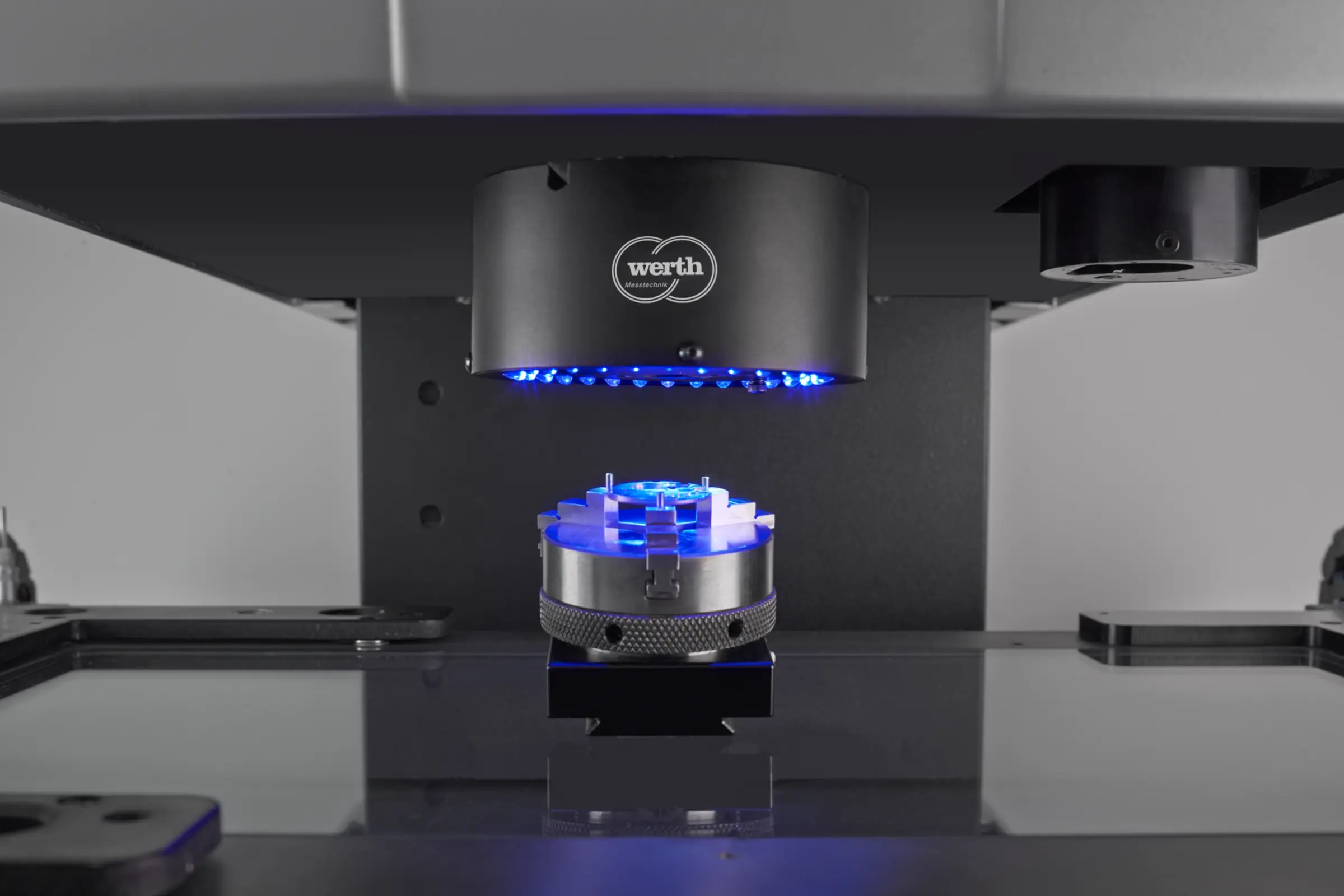

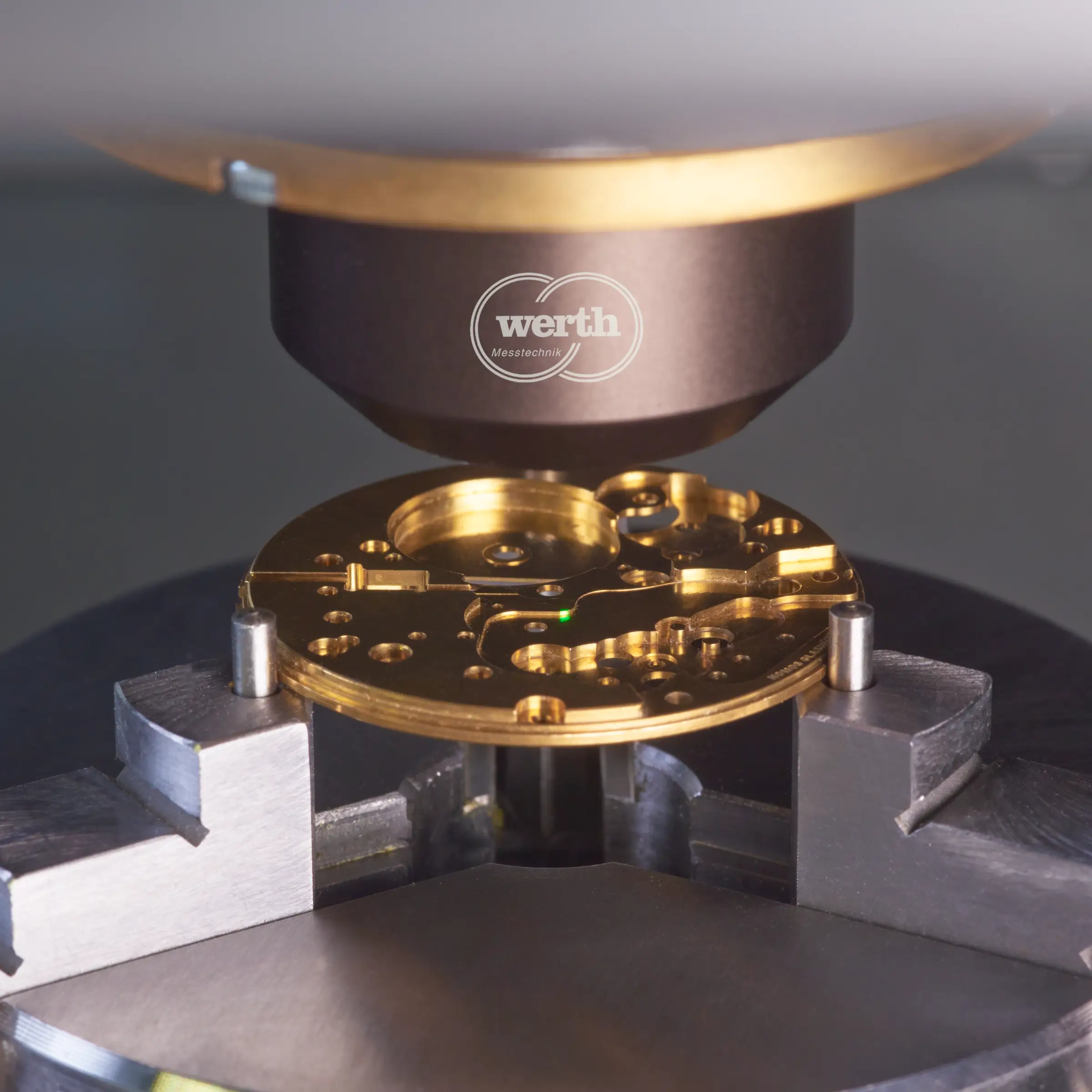

Özel hava yatağı teknolojisi, entegre titreşim yalıtımı, sıcaklığa dayanıklı ölçek ve tahrik sistemleri ve yüksek performanslı kontrol sistemi sayesinde, son derece hassas (ultra hassas) çok sensörlü koordinat ölçüm makinesinin elde edilebilir uzunluk ölçüm hataları birkaç onda bir µm aralığındadır. Başlıca uygulamaları hassas iş parçaları ve 3B mikro geometrilerdir.

