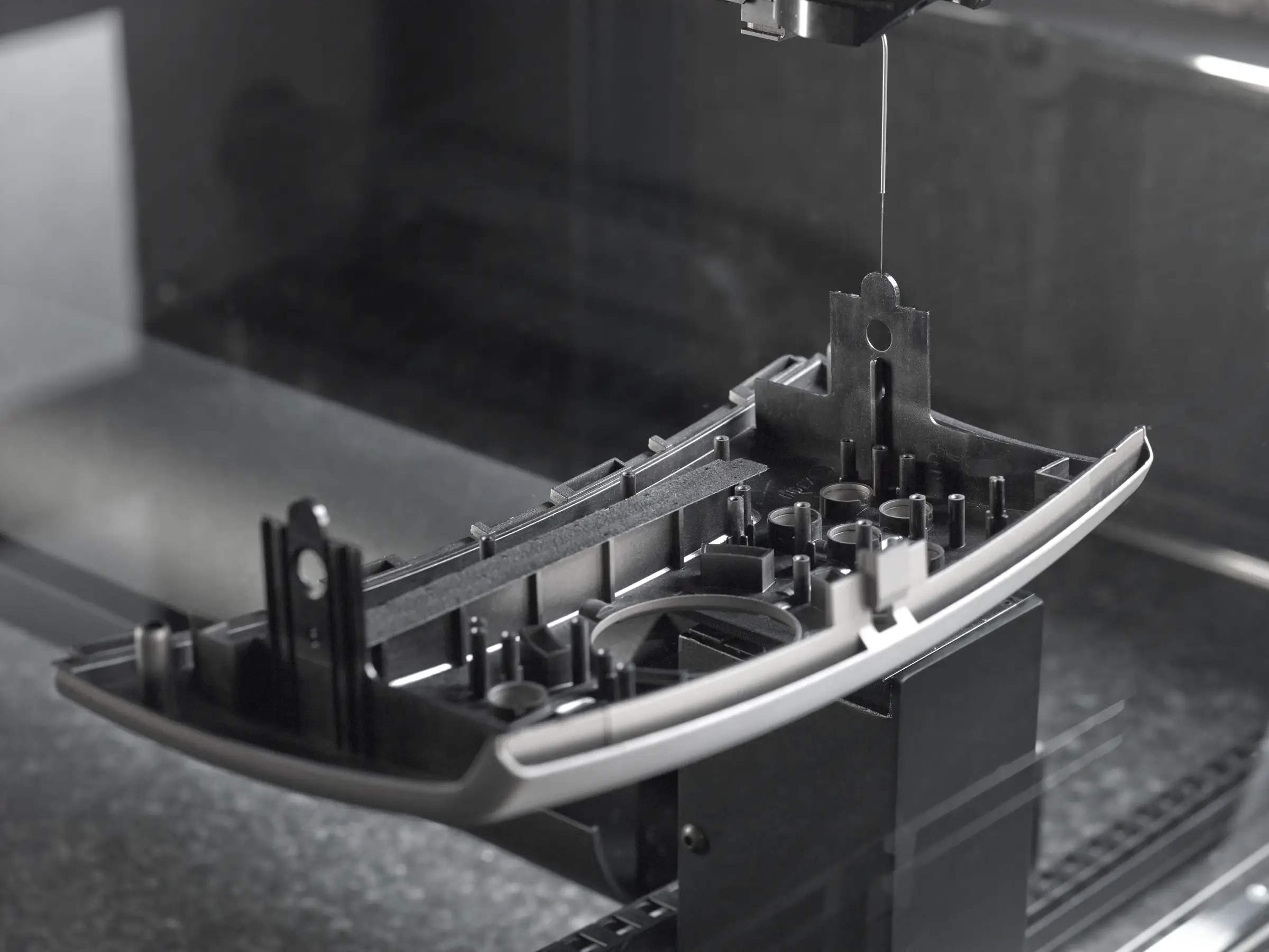

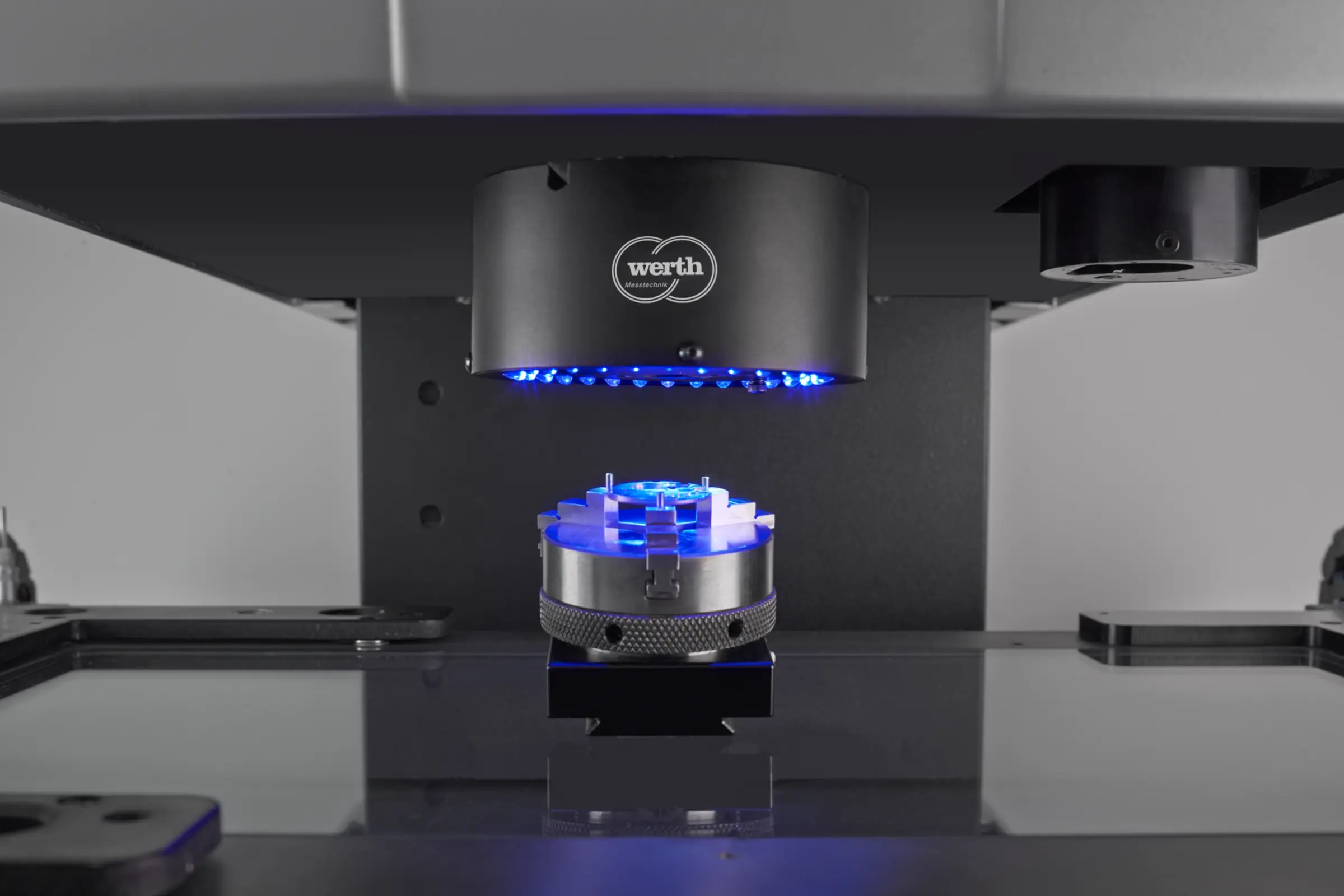

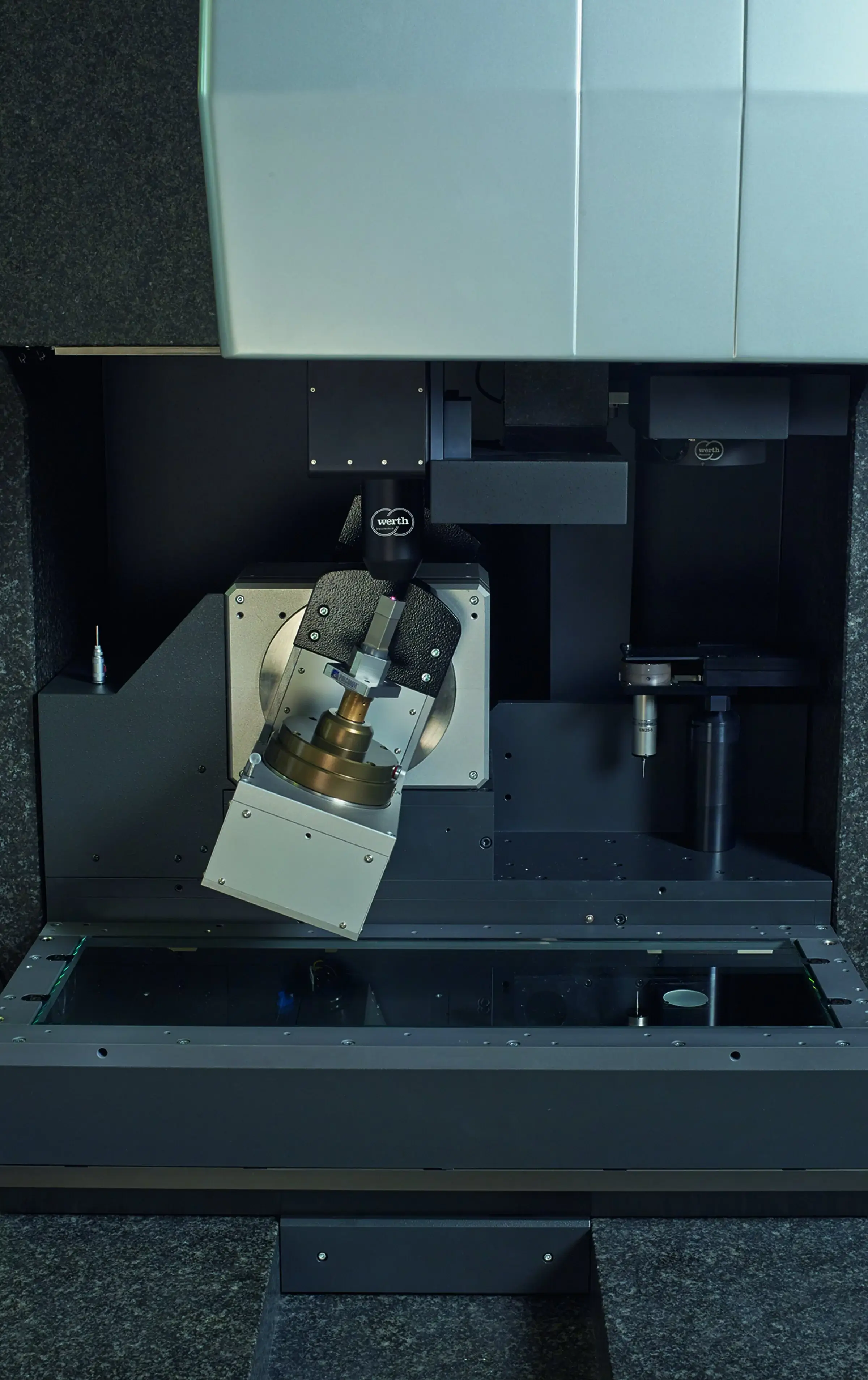

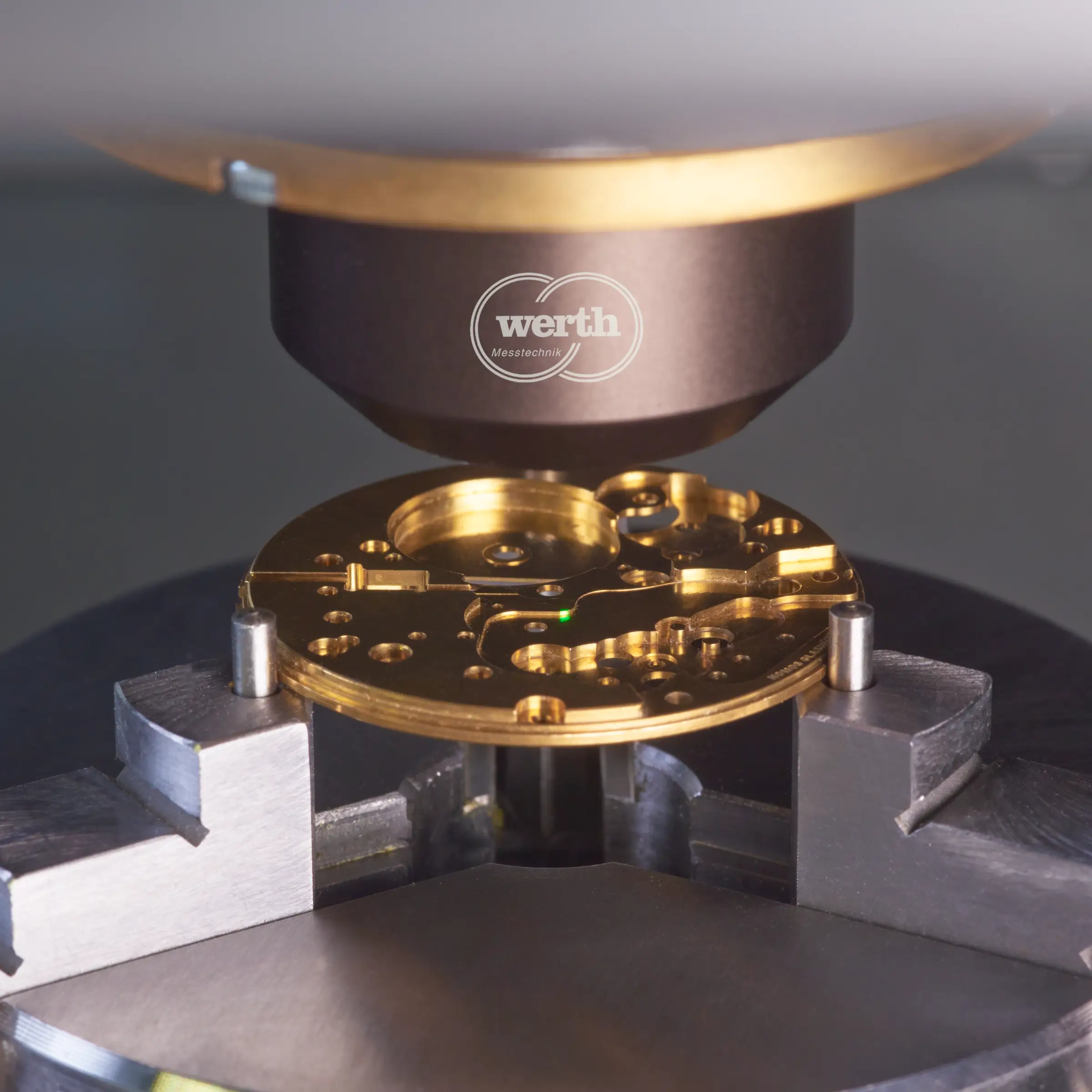

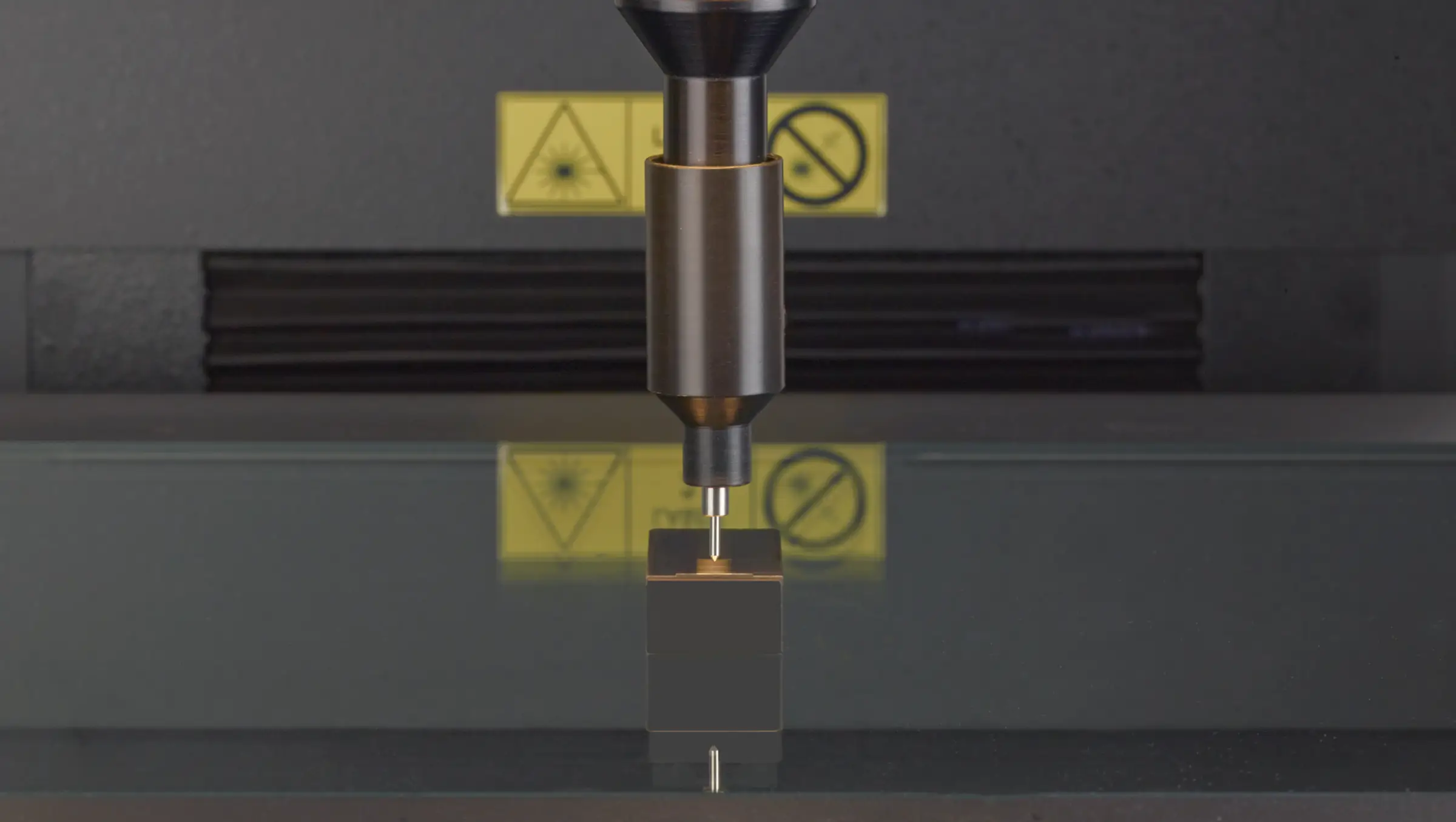

