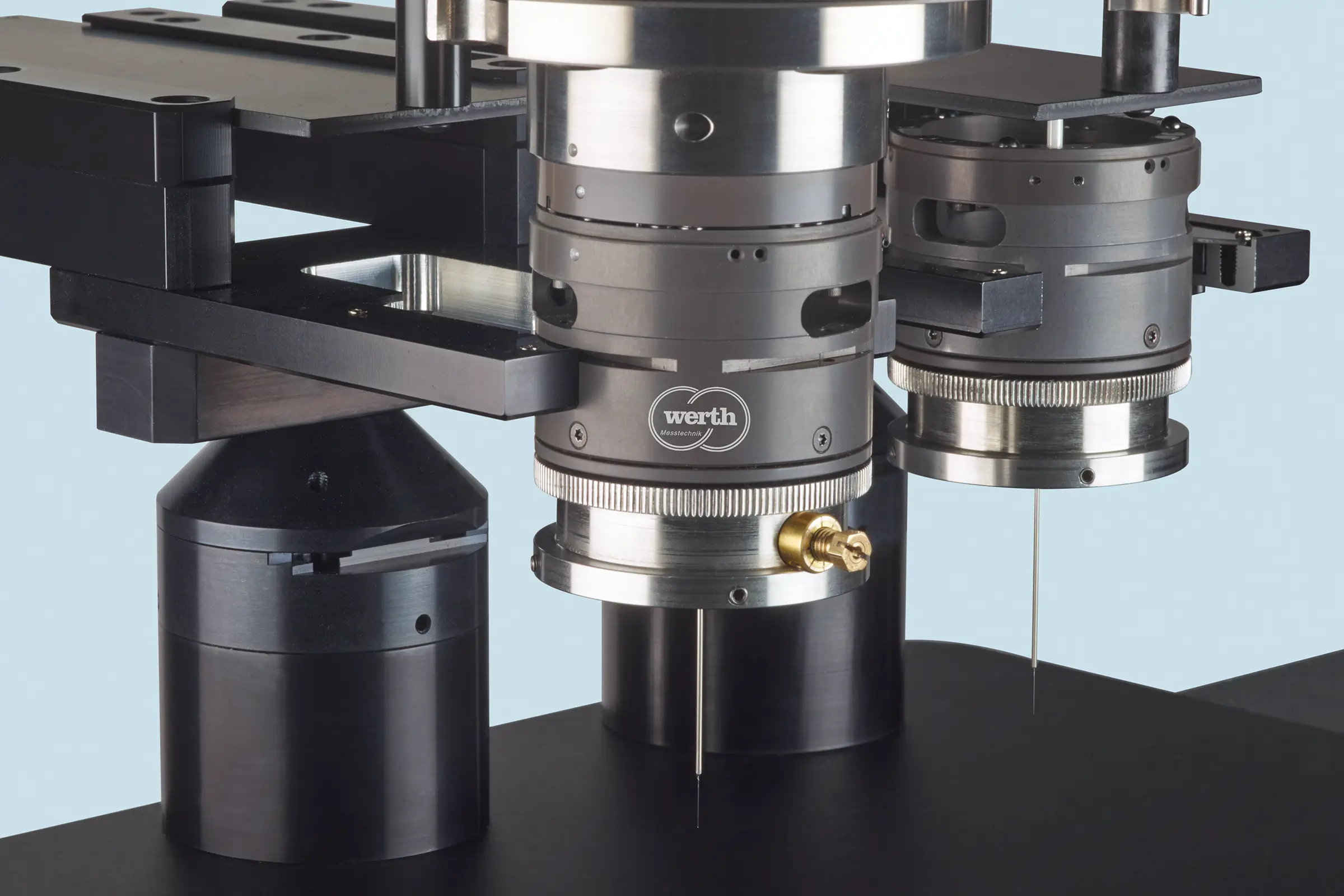

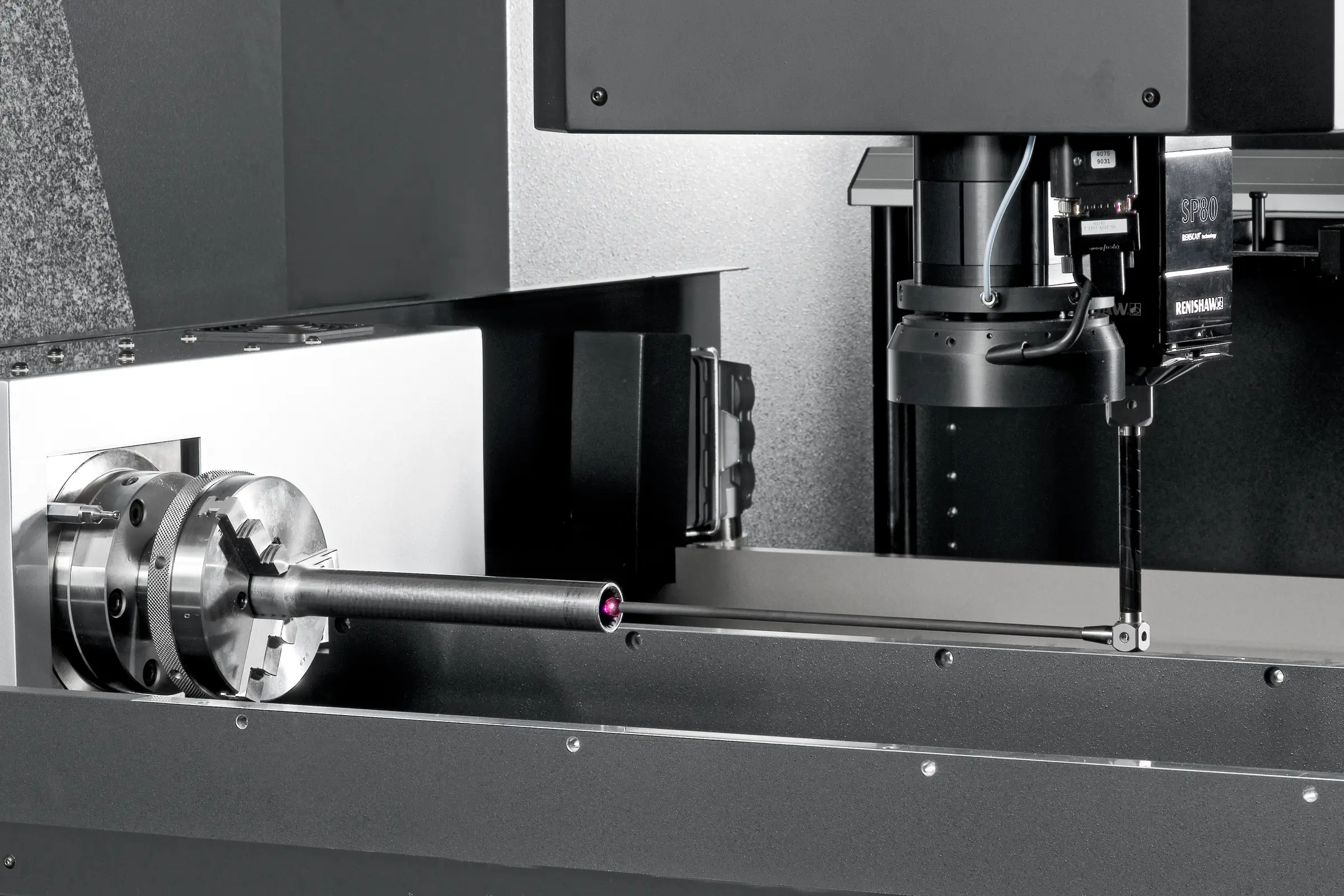

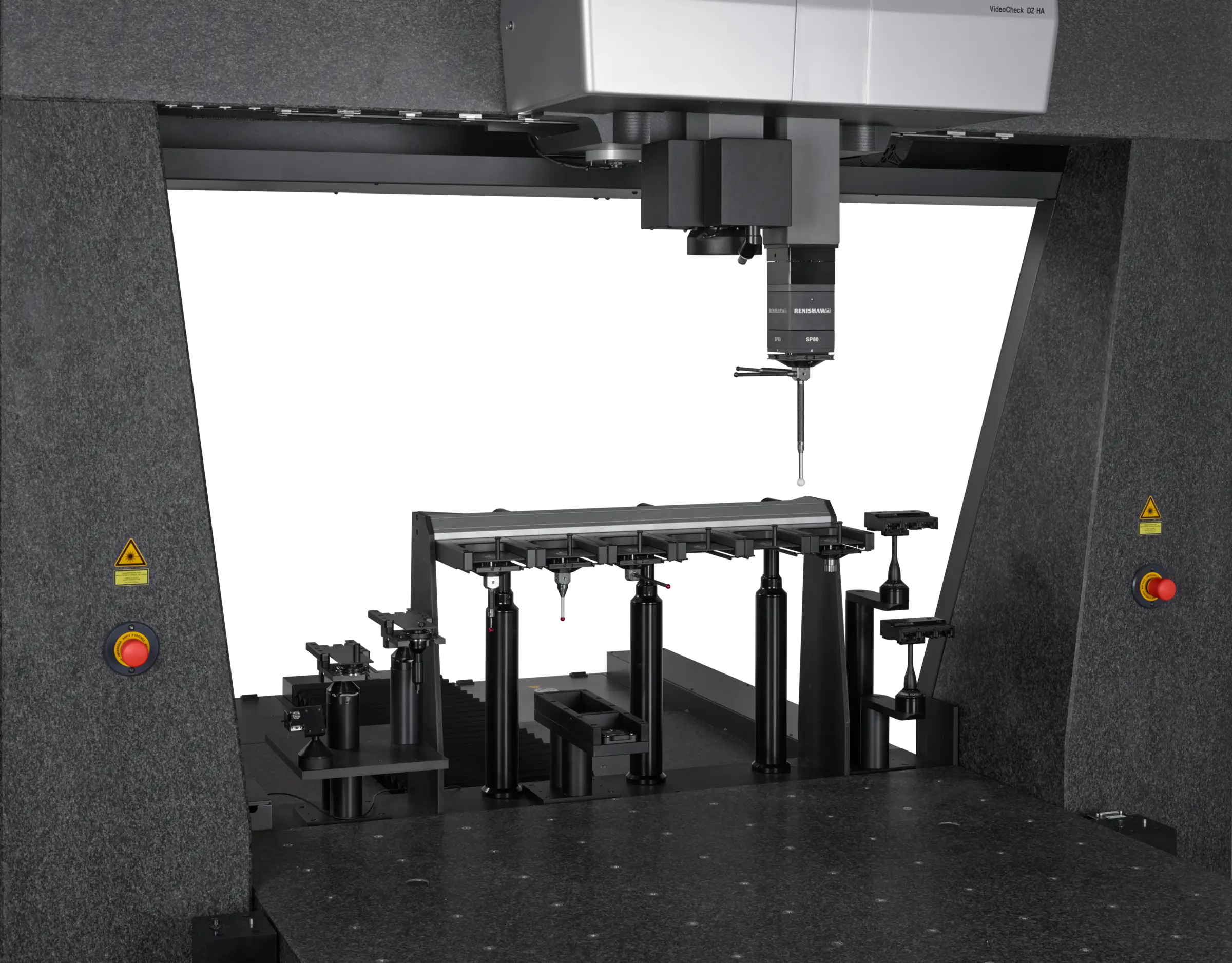

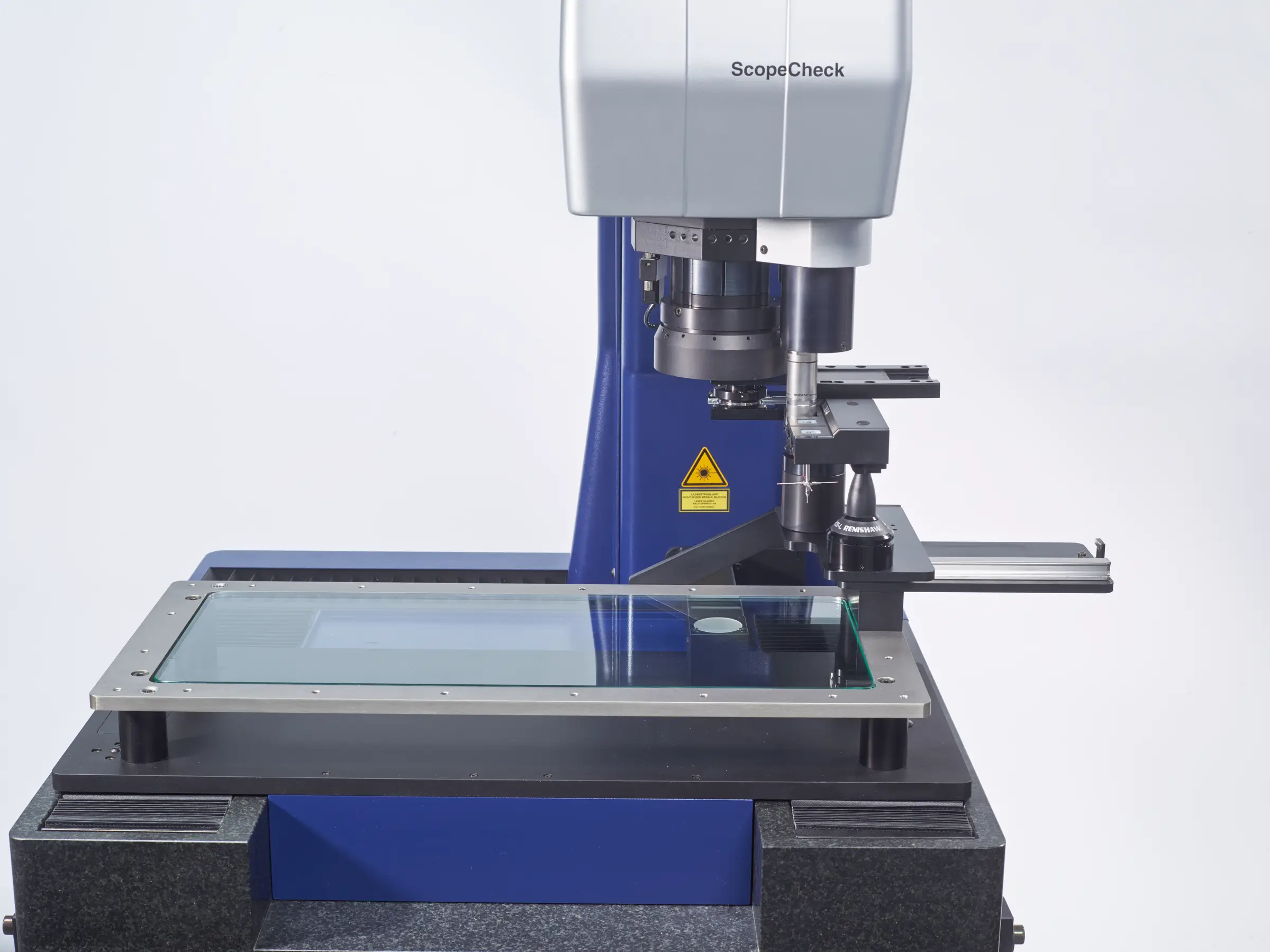