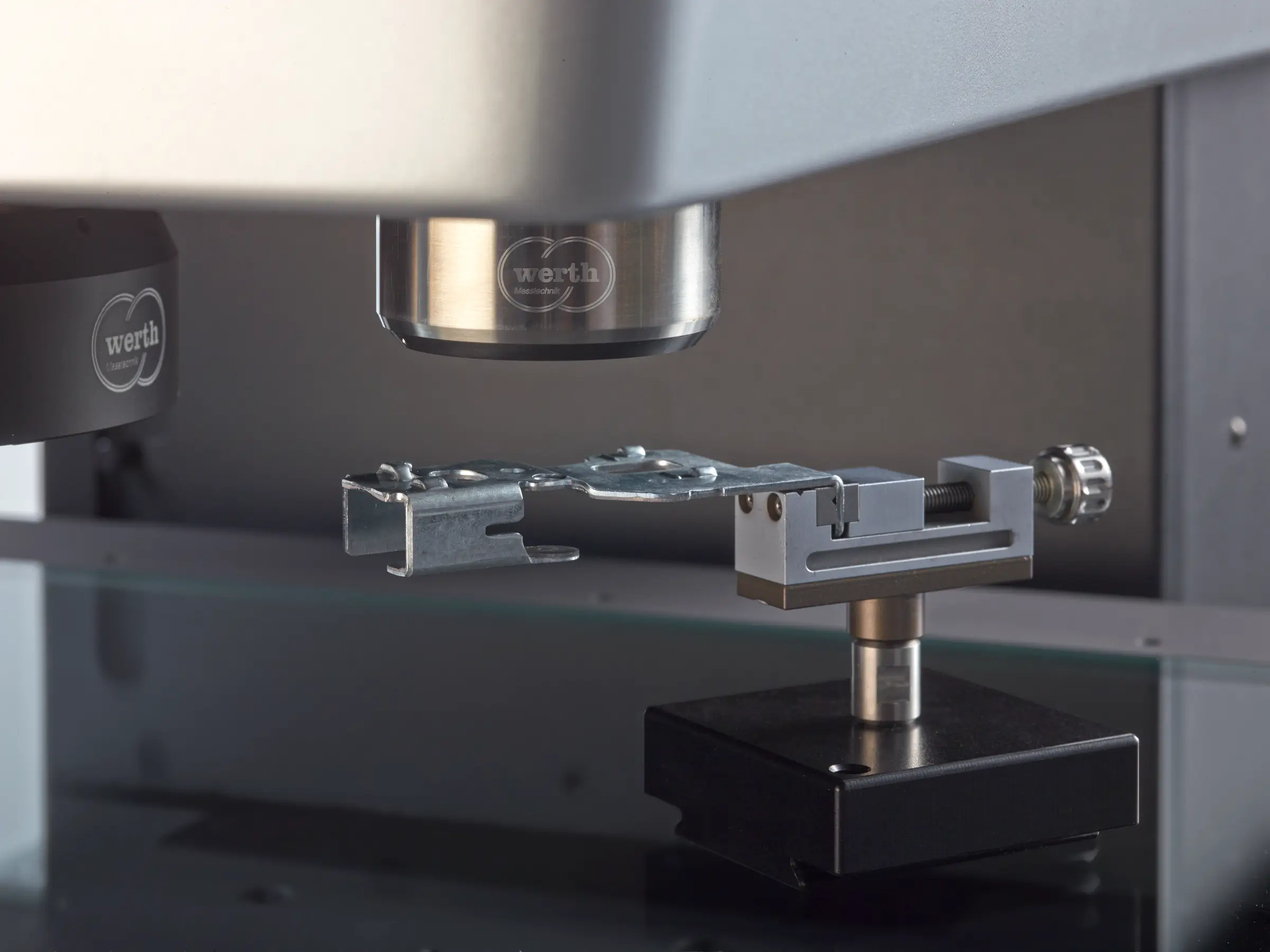

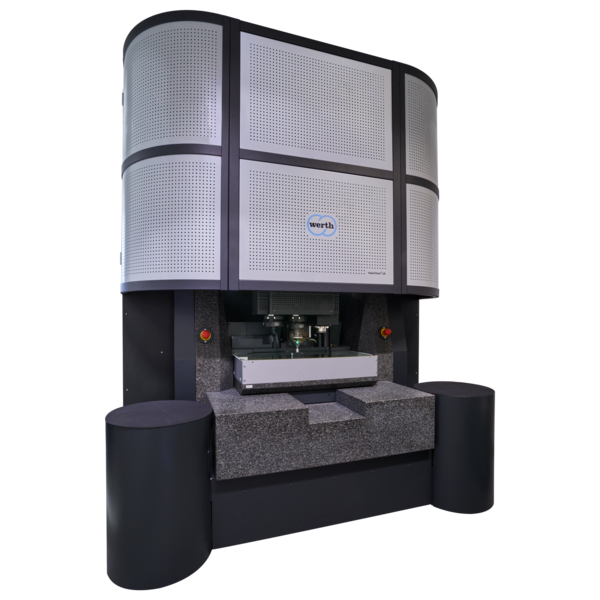

VideoCheck® UA

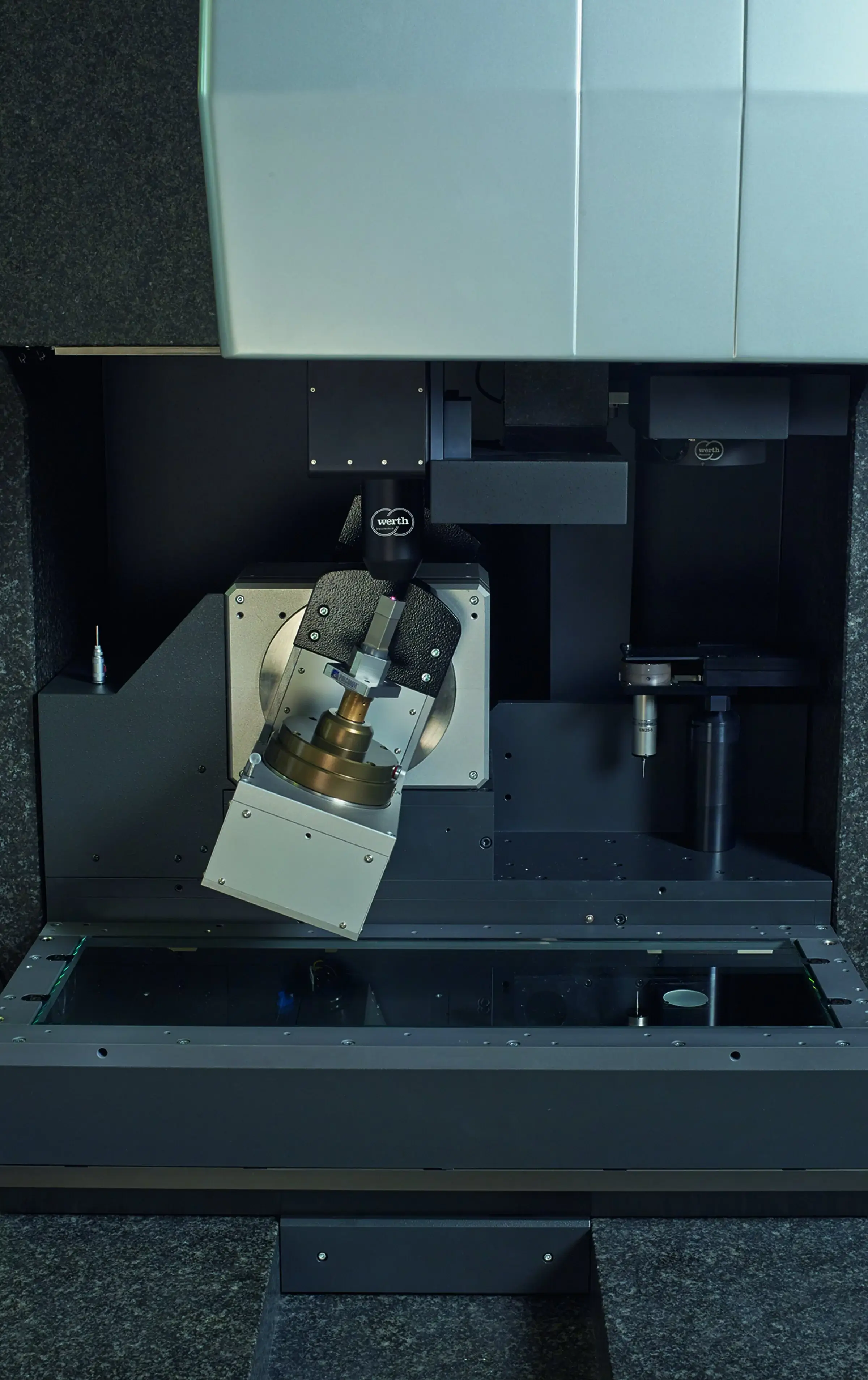

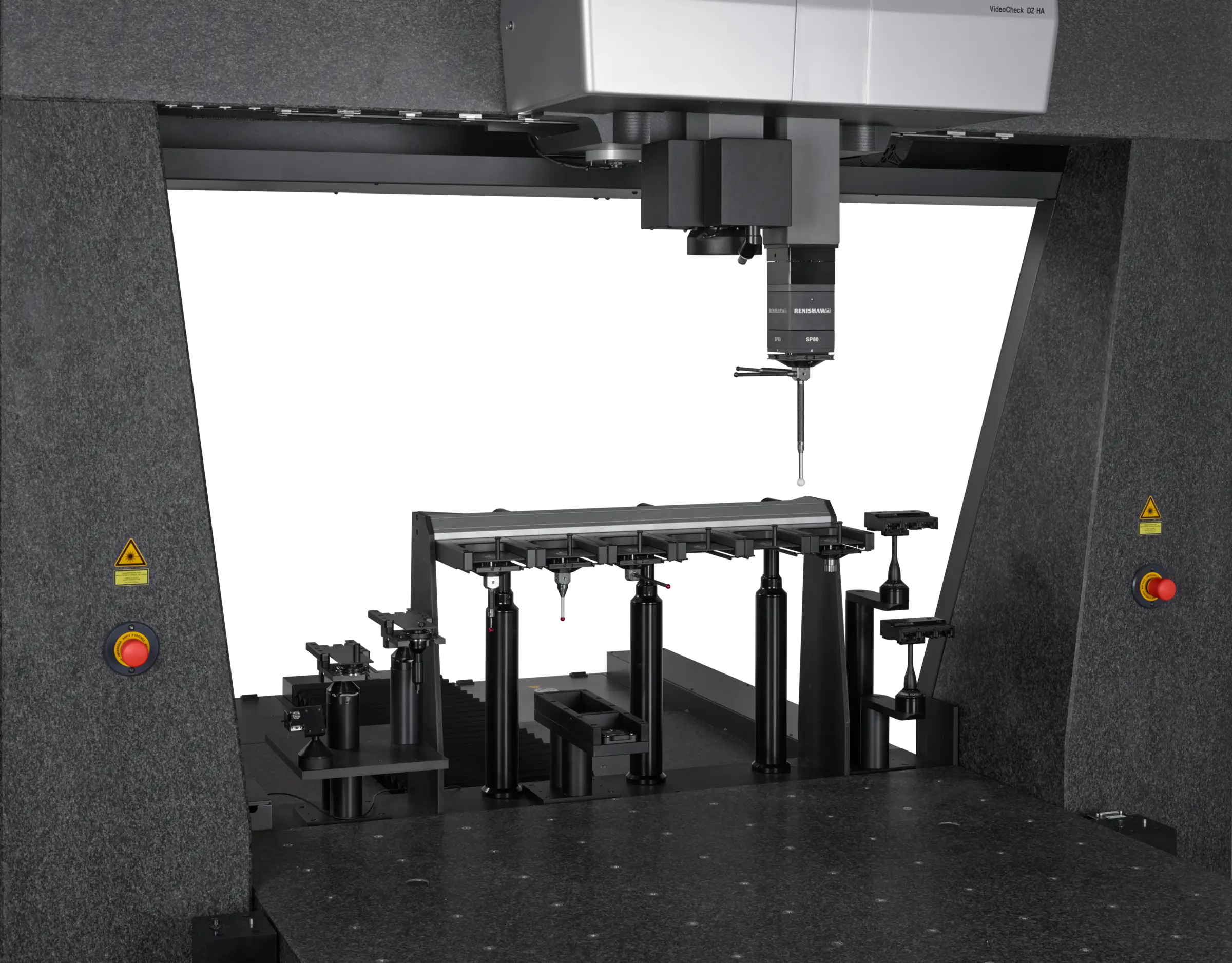

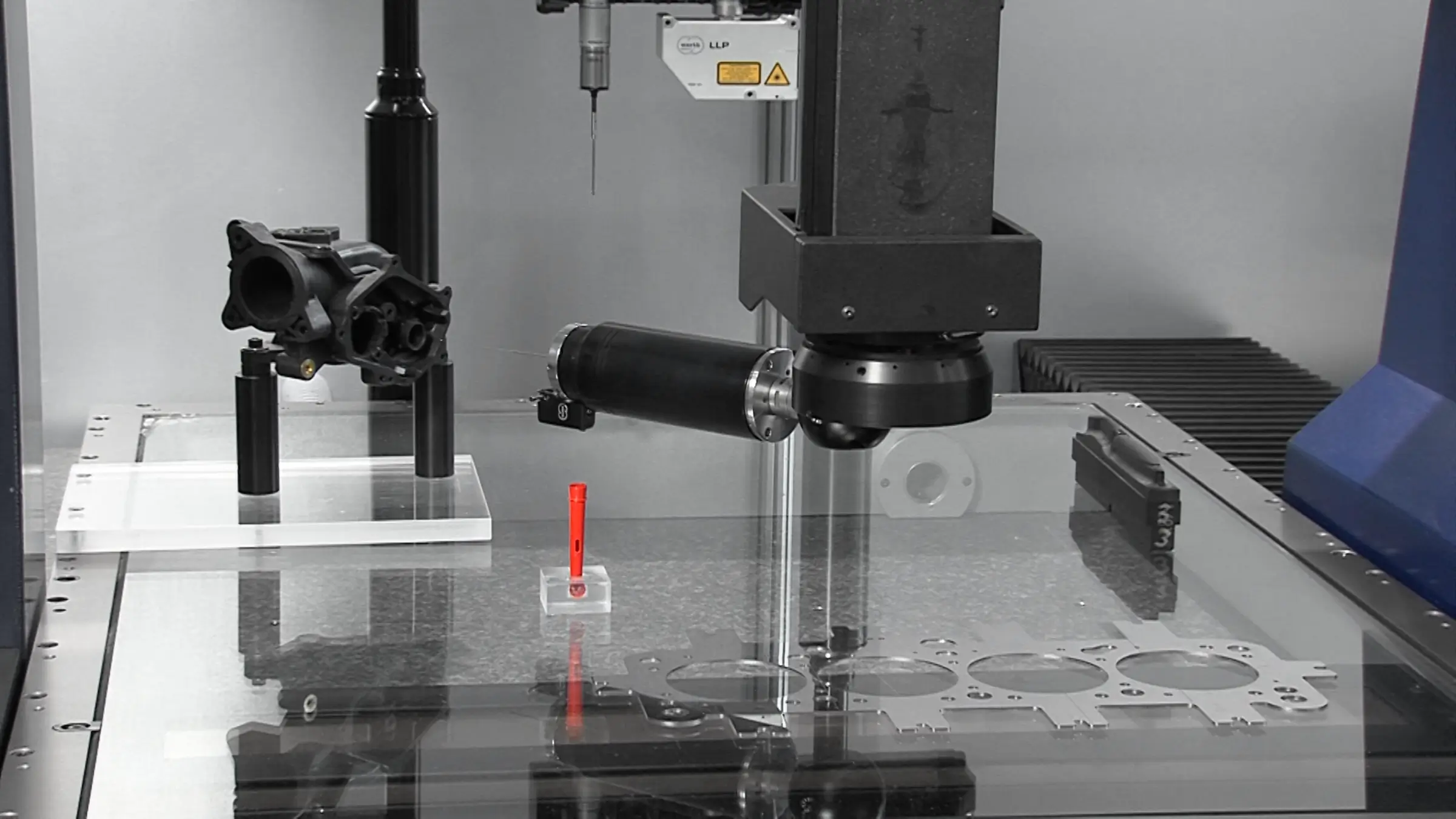