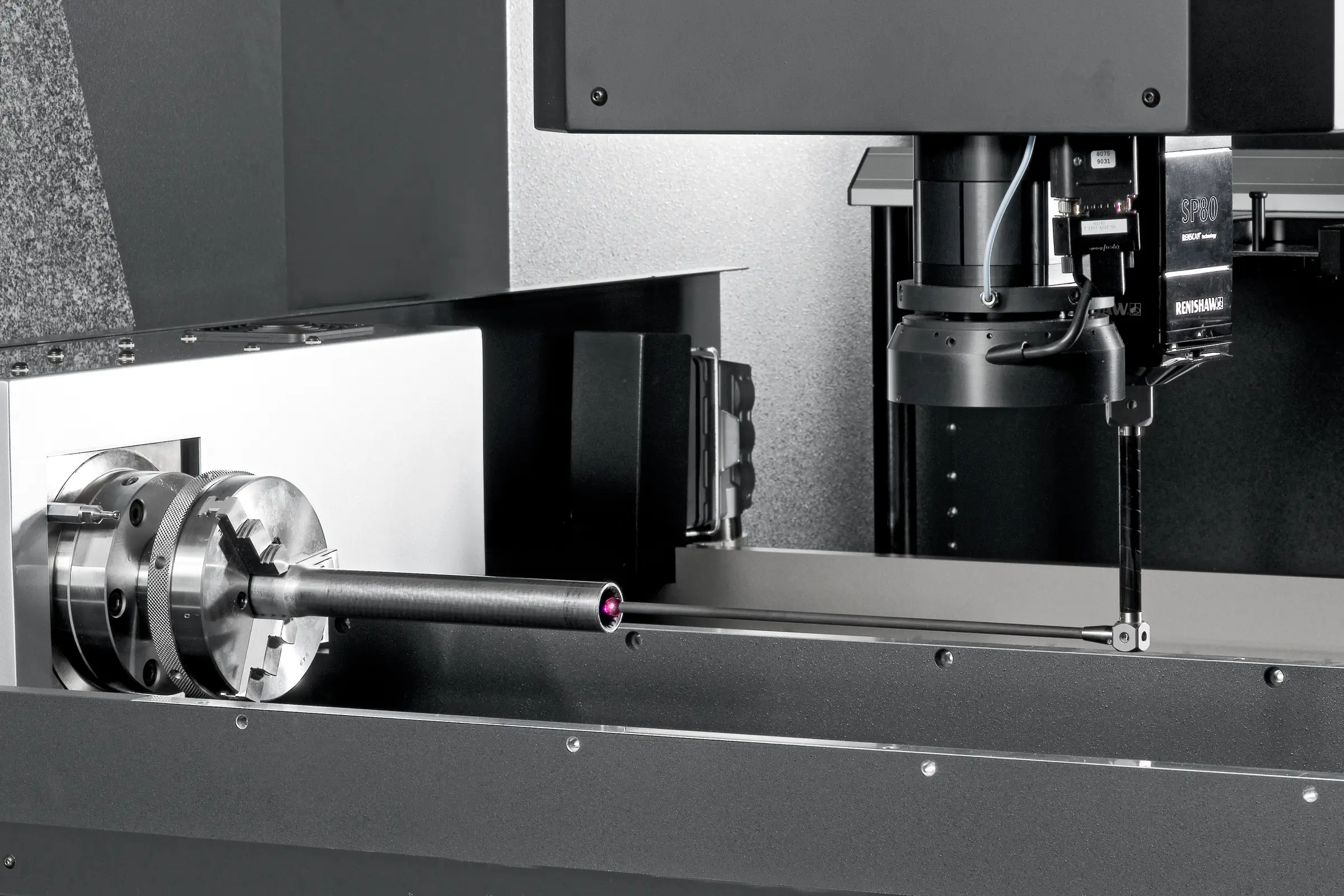

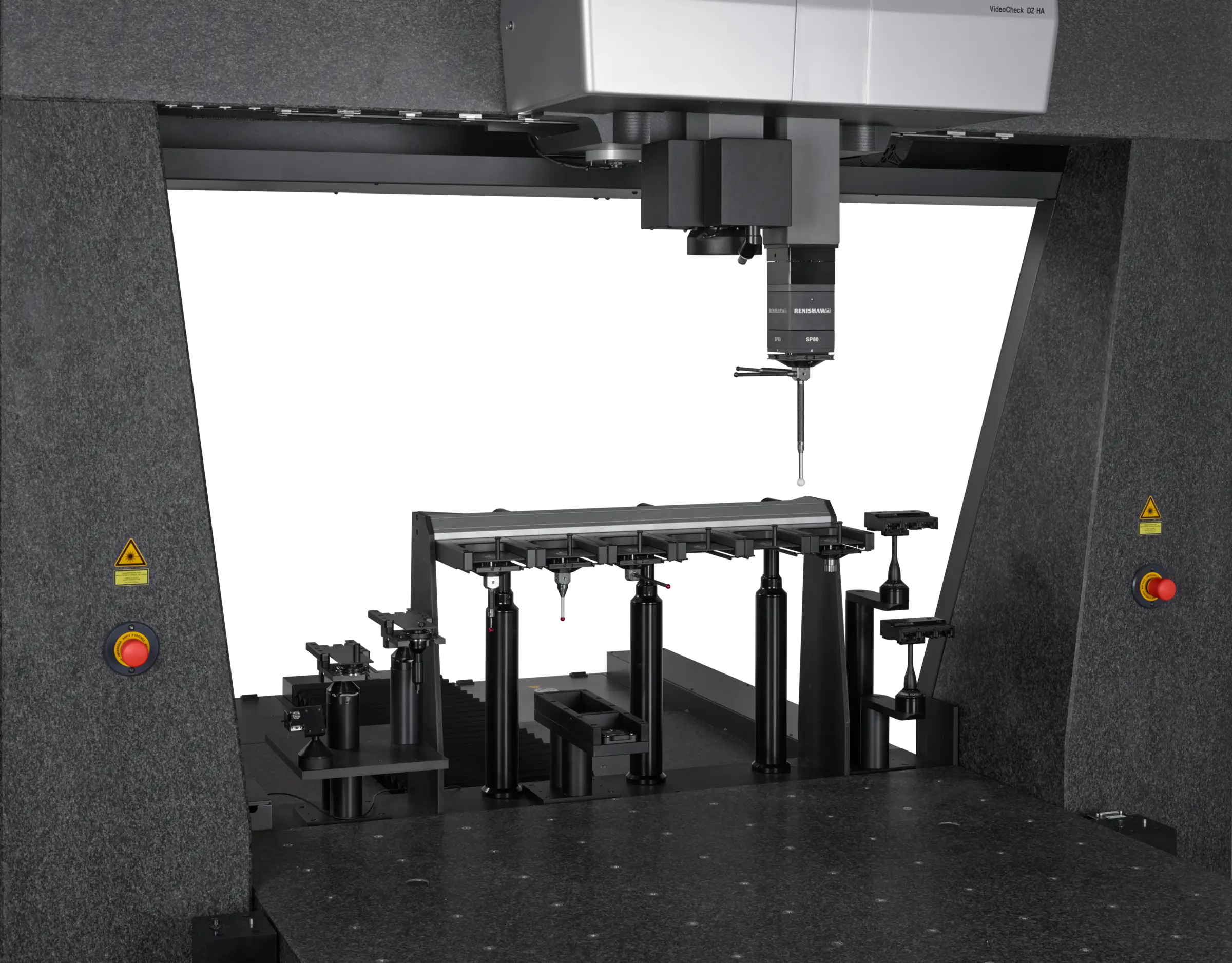

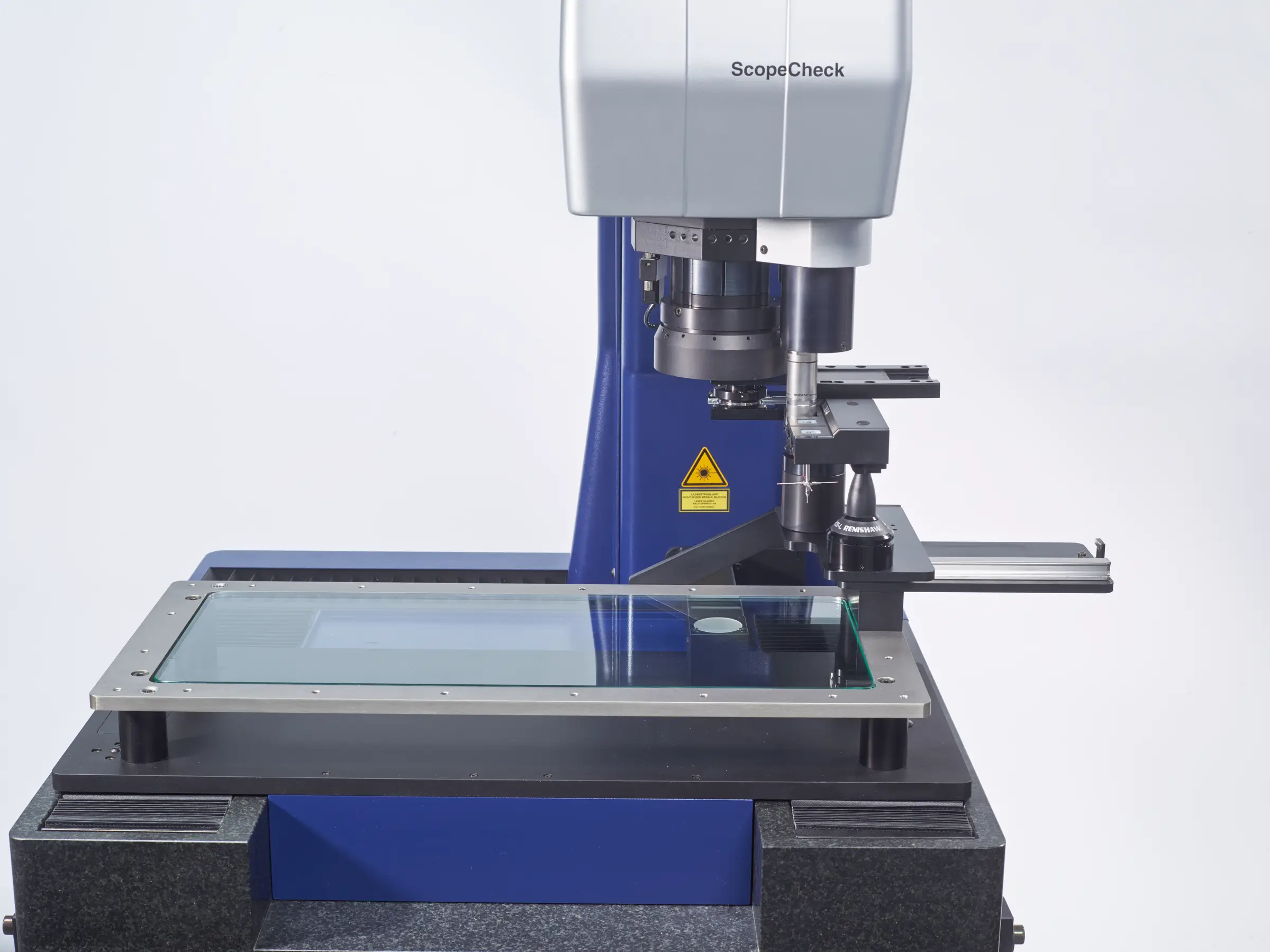

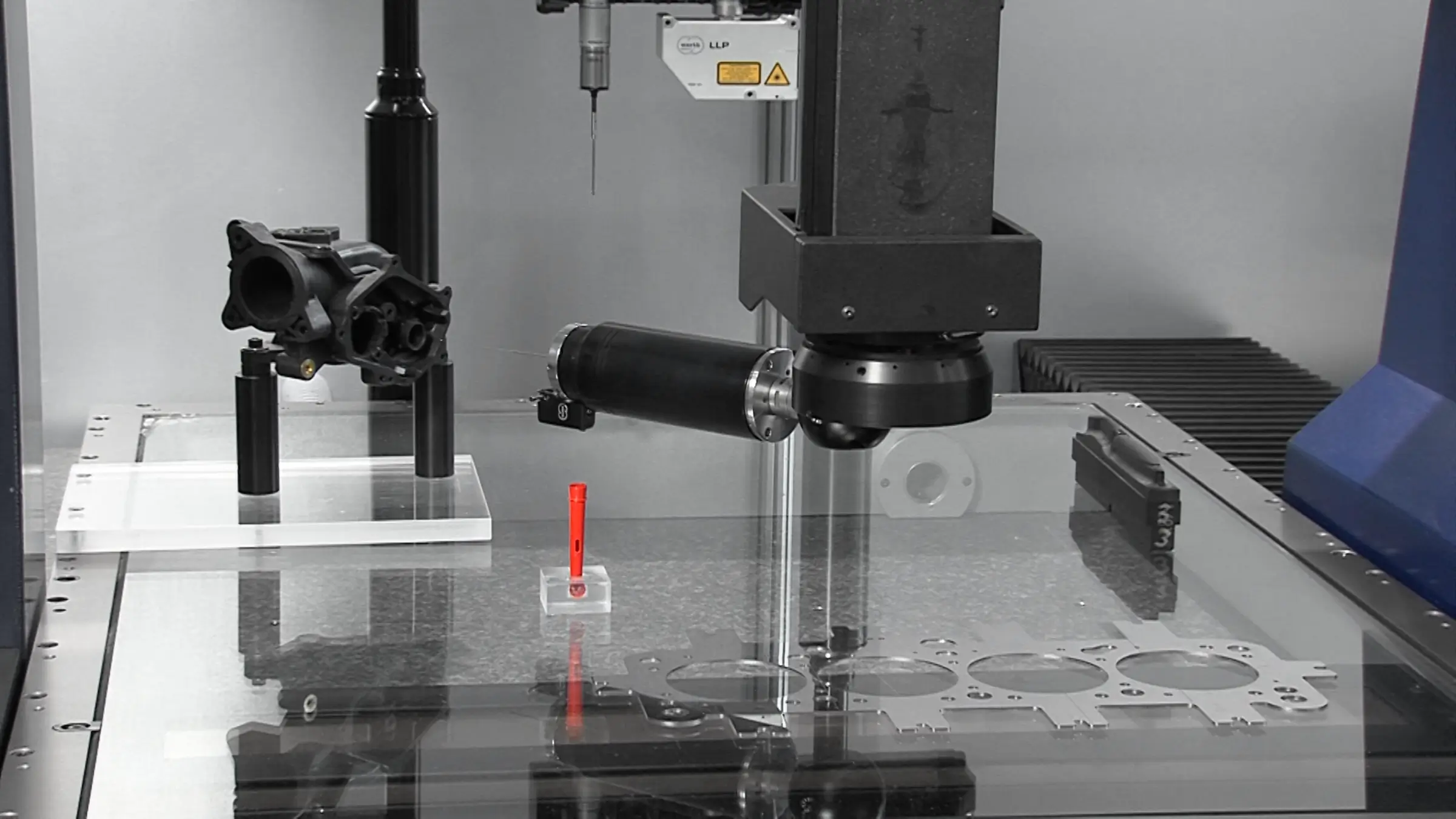

Sağlam granit yapısı, özel hava yatağı teknolojisi ve sıcaklığa dayanıklı ölçek sistemleriyle VideoCheck® V HA, mikrometrenin onda biri aralığında ölçüm belirsizlikleri sağlar. Yüksek hassasiyetli makine, şaftlar ve takımlar gibi dönme simetrisine sahip iş parçalarının ölü ağırlığından kaynaklanan sapmayı önleyen entegre bir dikey döner eksene sahiptir. Form frezeleri, spiral, kademeli ve dişli kılavuzları veya şaftlar gibi iş parçaları ölçülür.