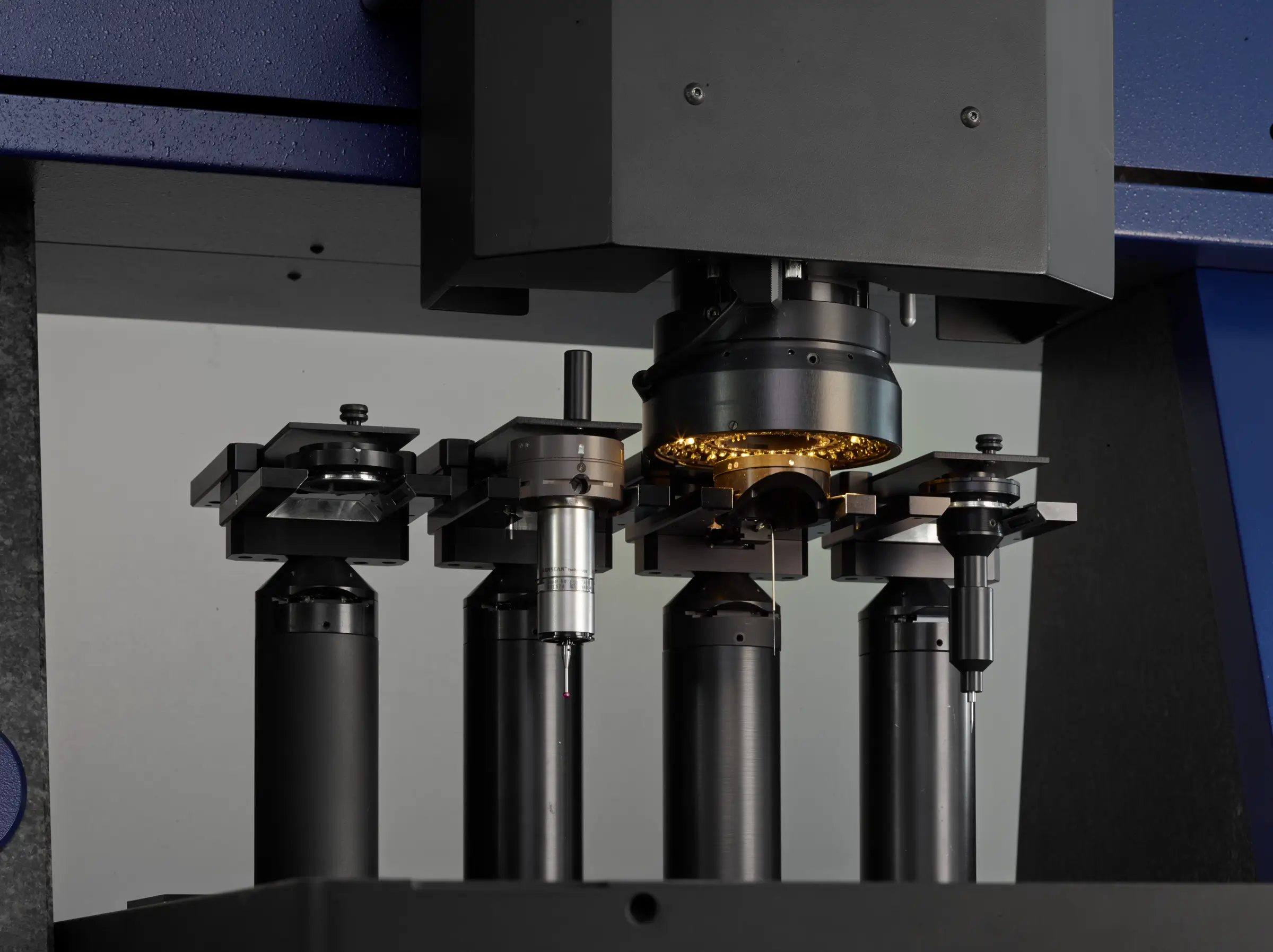

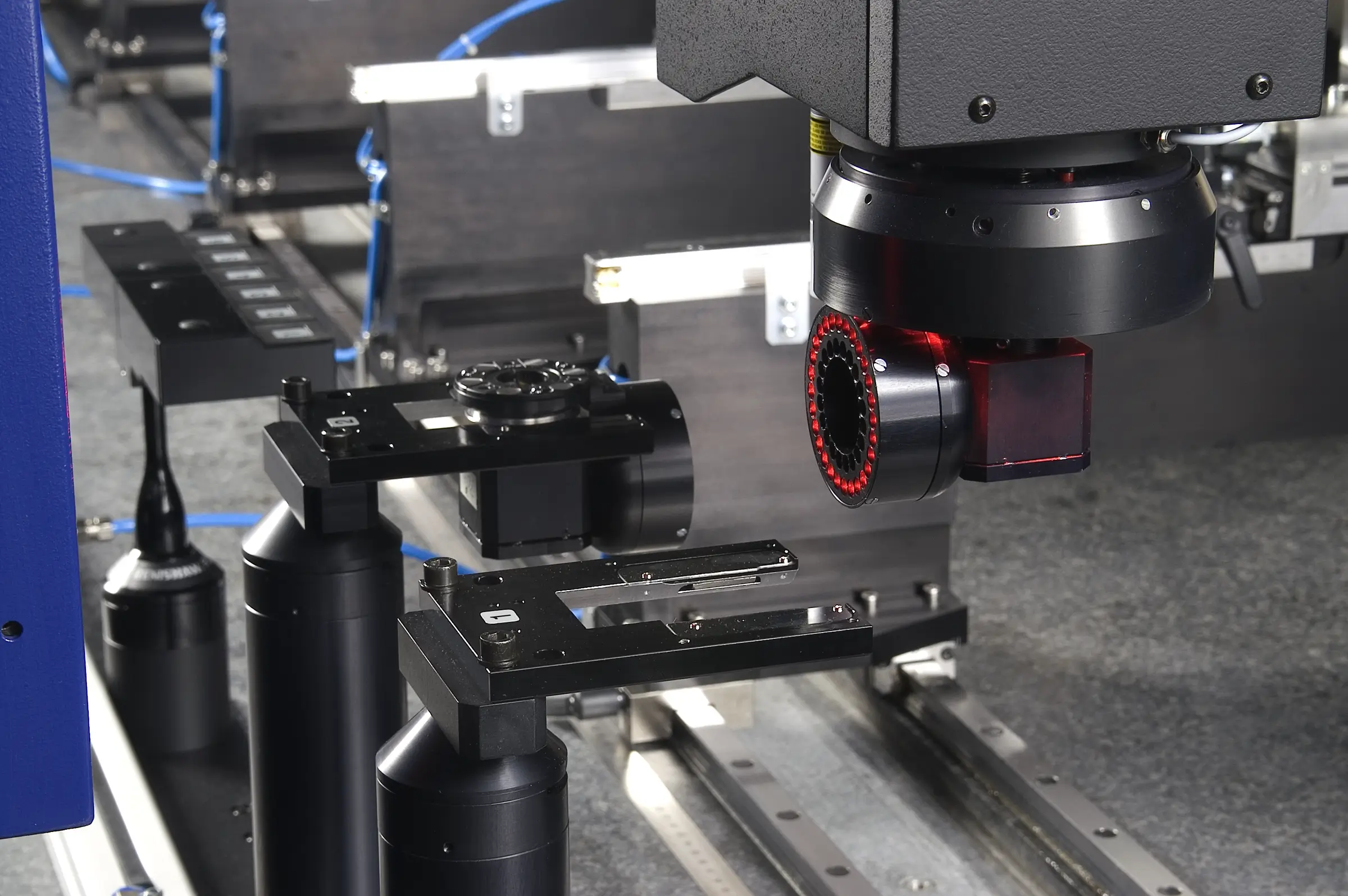

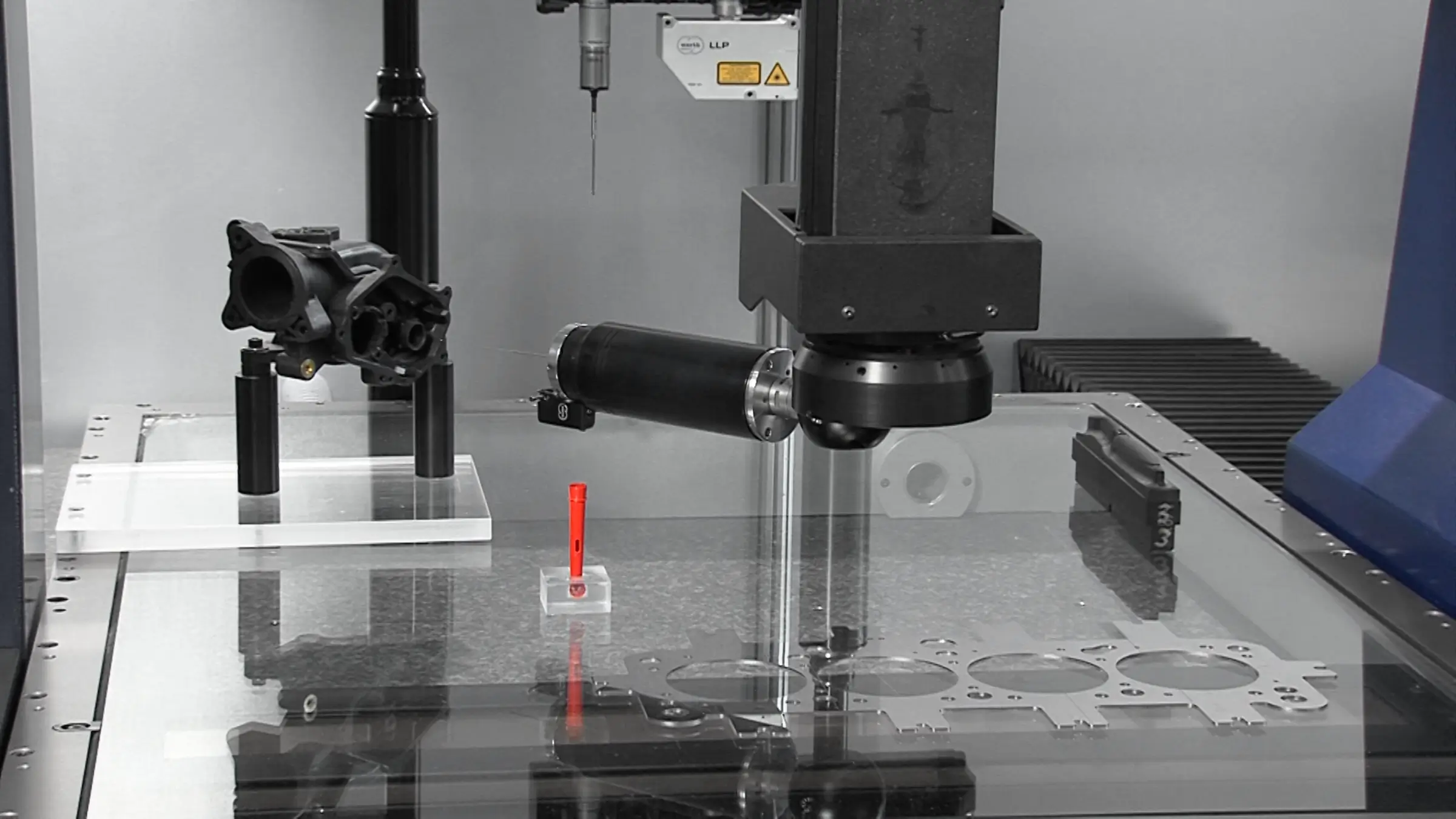

VideoCheck® S, birden fazla bağımsız sensör ekseni (ram) ile donatılabilir. X ve Y'deki kılavuz yollarının ön gerilimi, manyetik kuvvet ve yerçekimi ile sağlanır. Bu, genleşmeye bağlı gerilim değişimlerini önlerken aynı zamanda sürtünme ve boşluğu azaltarak çok yüksek uzun vadeli stabilite sağlar. Uygulama alanları arasında takım ve makine imalatı, otomotiv, elektrik, tıp, plastik, kauçuk ve cam endüstrileri yer almaktadır.