Sabit köprülü, doğruluk açısından optimize edilmiş, sağlam granit yapı

Bu makine sınıfında benzersiz olan 400 mm x 400 mm x 250 mm hacim ölçümü

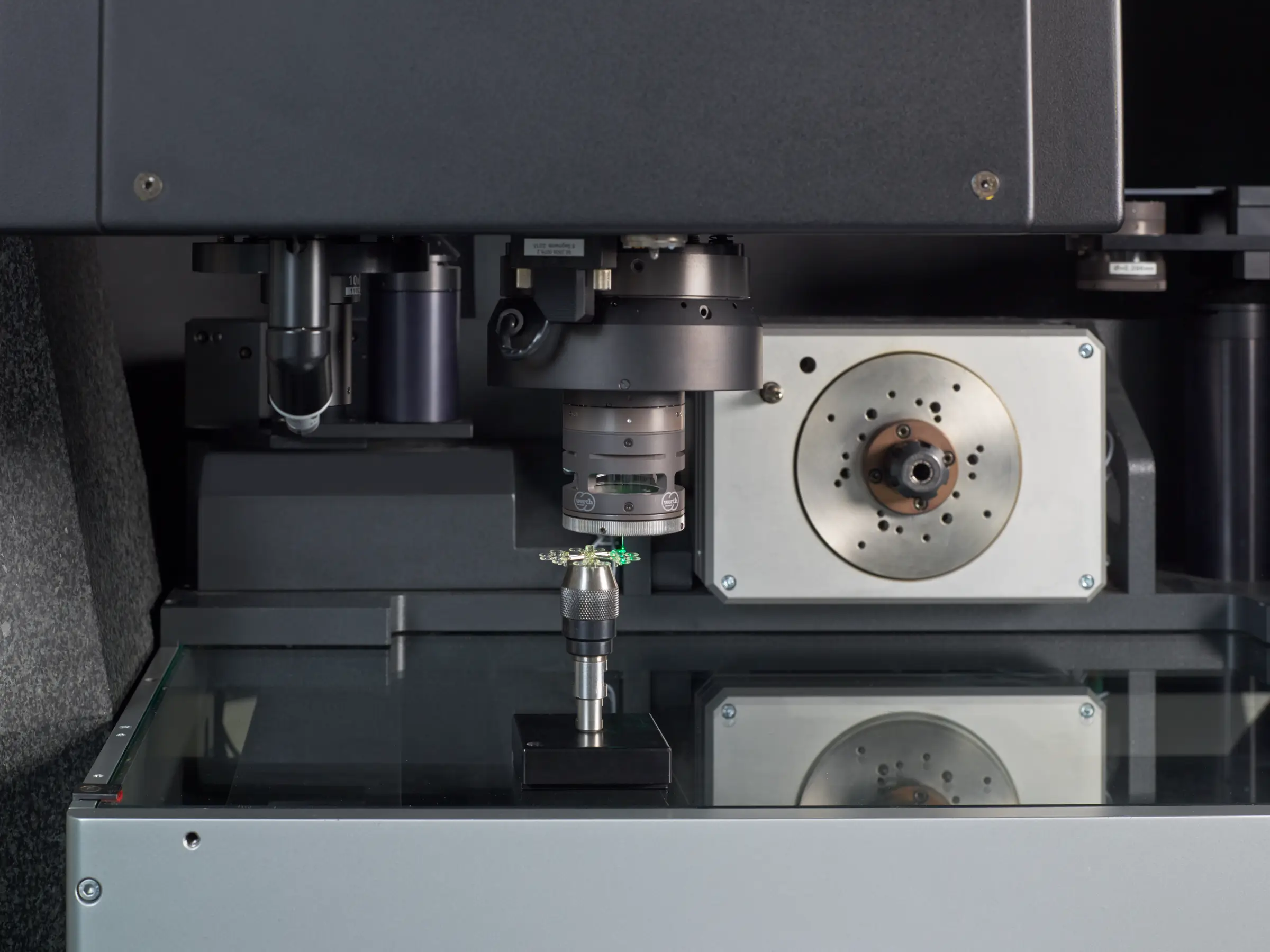