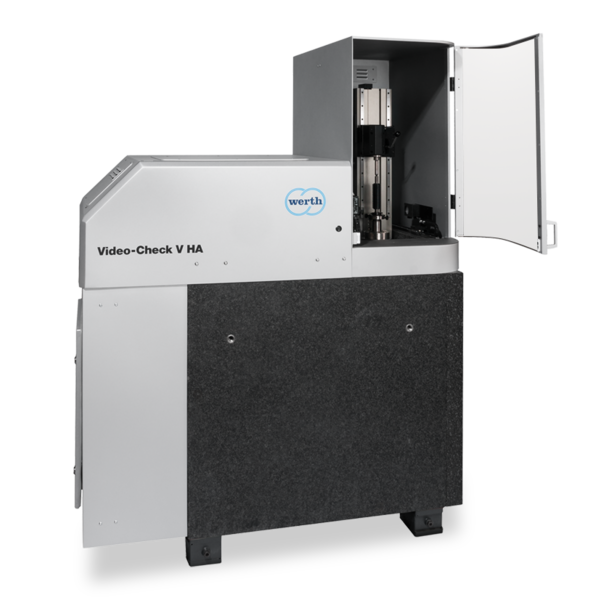

VideoCheck® V HA

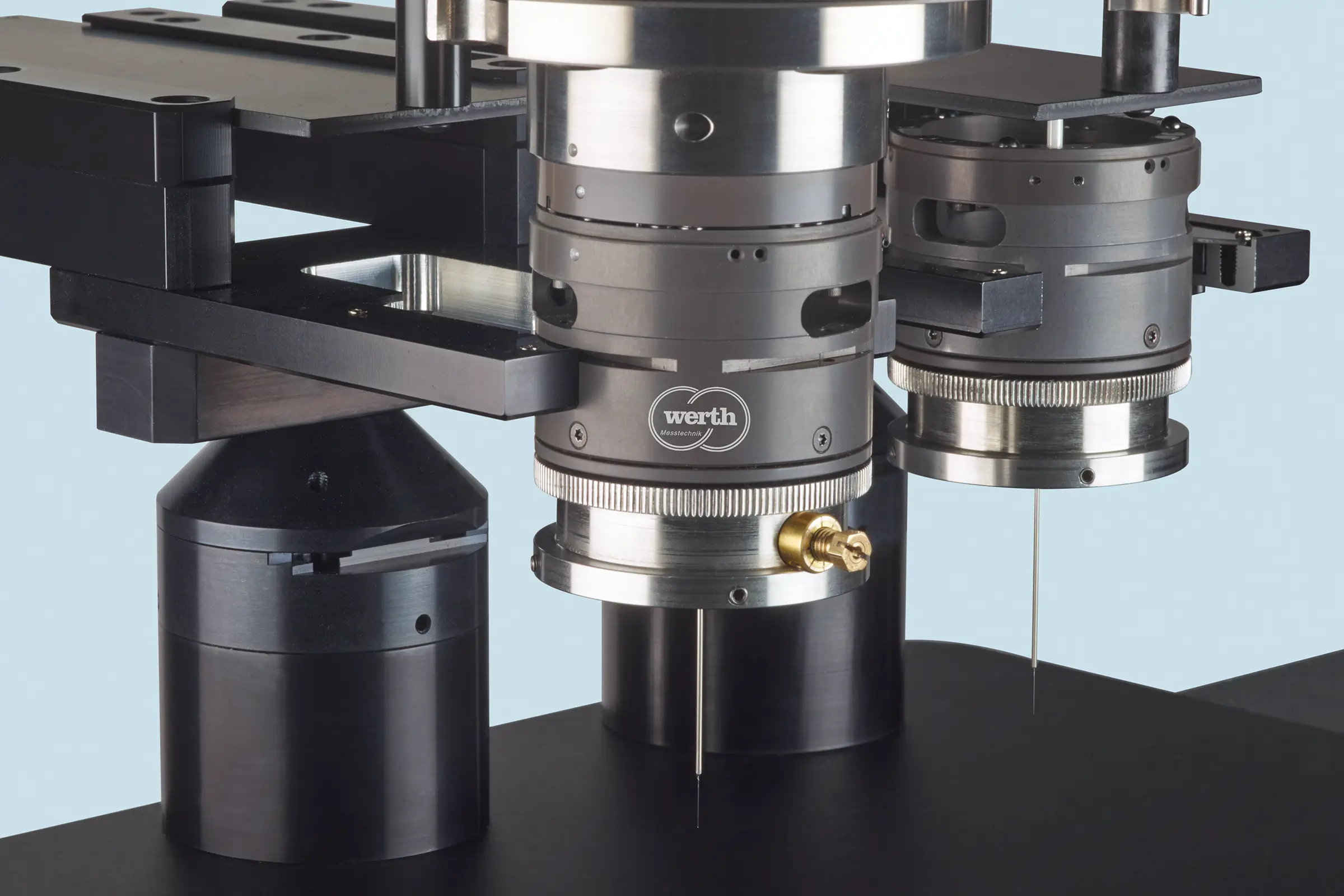

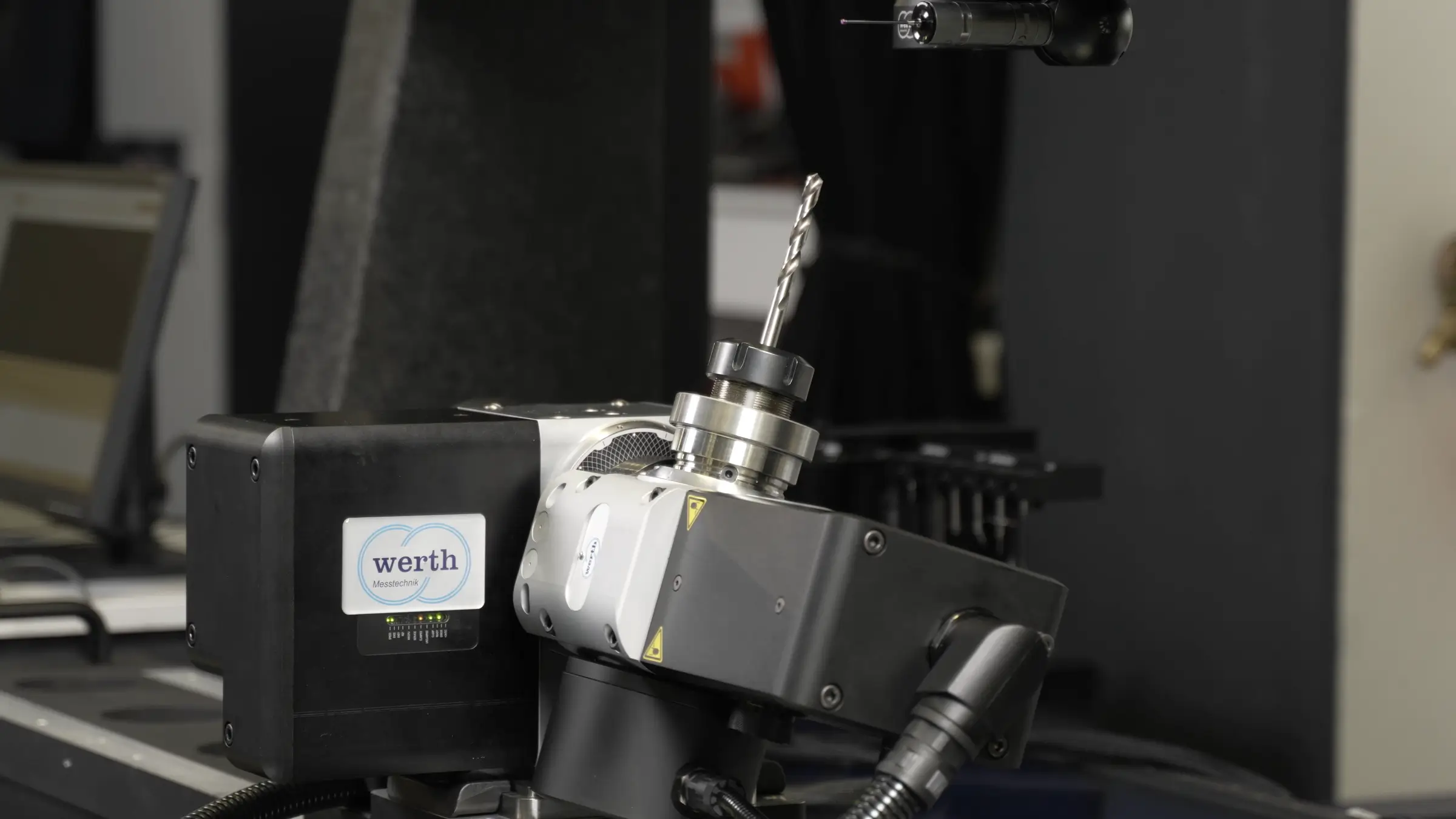

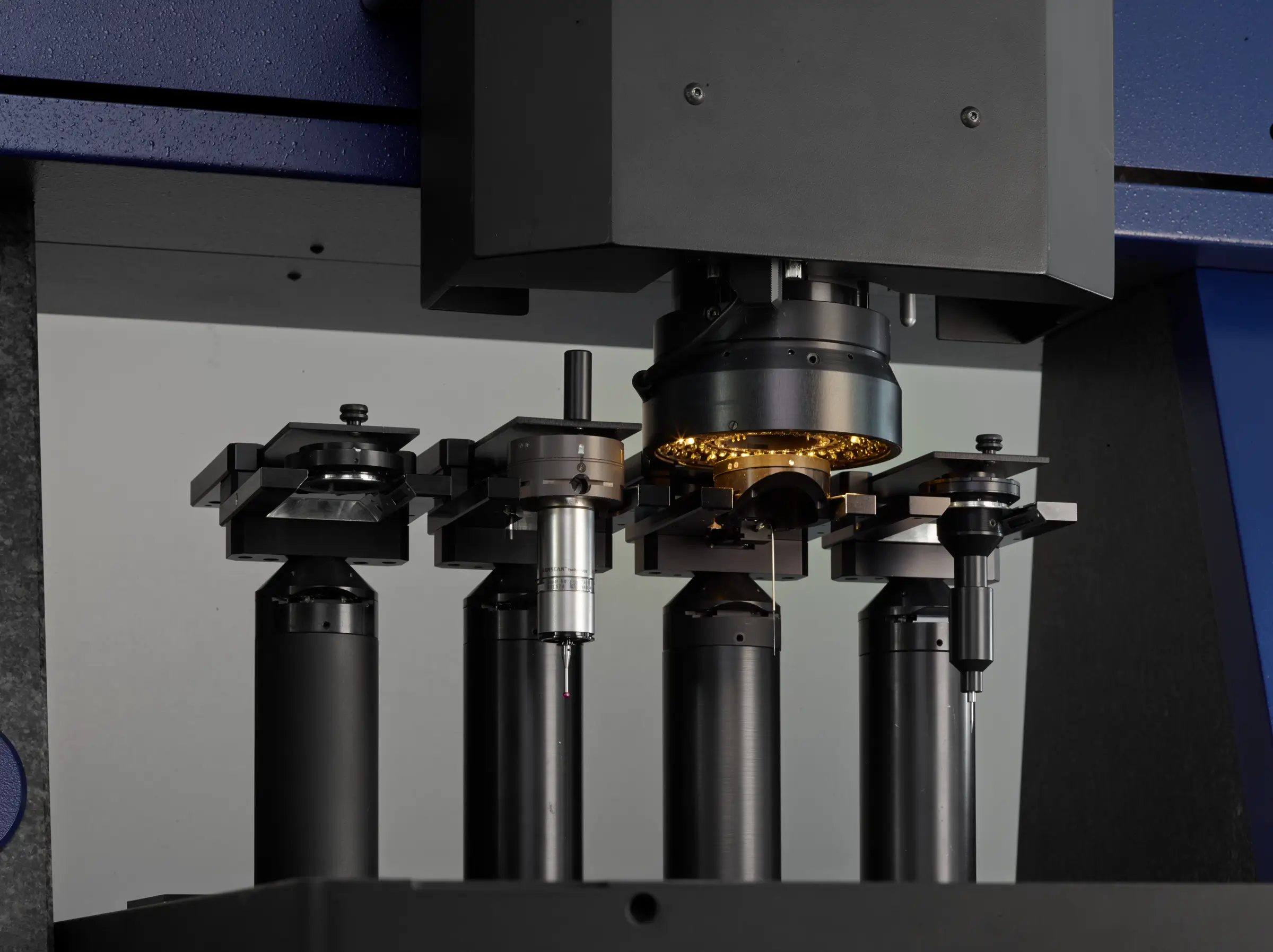

Son derece hassas hava yataklı döner eksenli ergonomik dikey iş parçası sıkıştırma