VideoCheck® S

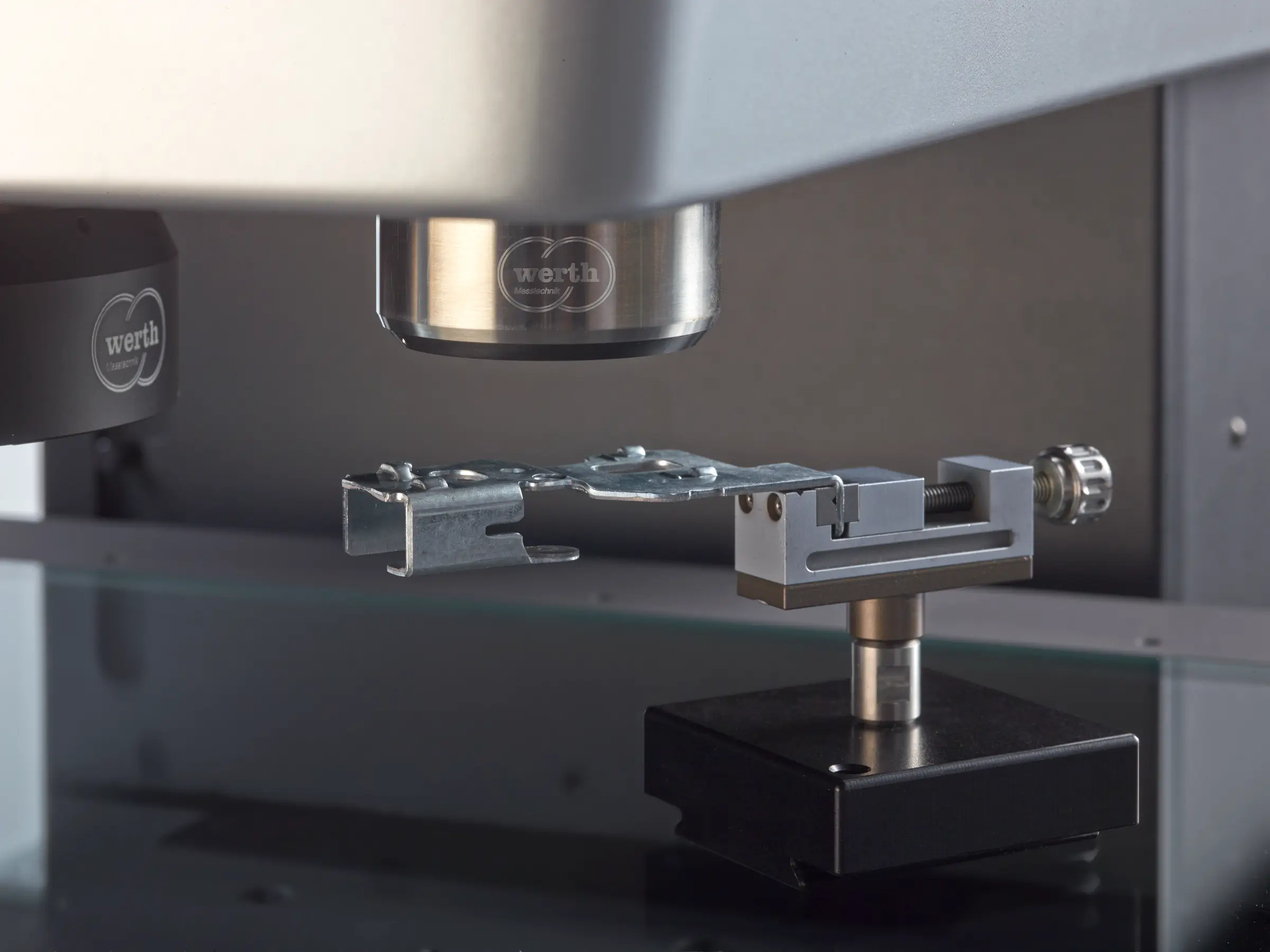

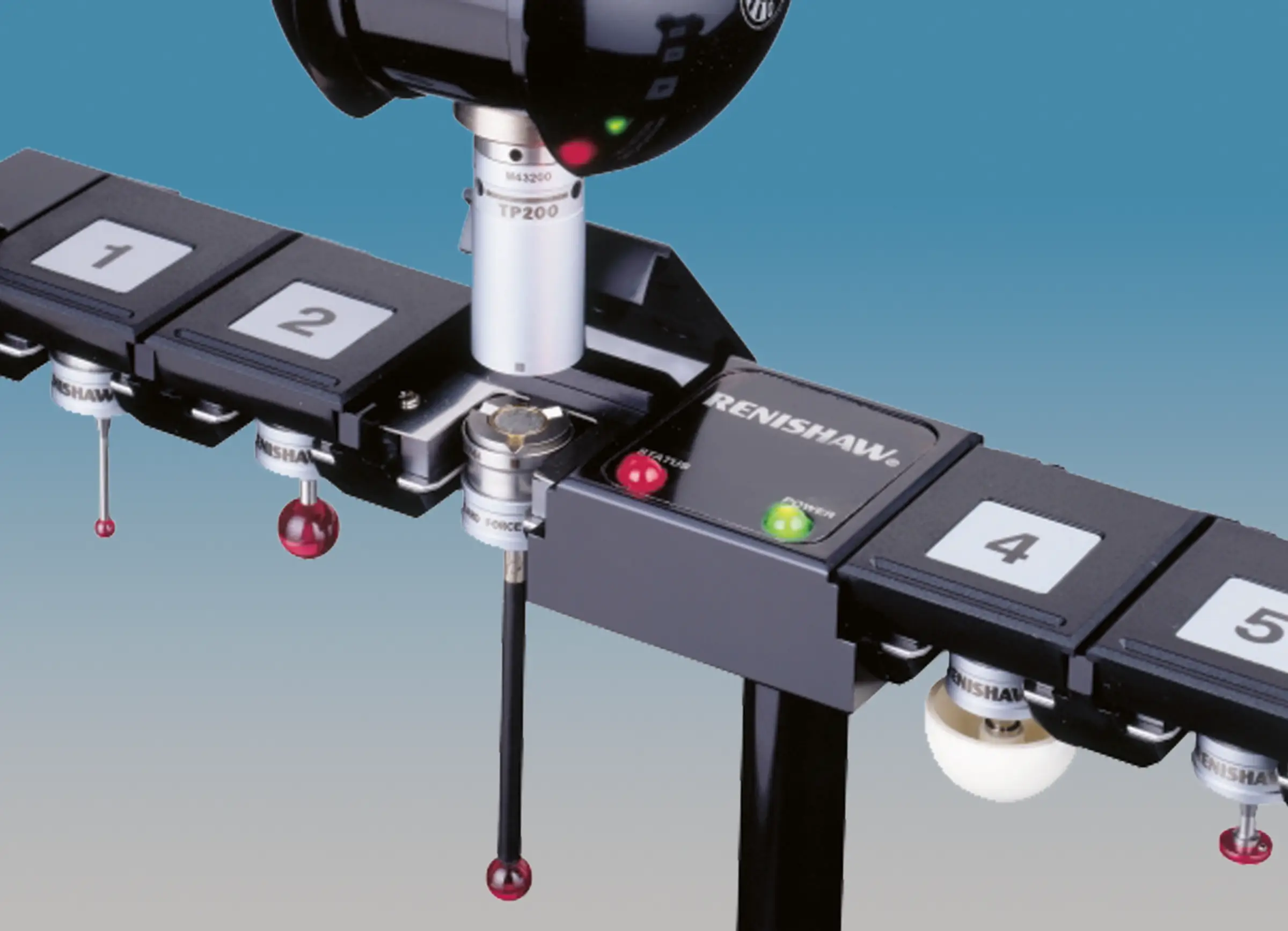

Düşük uzunluk ölçüm hataları nedeniyle makine çoklu sensör sistemleri için önceden belirlenmiştir