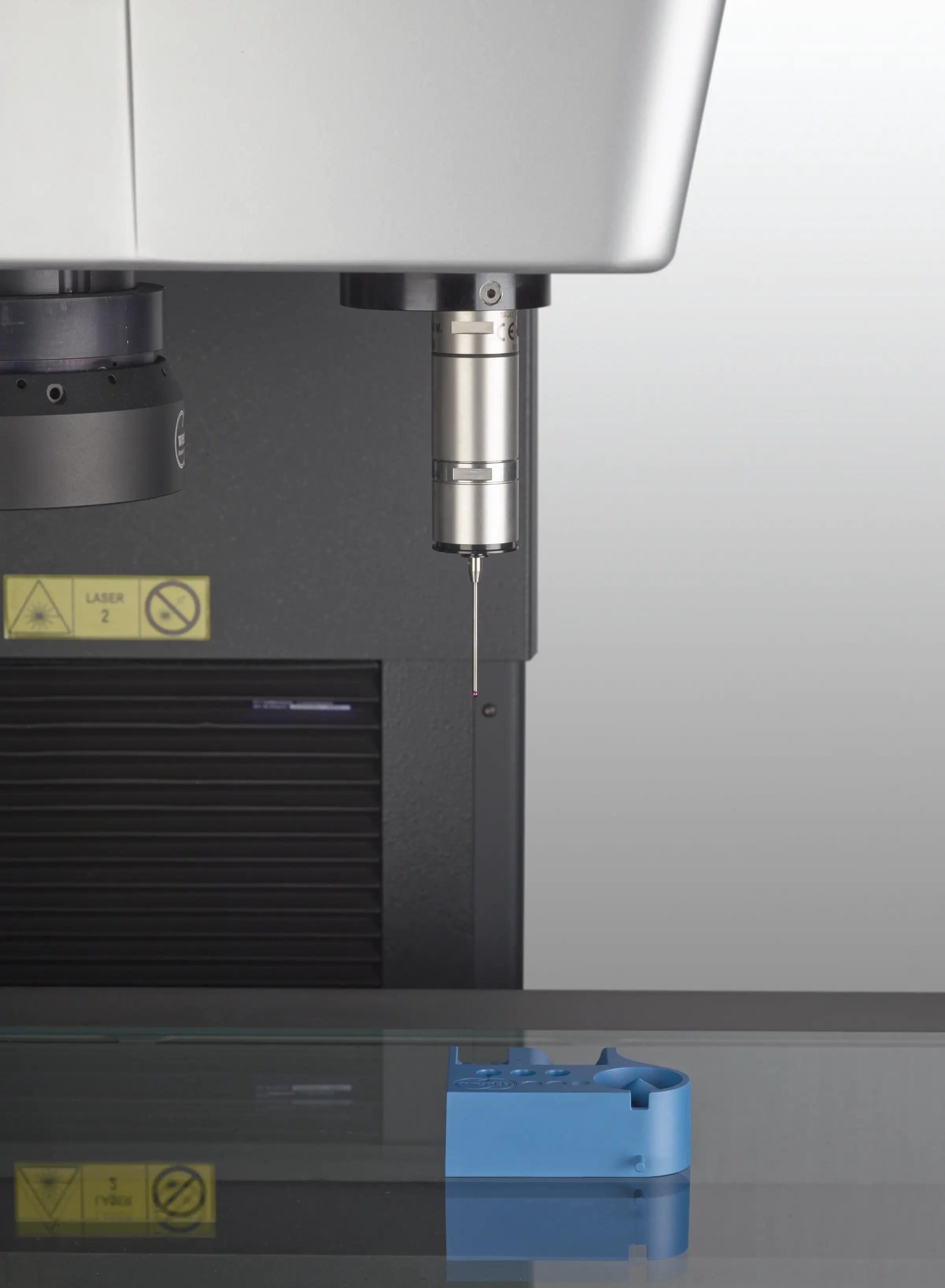

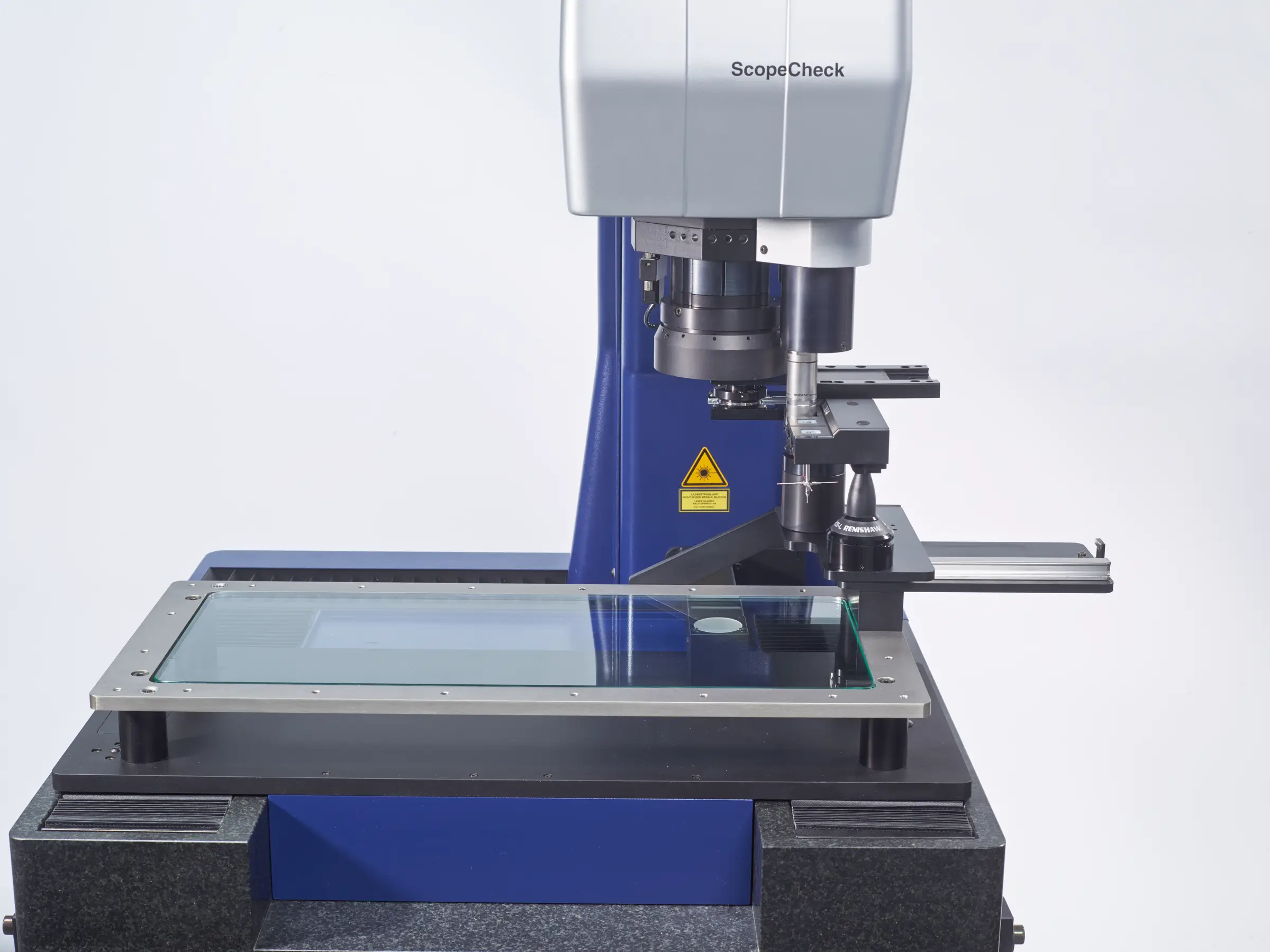

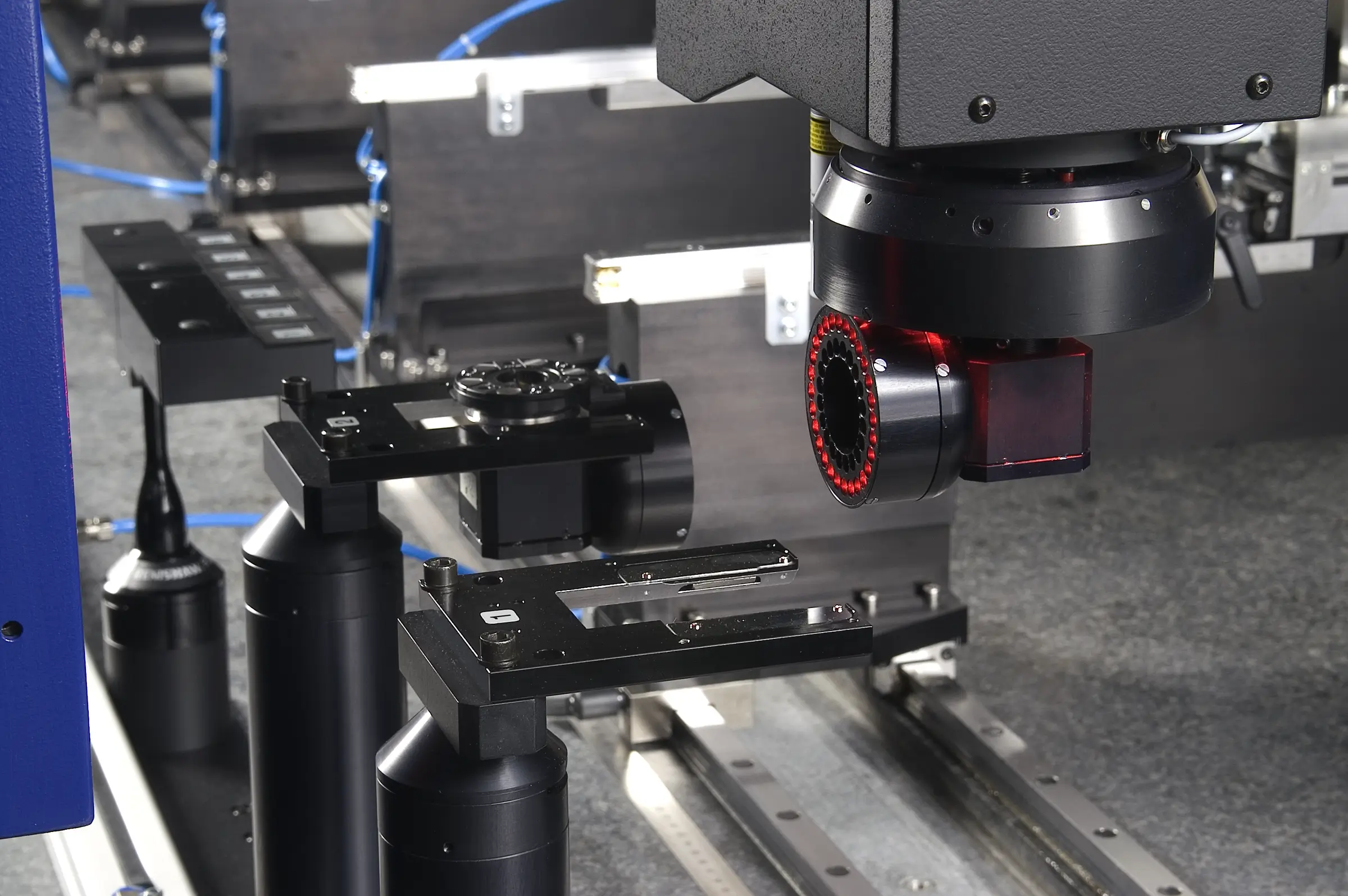

Son derece hassas optik ölçüm için telesentrik hassas optikler ve güçlü kontur görüntü işleme ile