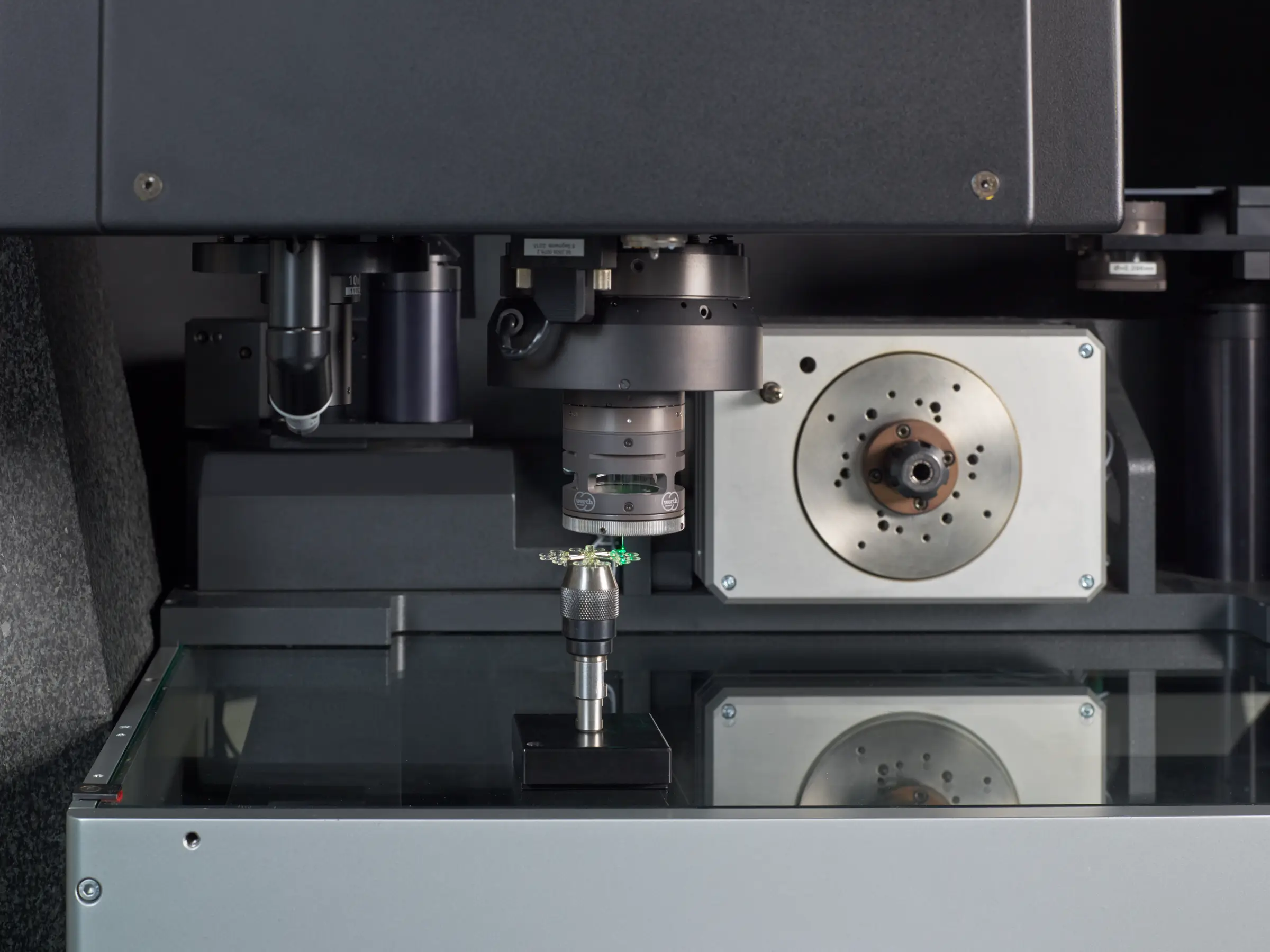

Tüm yaygın sıkıştırma sistemleri için fikstür, örneğin HSK, SK, hidrolik ayna, Capto, sabit ve döner merkez