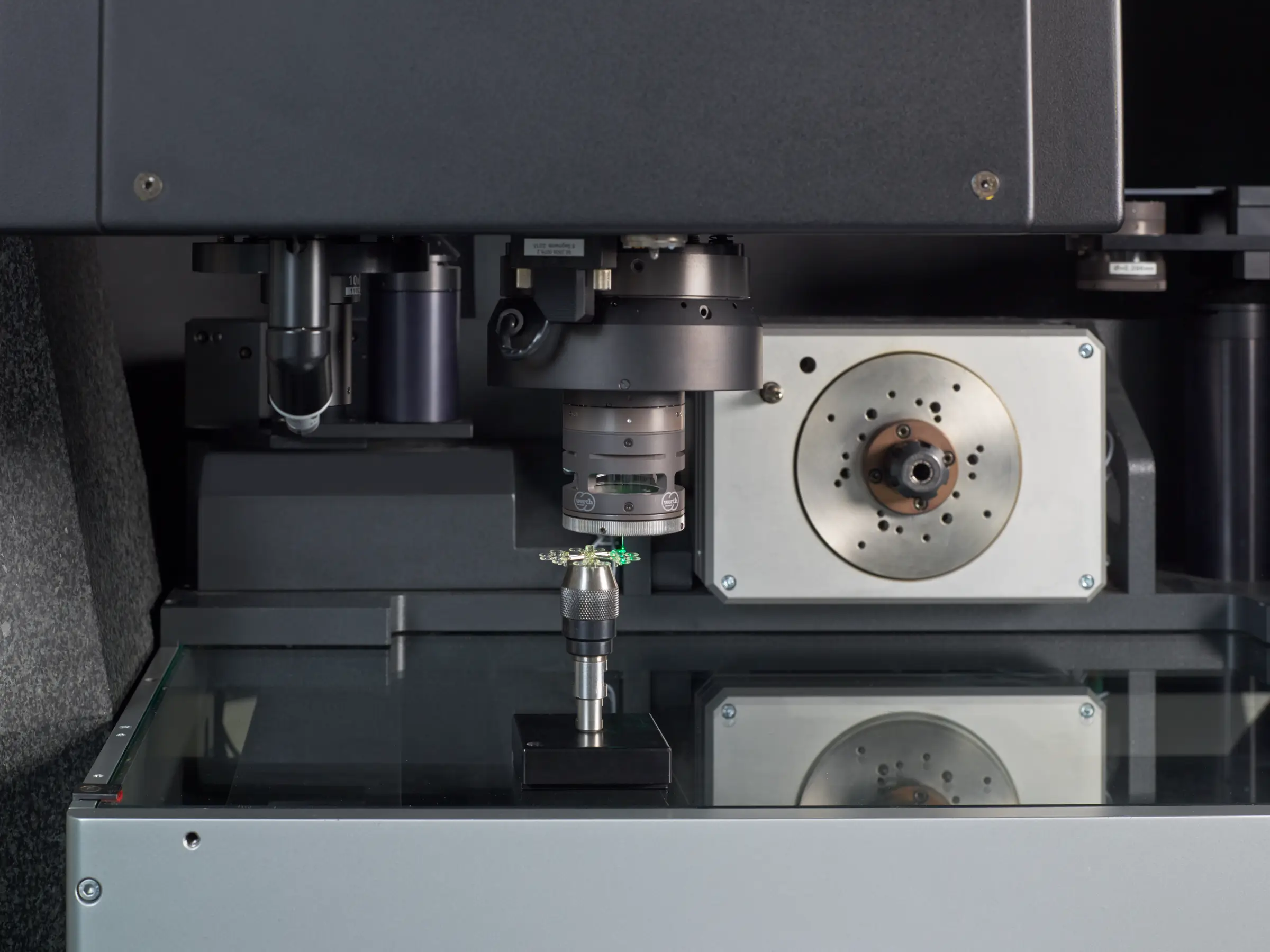

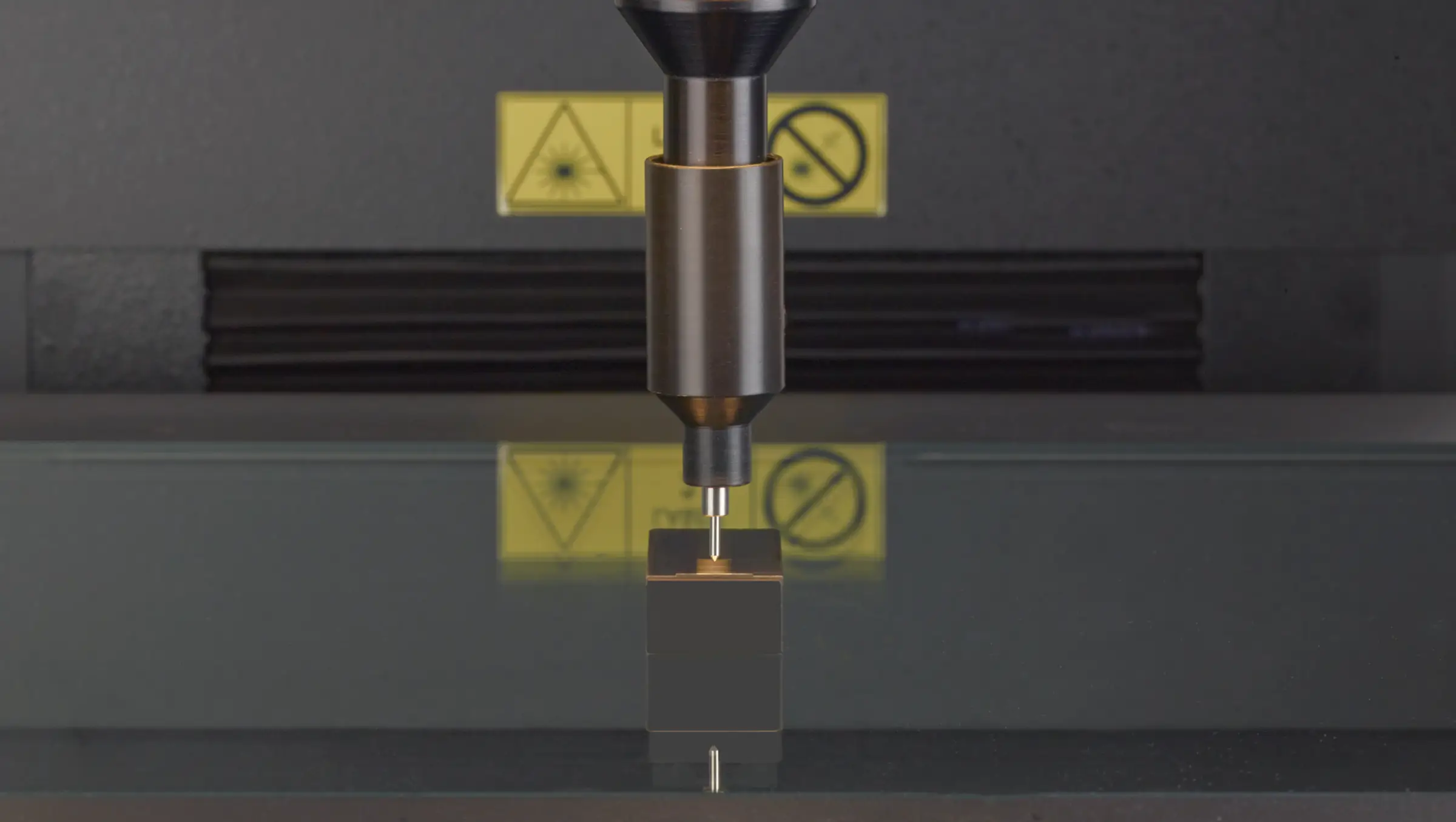

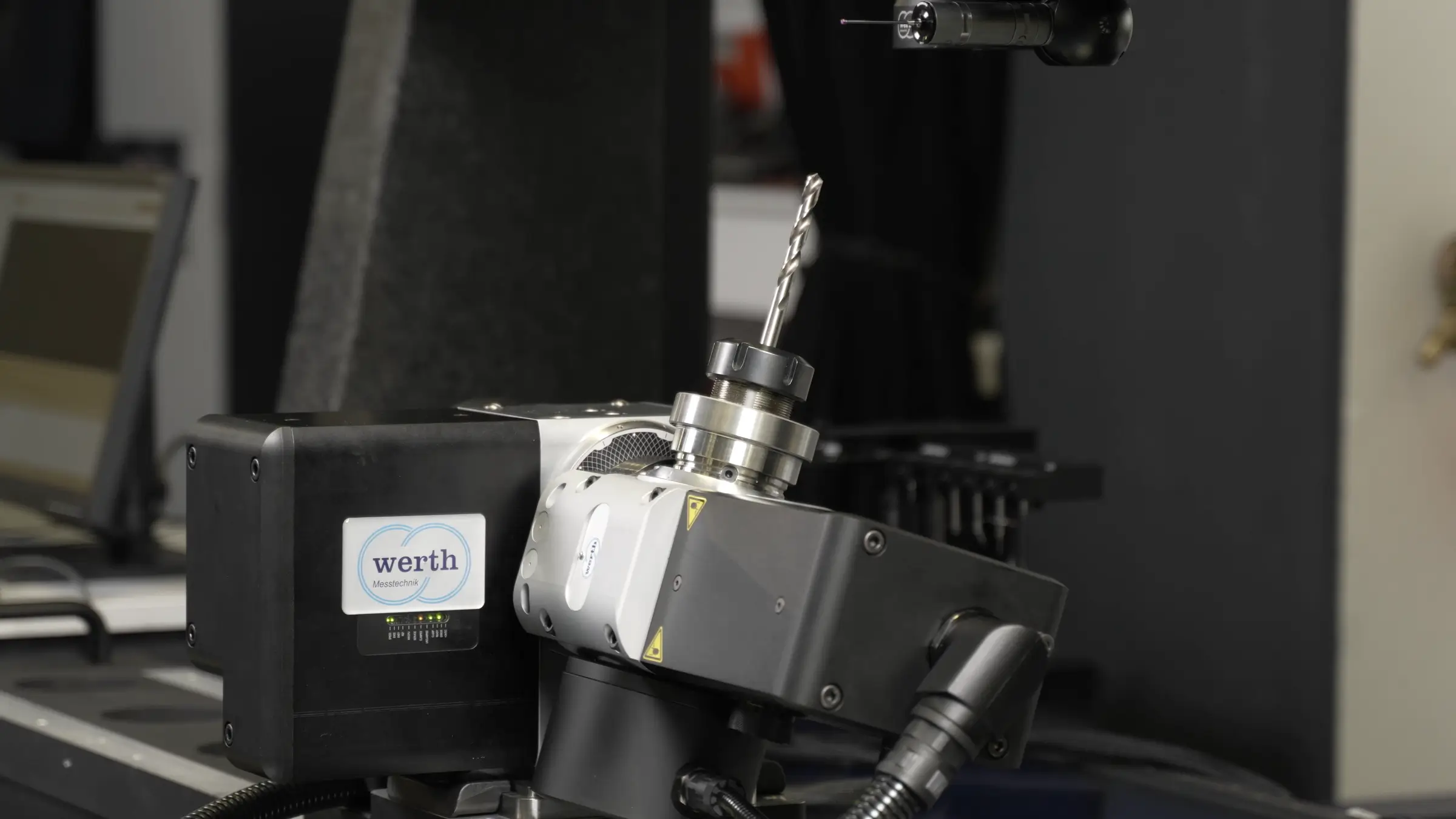

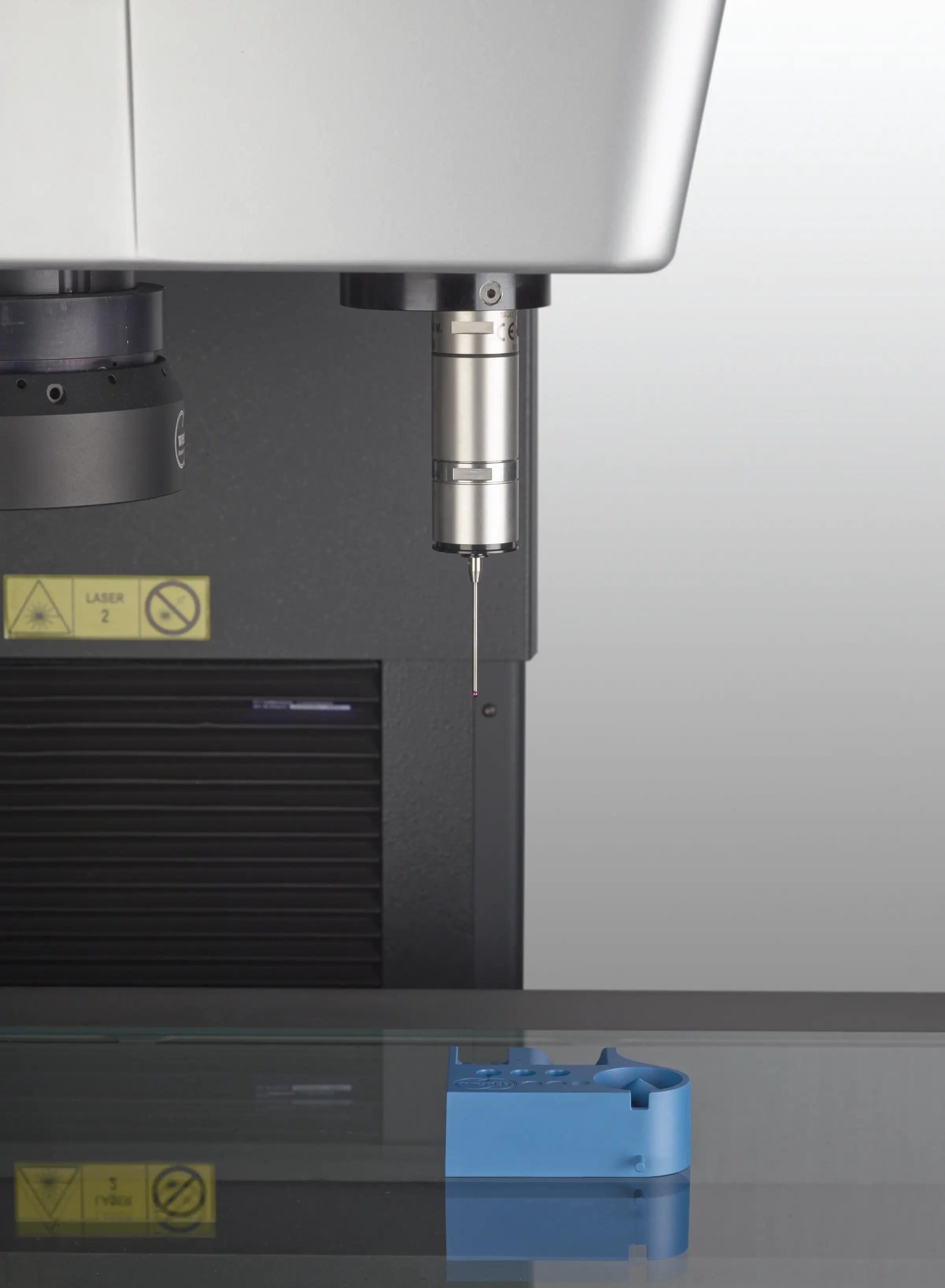

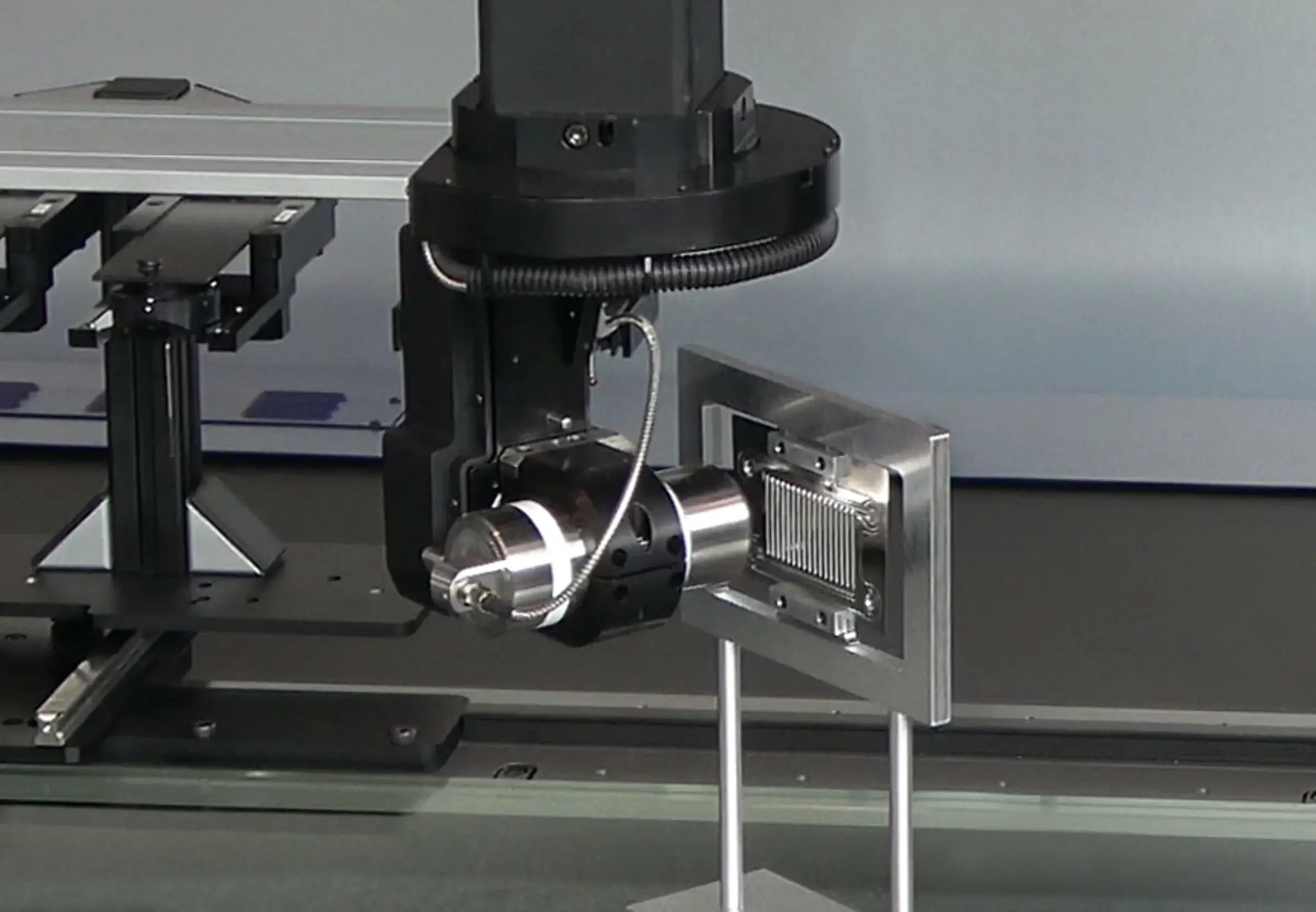

Pürüzlülük ve kontur ölçümleri, patentli mikro prob Werth Fiber Probe® veya Werth Kontur Probe ile otomatikleştirilebilir