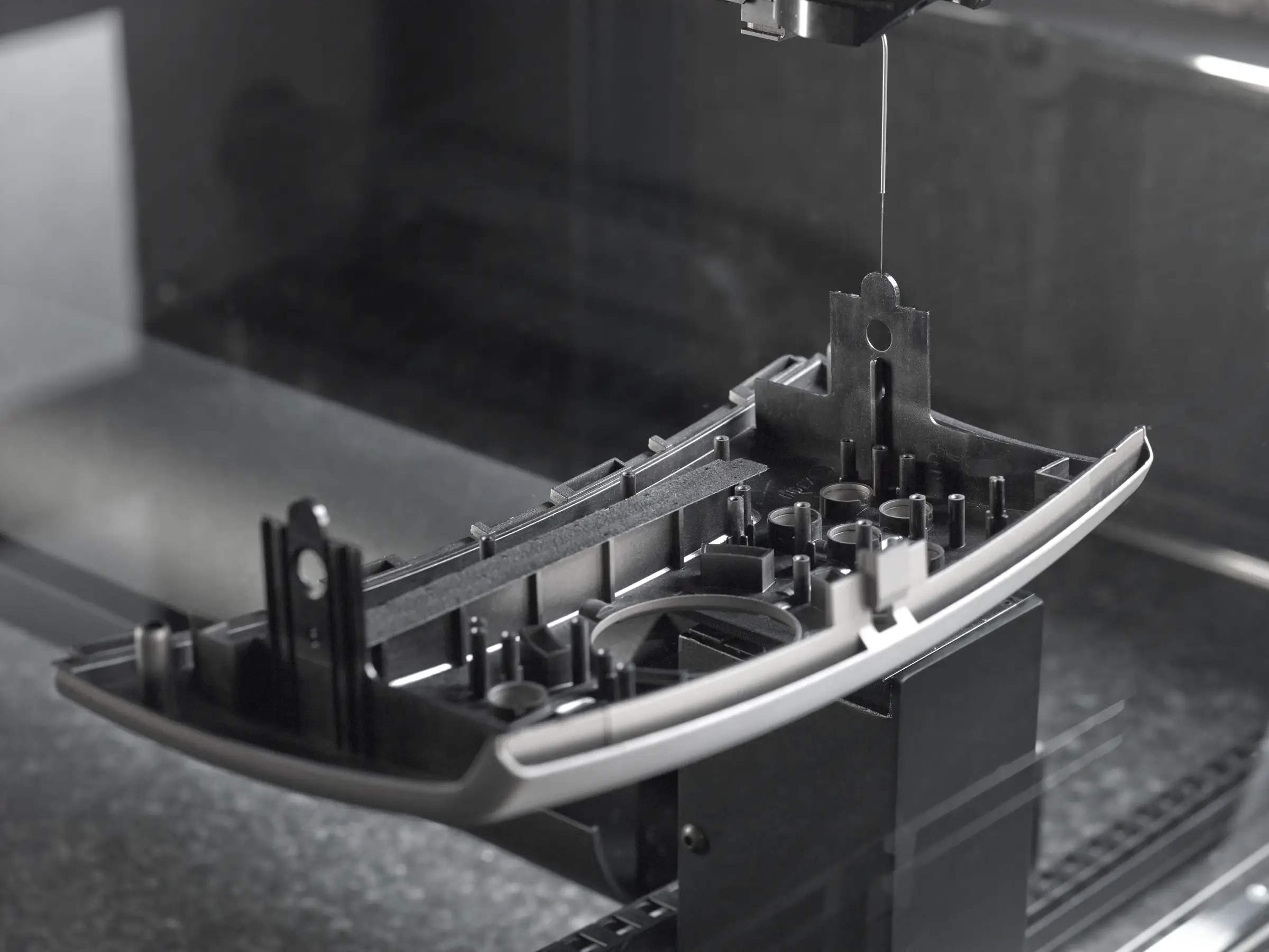

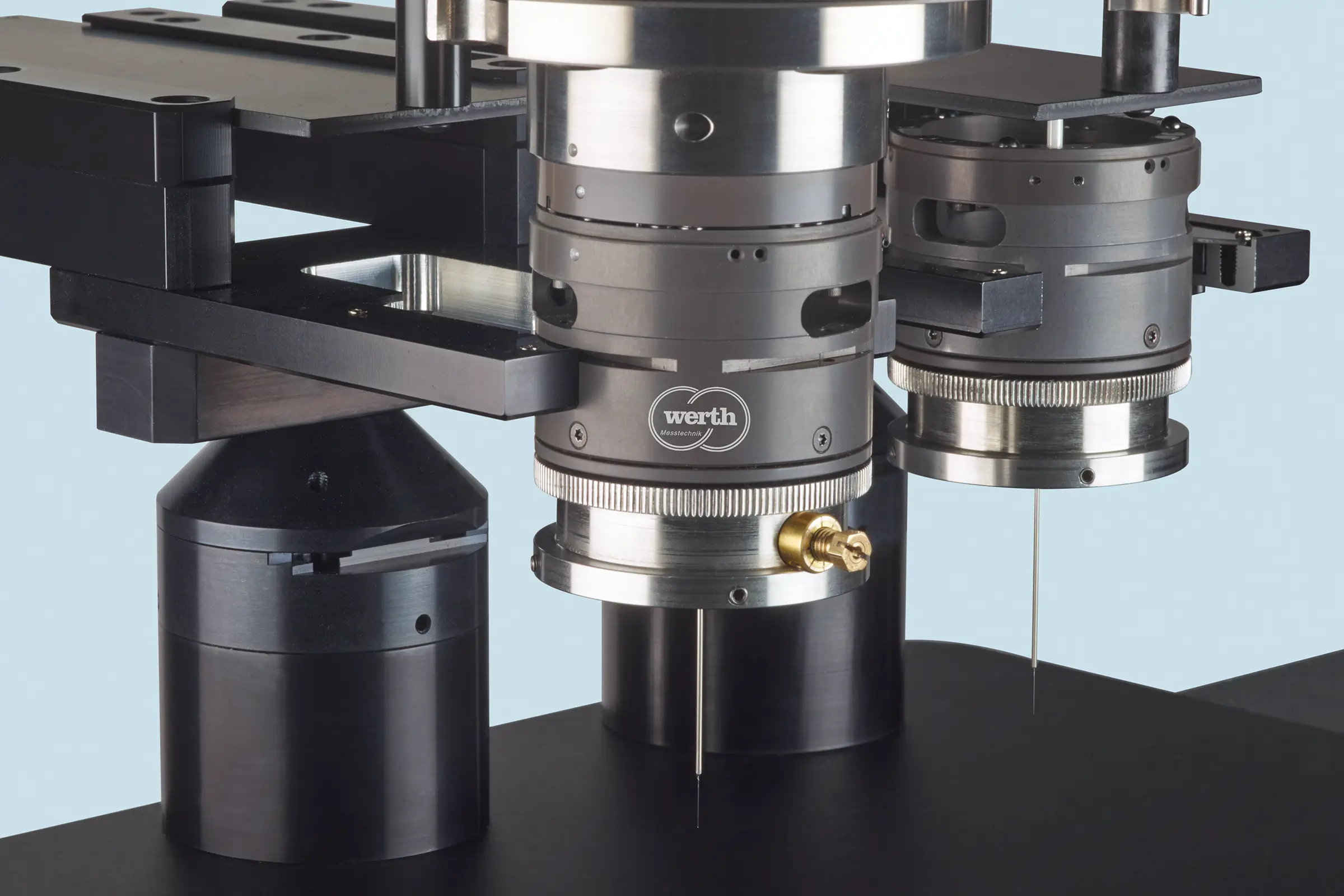

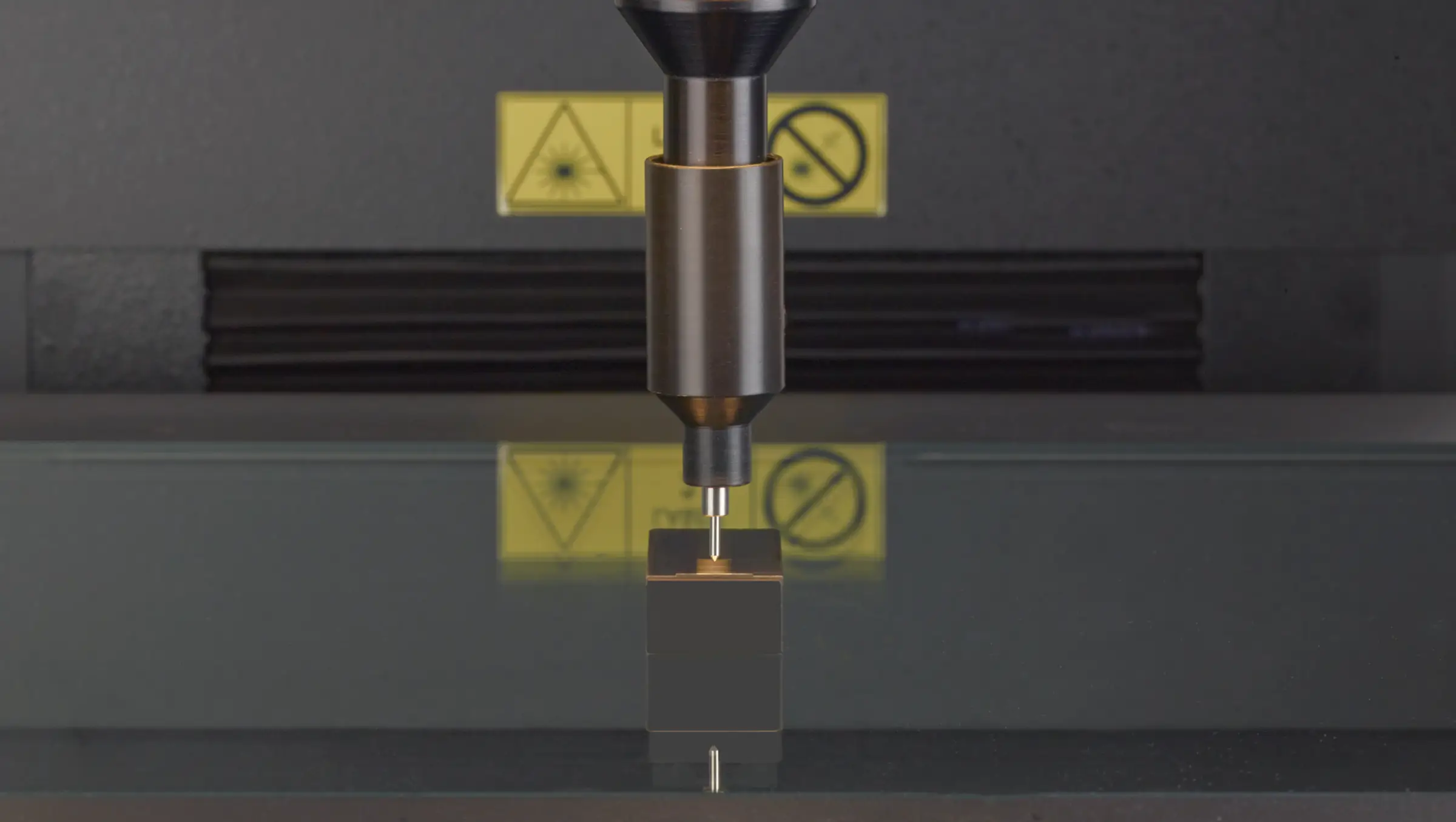

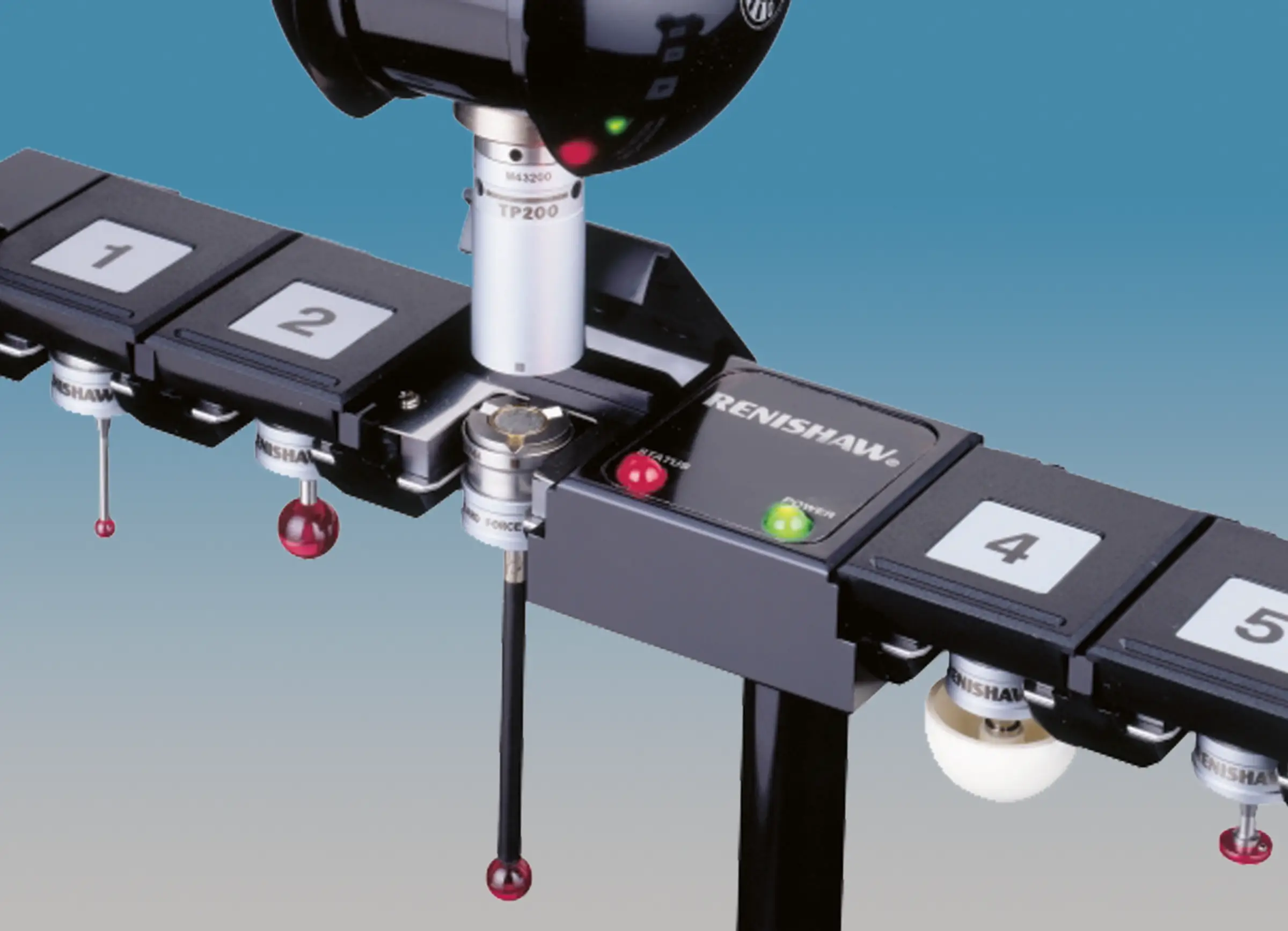

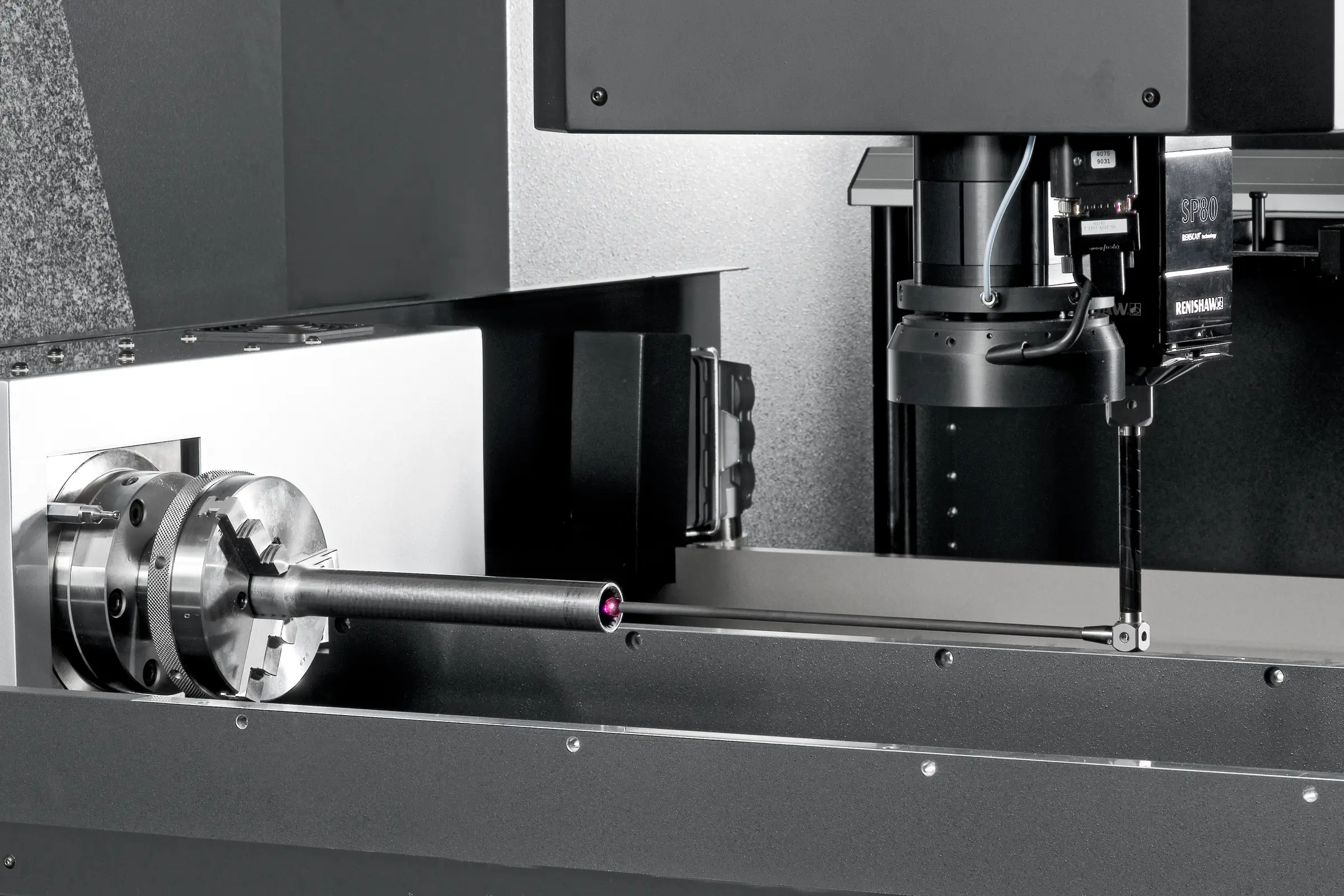