Yüksek ağırlıktaki aletler yüksek doğrulukla ölçülebilir

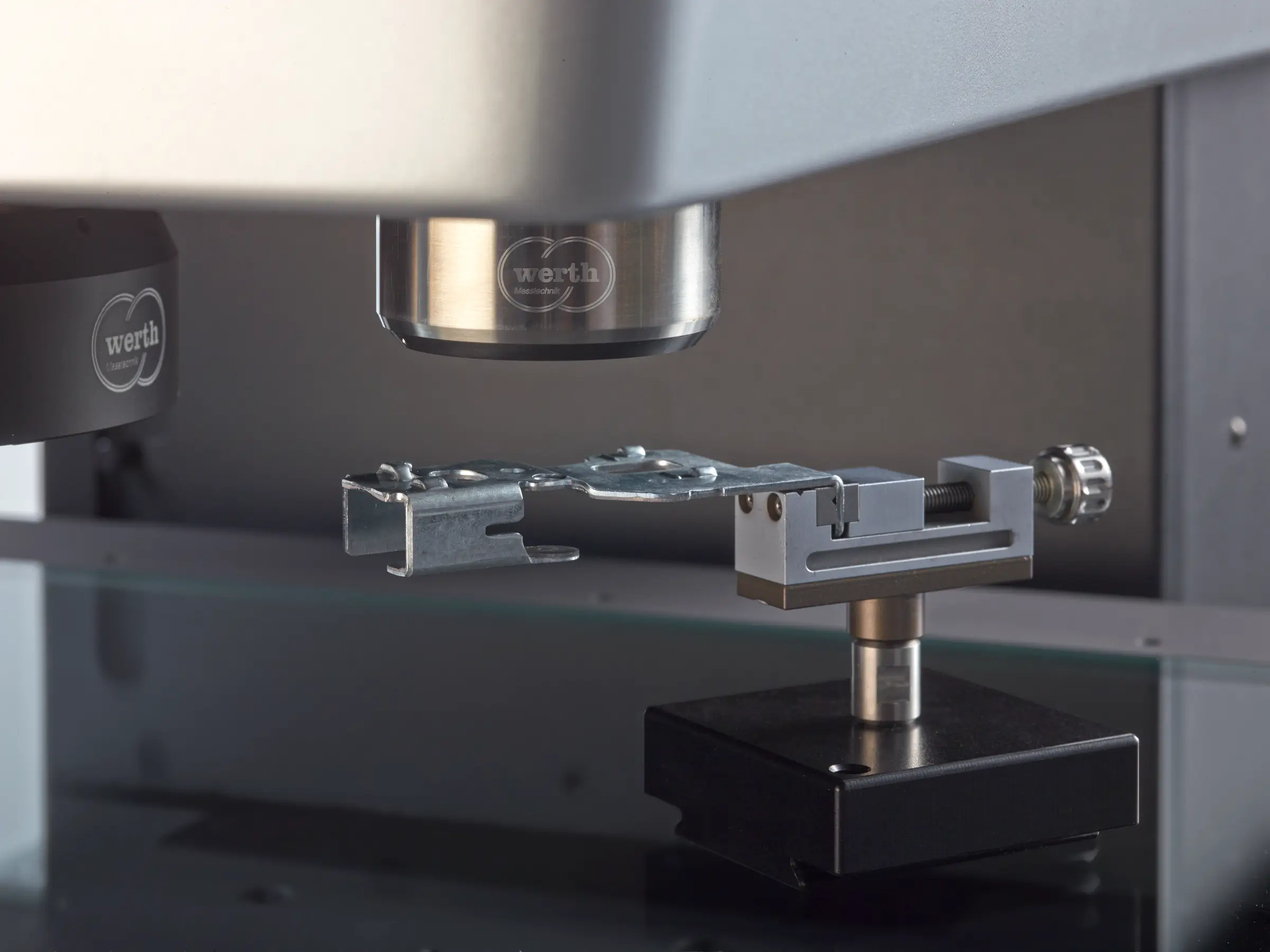

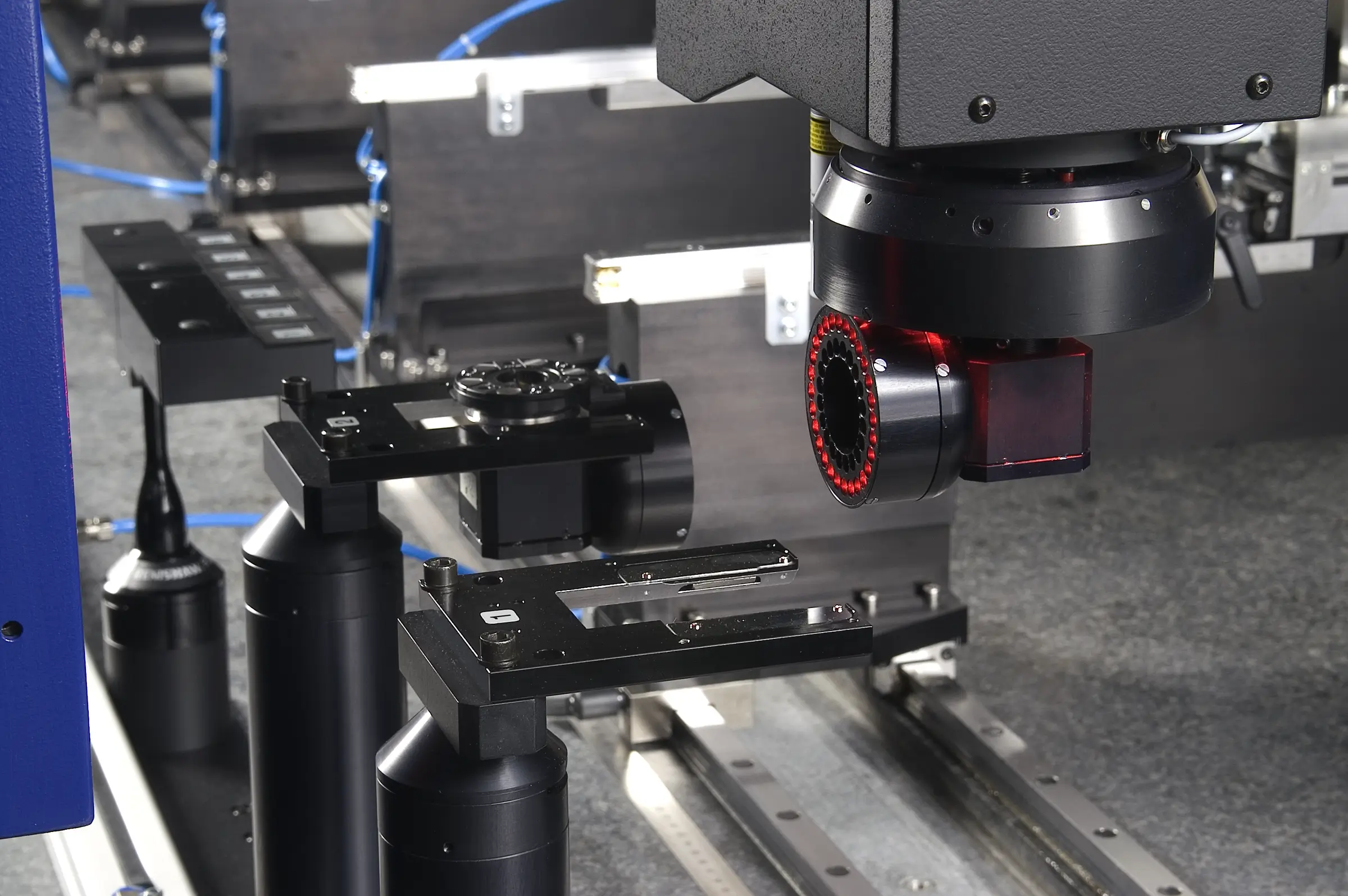

Ön yüzeylerin ölçümü için 90º optikli Werth Zoom'un kullanılması mümkündür

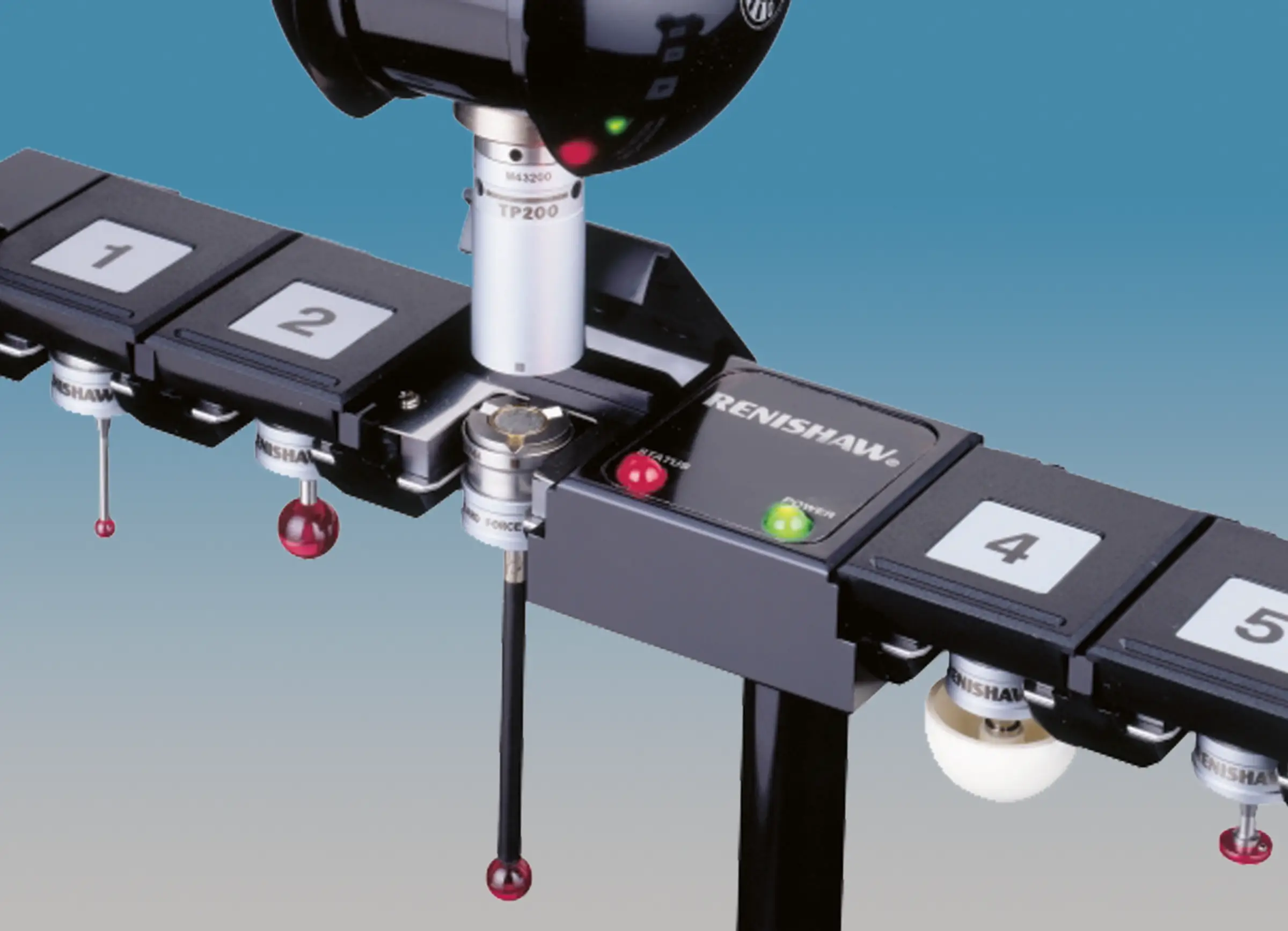

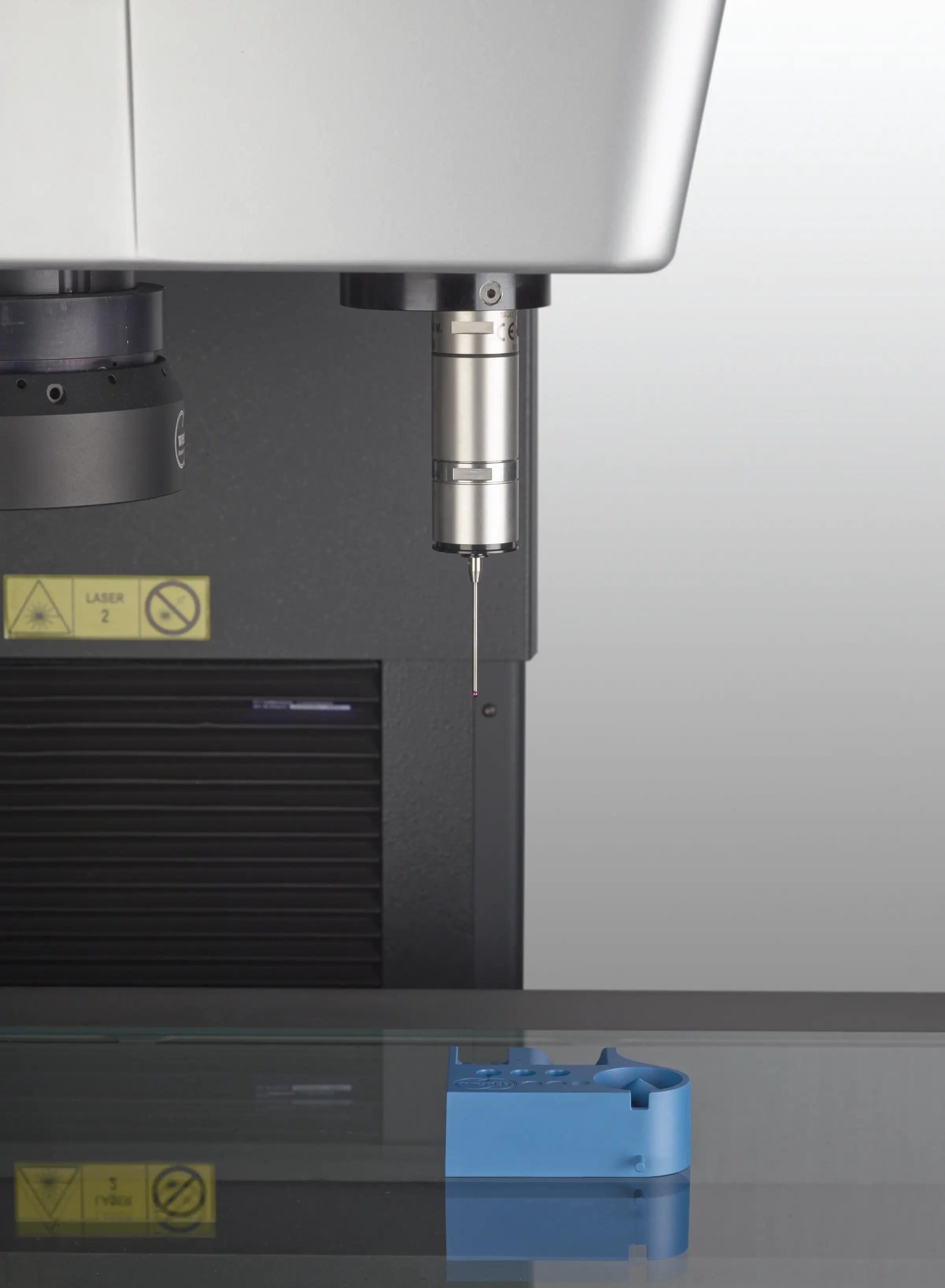

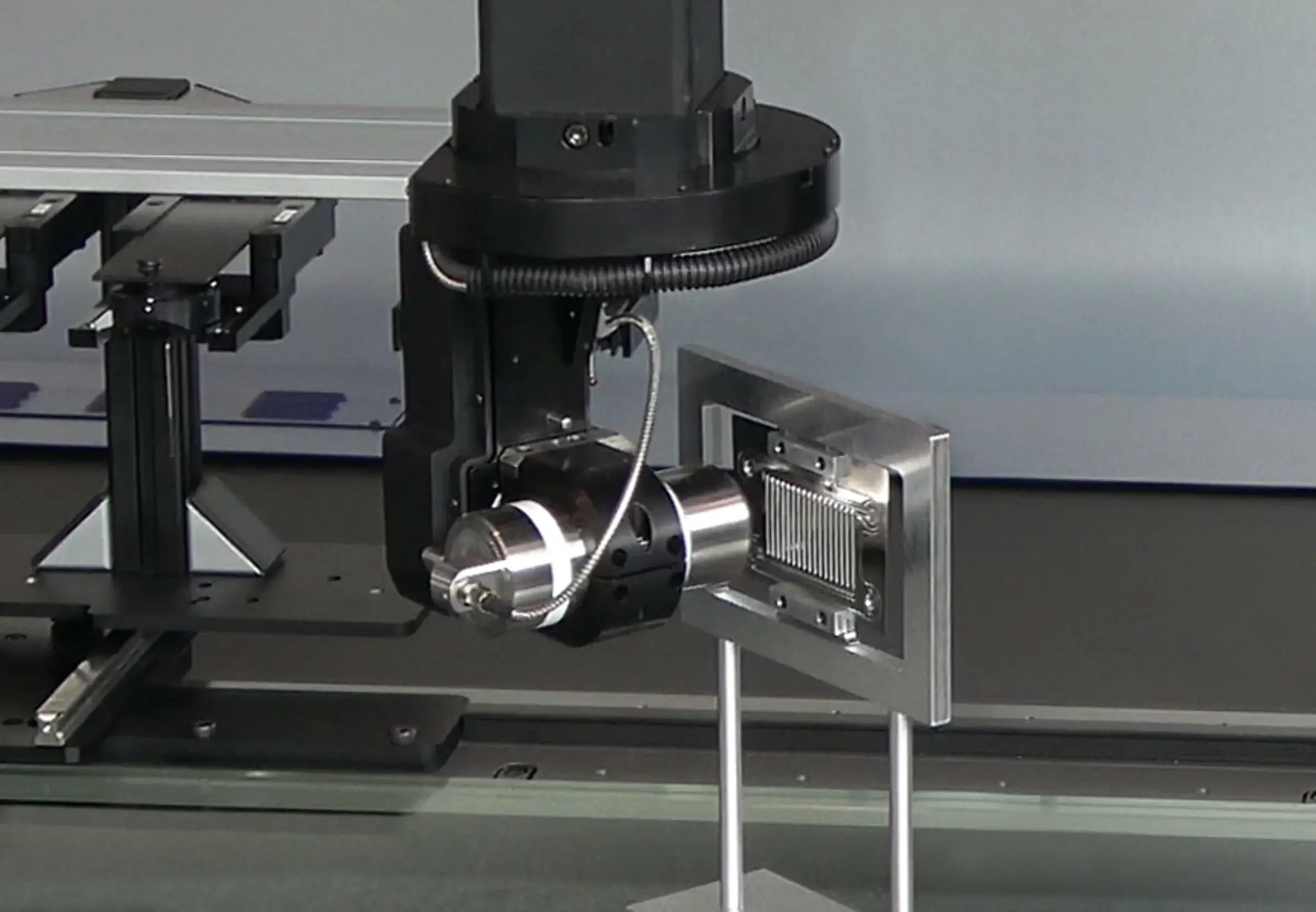

Çoklu sensör koordinat ölçüm makinesine daha fazla sensörün (geleneksel 3B tarama probu, patentli mikro prob Werth Fiber Probe®, optik mesafe sensörleri) entegrasyonu

İş parçalarının radyal sapma hataları (titreme) ölçüm yazılımı tarafından telafi edilir

Tip