Bağımsız sensör eksenleri, ölçüm aralığının optimum şekilde kullanılmasını sağlar

Sensörler ve iş parçası arasındaki çarpışma riskinin azaltılması

Daha sonra ikinci bir eksen de takılabilir

Döner/eğimli kafaların, değişen rafların veya hatta iş parçası döner veya döner/eğimli eksenlerin kullanımıyla yüksek derecede esneklik elde edilir

WinWerth® ölçüm yazılımının grafiksel kullanıcı arayüzü, verimli ve basit bir kullanım sağlar

Tip

X-Y tablalı 3D-CNC çok sensörlü koordinat ölçüm makinesi

Ölçüm aralığı

X = 250 mm / 400 mm, Y = 125 mm / 200 mm, Z = 250 mm

Hassasiyet

İzin verilen uzunluk ölçüm hatası 1,1 µm'ye kadar

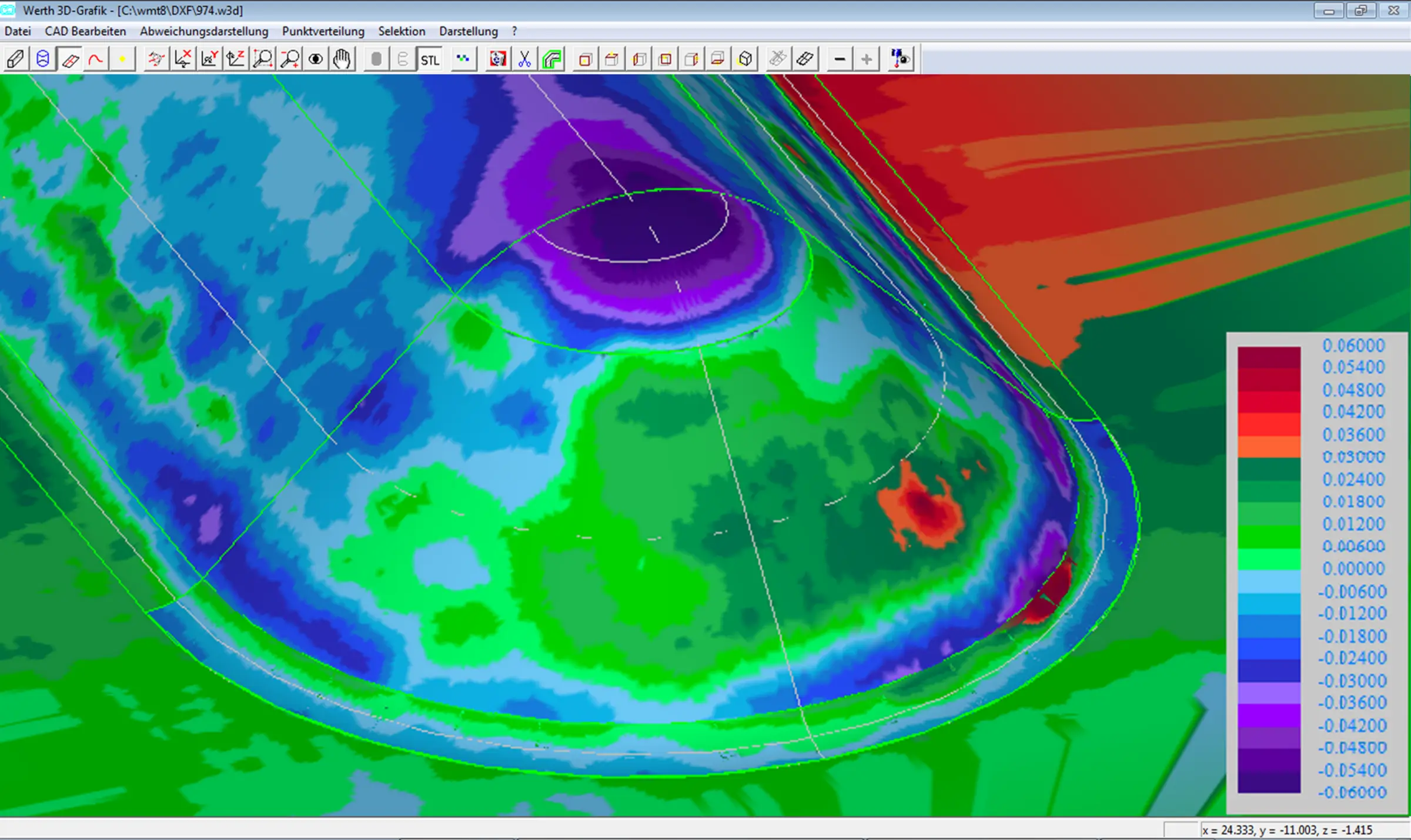

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...