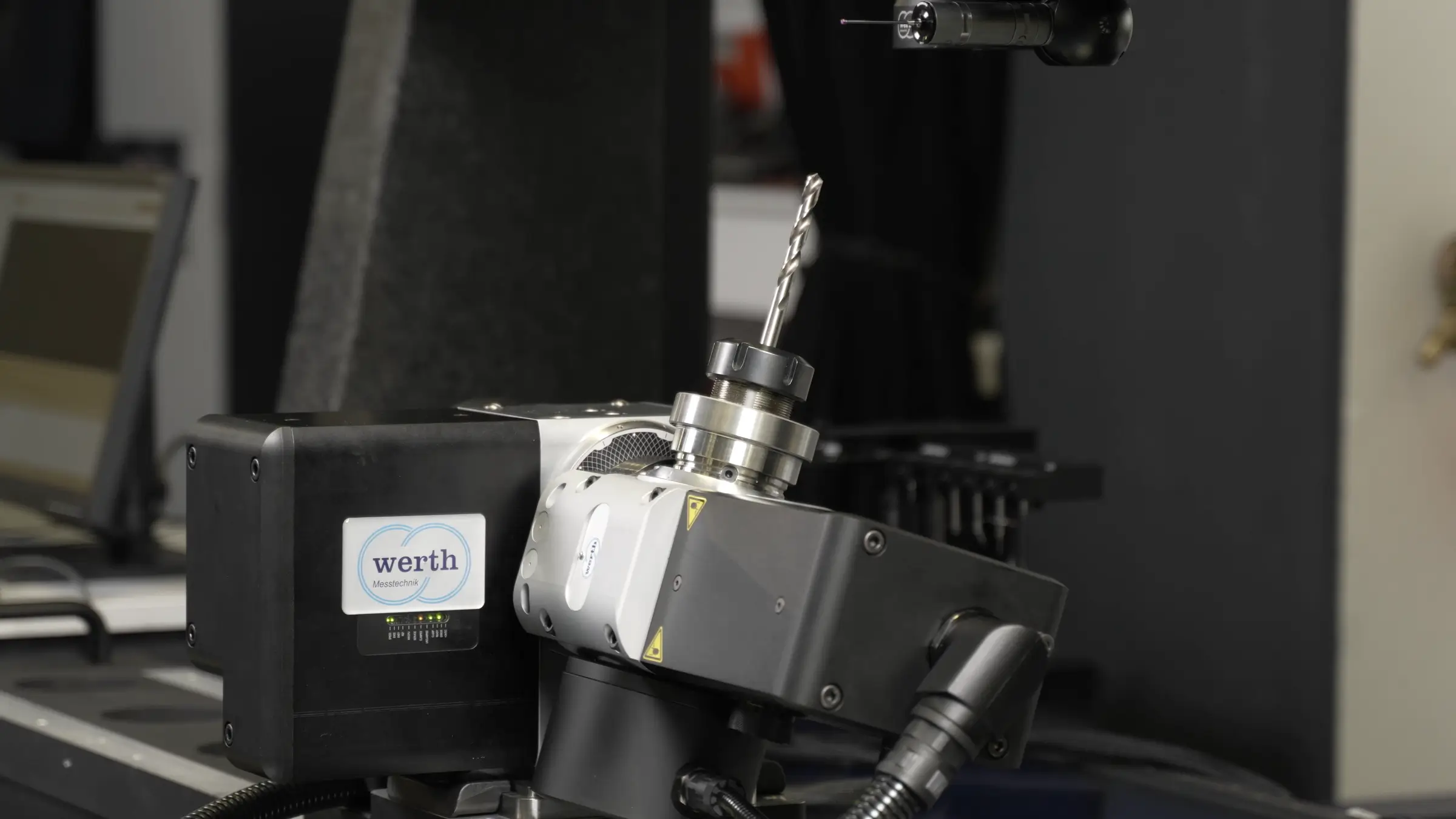

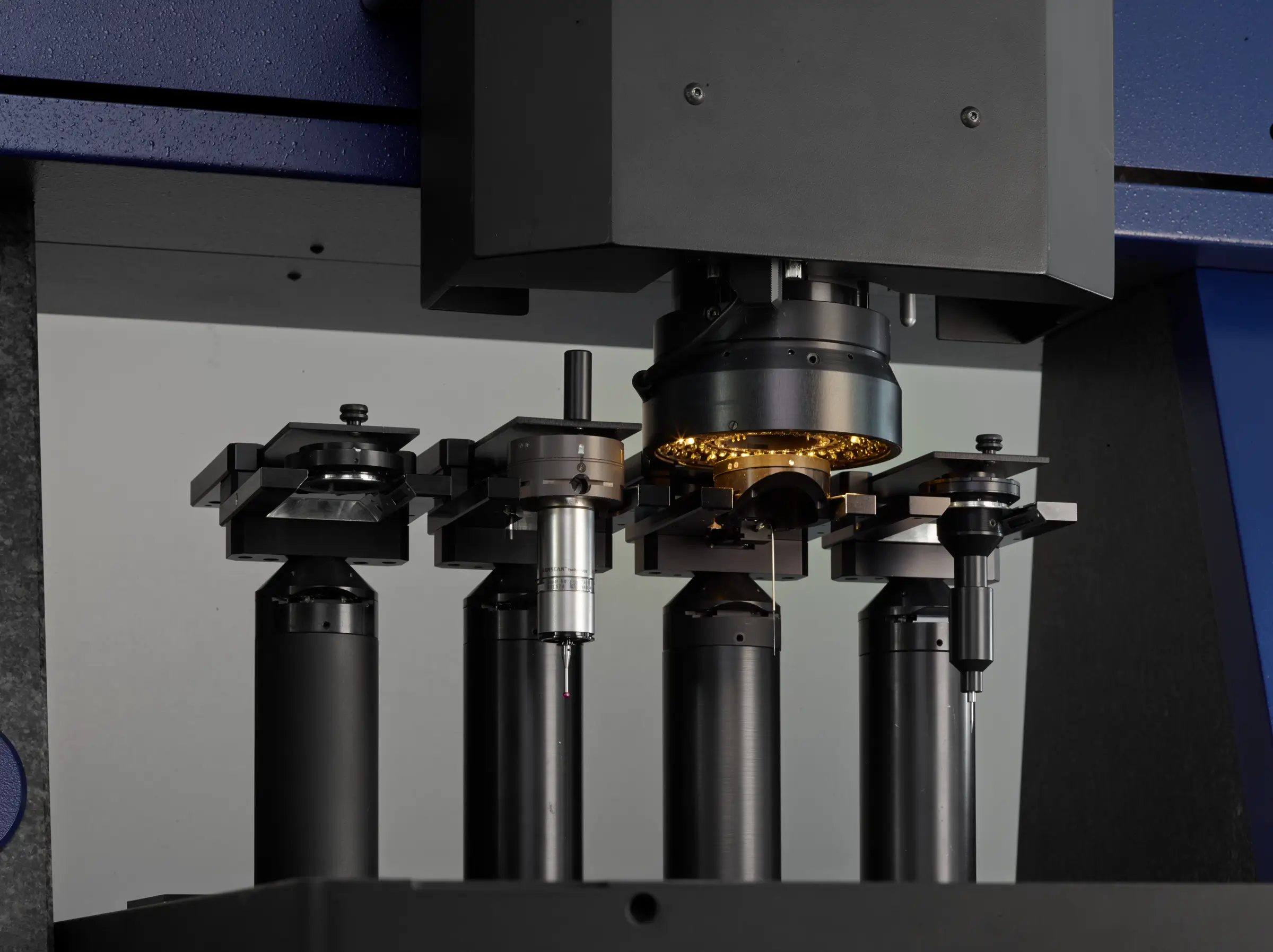

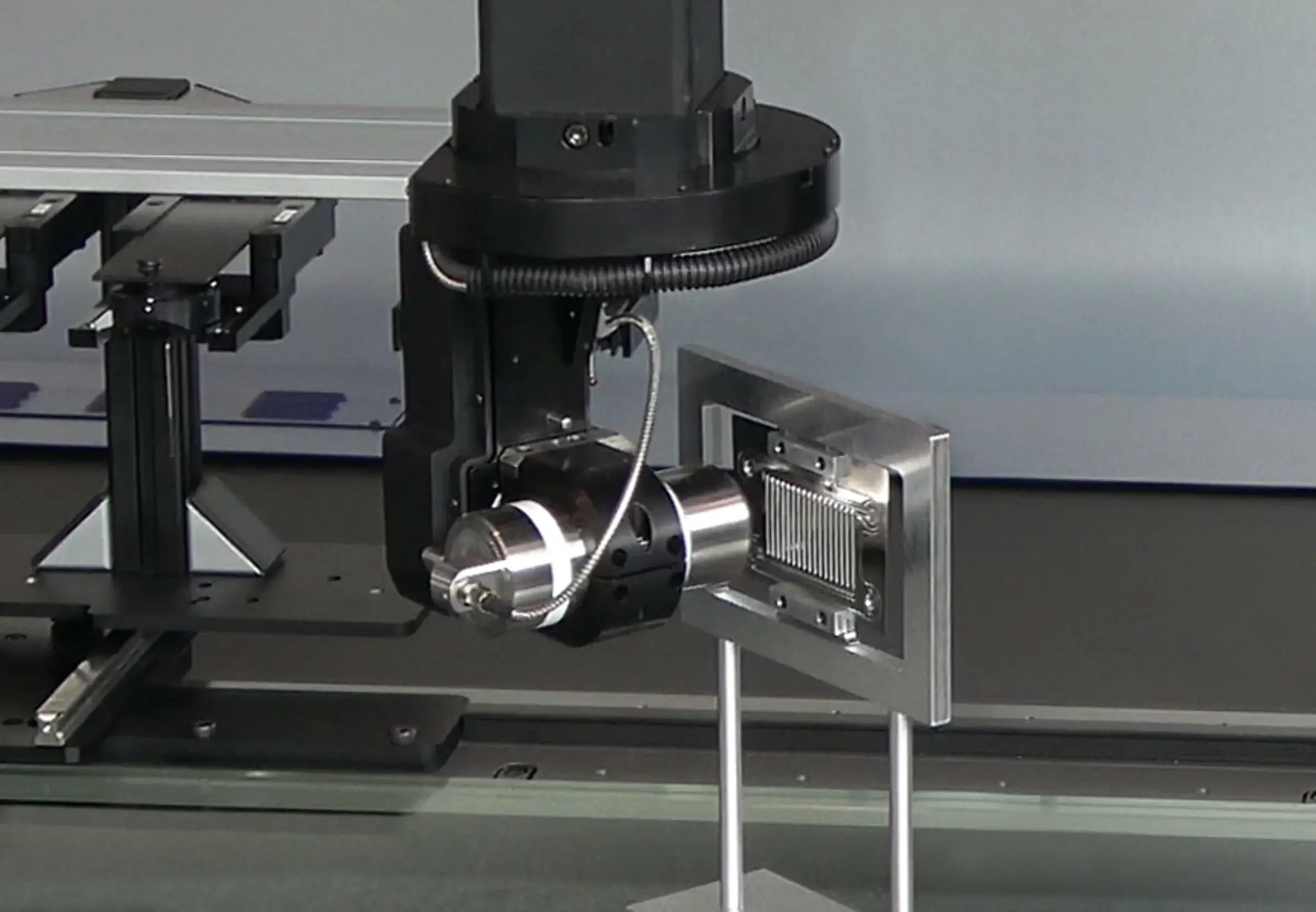

Patentli dokunsal-optik Werth Fiber Probe® mikro prob veya Chromatic Focus Point sensörü