Dikey döner eksenli, yüksek hassasiyetli 3D CNC çok sensörlü koordinat ölçüm makinesi

Ölçüm aralığı

İş parçası boyutları L = 300 mm / 500 mm / 800 mm, D = 200 mm / 350 mm / 200 mm

Hassasiyet

İzin verilen uzunluk ölçüm hatası 0,25 µm'ye kadar

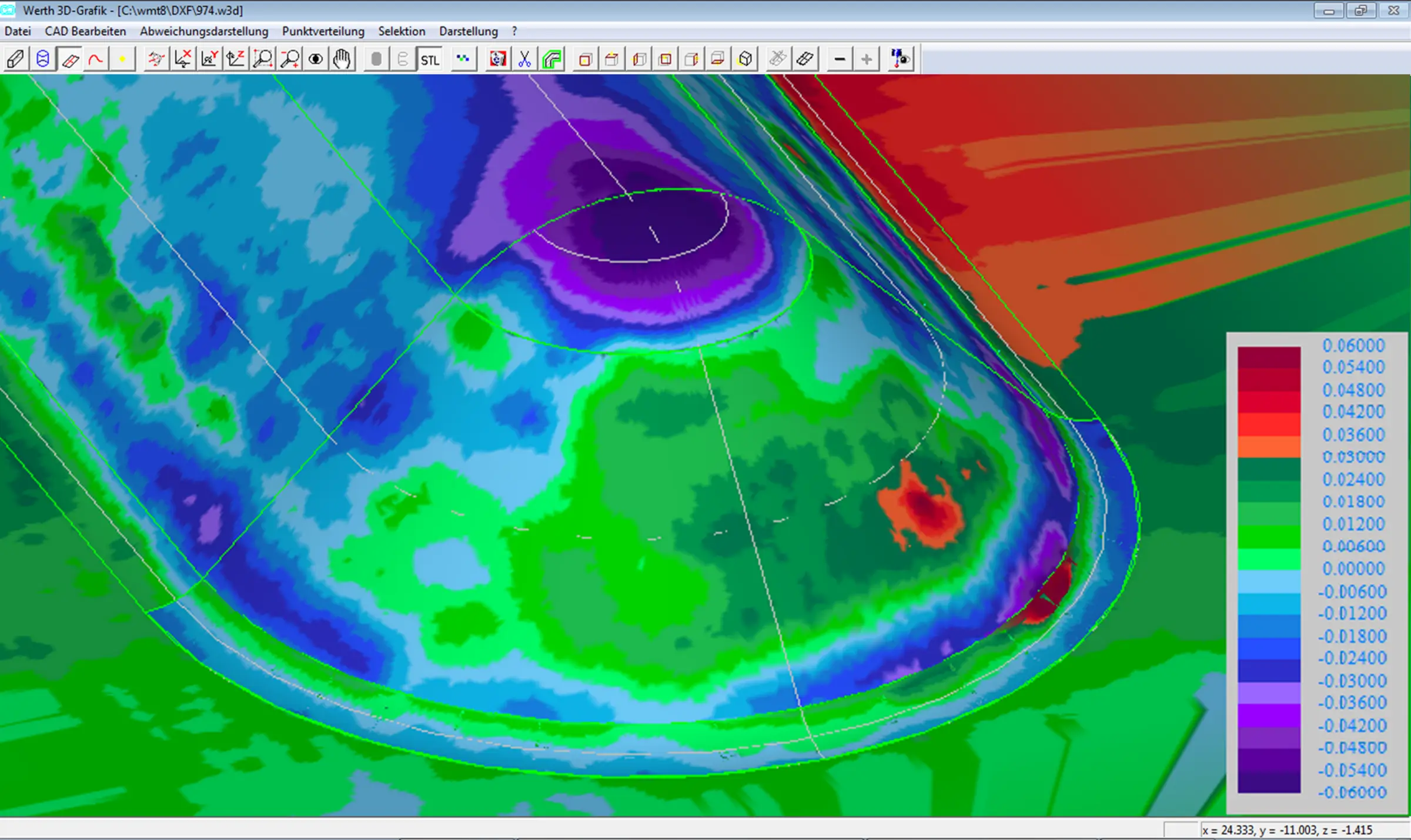

Optik, prob, bilgisayarlı tomografi ve çoklu sensör sistemlerine sahip koordinat ölçüm makineleri için evrensel ölçüm yazılımı

Çok çeşitli sensörlerle makinelerin çalıştırılması, hacim verilerinin ve nokta bulutlarının değerlendirilmesi...

Koordinat ölçüm makinesi etrafında kapsamlı hizmet

İlk devreye almadan, eğitime, bakıma ve yenilemeye kadar hizmetler...