gibi ek yüksek hassasiyetli sensörlerin entegrasyonu

Hızlı kontrast autofocus sayesinde Z ekseninde son derece hassas ölçüm

Tip

Sabit köprülü Ultra Hassasiyetli 3D CNC çok sensörlü koordinat ölçüm makinesi

Ölçüm aralığı

X = 400 mm, Y = 400 mm, Z = 250 mm

Hassasiyet

İzin verilen uzunluk ölçüm hatası 0,15 µm'ye kadar

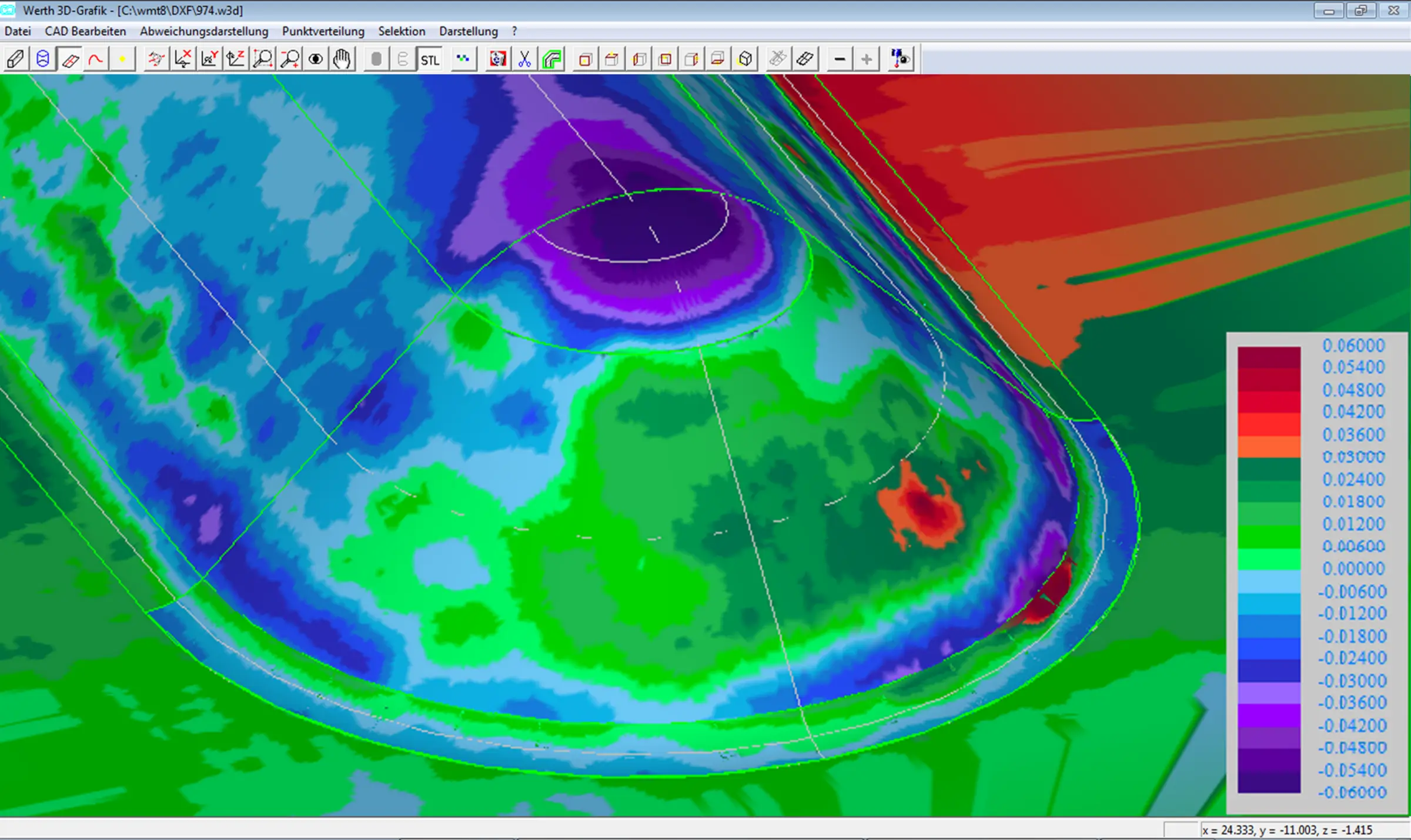

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...